This comprehensive guide will explore the game-changing features, capabilities, and applications of this advanced equipment across various industries.

Get ready to unlock new levels of productivity and success with the definitive resource on the 4 Chucks Heavy-Load Laser Tube Cutting Machines. You don’t want to miss this!

What Is Laser Cutting Technology?

Laser cutting technology is a precise, non-contact fabrication process that employs a focused laser beam to cut, engrave, or mark various materials. Directing the laser’s high-energy output onto the workpiece efficiently melts, burns, or vaporizes the material, resulting in clean, smooth-edged cuts. Moreover, it is widely used across numerous industries.

Laser cutting has become an indispensable business asset due to its numerous advantages. Its high precision allows for intricate and complex designs, while the non-contact nature of the process reduces material wear and tooling costs.

Additionally, laser cutting’s exceptional speed and automation capabilities significantly enhance productivity, enabling shorter lead times and increased output.

Furthermore, the technology’s flexibility accommodates a wide range of materials and applications, making it suitable for diverse industries. By adopting laser cutting, businesses can optimize their manufacturing processes, reduce waste, and ultimately increase their competitiveness in the market.

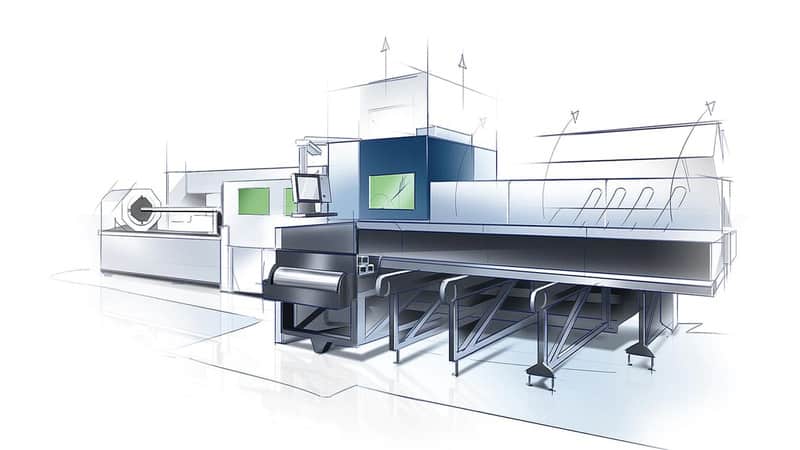

What Is a 4 Chucks Heavy-Load Laser Tube Cutting Machine?

Simply put, 4 Chucks Heavy-Load Tube Laser Cutting Machines are advanced pieces of machinery offering extreme productivity and precision. Its key features include a four-chuck clamping system, a high-precision laser head, and an automatic loading and unloading system.

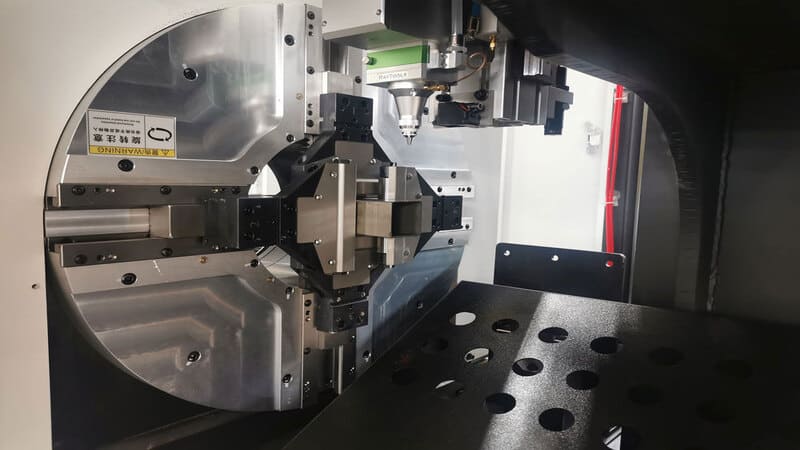

Four-chuck Clamping System

This innovative system ensures a firm grip on the workpiece. As a result, it reduces deformation and increases cut accuracy. Moreover, it also evenly distributes clamping force, minimizing material stress. This helps prevent tube distortion, even during high-speed cutting.

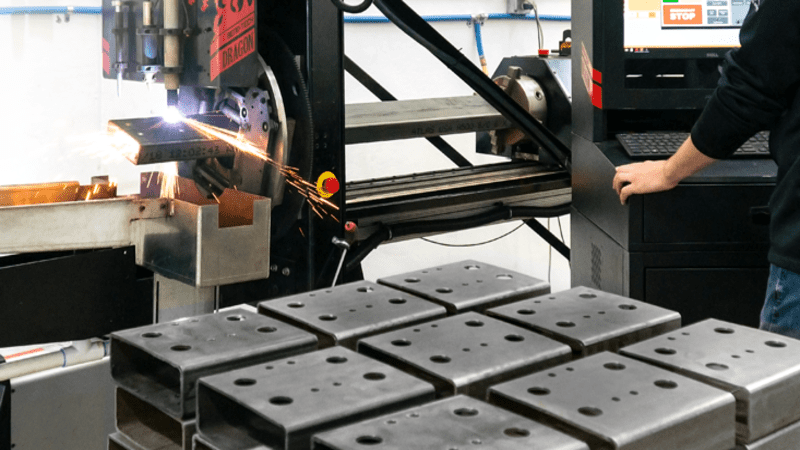

High-precision Laser Head

Equipped with a state-of-the-art laser head, the machine delivers precise cuts with minimal heat-affected zones. As a result, you can achieve smooth, clean edges, reducing the need for post-processing. This takes the overall part quality to the next level.

