Laser sitting systems are solely dependent on different equipment such as mirrors, lenses, etc. These components focus and direct the laser beam, ensuring precise and efficient interaction with your target material. However, dust, debris, and contaminants can accumulate on these delicate surfaces, leading to decreased beam quality, reduced power, and even permanent damage.

Maintaining clean laser optical surfaces is crucial for optimal performance and longevity of your laser system. This guide delves into the importance of proper cleaning, common contaminants, and the essential steps for both daily and deep cleaning, empowering you to keep your laser vision sharp.

What is Laser Optics?

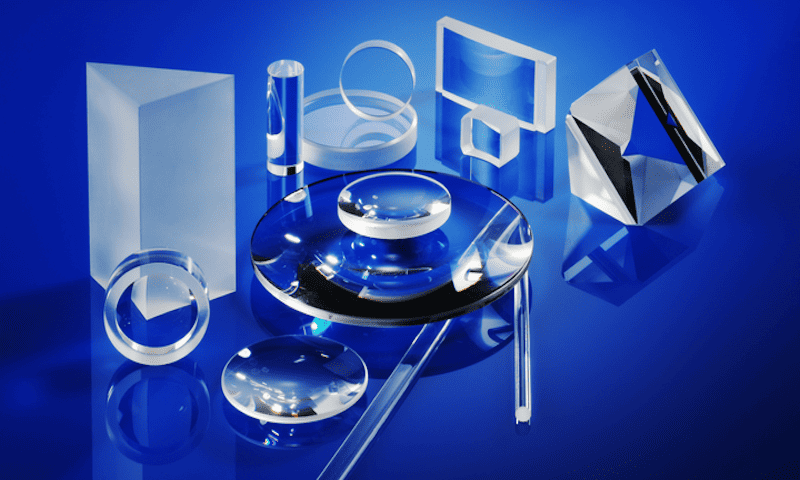

Beam steering and material processing are just two of the many laser applications and equipment that use laser optics. Laser optics offer better performance at a variety of laser wavelengths or at particular laser wavelengths by using particular substrates, coatings, or a combination of the two.

Basically, all optical components and systems utilized in lasers or for controlling or transferring laser light are collectively referred to as laser optics. Compared to ordinary imaging optics, the standards for surface quality and coating are stricter for a laser optical component.

Laser optics encompass various optical components:

- Focus lenses: These lenses work to direct and concentrate the laser beam onto the target area, no matter how small or large.

- Collimating lenses: These are used to correct beam divergence, ensuring consistency with beam diameter.

- Output couplers: Output couplers allow a portion of the laser beam to exit the cavity.

- Mirrors: The mirrors in the equipment set in the laser machine reflect and redirect the laser beam along the desired path.

Do You Have Any Questions?

Let Us Solve Your Problem

The Importance of Properly Cleaning Laser Optics

When working with a laser, precision is one of the biggest required outputs. For that to happen, the equipment needs to be perfect so that the output comes out as needed.

The optic surface needs to be cleaned properly. Any unwanted particles can damage the optical coating on the components by reacting with the laser beam. And ruined optical coatings mean ruined laser optics. Dirty optics can have several detrimental effects:

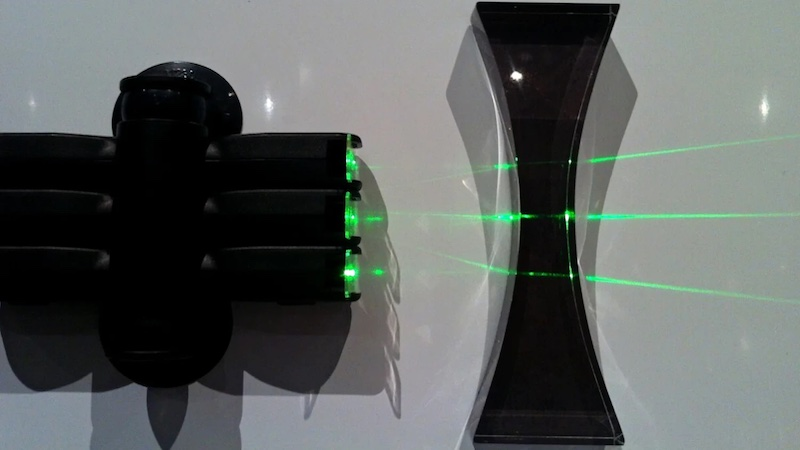

- Reduced beam quality: Contaminants harm the accuracy of the laser beam. Any contaminants have the potential to scatter and distort the laser beam, affecting its focus and precision.

