This article simplifies the process, outlining key factors to help you find an affordable and high-quality laser welding machine. By focusing on your specific needs and budget, you’ll be better equipped to make a wise investment that boosts your business’s productivity and profitability.

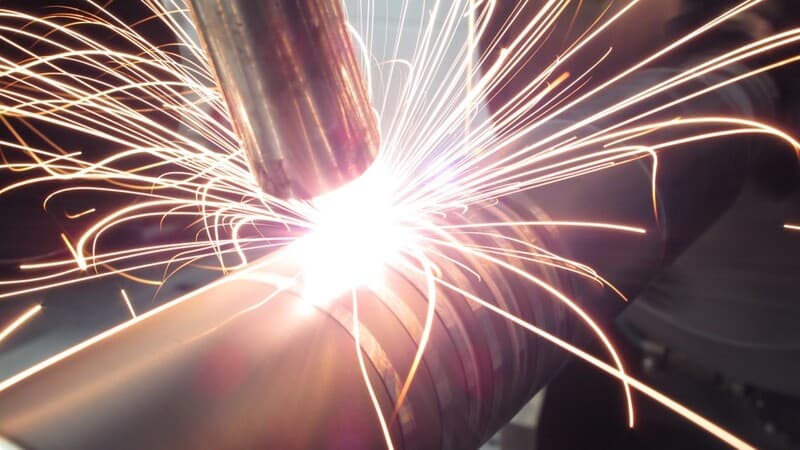

What Is Laser Welding?

Laser welding is a state-of-the-art manufacturing technique that utilizes a beam of light to fuse together materials, often metals or thermoplastics. This method is known for its precision, efficiency, and speed, which surpasses traditional welding techniques. Additionally, the use of laser welding brings a level of automation to the manufacturing process, resulting in quicker and more streamlined results.

Moreover, this advanced technology revolutionizes the way industries approach welding tasks. The process minimizes heat input, reducing distortion and damage to surrounding materials. Additionally, you can also get automatic laser welding machines. This is important for businesses that want consistent results. Also, automation can bring down production costs leading to increased revenues.

What Are the Different Types of Laser Welding Machines?

There are several types of laser welding machines available on the market. Each comes with its unique features and applications. Let’s take a closer look at some of the most popular options:

1. Handheld Laser Welding Machine: most used by manufacturers in the industry. Handheld laser welding machines are known for their user-friendliness and versatility. These portable devices are perfect for businesses looking for versatile solutions that can handle various welding tasks with precision and speed. Moreover, their ergonomic design allows for comfortable operation, making them a top choice for businesses requiring on-the-go welding capabilities.

2. Spot Laser Welding Machine: Spot laser welding machine specializes in creating localized welds on small, intricate parts. They are often used in the jewelry industry and for manufacturing electronic components and medical devices. Hence, spot laser welding machines deliver remarkable precision and negligible thermal distortion, rendering them perfect for intricate and sensitive tasks.

3. Fiber Laser Welding Machine: Fiber Laser Welding Machines provide exceptional precision and top-notch welds. They are widely employed in the automotive, medical, and electronics sectors. Not only do these machines boast energy-efficient laser capabilities, but they also require minimal maintenance and are compatible with numerous materials. Additionally, they offer the flexibility to experiment with high-energy laser pulses.

By the way, learn about how to choose a fiber laser welding machine.

4. Seam Laser Welding Machine: manufacturers use a seam laser welding machine to create continuous welds. Oftentimes these welds are created along the material’s edge. As a result, it helps ensure there is a strong bond. They are suitable for applications that require leak-proof, smooth, and high-quality welds, such as in the aerospace and automotive industries.

How Does a Laser Welding Machine Work?

A laser welding machine follows a simple yet precise process of joining materials. Here is a step-by-step breakdown that makes it easy to understand:

1. Preparation: Clean the materials to be welded, ensuring they are free from dust, grease, or any other contaminants. Make sure everything is properly aligned.

2. Focusing the Laser: This is where the typically generated laser beam, either by fiber laser source or solid-state source, is focused on the material being welded.

3. Melting the Material: The laser beam heats the materials at the point of contact, causing them to melt and form a small pool called the weld puddle.

4. Seaming: This is when the high-intensity laser melts the material and leaves behind a seam as it passes by. You can also call this the joint.

5. Cooling System and Solidification: The molten materials cool down and solidify, forming a strong and durable bond between the welded parts.

6. Inspecting the Weld: After the weld has cooled and solidified, it is inspected for quality and consistency to ensure a successful outcome.

What Are the Common Applications of Welding Machines?

The laser welding machine has a wide range of applications across various industries due to its precision, efficiency, and versatility. Some common industries that utilize these machines include:

1. Automotive: This is probably one of those industries that makes the most of the use of laser welding machines. Automakers use it for assembling vehicle components, such as body panels, chassis, and engine parts. As a result, it ensures high-quality welds with minimal distortion, resulting in lighter and more durable vehicles.

2. Shipbuilding: In shipbuilding, laser welding machines are used to join large metal sheets and structural components. The laser welder allows for faster production times and higher-quality welds. Hence, this improves the overall strength and durability of ships and marine vessels.

3. Construction: The construction industry uses laser welding machines for fabricating metal structures, such as steel beams, columns, and trusses. The technology ensures strong and reliable welds that can withstand heavy loads and harsh environmental conditions.

4. Aerospace: this industry requires high precision welding because there is no room for error. As a result, laser welding machines come in really handy for manufacturers. They use it for critical components like aircraft structures, turbine engines, and fuel systems.

5. Appliances: The appliance industry utilizes laser welding machines for joining various components of household appliances, such as refrigerators, washing machines, and ovens. This ensures a sleek and seamless appearance and enhanced durability and functionality.

