The Evolution and Fundamentals of Lasers

Laser is an acronym for Light Amplification by Stimulated Emission of Radiation. In 1960, Theodore Maiman discovered that light can be exponentially amplified, focused at tiny spots, or directed toward long distances when passed through certain crystals.

The very first laser included a cylinder of ruby surrounded by a high-powered xenon flash lamp tube. Such light was commonly used in photography at that time.

As soon as the light energy entered the ruby crystals, the atoms inside absorbed the energy and moved to a higher excited state from a neutral ground state. But when the atoms lose the energy and go back to the ground state, they release the light, thus creating lasers, also known as stimulated emission.

Ted Maiman further used identical silvered mirrors on the opposite side of the ruby cylinder to direct a single stream of high-intensity, single-wave, monochromatic light out through a tiny hole in the mirror. Eventually, this became the first Laser ever produced.

To summarize, laser technology has three basic characteristics that make it unique: a single wavelength, high intensity, and narrow beam. Nowadays, many types of laser sources exist, but they all are based on this basic principle.

This discovery led to huge advancements in thousands of fields, such as manufacturing, navigation, medicine, printing, communication, entertainment, and much more. In the manufacturing industry, Fiber lasers, Solid-state lasers, and CO2 laser machines are popularly used for laser marking, cutting, welding, and cleaning materials and are rapidly replacing traditional machinery.

Importance of Laser Classification

The precision and high intensity of Laser light is precisely the reason why it’s also so dangerous. Exposure to high-intensity lasers can cause serious eyesight damage, severe skin burns, and, in some cases, can be fatal. And all of this can happen in the blink of an eye.

Before you start to panic, let us assure you that there are some safety protocols that you can follow to stay on the safe side. These safety protocols are documented under “Laser Classifications.”

Over the years, scientists developed laser classifications to avoid the risk of accidents and injuries. Laser classification provides essential safety guidelines for working with lasers, and it aids in classifying hazardous lasers, helping us prepare in advance.

Typically, in a workplace, a laser safety officer monitors laser hazards using laser classification guidelines. Nevertheless, any machine operator or worker can receive training to effectively adhere to these safety guidelines.

Different Criteria for Laser Classification

The danger level of Laser radiation depends on many factors, such as wavelength, power, exposure time, and reflection. Experts have classified lasers into different categories, and nowadays, you’ll find many organizations establishing safety standards.

Don’t get confused by so many standards, as most are similar. Here’s the list of popular laser safety standards around the world.

1 – International Electrotechnical Commission (IEC)

IEC develops international safety standards for all electrical and electronic equipment. Around 88 countries are full-time members of this organization.

The laser safety standard IEC 60825-1 divides laser into different classes, such as class 1, 1m, and 2, etc., which are mostly followed worldwide. However, they don’t regulate or mandate organizations to follow safety standards.

2 – American National Standards Institute (ANSI)

Just like the imperial unit system, Americans have their own safety standards developed by the Laser Institute of America (LIA) and are known as ANSI Z136.1.

3 – European Norms (EN)

EN is the European equivalent of ANSI and is followed by EU member countries along with IEC standards. EN standards are generally more conservative than their American counterpart.

4 – Food and Drug Administration (FDA)

FDA is an American organization that actually regulates and enforces its own laser standard called the Code of Federal Regulations Title 21 in the food and medical industry. However, since 2019, they also approved manufacturing done using IEC standards.

5 – Occupational Safety and Health Administration (OSHA)

OSHA is also a safety regulator like the FDA but focuses specifically on laser-related safety hazards in the workplace. They mandate organizations based on both ANSI and FDA standards.

6 – Canadian Standards Association (CSA)

The CSA regulates laser machine manufacturers and workplaces in Canada using their own CAN/CSA-E60825-1 standard. They are almost identical to IEC standards with slight deviations.

Do You Have Any Questions?

Let Us Solve Your Problem

Dive into Laser Classes — An Easy-to-Follow Guide

Here, we’ll go into the details of IEC 60825-1, as they are the most popular safety standards around the world. Sometimes, they’re represented in Roman numerals like Class III, and IV, but mostly Arabic numerals are used.

The higher the class is, the better prevention and preparation are needed to avoid any potential damage to the human body.

Class 1

Class 1 are the safest lasers with low power output (few milliwatts) and pose no threat to the human eye and skin. Examples include Laser pointers, toys, DVD players, printers, etc.

