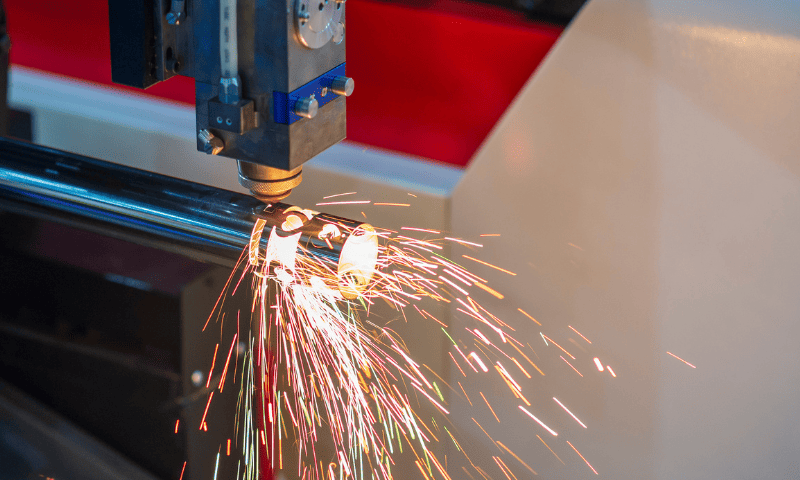

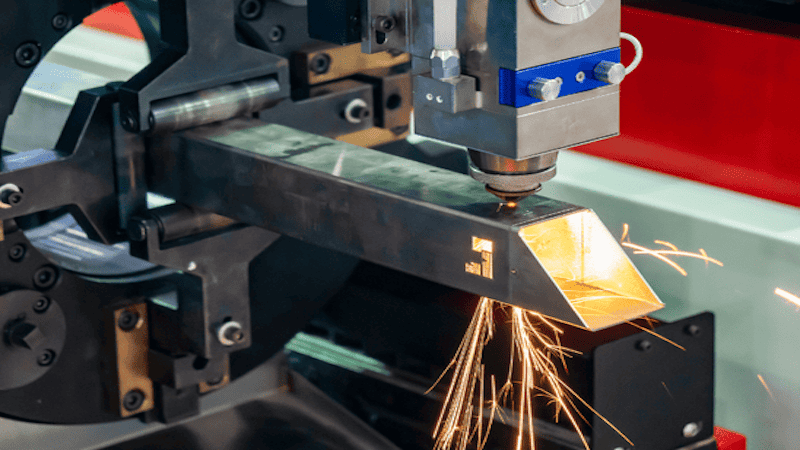

Laser tube cutting machines have rapidly become dominant in the market due to their extraordinary efficiency, versatile applications, and convenience for the manufacturing process.

This article compares, analyzes, and lists the world’s top 10 laser tube-cutting machines to provide insights into the latest available products.

What is a Good Laser Tube Cutter?

An efficient laser tube-cutting machine can propel your business to new heights. Here are the key things you must consider when exploring the market for a good laser tube cutter.

Criteria for an Excellent Laser Tube Cutter

The key factors to consider in exploring laser cutting technology are as follows:

1. Power and Wattage

The power of a laser cutter provides key insight into the capability and capacity of the machine. Typically, laser tube cutting machines are available in the range of 1500-6000 W. Contrarily, more isn’t always better. You need a proper feasibility report covering design complexity, material type, thickness, and compatibility to help you with power rating.

2. Laser Source Type

The main laser sources available in tube cutting machines are CO2 laser and solid-state laser cutting systems. These days, fiber laser cutting machines, an upgrade to solid-state, offer high productivity, precision, and efficiency.

3. Material Compatibility

Not all lasers are built the same. Different laser sources emit varying wavelengths of laser beam intensity, resulting in differences in compatibility with tube material types and thicknesses.

4. Bed Size and Work Area

The bed size of a laser cutting machine provides vital information about the maximum dimensions of a workpiece the machine can handle efficiently. Having an optimal bed size is critical for efficient production.

5. Software and Control System

A highly functioning cutting machine is nothing without its software. Ensure the manufacturer provides high-end laser cutting software capable of efficiently running the hardware. Also, it should be user-friendly.

