Are you looking for a high-quality laser welding machine for your business but need to know how much the laser welder costs? No worries! This quick article will give you a crash course on everything you need to know about laser welding machine pricing and the factors that impact its total cost.

We will break down various laser welding machines ranging from small handheld models to large industrial-grade units. By the end of this article, you will be an expert on the matter.

Types of Laser Welding Machines

Welding machines range from small portable laser welders to massive automatic welded workbenches. The performance gap between these machines is relatively small, and these machines mainly differ based on feature sets and convenience to the operator.

We can categorize laser welding machines into four sections.

I. Handheld Laser Welding Machine

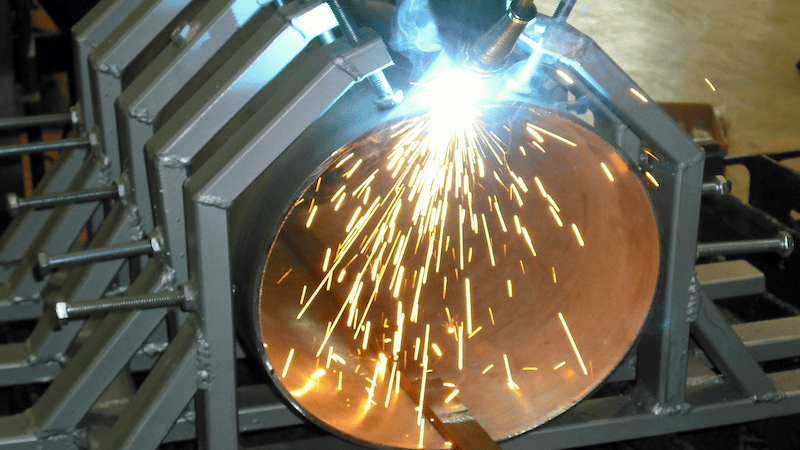

Mobile (Portable) laser welders consist of a main laser unit that houses all the necessary machine hardware and a welding gun that is an exit point for the laser.

Handheld laser welding machines excel at quick and simple welding projects, as you only need to turn the machine on and get to work.

Additionally, we see that these machines are quite compact and are easy to move around. The portability and the quick setup time make handheld laser welders an attractive choice for large factories with several projects at a time.

You move the welding cart to the desired workstation and start welding. The machine can be stored or sent to a different workstation when you’re done.

