Laser welding has become a vast approach with the evolution of new laser welding technologies. Fiber laser welding is the latest technique that revolutionizes the welding process. This technique is widely applicable due to its precision and efficiency.

In this blog post, you’ll discover the ins and outs of fiber laser welding. You’ll also explore its applications and how you can choose the best fiber laser welding machine. So, let’s get into it.

What is Fiber Laser Welding?

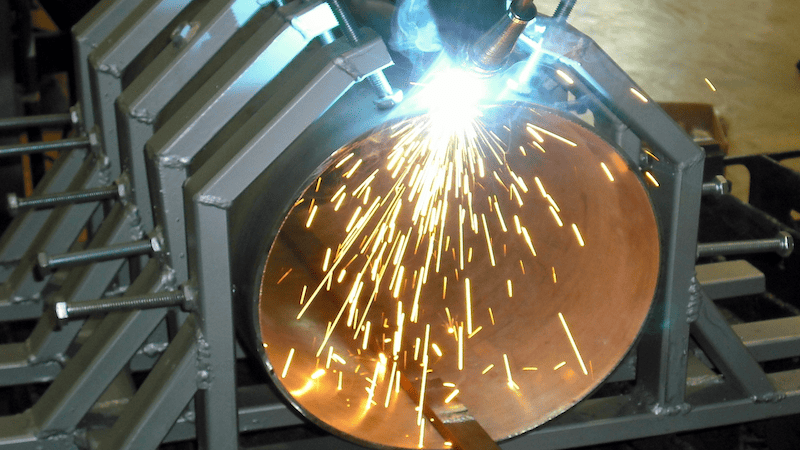

Fiber laser welding is a laser welding technique that employs optical fibers to transform ordinary light into laser beam. The optical fibers are made of phosphate or silicate glass and doped with ytterbium and neodymium. The laser diodes generate light by using electrical energy. A coupler merges the light from multiple diodes to create an intense, concentrated laser beam in the fiber optic cable.

The fiber cables direct the intense laser beam to the welding head, from where it is directed to the base metal. The metal absorbs the high energy of the laser beam and melts. On cooling, the metal workpieces fuse to create a strong weld.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

5 Types of Fiber Laser Welding Processes

Fiber laser welding is a versatile approach. It involves various laser welding modes depending on feed speed, beam focus, and power setting. The following are some common fiber laser welding processes:

1. Conduction-Mode Welding

In this process, the heat energy required for welding is transferred to the workpiece through conduction. Conduction-mode welding offers limited weld depth as the heat is conducted through the material. This mode is applicable for fusing thin metals and spot welding.

Sufficient power density in conduction-mode welding results in smooth melting of the metal. It creates perfect welds that do not need post-treatments, like grinding or finishing. You can employ this welding mode for sealing batteries and corners of electrical devices.

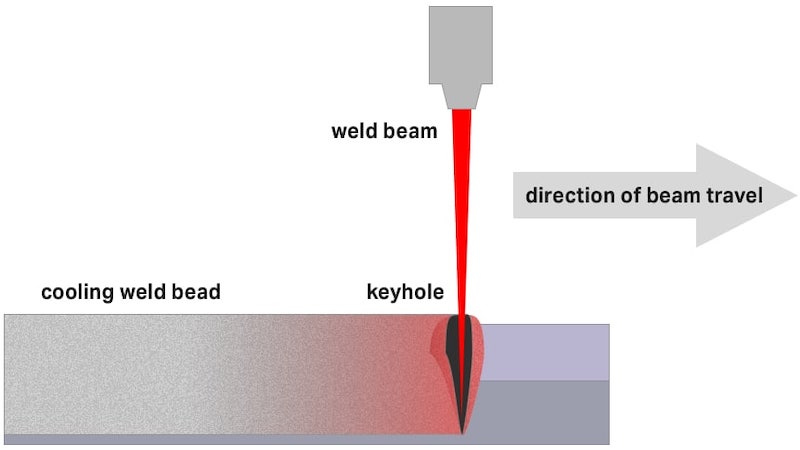

2. Keyhole-Mode Welding

The keyhole welding process is characterized by the formation of a keyhole. Excessive laser energy deeply penetrates the workpiece and vaporizes the material. The high power density of the fiber laser results in effective joining. The molten metal from the surrounding fills the keyhole, creating a strong weld. This mode is used for creating deep welds for various heavy equipment.