However, there is another classification called Class 1 Laser Products, which are laser machines having dangerous levels of lasers such as class 3M and 4 but are enclosed in a protective covering, making them safe for regular use and requiring no precaution.

Most laser systems like printers, scanners, laser cutting, welding, and marking machines fall into this category.

Class 1M

Class 1 magnified (M) classifies laser beams which are unsafe when viewed with a magnifying lens (binoculars, etc.). Mind you, this doesn’t include prescription glasses.

Viewing the Class 1M laser system through any optical instrument increases its Maximum Permissible Exposure (MPE), which is why it’s dangerous. Examples include fiber communication, laser speed meters, and laser diodes.

What is the difference between Class 1 and Class 1M lasers?

Class 1 lasers are safe to look at and work within any condition. However, Class 1M lasers are unsafe when viewed through an optical instrument that can magnify its laser power density.

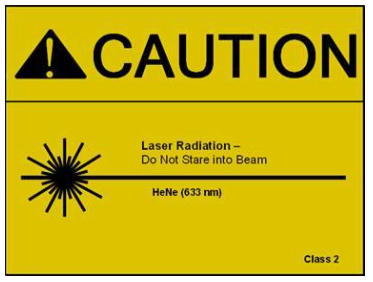

Class 2

Direct eye contact with class 2 lasers and their reflection must be avoided. Workplaces with class 2 lasers are labeled with a warning. As long you don’t stare at such lasers, it’ll be fine. Our natural blink response also protects us from exposure.

Class 2M

Class 2 M (magnified) lasers are generally safe but don’t view them using any optical instruments. Unlike class 1M lasers, your blink response won’t protect your eye if you view class 2M using an optical device, and even the slightest exposure can cause eye injury.

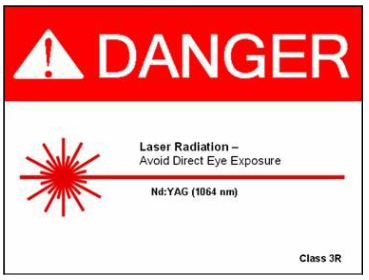

Class 3A

Now, we are getting into the danger zone. Viewing Class 3A lasers can be injurious to the eye, and direct exposure can harm the skin. They’re also known as Classe 3R lasers.

Class 3B

The reflections of class 3B lasers are just as dangerous as the direct contact. So, proper precaution is needed while working with such lasers.

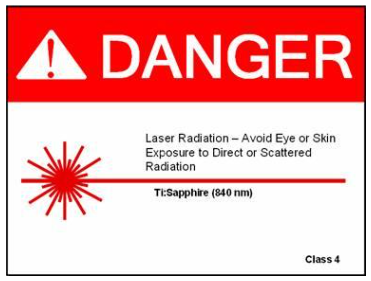

Courtesy of https://ehs.princeton.edu/

Class 4

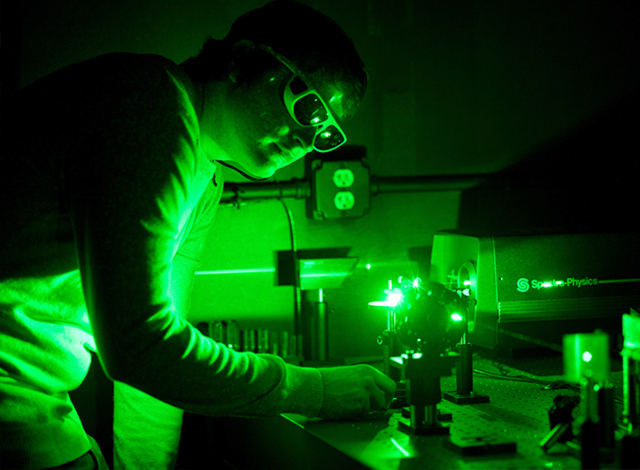

Class 4 lasers are the most dangerous and lethal ones out there. Their power output is larger than 500 mW. The radiation can be visible or invisible or in the infrared range.

Direct and indirect exposure can cause severe skin burns or blindness. High-end laser manufacturing machines use Class 4 lasers. Trained individuals should handle these machines.

