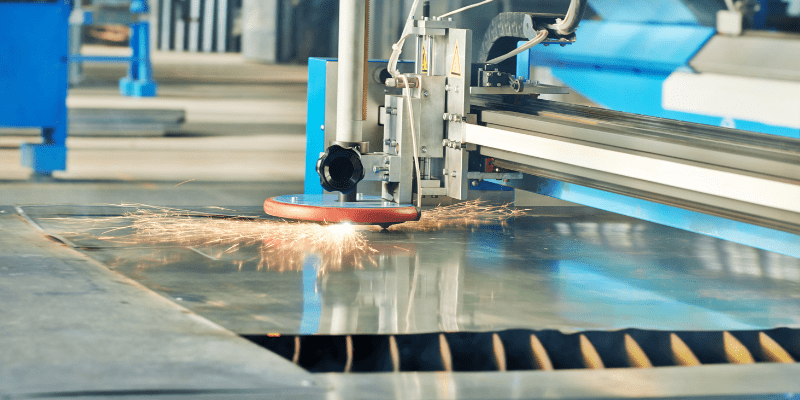

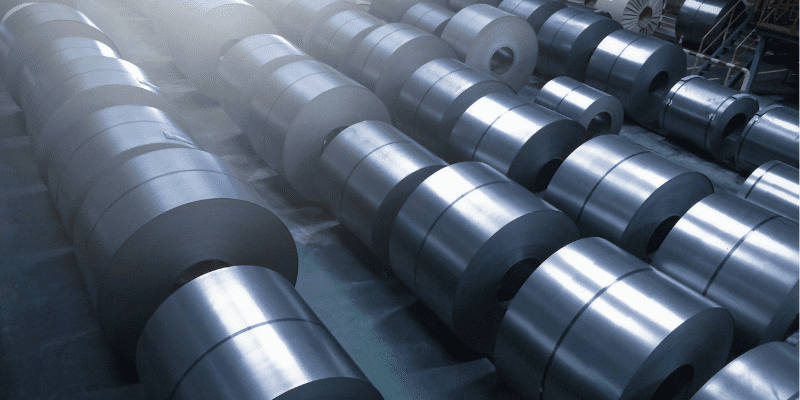

Coil-fed Laser Blanking System

Our coil-fed laser blanking systems at Baison are a flexible solution for any-sized manufacturing operation. Ideal for saving space, reducing material costs, and expediting productivity.

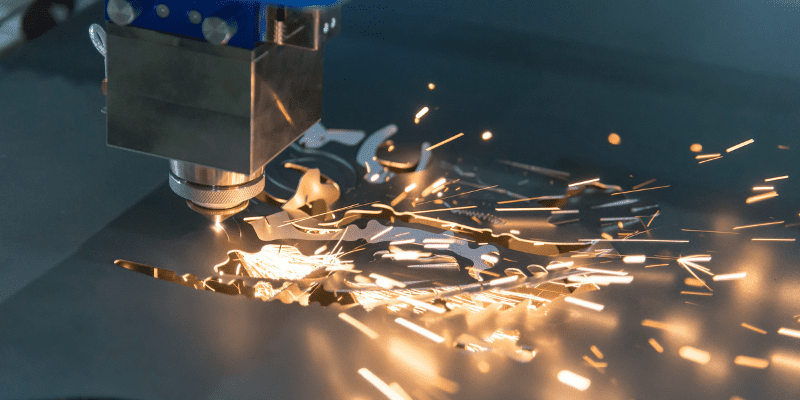

Performance-Driven Features that Facilitate Higher Output

Today, there’s a worldwide shift toward the improved efficiency of coil-based laser cutting. Here are just a few features and advantages forward-thinking manufacturers are discovering.

Zero-Delay Cutting

Removing time-latent material transport processes with direct-from-coil cutting.

Simple Learning Curve

Easy to use for new operators and seasoned manufacturing professionals alike.

Heightened Precision

Leveraging a high-accuracy leveling system to ensure precise cuts, every time.

Full-Spectrum Automation

Saving time that would have been spent transporting materials, sorting, and more.