3. Pulsed-Wave Welding

Pulsed fiber laser welding involves the delivery of laser energy in short pulses. In this mode, the pulsed fiber lasers result in high peak powers to create spot welding. The short duration and low heat make it a perfect fit for spot welding.

It is also an effective technique for welding heat-sensitive materials and reflective metals as the intermittent heat dissipates. This approach is employed in applications that demand minimal heat distortion and precise weld depth.

4. Continuous-Wave Welding

In this mode, the fiber laser welding machine emits a continuous laser beam. The continuous laser energy delivers a stable weld pool with deep penetration. Continuous welding with high-speed results in effective welds for thin materials. The high feed rate limits heat distortion. A precise balance between power and feed speed is crucial for effective penetration and strong welds.

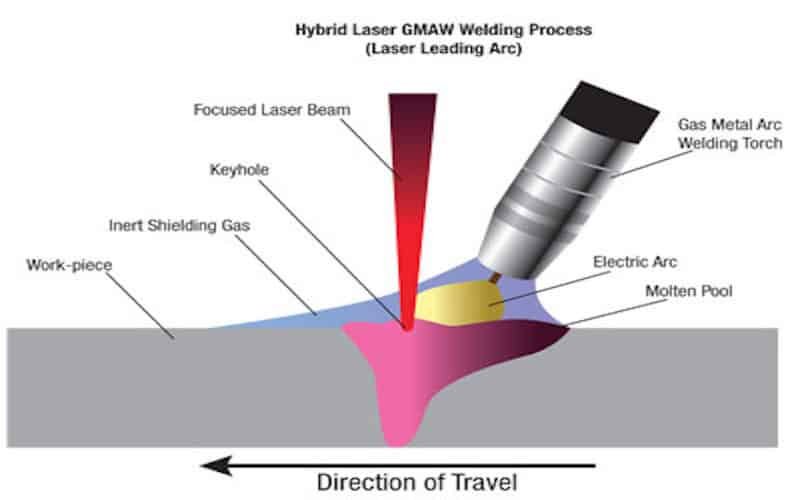

5. Hybrid-Laser Welding

According to Wikipedia, this process of fiber laser welding combines laser welding with traditional welding methods, like gas metal arc welding, metal active gas welding, or plasma welding. This mode boosts the processing speed, leading to greater penetration depth. It also enhances tolerance to joint fit-up and weld quality.

The combination of the two approaches results in low energy consumption and effective control of the material. This mode also minimizes the production cost. It is employed in applications requiring deep welds, like construction, transportation, and shipbuilding.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

6 Advantages of Fiber Laser Welding

Manufacturers opt for fiber laser welding due to its effectiveness and advantages over traditional welding techniques. Here are some benefits of employing fiber laser welding machines for the welding process:

1. Creation of Complex Welds

Creating complex welds with traditional methods is a daunting task for welders. High power and focused laser beam enable you to create intricate welds at hard-to-reach spots. It also allows you to work with various types of materials and varying thicknesses.

Moreover, you can use it to create complex prototypes that need precision. You can adapt fiber laser welding machines to new designs with minimum adjustment.

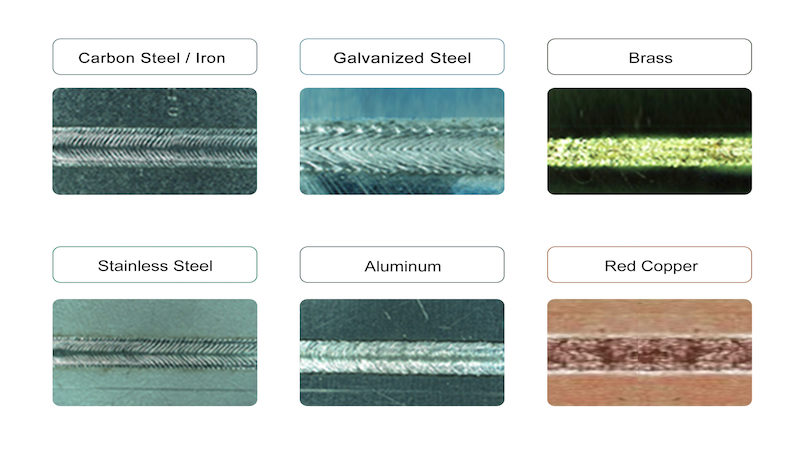

2. Material Versatility

Traditional welding techniques have limited applications. However, fiber laser welding applies to a wide range of materials, including metals, non-metals, thermoplastics, organic compounds, and composites. This technique also enables you to accomplish weld dissimilar metal welding. It makes it a perfect fit for industries where you need to join different materials.