- Power loss: Any dirt particles present in the optics can hamper the laser. Dirt absorbs some of the laser energy, weakening the beam and reducing its overall power.

- Heat generation: Absorption of laser energy by contaminants can lead to localized heating, potentially damaging the optics.

- Premature component failure: The uncleaned optical surface is more susceptible to permanent damage, requiring costly replacements.

What Causes Dirty Laser Optics?

We use laser machines in workshops and other spaces where it is pretty normal for the lenses to gather dust particles but clean optics is a priority. And so, cleaning the instruments at a certain interval is a must. Several factors contribute to dirty optics:

- Ambient dust and airborne particles: There are a lot of various types of particles floating in the air. These ambient airborne particles, such as dust, smoke, and other microscopic contaminants, readily settle on exposed surfaces.

- Material residue: A lot of the time, the main issues caused by dirty lenses come from the residue from a previously worked-on material. Traces of processed materials like metal splatter or vaporized plastic that can adhere to the optics.

- Organic contaminants: Many types of organic components, for example, oils and other organic substances, can leave residue on the optics.

Do You Have Any Questions?

Let Us Solve Your Problem

Preparing for the Cleaning Process

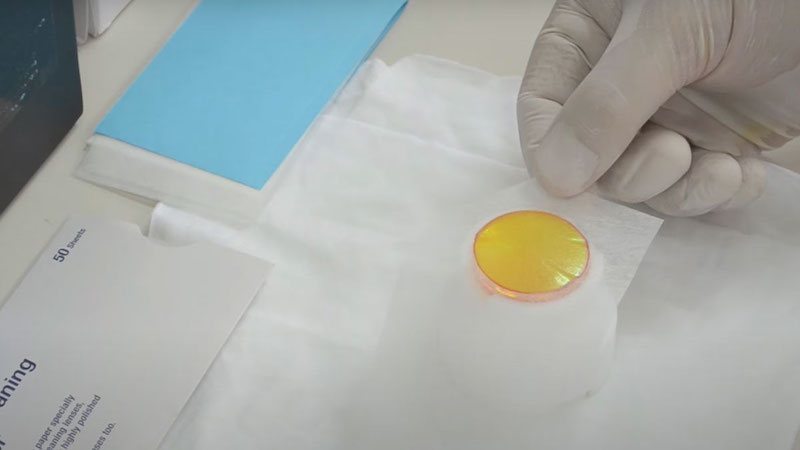

Some optical surfaces are very sensitive. They can be damaged by any physical touch from hands or optical handling instruments. Examples of these surfaces are ruled and holographic gratings, and the first surface unprotected metallic mirrors and pellicle beamsplitters. So, it is important to keep these in mind when attempting to clean optics.

Before diving into the cleaning itself, you must make sure that you are properly equipped to carry out the processes. To ensure proper preparations, you need to follow some steps:

- Step 1: Turn off the laser system and unplug it from the power source.

- Step 2: Consult the user manual for specific cleaning instructions and safety precautions.

- Step 3: Gather necessary cleaning supplies such as compressed air duster, optic tissue, lint-free lens tissue, cleaning solutions (such as isopropyl alcohol or anything specific to your optic type), cotton swabs (for hard-to-reach areas), and appropriate solvents (acetone or isopropanol, but always double-check compatibility with your specific optics!).

- Step 4: Wear appropriate safety gear: safety glasses, gloves, and lab coat, depending on the cleaning solvents used.