6. Value Added Service

A good laser tube cutting machine also provides convenient value-added services such as free machine training, repair services, and after-sales customer support.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Top 10 Laser Tube Cutting Machines in the World

Here is a brief overview of all laser cutting machines.

| Sr. | Brand | Machine Model | Power (W) | Thickness (mm) | Max. Tube Diameter (mm) |

|---|---|---|---|---|---|

| 1 | Baison Laser | All-round tube cutter G22 | 1500-6000 | 0.8-10 | 220 |

| 2 | Trumpf | TruFiber 3001 | 3000 | 4-8 | 152 |

| 3 | LightObject | Pro Fiber Tube Cutter | 3000 | 5-15 | 210 |

| 4 | Bystronic | ByTube Star 130 | 4000 | 10-15 | 130 |

| 5 | Bodor Inc. | Q0 Pro Tube Cutter | 3000 | 10-60 | 10-60 |

| 6 | Golden Laser Co. | S12 Plus Tube Cutting Machine | 3000 | 10-15 | 10-120 |

| 7 | ACCURL | TubeLINE 6020BK | 3000-6000 | 10-15 | 12-610 |

| 8 | LVD | LVD TL 2665 | 3000-4000 | 10-15 | 20-160 |

| 9 | StyleCNC | ST-FC60M Laser Tube Cutter | 1000-3000 | 10-15 | 20-220 |

| 10 | ManTech | Titan Metal Tube Cutter | 1000-3000 | 10-20 | 20-220 |

1. Baison Laser All-round Tube Cutting Machine

Baison Laser is a leading Chinese manufacturer of laser cutting machines specializing in fiber laser technology. The All-around tuber cutter is the most versatile laser cutting machine in our product catalog. It features a solid-state laser source that enables the dynamic cutting of metal tubes and pipes. The pneumatic chuck provides full control of the material and zero tail material handling, making the process waste-free.

It comes in three models: G22, G22X, and G22X-E, suitable for various industrial needs. The All-round tube cutters are available in power ratings ranging from 1500 to 6000 Watts. This machine can handle a wide range of thicknesses, from 0.8 to 10 mm, max. dia 220 mm and is compatible with almost all kinds of reflective and non-reflective metals.

All of the machine’s laser equipment is assembled using high-quality materials and cutting-edge technology. Baison Laser collaborates with world-leading industries such as IPG, Ospri, Motovario, and Yaskawa.

Baison Laser’s All-round tube cutting machine is equipped with smart software, enhancing precision, cutting speed, and the ability to handle complex designs with extraordinary accuracy. Additionally, the brand offers valuable services such as sample proofing, project evaluation, and warranties.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

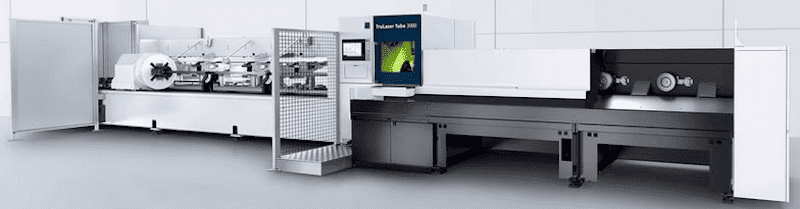

2. TruLaser Tube Cutter

Trumpf, a renowned German brand, is known for producing high-quality laser-cutting machines. Their TruLaser TruFiber 3001 is a reliable and efficient tube cutter operating at 3000 W. It can handle material thicknesses ranging from a minimum of 4 mm to a maximum of 8 mm, with a diameter of 152 mm. However, its performance may vary depending on the type of material used.

Tru Laser also features Rapid Cut technology, capable of creating intricate designs at ultra-fast speeds. It offers flexible digital integration of third-party software, which is an appealing option. However, it’s important to ensure that the software is compliant with the OPC UA standard.