6. Electronics: In the electronics industry, laser welding machines help connect small, delicate components like circuit boards and sensors. The process provides highly accurate and clean welds essential for properly functioning electronic devices.

What Should You Consider While Choosing a Welding Machine?

When choosing a laser welding machine, you must consider the following key factors to find the right fit for your business needs:

1. Material Type: Consider the materials you’ll be welding, as different machines may have varying capabilities to handle specific materials, such as metals or thermoplastics.

2. Welding Requirements: Assess the complexity, size, and precision required for your welding tasks. This will help you choose a machine that meets your specific application needs.

3. Budget: Determine your budget and weigh it against the machine’s features, quality, and long-term value. While affordability is important, investing in a reliable and efficient machine can save you money in the long run.

4. Machine Type: Based on your requirements, select the most suitable type of laser welding machine, such as handheld, fiber, spot, or seam welding machine.

5. Power Output: Consider the machine’s power output; higher power can result in faster welding speeds and increased penetration depth.

6. Ease of Use: Look for machines with user-friendly interfaces and controls, as this can enhance productivity and reduce the operator learning curve. Also, looking for easy-to-use laser welding equipment would be best.

7. Automation Capabilities: If your business requires high-volume production, consider an automatic laser welding machine to improve efficiency and consistency and reduce labor costs.

8. Service and Support: Opt for a machine from a reputable laser welding machine manufacturer that offers reliable after-sales support, maintenance, and training services. Laser welders often need this assistance in the initial phases.

9. Integration: Ensure the laser welding machine can easily integrate into your existing production processes and workspace.

10. Safety Features: Check for built-in safety features, such as protective enclosures and warning systems, to ensure the well-being of your operators and maintain a safe working environment. This is vital for continuous laser welding machines because of their high-intensity laser energy,

How Much Does a Laser Welding Machine Cost?

Here’s a table displaying the general price range for different types of laser welding machines:

| Type of Machine | Price Range |

| Handheld Welding | $5,000 – $30,000 |

| Fiber Laser Welding | $20,000 – $100,000 |

| Spot Laser Welding | $10,000 – $50,000 |

| Seam Laser Welding | $30,000 – $150,000 |

Please note that these price ranges are approximate and may vary depending on factors such as brand, features, and regional differences. Researching and comparing different manufacturers and models is always advisable to find the most suitable machine for your needs and budget.

Common Misconceptions about Laser Welding Machines

1. Limited Material Compatibility: Many believe that a laser welding machine can only handle specific materials. In reality, they can weld a wide range of metals and thermoplastics, making them versatile and suitable for various industries.

2. High Costs: Some assume that laser welding machine is too expensive for small businesses. However, affordable options and long-term cost savings from increased efficiency and reduced labor make them viable investments for companies of all sizes.

3. Complexity: The misconception that laser welding machine is too complex to operate often deters potential users. Modern machines feature user-friendly interfaces, making them easy for operators with varying skill levels to learn and use.

4. Safety Concerns: People often associate laser technology with safety risks. A properly designed laser welding machine comes with built-in safety features and guidelines to ensure operator safety and maintain a secure working environment.

5. Low Weld Strength: There is a misconception that laser welds are weaker than traditional welds. In fact, laser welding machines can produce strong, high-quality welds with minimal distortion.

6. Limited Weld Types: Some believe that a laser welding machine can only produce specific weld types. However, depending on the application, these machines are adaptable and capable of creating a range of welds, such as butt, lap, or fillet welds.

By dispelling these common misconceptions, businesses can make informed decisions about implementing a laser welding machine and harnessing its benefits to improve productivity, efficiency, and product quality.

What Is the Most Affordable Laser Welding Machine?

The most affordable laser welding machine is the handheld laser welding machine. Our company, Baison Laser, primarily promotes these portable devices due to their cost-effectiveness, versatility, and ease of use. This makes them an ideal choice for businesses seeking a budget-friendly welding solution.

Benefits of Handheld Laser Welding Machines:

1. Cost-effective: As a business with a low budget, handheld welding machines are generally more affordable. As a result, they offer an attractive option for small businesses and budget-conscious buyers.

2. Versatility: These machines can handle a wide range of materials and applications, making them valuable assets in various industries.

3. Portability: Their lightweight and portable design allows for easy transportation, enabling on-the-go welding tasks and quick adjustments.

4. User-friendly: Handheld laser welding machine is easy to learn and operate, reducing the learning curve for users with different skill levels.

Limitations of Handheld Welding Machines:

1. Manual Operation: Handheld laser welding machine requires manual operation, which may affect consistency and precision compared to automated welding systems.

2. Operator Fatigue: Prolonged use of a handheld laser welding machine may cause operator fatigue, impacting productivity and weld quality.

Investing in a handheld laser welding machine is a smart decision for businesses purchasing small laser cutting machines. Many materials typically require welding after cutting and by purchasing both machines together. Hence, you can save on freight costs and streamline your production process.

Conclusion

Laser welding machines have revolutionized the manufacturing industry by offering precise, efficient, and versatile welding solutions. Choosing the right machine for your business is crucial in optimizing productivity and cost savings.

The handheld welding machine, in particular, provides an affordable and portable option that can cater to various applications across different industries.

Elevate Your Business With Baison’s Tailor-Made Solutions

At Baison, we understand that every business has unique needs and challenges. Our team of experts is dedicated to providing personalized guidance and support, ensuring you find the perfect laser welding technology or cutting solution to elevate your operations.

With our industry-leading technology, exceptional customer service, and commitment to excellence, Baison is your trusted partner. Ask for a quote today.