3. Precision and Accuracy

Fiber laser welding can work at the micro-level. You can weld small spots with minimal heat distortion with this technique. Minimum heat affected zone and maximum control over the welding process allows you to achieve strong welds.

Laser welding also creates deep keyholes to create deep welds with smooth welding seams. Moreover, the speed of the process helps you create intricate welds in a short duration.

4. Low Footprint

The latest fiber laser welding machines have compact designs. They occupy less space compared to traditional laser machines. Most traditional lasers are bulky and need a large space.

A low footprint also enables you to accommodate the equipment in your existing space. This feature of fiber laser machines facilitates manufacturers to optimize their floor space and utilize it efficiently. It is valuable for modern manufacturing units as it organizes your production space.

5. Lower Distortions

Fiber laser welding limits heat distortion. A focused laser beam affects the required area, preventing the surrounding material from melting. It minimizes the risks of warping or distortions. Employing shielding gas also helps minimize heat distortion by quickly cooling the welds.

This feature makes it a valuable asset for industries where you need to maintain high-quality standards. Minimum distortion also contributes to improving the structural quality of the workpiece. It reduces the need for post-welding treatments.

6. Easy to Master

Unlike traditional welding methods that involve intricate welding techniques, fiber laser welding is a user-friendly approach. You don’t require extensive training to master it. You can learn to operate the laser machine and create perfect welds in a few training sessions. Simple operation makes it convenient for manufacturing facilities to train new employees and boost their productivity.

Comparison with Other Welding Methods

Fiber laser welding is gaining prominence due to excellent control over the welding process and extraordinary production speed. Here is a comparison of fiber laser welding with other welding processes:

| Base of Comparison | Fiber Laser Welding | Gas Metal Arc Welding (GMAW) | Tungsten Inert Gas (TIG) Welding | Resistance Welding |

|---|---|---|---|---|

| Weld formation | Laser beam melts and fuses the metal workpieces | Electric arc from consumable electrode facilitates the weld formation | Electric arc from non-consumable tungsten electrode creates a weld formation | Resistance between metal workpieces due to the passage of current creates a weld |

| Weld quality | High-quality welds | Weld quality is not as good as fiber laser welding. | Aesthetically pleasing welds are made | Weld quality is not as good as fiber laser welding. |

| Thermal distortion | Minimum thermal distortion | High thermal distortion than fiber laser welding | High thermal distortion than fiber laser welding | High thermal distortion than fiber laser welding |

Comparison With Gas Metal Arc Welding (GMAW) Welding

Gas metal arc welding (GMAW) employs an electrode wire during the welding process. The electrode generates an electric arc that heats the workpieces. The electrode is consumed during the process of welding. An inert gas is applied to prevent the weld pool from contaminating. On cooling, the metal fuses to create a weld.

In contrast, fiber laser welding employs a laser welding system to create high-quality welds. These welds are stronger than those created by gas metal arc welding. It makes fiber laser welding a preferable choice for applications where precision and strength of welds are paramount.

Comparison With Tungsten Inert Gas (TIG) Welding

Tungsten inert gas (TIG) welding is another traditional welding technology. It employs a tungsten electrode to generate an electric arc. However, the electrode is non-consumable. A filler metal wire is used to fill the gap between the workpieces during welding. This process requires skills to control the heat input. A slight mistake in handling the heat input and filler metal can damage your workpiece.

In contrast, fiber laser welding machines create a limited heat-affected zone, resulting in precise melting and fusion of workpieces. It minimizes the risks of damage to the material as it is easy to handle. However, TIG welding is preferred over fiber laser for applications where you need aesthetically pleasing welds.

Comparison With Resistance Welding

Resistance welding creates resistance between the metal workpieces by passing an electric current. As the current is passed through the metal, the resistance created generates heat. This heat energy is sufficient to melt workpieces. You can also employ electrodes for spot welding. However, the weld quality is not up to the mark. Moreover, it is hard to control as the electrode can wear off during the process.