Implement Flexible Changes

It alleviates the need for bending tools while allowing for agile production modifications.

Exceptional Cost Savings

We are reducing costs through tight nesting and bulk material purchases.

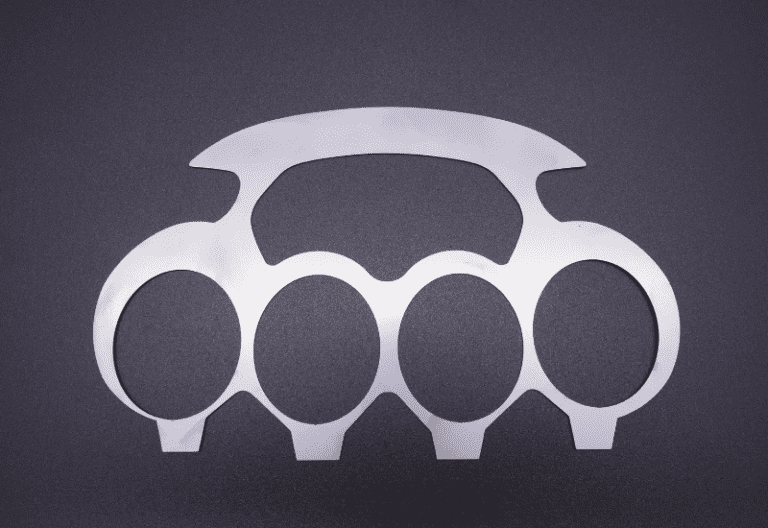

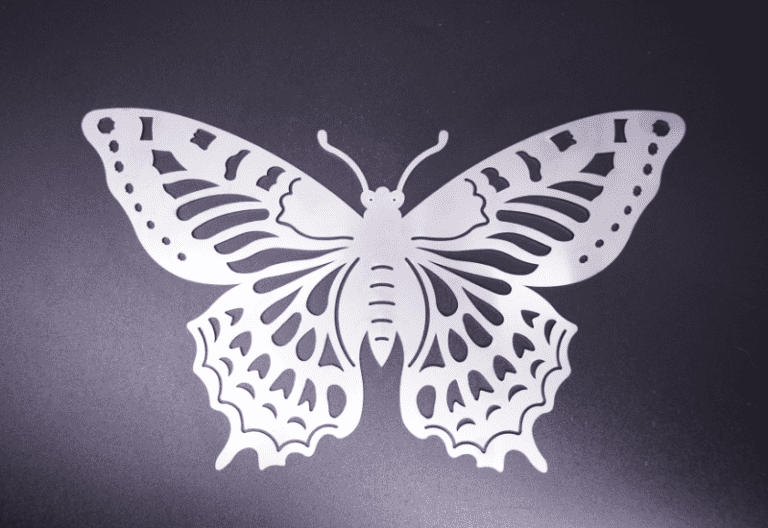

Boosting the Production Process Across Use Cases

From heavy-duty equipment to everyday products, investing in a coil-fed laser cutting machine is worthwhile for manufacturers of all specialties.

Billboards

Aluminum Curtain Walls

File Cabinets

At the Crossroads of Power, Accuracy, and Speed

Take an up-close look at the specs of our coil-fed laser blanking systems at Baison for an idea of how much more efficient your operations could be.

| Model | EJ | SJ |

|---|---|---|

| Laser Power | 1500W~3000W | 1500W~3000W |

| Cutting Area | 3000×1500mm 6000×1500mm | 3000×1500mm 4000×1500mm 6000×1500mm 6300×2000mm |