II. CNC Laser Welding Machine

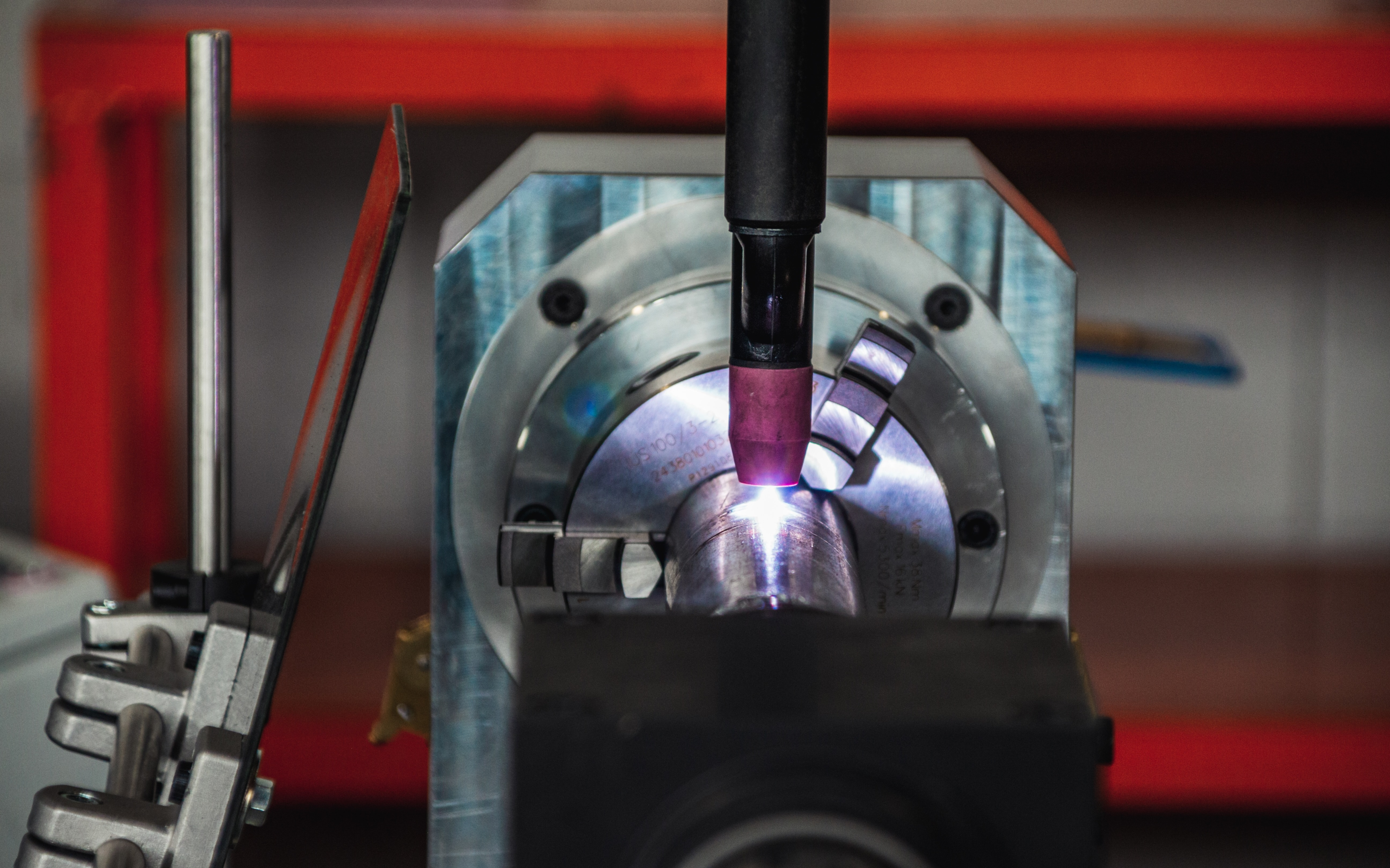

CNC laser welders use the same technology as a handheld welding machine but utilize a CNC-controlled arm to hold and move the welding gun.

You trade the portability and simplicity of handheld units for higher welding precision, cleaner welds, and versatility of CNC.

A CNC (computer numerical controlled) laser welding machine is best suited to mid-size factories that deal in large-volume production cycles.

III. Industrial Laser Welding Robot

Welding robots are 6-axis computer-controlled units that can accurately weld large and complex projects.

The robotic arm operates similarly to the CNC machines but can weld a single project from multiple angles without removing and re-clamping the workpiece to a workbench.

Industrial units are typically reserved for projects that are complex, time-sensitive, and demand high accuracy & precision.

If you are interested, we have also prepared a comparison article between handheld welding machines and welding robots.

IV. Combination Laser Cutters and Welders

Laser welders are a less powerful and more diffused version of laser cutters. Therefore, using the same laser beam to cut and weld metal is possible.

Combination machines do precisely this by offering a low-powered fiber laser that can perform multiple tasks. At its highest power, the laser can cut through thin metal sheets. At the mid-power level, it can weld thin plates; at its lowest power level, it can be used as a laser marking and cleaning system.

Such devices can accomplish multiple tasks simultaneously but don’t excel in one specific field.

Cost of a Laser Welding Machine

The cost of a laser welding machine can vary widely from model to model. A cheap portable laser welding machine costs the same as an expensive smartphone. In contrast, the top-of-the-line industrial model will cost more than the price of an average house in the US.

