Laser cutting is essential if you’re in the packaging, printing, automotive, medical, HVAC, or other industries that must comply with strict quality guidelines. It’s known for its speed and accuracy in manufacturing applications; it’s an essential tool for advancing over your competitors.

After all, there is an increasing demand for fiber lasers on the global market; these laser-cutting machines are predicted to reach $7.73 billion by the end of 2030.

The short answer to why this market is growing exponentially and many people are adopting laser-cutting technology is its speed and precision. Yet, to truly understand the precise cuts it can give your business, you must first be familiar with the laser cutter.

In this post, we’ll discuss laser cutting in greater detail, laser cutter precision, and the factors you need to consider to achieve positioning accuracy.

Laser cutters explained

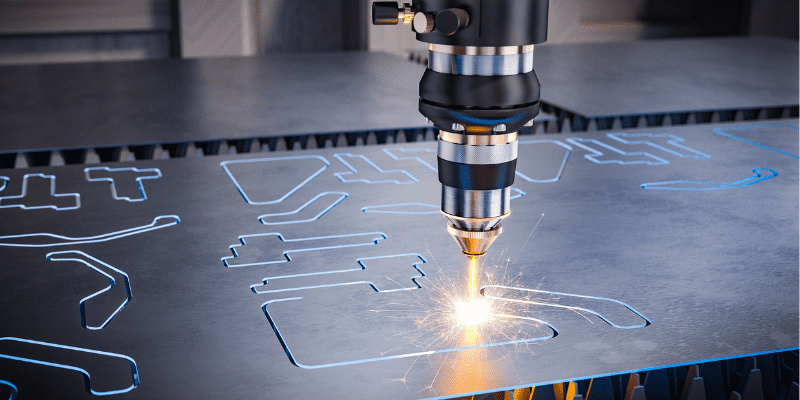

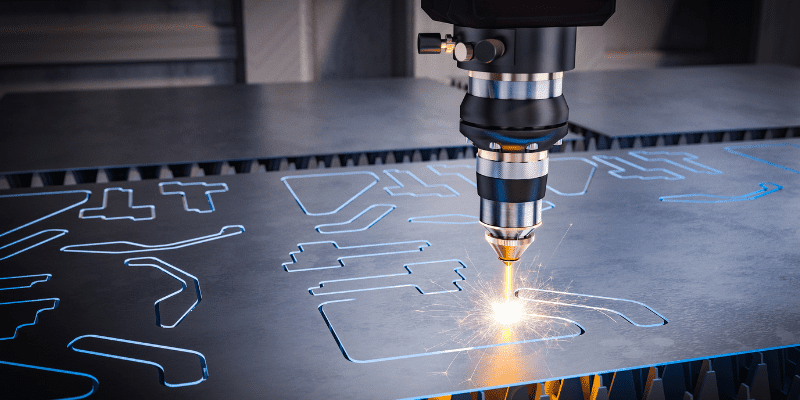

Laser cutters are automated machines that provide different forms of cutting using a laser. All laser cutting machines are carefully operated by Computer Numerical Control (CNC) technology, making different cuts, cutting shapes, and engraving designs on the surface of materials.

They can cut through a highly concentrated stream of photons through an optic lens through metal, wood, glass, and plastic. With laser cutting, no dangerous blades are making them safer to operate and reducing the risk of workplace accidents.

If you pair laser cutting machines with CAD software and CNC technology, they’re proving much safer and quicker than traditional methods. These machines require fewer outgoings for your business, saving you from paying a high salary for an experienced machine operator, hiring more manpower to help with the production line, and less supervision.

Three main types cut various materials, they are:

CO2 Lasers

This is the most popular laser cutter, and it often has the most competitive prices. It’s mainly used for laser cutting metals, as it tends to cut through the thickness. The laser uses gas, carbon dioxide, and nitrogen.

Crystal Laser cutter

These laser-cutting machines use a laser beam with different light wavelengths to cut through extremely small and thick metals. One of this machine’s main advantages is that it has more power and intensity than other machines.