Courtesy of https://ehs.princeton.edu/

Comprehensive Comparison of Laser Classes

We know understanding laser classes can be complicated, and it’s a lot to take in if you aren’t familiar with Lasers. So here is a comprehensive comparison between different laser classes presented in a simple table.

Insert Table

Factors to Consider When Choosing Protective Gear for Different Laser Classes

As we’ve already established, there are many kinds of lasers. It’s only natural to discuss the factors you must consider before choosing the proper protective gear. Here are some critical things to look for.

1. Warning Signs or Labels

Apart from class 1/1M laser systems, all other classes 2,3 and 4 have warning labels. The most straightforward way is to tally warning labels on the device and the protective equipment.

2. Wavelength

Eye protection goggles are wavelength sensitive, which means the goggles designed for lasers from CO2 sources will not protect against Nd: Yag-sourced lasers even though they might be of the same laser safety class.

Lasers produced with different sources will naturally have different wavelengths. So, always remember your laser machine’s source while buying protective equipment. Some high-quality eyewear can protect against multiple wavelengths.

3. Reflection

Avoiding direct stares isn’t enough. Some lasers (class 3b, 4) can reflect and emit radiation (invisible light) that can harm you even if you aren’t in direct contact. Laser reflection can be of two types.

A laser beam bounces off shiny surfaces and reflects directly into the eye or onto the skin, causing serious damage.

A laser beam hits a rough surface, causing it to scatter unevenly into multiple, less intense beams, each of which can still be hazardous.

4. Material Interactions

Protective equipment uses unique materials and coating for protection. Some materials can bleach out over time due to laser exposure.

A continuous wave by 10 W CO2 laser can even fracture glass. So, always consider the material before buying protective gear. Also, regular inspection is needed to monitor material degradation due to intense exposure.

Type of Laser Protective Gear

Lastly, let’s discuss the types of protective gear typically available for protection against lasers.