We can take laser welding machines and break them down into four price points.

Please note the prices are in $USD and are subject to change after publishing this article.

I. Low Cost – Small Laser Welding Machines

Let’s talk about the cheapest laser welding machine you can buy now. You can get a functioning 500W fiber laser welder for sub $2,500.

These machines are mostly helpful for welding thin metal sheets and low-strength metal plates. These machines are primarily suited to small workshop owners and hobbyists.

II. Entry-Level Fiber Laser Welders

Proper entry-level laser welders range between $2,500 and $10,000. You can expect at least a 1kw laser-equipped laser machine at this price point.

These machines will come with quality features like adjustable laser power output power. The adjustability results in higher material compatibility and more versatility when welding.

You are still stuck with a handheld laser welding gun at this point. But the machine’s quality, fit, and finish will improve over cheaper models.

III. Mid-Ranged Fiber Laser Welders

You’ll see a lot of variety from $20,000 to $100,000 in this price range. Mid-range machines range from high-quality handheld laser welders to automatic CNC laser welders with 2-3kW lasers.

A mid-level welding machine is best suited to factories that perform welding operations daily. You can deploy these machines in practically any industry.

A CNC laser welding machine is particularly useful for small electronics welding, medical equipment manufacturing, and light automotive work.

IV. High-End Fiber Laser Welders

Finally, we jump over to the big leagues. Industrial manufacturing equipment is always expensive, and laser welding is no exception. A high-end laser welding machine will start at $100,000 and go up to a million.

All industrial welders will have 2kW or greater laser power output. Its performance or laser power does not define the cost of a high-end laser welder.

Industrial machines must run consistently without fail and come with several safety features and redundancy. You’re not just paying for the performance but also the reliability.

The biggest cost factor here is going to be the automatic feature set. Such laser welding machines are typically deployed in automotive and aerospace industries, where their precision, reliability, and production capacity are highly valued.

Benefits of Fiber Laser Welding

Fiber laser welding has slowly reached the point where it outpaces traditional MIG or TIG welding by a country mile. The most significant advantage of laser beam welding is a lack of consumable filler metal and inert gas.

Following is a short list of the benefits of a fiber laser welding machine over traditional arc welding machines.

- Higher precision when welding smaller or fragile parts

- Faster welding speed.

- Lower heat output from the laser results in minimal warping

- Higher quality weld finish.

- Unlike shielded metal arc welding, fiber lasers do not produce welding slag.

- No-filler metal is required.

- No tool wear, as laser welding is a non-contact welding process.

- Easier automation capabilities for high-volume productions

Additionally, a manual fiber laser welder is much easier to handle than any manual metal arc welding gun due to its compact size.

Table 1 - Fiber laser welder vs. traditional laser welders (metal inert gas welding)

| Property | Fiber Laser | Traditional Laser |

|---|---|---|

| Laser Efficiency | Very High | Low |

| Laser Precision | Very High | Medium |

| Heat Output | Medium | High |

| Size | Compact | Large |

| Welding Speed | High | Slow to Medium |

| Filler Metal Required | No | Yes |

| Inert Gas Required | No | Yes |

| Automation Capabilities | High | Very Low |

| Weld Quality | Excellent | Acceptable |

| Material Compatibility | Limited Compatibility With Reflective Surfaces | Incompatible with Sensitive or Volatile Materials |

| Post Weld Cleaning | Not Required | Required |

8 Factors that Affect the Price of Laser Welding Machines

The price of a laser welding machine is dependent on several complex factors. Each element listed below contributes to the overall cost of a laser welding machine in different ways.

1 – Machine Type

A handheld laser welder is the cheapest laser welding machine available. Comparatively, any automated laser welding solution will increase the cost of the machine by a few thousand dollars.

2 – Laser Power

Laser power is another big cost contributor, as higher-power lasers require better construction materials, higher-quality lenses, and additional cooling.

Most laser welding machines don’t exceed 2kW of power, which is enough for most welding operations.