Fiber Lasers

Fiber laser cutting machines work like fiber optic lights. Light enters a tube of glass and is reflected, gaining strength. Fiber optics allow the laser to achieve a smaller cut width and gain more precision. However, because they have higher precision rates than other methods, they have higher costs when buying the machine and its replacement parts.

How do laser cutters work?

A high-powered laser beam is distributed through a glass, creating a pattern that follows a CNC or C-code to cut onto metal or mother materials. The computer code follows specific details you input about the type of material, metal, and pattern. The laser will move around at different speeds, lengths, and depths based on the details you input into the machine.

How precise are laser cutters, and what do they typically use for?

Laser-cutting machines are highly accurate and precise compared to other tools. The computer-operated program it follows allows it to cut materials carefully and with great accuracy. If also integrated with CAD software, the accuracy rate is even higher.

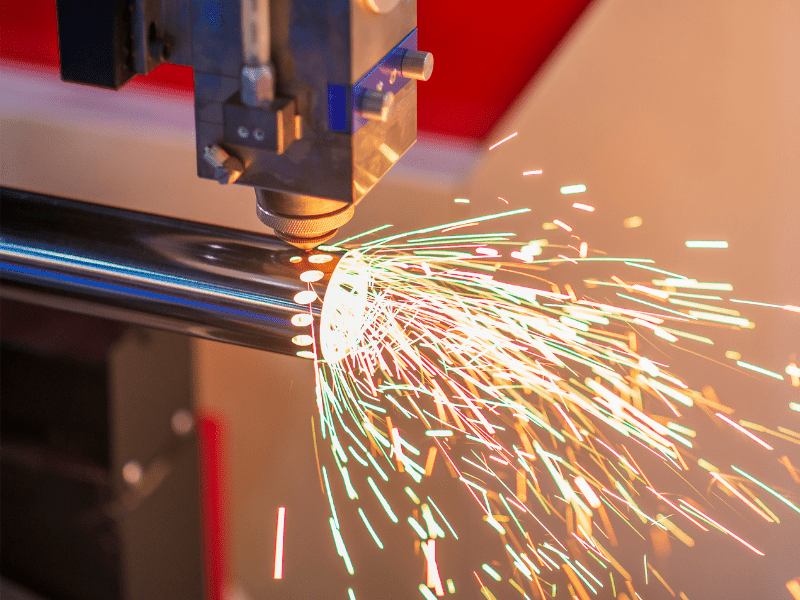

While precision laser cutting can vary based on the laser beam, many retain a high focus of 25 microns, which is around 1/4 of the width of your hair. Cuts can be made small, lower than 0.001 inches, and have a dimensional accuracy of 0.0005 inches.

The designs you cut into using laser machines can be much smaller, allowing you to cut through more products from one piece of material, creating less waste. The laser intensity ratios you can cut through allow you to make smaller cuts than you can achieve from other machines. Plus, the laser intensity ratio can be adjusted for the ctr lasers, enabling consistent results when cutting.

What can it be used for?

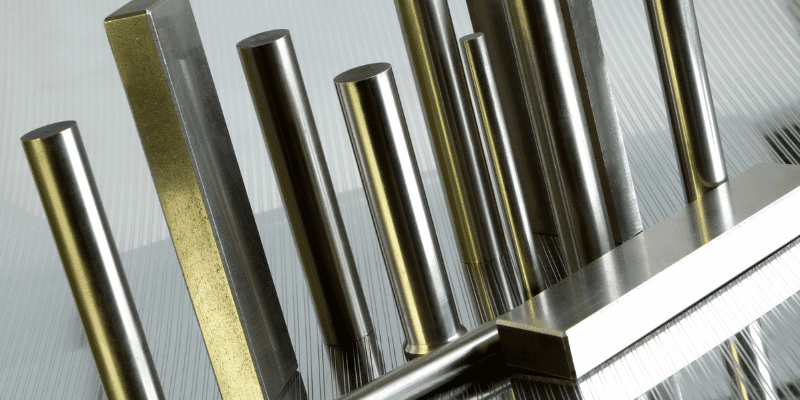

With laser cutting, there’s no limit to the sector you serve. Compared to other cutting methods, laser cutters can be used on sheet metal such as stainless steel, aluminum, mild steel, and titanium. It’s best used for parts and components in a range of industries. Ideally, it’s best for industrial manufacturing applications that require a high volume of components to be cut simultaneously.