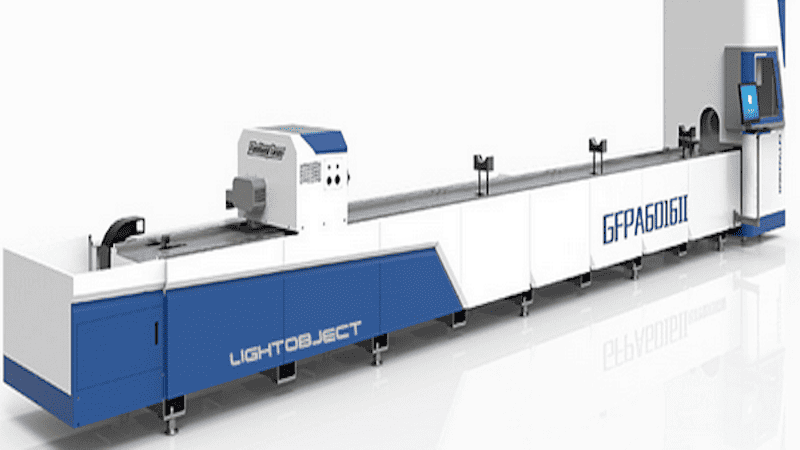

3. Pro fiber Laser Tube Cutter

Pro Fiber is an industrial laser tube cutter manufactured by Light Object, based in California, USA. The machine boasts a robust dual chuck pneumatic clamping system capable of handling materials up to 20 feet in length, with a thickness range from ¾ inches (19 mm) to 8.5 inches (210 mm), making it suitable for heavy-duty manufacturing.

This 3000 W laser tube cutter is equipped with an auto-focusing cutting head, making work on large workpieces more efficient. It is operated using Cypcut, a popular third-party CNC and nesting software.

4. ByTube Star 130

ByTube Star 130 is a highly functional tube cutter manufactured by Bystronic, a multinational machine manufacturer based in Switzerland. Operating at 4000 W, this machine is a solid option for mild to heavy manufacturing tasks. It can automatically set up and load different types of circular and elliptical tubes, reducing chances of human error.

ByTube can handle material thicknesses ranging from 10 to 15 mm and diameters up to 130 mm. It features an additional linear cutting head for increased speed and precision. The machine includes a Laserscan feature compensating for tube bending, ensuring precise and accurate cuts. Also, it has a laser weld seam camera, which enhances cut quality, resulting in finer and mechanically sound cuts.

5. Q0 Pro Small Tube Laser Cutting Machine

The Q0 Pro Tube Cutter is a remarkable Chinese brand Bodor Inc product. This laser cutter is designed for small tube-cutting applications. Its fully automatic loading system can handle diameters between 16 and 60 mm for round or rectangular tubes, processing at 120 m/min cutting speeds. Additionally, the Q0 Pro features extremely short tube-cutting tailings, making the process highly sustainable.

Q0 Pro small tube laser cutting machine operates on the BodorThinker tube system, which is user-friendly and powerful design software.

6. S12 Plus Tube Cutting Machine

Golden Laser Co., a Chinese brand, presents the S12 laser tube cutter designed for small tube processing, similar to the Q0 Pro reviewed above. It handles tubes and pipes ranging between 10 and 120 mm, making it a highly versatile option.

The S12 features a fiber laser source in combination with advanced pneumatic chuck and servo controls, enabling high cutting speeds and efficiency. Moreover, the 3000 W laser tube cutter has a small footprint, making it a convenient option for smaller workshops.