| Max Moving Speed | 120m/min | 120m/min |

| Positioning Accuracy | ±0.03mm/m | ±0.03mm/m |

| Repositioning Accuracy | ±0.03mm | ±0.03mm |

| Max. Acc. Speed | 1.2G | 1.2G |

| Coil thickness | <3mm | <3mm |

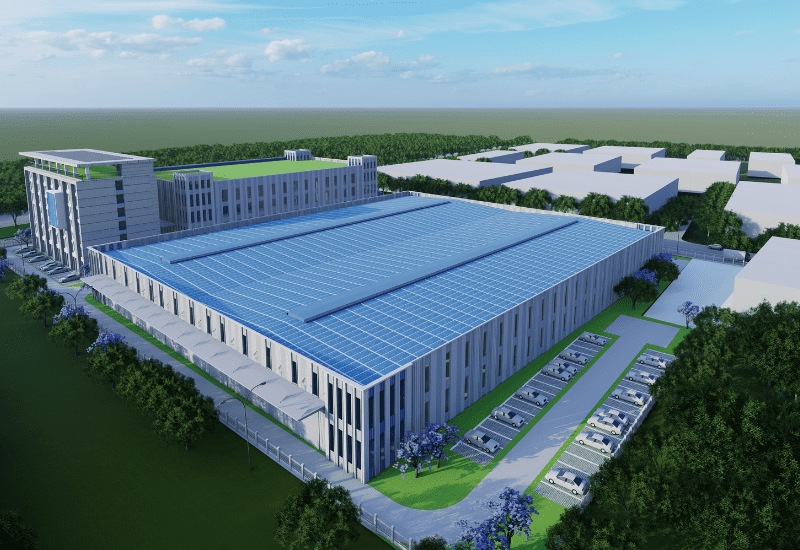

Import Laser Machine from China is Pretty Easy

While we handle the logistics process, you can continue doing what you do best. In the meantime, we will bring your new laser blanking system directly to your manufacturing floor.

Hassle-Free Logistics

From creating custom laser blanking solutions in our state-of-the-art manufacturing plant to ensuring a smooth shipping process, we take care of our partners at every turn.

In-House Installations & Commissioning

With Baison, you don’t need to worry about getting your laser cutting system to your doorstep or even installation. We handle everything, including commissioning.

Actionable Training Walkthroughs

With the end-user in mind, we conduct relatable, casually-paced trainings that even the newest operator can keep up with.

24/7 Technical Support Available

Don't let unexpected roadblocks curtail your production. Our 24/7 support team is here to assist you at any time.

Putting Power into Your Production with Baison

We take our reputation as the best metal laser blanking machine manufacturer seriously. Our end-to-end system and service solutions unveil new possibilities for manufacturers worldwide.

Whether we’re carrying out R&D for a custom solution or ensuring that every stage of the logistics process goes according to plan, you can take confidence in partnering with our team.

While offering the most competitive coil-fed laser blanking machine prices, we integrate the best-in-class software to match. In turn, you can maximize your production potential.

- Rated 5-stars by industry-leading manufacturers

- Over 20 years of committed laser blanking expertise

- An expansive dealer network for anywhere, anytime support.

Laser Blanking Knowledge

Explore our resources below for a deep look at the technology driving tomorrow’s manufacturers. Our leading engineers, who design our coil-fed laser blanking line, write our articles.

7 Advantages of Coil-Fed Laser Cutting You Need to Know

What is coil-fed laser blanking and How does it work?

What is Fiber Laser Cutting?

Common Questions

Whether you have prior exposure to laser blanking or are new to the technology, we invite you to explore the answers to the common questions below.

What configuration does your coil-fed laser blanking use?

Our coil-fed laser blanking systems are made with world-class components. The laser source uses an IPG or Raycus laser source, a WSX laser head, and an FSCUT (CypCut) control system.

Can I place an order from a local Baison dealer?

Yes. While all our orders are designed and produced from our facilities in China, you can order your coil-fed laser blanking directly from a local dealer.

How long are your shipping turnarounds?

You can expect a 10 to 15-day production process (longer for custom solutions) and a 15 to 30-day shipping pipeline. In total, our customers receive their machines within 25 to 45 days.

Do you offer a machine warranty?

Yes, all of our laser machines are protected by a 3-year warranty, including remote support, on-site repairs, and part replacements for machine breakdowns.

Raise the Bar for Your Productivity with Baison

Whether you have questions about our coil-fed laser blanking systems or are interested in a complimentary quote, we invite you to contact us using the form below.