Laser cutting machines can be fantastic if you’re a machine shop and must prototype your product to test the main features and review defects. These highly automated machines speed up production by creating exact cuts and adjustments.

Moreover, in the medical industry, laser-cutting machines are used over scalpels to create precise cuts for tedious and intricate shapes in eye surgery. While these are just a few industries adopting laser technology, many can use them to enhance their production process.

What factors affect the precision of a laser cutter?

If you plan on using a laser cutter, the following factors can influence the dimensional accuracy of a laser cutter. Therefore when using a laser, you’ll want to consider the following:

- Material type: The smoother or thinner the sheet metal or material you use, the more precise the cut will be. To help you cut through the right material thickness, you’ll want to implement the right settings in your machine based on the type and composition of the material.

- Laser power: If you’re using thick materials, you’ll want to buy a more powerful laser beam with higher intensity. Doing this will allow you to cut through thick materials with even consistent cuts.

- Spot size: Smaller lasers ensure smoother cuts compared to wider spot sizes. The smallest laser spots can reach up to 0.01mm, which is highly accurate.

- Workbench accuracy: It’s essential to position the material on the bench. Your workbench must be stabilized to ensure consistently good quality cuts. If it’s not, vibrations can disrupt the process straying away from the original design you input into the software.

How to get the most accurate cuts from your laser cutter

To ensure you elevate your laser cutting accuracy, you’ll want to do the following:

- Select settings on the machine closest to the material you’re trying to cut through.

- Confirm the beam’s window and lens are clean and in good condition.

- Check the nozzle is clean and placed in a central position for the cut.

- Use a test part that has different cutting requirements before beginning your operations.

- Next, you’ll want to adjust the focus and quality of the laser before starting the machine.

Other ways to achieve accurate cuts

The other things you might want to consider are:

Choose the right material

Before using your laser cutter, you will want to have the right material. Depending on what you use, the qualities of the material can be flexible, rigid, opaque, and even translucent. Therefore, whether you’re using wood, plastic, glass, or anything else, you should be familiar with the properties first. You’ll want to consider the design guidelines, color, material thickness, and more.

Controlling the cut order on laser cutting machines

When using your laser machine, you may be able to select specific options on your software to determine the order of the cuts. If you input this, you’ll be able to decide on the right way for lines to be cut and on different layers. However, if you can’t do this, you can turn the print of each layer on and off to achieve different cuts.

Keep everything on the same file.

Instead of having separate files storing designs and parts, having them on the same design can be much faster. Keeping them on different layers on the same file can be more efficient, allowing you to print them one at a time.

Create a guide for laser cutting.

If the same type of cut is needed, you might typically want to create a guide for laying out the required design.

Measure the material first.

Many laser-cutting machines differ slightly from the dimensions mentioned in their catalog. To ensure you get accurate cuts on thicker materials, you’ll want to measure them before positioning them and inputting them into the illustrator. Doing this will ensure the machine fully fits the material, and you won’t have to spend much time fixing the file.

Look for overlapping vector lines.

If you have several cuts with the same position, they are more likely to burn. That’s especially if you use materials like wood, which can cause the job to take a lot longer to complete. You’ll want to separate the laser cutter file into two parts to stop this from happening.

Conclusion

Laser cutters are extremely accurate compared to other traditional methods and feeding systems. To know how accurate laser cutting is, you must consider the different materials, cut width, laser power, and spot size. Laser cutting can usually help you cut extremely small shapes and designs up to a quarter of the size of a human hair strand!

Not only can they help achieve consistent, high-quality cuts, but if used effectively, one machine can significantly save on the cost of manpower due to their innovative software. Plus, with a laser, you’re less likely to encounter workplace accidents as you don’t have any dangerous blades to cut metal. Laser cutting can be used in a wide range of industries and can truly enhance your efficiency.

At Biason, our laser cutting machines are cost-effective and manufactured to elevate the production process of businesses like yours. To learn more about our machines, get a free application evaluation before investing in a laser-cutting system. We’re on standby to ensure businesses like yours operate at higher power and capability and lower costs.