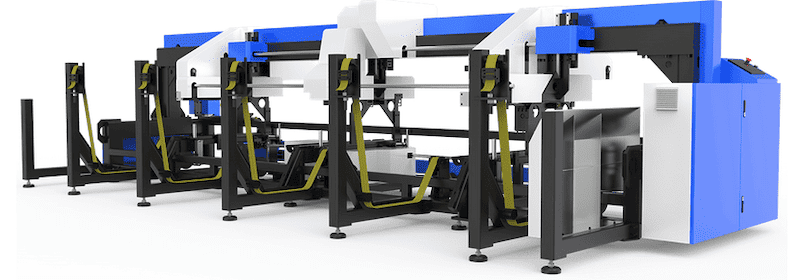

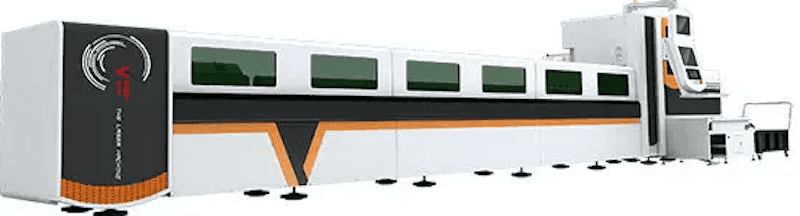

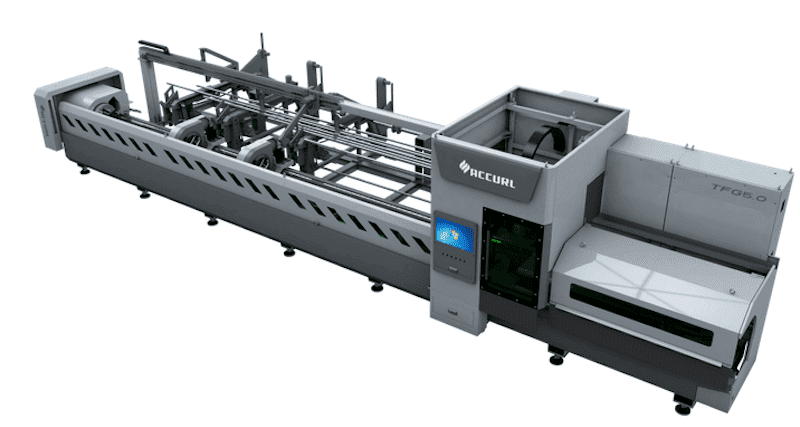

7. TubeLINE 6020BK Tube Cutting Machine

The ACCURL TubeLINE laser cutter is another Chinese product capable of managing large pipe diameters ranging between 12 mm to 610 mm and lengths of around 18 meters.

This heavy-duty machine is designed with fully automatic loading, premium synchronous rotating chucks, and high build quality to support heavy workloads. Managed by the FSCUT-5000 control system, it offers a versatile and user-friendly operating experience. Lastly, It can deliver power between 3000 to 6000 Watts.

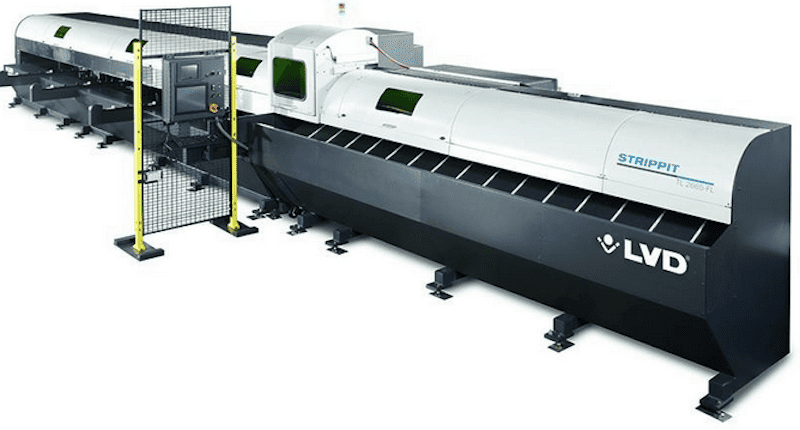

8. LVD TL 2665 Flexible Tube and Profile Cutting Machine

LVD is a European brand based in Belgium, known for its high-quality laser cutting machines. The TL 2665 is another such product, capable of advanced machining and efficiency. Its 7-position front loader enables semi-automatic loading, making it suitable for high-volume production.

With a power output of 3 to 4 kW, it can machine diameters up to 160 mm and lengths close to 8 meters. Additionally, it features bow detection and twist compensation sensors, which enhance precision and accuracy by detecting any ambiguities during the cutting process.

9. ST-FC60M Laser Tube Cutter

StyleCNC is a laser machine manufacturer based in China and the company behind the ST-FC60M laser cutter. This machine can deliver between 1 to 3 kW of fiber laser power, depending on factors such as material type, thickness, and cut requirements.

The CNC laser tube cutter can handle a wide range of products, with diameters ranging between 20 to 220 mm and lengths up to 6 meters. It features an automatic loading system and is capable of simultaneously performing multiple machining processes such as sawing, drilling, cutting, and punching. Similar to Light Object’s Pro Fiber laser, it relies on CypCut for design input.