How to Clean Laser Optics?

As someone who has to work with laser cutting machines and other laser-related projects, it is mandatory for you to know how to clean laser optics. It may not seem as important, but clean lenses are very important for a better-performing laser machine. You can approach the cleaning process in two separate stages.

I. Daily Cleaning

Daily cleaning is essential to keep the quality of the job on par with the requirements. Just like any other types of sensitive materials In the business, optics are very sensitive, and regular cleaning attempts can reduce damage and production costs.

- Blow away loose dust and debris: Use a compressed air duster to gently remove surface contaminants. Avoid touching the nozzle directly to the optics.

- Wipe with lens cleaning tissues: Use dry, clean lens tissue to wipe the optics in a circular motion, starting from the center and moving outwards. Avoid touching the surface with bare hands.

- Inspect for remaining contaminants: Use a bright light to inspect for any remaining dust, smudges, or fingerprints.

II. Deep Cleaning

Aside from daily cleaning, you need to do some deep cleaning every few months to follow through with a more in-depth cleaning procedure.

- Moisten a lint-free wipe with a suitable cleaning solution. Apply the minimal solution to avoid leaving streaks. Different types of optics require specific cleaning solutions, so always refer to the manufacturer’s recommendations.

- Gently wipe the optics. Use a light touch and avoid applying pressure. Wipe in a circular motion, starting from the center and moving outwards.

- Dry the optics completely. Use clean, dry wipes or compressed air to ensure no cleaning solution residue remains.

- Inspect for damage. Before restarting the laser, carefully inspect the optics for any scratches, cracks, or other damage. If damage is observed, consult a qualified technician.

Do You Have Any Questions?

Let Us Solve Your Problem

Routine Maintenance of Laser Optics

As mentioned, it is clear that cleaning laser optics is something that cannot be ignored. But even then, sometimes it is important to do proper maintenance for the equipment to make sure everything is working correctly. Routine maintenance and replacements are all part of the job.

- Develop a regular cleaning schedule: Daily cleaning is recommended for most laser systems, with deeper cleaning performed at specified intervals according to the manufacturer’s guidelines and usage frequency.

- Store optics properly: When not in use, store optics in their protective covers or sealed containers to minimize dust accumulation.

- Handle with care: Avoid touching the optics with bare hands, and use appropriate handling tools to prevent accidental contamination or damage.

FAQs

1. What safety precautions should I take when cleaning laser optics?

While cleaning laser optics, you can take some precautions like- turning off and unplugging the laser system before cleaning, and never looking directly into the laser beam, even when it’s off.

Wear appropriate safety gear, including safety glasses, gloves, and even a lab coat, especially when using solvents. You can make sure that there is proper ventilation.

2. Can I clean my laser optics with water?

Generally, you cannot clean the optics with water as it can leave residue and potentially damage the delicate coatings on some optics. Use only approved cleaning solutions designed for laser optics.

3. What should I do if I accidentally touch the optics with my bare hands?

It is good to not panic when something like that happens. Wash your hands thoroughly with soap, then follow the daily cleaning procedure using a suitable cleaning solution. Also make sure not to further rub or apply pressure, as this can spread the oils and contaminants.

Do You Have Any Questions?

Let Us Solve Your Problem

Conclusion

Maintaining clean laser optics is not just a chore; it’s an investment in the performance, longevity, and overall health of your laser system. By following the steps outlined in this guide, you can ensure your laser operates at its peak potential, delivering consistent, precise results for years to come.

Remember, prevention is key – regular cleaning routines are far easier and more cost-effective than dealing with the consequences of neglected optics. For additional resources, refer to your laser system’s user manual or consult with the manufacturer for specific cleaning recommendations.

Successful Project With the Help of Baison!

Don’t hesitate to seek professional help if you feel uncomfortable tackling the cleaning yourself. Contact us at Baison and we will always try to help you gain as much knowledge as possible. Invest in the clarity of your laser vision, and watch your projects come to life with unmatched precision and power.