On the other hand, fiber lasers create smooth welds. The focused, non-contact process creates minimum heat-affected area and limited thermal distortion. It results in high-quality welds.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Applications of Fiber Laser Welding Technology

Fiber laser machines are extensively used in several industries. The following are some applications of fiber laser welding:

1. Aerospace Industry

The aerospace industry requires robust welds. You can’t achieve complex welds in turbines, frames, blades, and other structural elements with traditional welding. Fiber laser welding allows you to create spot welding. It is also used for joining various materials, like titanium, that you can’t weld with traditional welding technology.

2. Automotive Industry

Fiber laser welding has boosted automotive manufacturing by offering high feed speed and control over the welding process. It is employed for joining various dissimilar metals, like aluminum and mild steel, to create engine parts. Moreover, fiber laser welding offers better joint strength that ensures the durability of the automobiles.

3. Medical Device Manufacturing

Manufacturing medical devices require exceptional precision. Fiber laser welding works at the micro-level and allows you to create intricate structures, like implants. You can also use a handheld laser welding machine to create a weld at the required spot without distortion.

4. Construction Sites

In the construction sector, fiber laser welding joins structural components. Precise weld creation ensures the structural integrity of metal frames. Its high speed and minimum thermal distortion provide high-quality welds.

5. Defense Sector

The military and defense sector also employs fiber lasers to create heavy machinery and robust armor. This laser welding helps you create precise welds for strengthing metal frames. It also ensures the structural integrity of various military equipment.

Cost of Fiber Laser Welding

The cost of fiber laser welding varies. It depends on laser power, focus, and speed. Customization and configuration of the machine also affect its cost. The cost of automated fiber laser welding machines ranges from $15k to $40k. Handheld laser welding machines are a cost-effective investment. Their costs range from 1k to 10k, making it an affordable option.

In addition to the initial investment, you need to consider the operational and maintenance costs. A 4kW fiber laser welding machine has an average operational cost of about $6.24 per hour. It includes the power consumption your laser consumes during welding.

A 1kW laser welding machine requires an average of 5kw per hour of electricity. A 3kW laser needs about 12kw per hour of electricity. Choosing an energy-efficient laser can help you significantly minimize the operational cost.

Your machine also needs regular maintenance. It’s nozzle and lens consumes over time and you need to buy new ones for smooth operation. Moreover, routine inspection and cleaning are also crucial. Maintenance of a fiber laser welding machine costs a few hundred dollars. It usually ranges from $300 to $500 depending on the condition of your machine.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

How to Choose the Right Fiber Laser Welding Equipment?

Several factors are involved in determining the right fiber laser welding machine for your needs. Here are the factors you should consider when choosing the right fiber laser welding machine:

1. Material Compatibility

Material compatibility is a crucial aspect of determining the type of laser machine. Fiber laser machines are compatible with welding metals, including aluminum, copper, and steel.

However, they are not effective for welding non-metals and thermoplastics. Welding non-metals and thermoplastics with fiber laser results in weak welds. You need to consult the manufacturer to learn about the material compatibility of your machine.

2. Material Thickness

Material thickness is another important factor. Each laser welding machine is designed for welding up to a particular thickness. According to LinkedIn, the power of laser welding equipment affects the thickness of the material it can weld. Check the manufacturer’s instructions to learn about the maximum thickness it can handle.

3. Welding Application

Various laser welding machines are designed for particular welding applications, like spot welding, 3D welding, or seam welding. Look for a fiber laser that you can use for multiple applications.

FAQs

1. What are the parameters for fiber laser welding?

Crucial parameters for a fiber laser welding system include laser power, speed, beam focus, and beam diameter,

2. What precautions should be taken during laser welding?

Laser welding creates a high-energy laser beam. Never direct the laser beam to your eyes. Avoid directly looking at the laser beam. Wear protective gear to prevent the harmful effects of the laser beam.

We have prepared an article on laser safety.

3. What is the principle of fiber laser?

A fiber laser contains optical fibers that generate light from electrical energy. The optic fiber cables absorb light beams from multiple pump laser diodes and emit an intense laser beam.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Conclusion

Fiber laser welding is an innovative technology that can transform manufacturing processes. Its precision and efficiency enable you to create strong welds. You can employ various modes of fiber laser to create stunning results. It is an easy-to-use technology, and you can learn to operate it in a few sessions. However, choose a reliable fiber laser welding machine.

Unleash the Potential of Fiber Laser Welding with Baison Laser!

Today, various brands offer high-quality fiber lasers. However, choosing the right laser machine is not easy. Baison Laser offers you the best fiber laser welding machines. Contact us today to learn about our laser welding solutions. Our experts will guide you to get the best fiber laser.