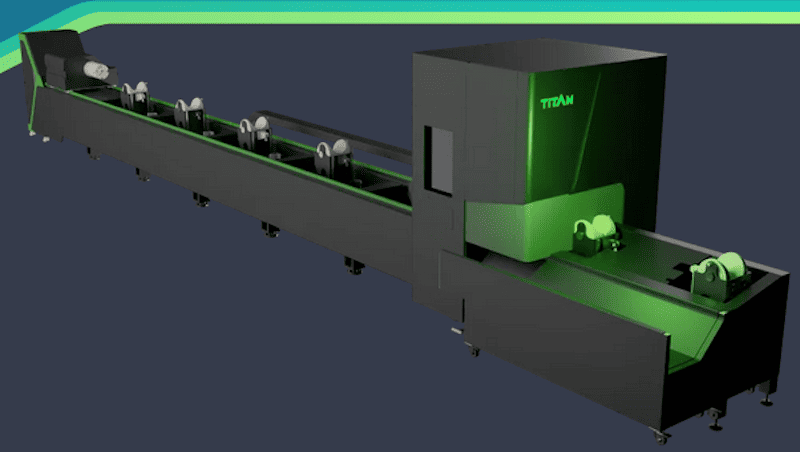

10. Titan Metal Tube Fibre Laser Cutter

The Titan Metal Tube Cutter is a premium-quality machine by ManTech, a leading laser machine manufacturer based in Halesowen, England.

It delivers impressive performance with lower laser output, ranging from 1 to 2.2 kW, but can be configured up to 3 kW. The Titan can easily machine tubes with a maximum diameter of 220 mm and lengths of up to 6 meters. While capable of handling various materials, it is most efficient at machining carbon steel and stainless steel pipes.

Why Choose Baison Laser Tube Cutters?

What sets Baison Laser’s all-around tube cutter apart is its extreme versatility, which can handle multiple machining processes. The power intensity can be configured between 1.5 kW to 6 kW, making it a highly adaptable option for various-sized manufacturing industries. It can handle numerous material types, such as aluminum, brass, copper, stainless steel, and carbon steel of varied thicknesses.

The machine’s work bed can process pipe lengths up to 6.5 meters and diameters up to 220 millimeters. In addition to providing high-quality machines, Baison Laser offers remarkable value-added services such as extended warranties and training.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

FAQs

1. Which Laser-Cutting Machine Is Best?

Baison Laser’s All-round tube laser cutting machine is the best option for all types of industries and workshops. It can machine pipes and tubes ranging from 10 to 220 mm and offers different power intensities between 1.5 kW and 6 kW with a solid-state source, making it highly flexible. The automatic controls and fully integrated software are the cherry on top.

2. Which Laser Is Best For Cutting?

There are different types of laser sources, each serving a different function. Solid-state and fiber laser sources are typically the most efficient and versatile options on the market.

Solid-state lasers are well-suited for thick and reflective materials when considering tube-cutting applications, while fiber lasers excel at the precise cutting of thin and medium-thick materials.

3. Which Is The Best Chinese Laser Company?

Regarding tube-cutting machines, Baison Laser stands out as one of the best Chinese companies. The company specializes in fiber laser cutting, welding, cleaning, and marking machines. It delivers premium-quality products, ensures timely delivery, offers affordable laser cutting machines, and provides comprehensive after-sales services.

4. What Are The Laser Tube Cutting Machine Prices?

Laser tube-cutting machines typically cost $40,000 to $80,000, although high-end models can cost more than $120,000. The price is determined by factors such as the type of material processing, power output, automatic features, and machine characteristics.

Conclusion

We’ve curated a list of the most popular tube laser cutters on the market, including products from world-leading machine manufacturers.

Before deciding, we recommend thoroughly discussing your project requirements with your laser cutting machine manufacturer, as no two products are alike. Our list of the top 10 laser tube-cutting machines aims to significantly reduce your research time and assist you in purchasing the best product for your business.

Baison Laser: Your One-Stop Shop for All Laser Tube Cutting Needs

Baison Laser is a market-leading Chinese fiber laser cutting machine manufacturer catering to clients worldwide across various industries. Our machines are constructed using premium-quality components under the supervision of industry experts. With two decades of experience in laser processing and intensive R&D, we produce durable and highly efficient CO2 and fiber laser cutting machines, as well as laser handheld welding, laser engraving, and marking machines.

At Baison Laser, we offer customized solutions to our customers at competitive prices, ensuring timely delivery. Take advantage of our FREE sample proofing or request a FREE application evaluation for your project today. Contact our expert helpline, available 24/7, to propel your business to new heights.