Advantages of Fiber Laser Cleaning

- Home

- Laser Cleaning

What is Laser Cleaning?

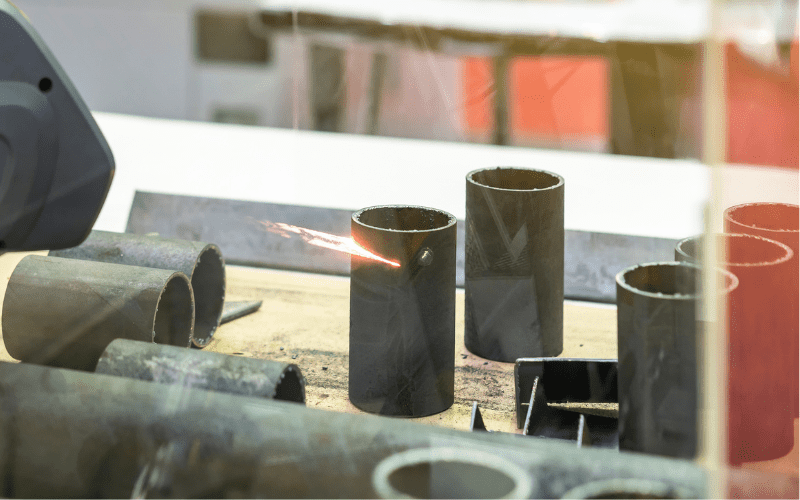

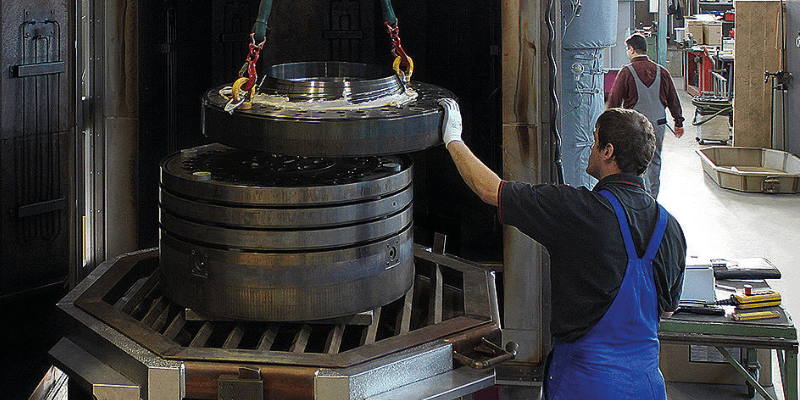

Laser cleaning is an eco-friendly, cost-effective, and easy-to-use method for metals and non-metal surfaces. The heat vaporizes gunk, rust, corrosion, paint, etc., from any surface. It’s the fastest cleaning method, making it an industry go-to choice. Fiber laser cleaning is also best for pre-treating a workpiece before the paint. It’s exceptional for the restoration and recycling of mechanical products.

Applications of Fiber Laser Cleaning

Fiber laser cleaning has vast applications in the modern manufacturing industry, such as:

- Extremely fast cleaning.

- Easy to use and needs no prior training.

- Small and portable equipment.

- Environment friendly and saves resources.

- Cleans without damaging the material.

- Good for high-precision tasks

- Cost-effective and chemicals are involved.

- Cleaning process can be automated.

Fiber Lasers vs. Traditional Cleaning

Fiber lasers involve the heating and evaporation of unwanted material from any surface. This is different from many traditional cleaning methods. Let’s explore how some of the cleaning methods differ.

Abrasive Blasting vs Fiber Laser Cleaning

Dry Ice Blasting vs. Fiber Laser Cleaning

Chemical Cleaning vs Fiber Laser Cleaning

Thermal Cleaning vs Fiber Laser Cleaning

Looking for Fiber Laser Cleaning Machine for Your Business?

If you are looking for a fiber laser cleaning machine for your business, we are here to help. We offer a wide range of machines that are designed for different applications.

Advantages of Baison Fiber Laser Cutting Technology

Premium Quality

Our expert technicians and engineers use contemporary technology to produce high-quality fiber laser cleaning machines.

Customization

We believe every project is unique, so we customize our products to each client’s project specifications.

Low Noise

Traditional cleaners generate a lot of noise pollution. Our fiber lasers can get more work done with little to no noise.

Portable

We offer fiber laser cleaning machines that are easy to move and can reach tight areas.

Eco friendly

We manufacture eco-friendly cleaning machines which dissipate less residual dust into the environment.

Low Maintenance Cost

Fiber laser technology doesn’t need a regular abrasive material refill, thus saving operational costs.

Ready to Speak to one of Our Experts?

If you are not sure which machine is right for you, our team of experts would be happy to advise you. We can also provide training on how to use our machines, so you can get the most out of them. Contact us today to find out more.