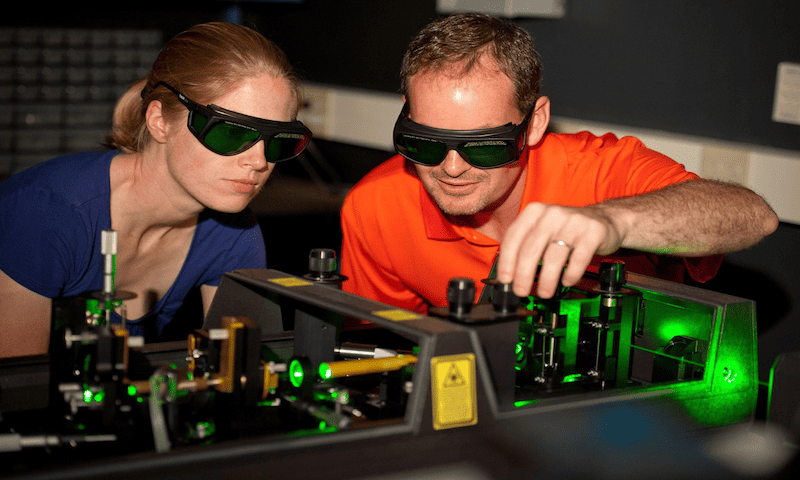

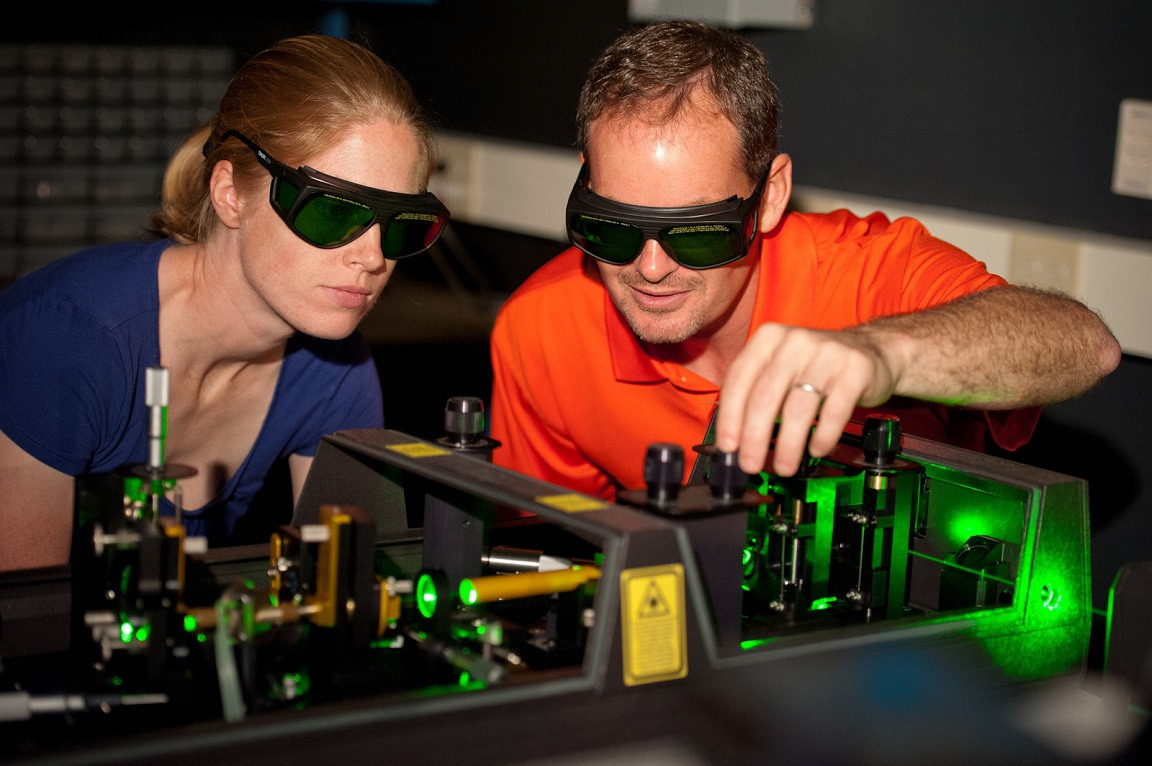

Laser Safety Goggles

Laser protective eyewear made from laser-resistant materials.

Laser Safety Face Shields

Similar to safety goggles, but protects a broader area of the face and neck.

Laser Safety Clothing

This personal protective equipment (PPE) is made from laser-resistant fabric and materials. They can block laser radiation effectively.

Laser Safety Curtains

Recommended for invisible laser radiations.

Key Safety Measures for Your Project

Every laser project needs serious safety considerations to avoid an unfortunate incident. Adhering to rules and regulations will keep your business profitable and long-lasting.

Maximum Permissible Exposure (MPE)

Laser safety standards like IEC and ANSI have devised MPE values for different laser classes. It’s the maximum laser exposure a human can endure without risking eye and skin injuries.

Using MPE, we can determine the optical density (OD), which is the tendency of a laser to absorb by a material.

Moreover, it helps in calculating the nominal hazard zone (NHZ), which is the area within which laser exposure is greater than MPE. MPE, OD, and NHZ help in setting up safety protocols for the laser project.

Follow Guidelines

Always follow the guidelines set up by the manufacturer. Also, most heavy-duty laser equipment have Interlocks and Automatic shutdown systems.

The laser safety program inside the class 3B and 4 laser machines automatically shuts down the machinery if it malfunctions or fails to meet some prerequisite conditions.

Remove Flammable Material

Remove any debris or flammable material, as it can catch fire with direct or indirect laser exposure.

Test Protection Gear

Always test the protective gear before using it in an actual situation. As they say, better safe than sorry.

Do You Have Any Questions?

Let Us Solve Your Problem

Final Thoughts

Kudos! If you made it this far. We’ve covered in detail the four major laser safety classes and precautions needed for safe operation.

Whether you’re an entrepreneur entering the laser industry and seeking to familiarize yourself with laser safety standards or a large manufacturer aiming to enhance productivity and workplace safety, this comprehensive comparison of different laser classes is tailored for you.

Baison Laser Offers a Perfectly Safe Solution for Your Laser Project

Are you searching for a safe, efficient, and powerful laser solution for your next project? At Baison Laser, we offer cutting-edge laser solutions to clients worldwide. Our extensive catalog features top-tier laser cutting, engraving, welding, and cleaning machines designed for various materials. All our laser machines are crafted under expert supervision in state-of-the-art facilities, and they’re all rated as excellent products for safety.

That’s not all, our dedicated team of specialists provides tailored solutions to meet your unique needs, ensuring remarkable results. Still unsure? Give our Free Project Evaluation and Sample Proofing a try to kickstart your project.