3 – Laser Precision

The laser spot diameter defines laser precision. A smaller diameter will result in higher precision but requires higher-quality optics.

Cheaper laser welding machines use less quality optical fiber transmission, which results in poor overall precision.

4 – Productivity

The productivity of a laser welding machine is defined by its welding speed. Welding speed, in turn, is directly linked to laser power and precision.

A low-power laser will move more slowly to compensate for its lacking energy output.

5 – Maintenance Costs

Any laser welding machine will use high-quality parts and materials that will not wear or degrade over time.

Fiber lasers, in particular, have a much longer lifespan (over 25,000 hours) than traditional manual arc welding, which uses consumable filler rods.

6 – Brand Recognition

Well-known brands typically cost more due to their widely known presence in the market. The added cost has less to do with quality and more to do with better customer care.

7 – Automation Capabilities

Not all automation setups are equal. A standard CNC laser welding machine will only have a 3-axis motion, allowing it to weld over a flat workbench.

Additionally, these machines require manual oversight from operators to ensure accurate welds.

Fully automatic welding robots are much more versatile and can move in 6-axis. They also come with self-monitoring and correction capabilities, removing the need for operator oversight.

8 – Additional Features

The biggest cost factors for any laser welding machine have nothing to do with lasers or welding. Product warranty, after-sale services, and on-site maintenance support are the biggest cost additives.

Large-scale factories typically don’t have the time to train operators for maintenance and troubleshooting. Therefore, business owners highly value after-sale maintenance, diagnostics, and repair services.

Choosing the Best Laser Welding Machine for Your Business

Not all laser welding machines function equally, and one machine might be best suited to someone else’s business but be incompatible with your business needs.

Consider the following factors before selecting your laser welding machine..

1. Understanding Your Business Needs

Take a look at your business’s current welding needs. A higher-end laser welder might seem more attractive, but you should avoid it if your business cannot fully utilize its flexible processing capabilities.

Businesses requiring occasional welding solutions or dealing with low-volume products should stick with budget machines.

If you have concrete expansion plans for your business in the upcoming few years, you can splurge for the more expensive models. But if your expansion plans are 5-10 years away, it’s best to stick with a low-cost model for now.

2. Comparing Prices and Brands

Always get two to four quotes from different vendors/brands. Most manufacturers sell directly to customers and offer lower rates than hardware importers.

Additionally, you can get customized quotes and discounts according to your needs.

3. Confirm Shipping Costs Before Purchase

A laser welding machine can be heavy and requires robust packaging for international shipping. Fluctuating shipping costs, taxes, and other small charges can significantly increase the total price of your laser welder.

Confirm your expected shipping costs beforehand. If a supplier is closer to your location, you will see significant cost savings.

4. Checking the After-Sale Service

A good value add for new buyers is the after-sale services. Most sellers will offer free installation or maintenance services with the sale of such products.

Replacement parts are another big selling point for some suppliers. Laser welding machines are fairly robust, but in the case of accidental damage, you should at least have the option for replacement parts.

Conclusion

Laser welding machines come in various shapes and sizes at different price points. Choosing the best laser welding machine for your business is about assessing your business’s current needs and getting the most suitable product.

Traditional laser welding technology might seem appealing due to its lower price. But over time, you will benefit more from the compact size, higher reliability, and versatility of a fiber laser welding machine.

Take Your Business to New Heights with Baison Laser

Baison Laser is a leading Chinese manufacturer and supplier of fiber laser systems. We have served customers in over 100 countries and regions for over two decades.

Our commitment to quality, attention to detail, and manufacturing expertise have allowed us to establish a foothold in the international market.

Get a premium handheld laser welding machine or a state-of-the-art laser welding robot. We also offer training sessions to help get your workforce acquainted with your new laser welding machine.

Please take advantage of our FREE application evaluations before you invest in a laser welding machine. Make your business a massive success with Baison.