Automatic Loading and Unloading System

By automating material handling, the machine significantly improves productivity. The system streamlines the loading of raw tubes and the unloading of finished parts, reducing manual labor and downtime while optimizing workflow and throughput.

Advantages of Using the 4 Chucks Heavy-load Laser Tube Cutting Machine

Given the popularity and laser power of the machine, it offers incredible benefits. In fact, it is among the top choices for businesses who wish to optimize their tube-cutting processes to the fullest. Key advantages include high precision, fast cutting speed, and versatility.

1. High precision: Thanks to its four-chuck clamping system and advanced laser cutting head, the machine delivers exceptional cutting accuracy, ensuring minimal material deformation and clean, smooth edges.

2. Fast cutting speed: The combination of the high-precision laser head and efficient material handling system enables rapid cutting speeds, leading to increased productivity and shorter lead times.

3. Versatility: The machine can accommodate a wide range of materials, thicknesses, and tube shapes, making it suitable for diverse industries and applications.

In the table below, we have compared the 4 Chuck Heavy-Load Laser machine with other laser cutting machines head-to-head:

| Feature | 4 Chucks Heavy-Load Laser Tube Cutting Machine | Other Laser Cutting Machines |

| Clamping System | Four-chuck clamping system | Two or three-chuck systems |

| Deformation Control | Minimized deformation | Moderate deformation |

| Cutting Precision | High precision | Moderate precision |

| Cutting Speed | Fast cutting speed | Varies by model |

| Versatility | Wide range of materials and shapes | Varies by model |

| Handling Heavy-Load Pipes | Optimized for heavy-load pipes | Varies by model |

From the table above, we can conclude that the 4 Chucks Heavy-Load Tube Laser Cutting Machine is specifically designed to handle heavy-load pipes and tubes.

Moreover, its robust construction and enhanced clamping system ensure stability and accuracy even when working with large or heavy materials. This capability allows businesses to tackle more demanding projects and expand their service offerings.

Applications of the 4 Chucks Heavy-Load Laser Tube Cutting Machine

Regarding industrial applications of 4 Chucks Heavy-Load Tube Laser Cutting Machines, the usage is endless. Here are some of the most prominent industrial names that use this machine for its efficiency:

1. Automotive: The machine is ideal for producing vehicle components such as exhaust systems, chassis, and suspension parts, where high precision and strength are crucial.

2. Furniture: The machine allows for creating modern, minimalist designs and intricate components for residential and commercial furniture applications.

3. Construction: In the construction industry, the machine can be used for sheet metal fabrication of structural elements like beams, columns, and trusses that require accurate cutting and seamless assembly.

But what about material compatibility? Just like versatile industrial applications, the machine also supports various materials, including:

1. Stainless steel: Stainless steel is known for its corrosion resistance and aesthetic appeal. It It can also be precisely cut with the machine, making it suitable for food processing, medical, and decorative applications. Learn about methods for cutting stainless steel.

2. Aluminum: With its lightweight and corrosion-resistant properties, aluminum is another material that can be effectively cut by the machine, enabling its use in aerospace, automotive, and other industries where weight reduction is essential.

3. Carbon steel: The machine can easily cut carbon steel tubes and pipes, which are commonly used in the construction and automotive industries due to their strength and affordability.

Here Are the Types and Shapes of Tubes It can Easily Cut Through for Businesses:

1. Round tubes: The machine can accurately cut round tubes, which are widely used in various applications due to their inherent strength and resistance to bending.

2. Square and rectangular tubes: The machine can also handle square and rectangular tubes, providing precise cuts and angles for better fitting and assembly, which are essential for structural components and furniture manufacturing.

The 4 Chucks Heavy-Load Tube Laser Cutting Machine is a versatile solution for industries requiring high-precision and efficient tube-cutting processes. Its ability to handle different materials and tube shapes makes it valuable for various applications across numerous sectors.

How Businesses Can Benefit from a 4 Chucks Heavy-load Laser Tube Cutting Machine

Embracing Industry 4.0 with the 4 Chucks Heavy-Load Tube Laser Cutting Machine

The 4 Chucks Heavy-Load Laser Tube Cutter Machine is specifically designed to support automation, enabling businesses to align with Industry 4.0 principles and revolutionize their production processes.

Industry 4.0, also known as the Fourth Industrial Revolution, involves the integration of advanced technologies such as IoT (Internet of Things), AI (Artificial Intelligence), and big data analytics, resulting in intelligent and connected manufacturing systems.

The 4 Chucks Heavy-Load Tube Laser Cutting Machine achieves increased efficiency by automating various tube-cutting tasks, reducing human intervention and potential errors. Its automatic loading and unloading capabilities streamline material handling, cutting down on manual labor and production downtime.

Adopting Industry 4.0 concepts allows for real-time monitoring and data analysis, leading to predictive maintenance and data-driven decision-making.

This approach helps businesses fine-tune production processes, minimize waste, and boost overall productivity. Moreover, the machine’s ability to integrate with advanced software solutions creates a cohesive, interconnected manufacturing environment.

Maximizing Energy Efficiency and Cost Reductions

The 4 Chucks Heavy-Load Tube Laser Cutting Machine offers advanced features that enable energy efficiency and contribute to substantial cost savings for businesses. Its state-of-the-art laser head technology demands less power to deliver precise cuts, leading to lower energy consumption and operational costs.

Furthermore, the machine’s precision and speed eliminate the need for additional processes like grinding and polishing, conserving more energy and resources.

Adopting energy-efficient machinery allows businesses to lower operating costs and lessen their environmental impact. In a highly competitive market, sustainability and cost-effectiveness are essential for maintaining an edge and appealing to eco-conscious customers.

Prioritizing Safety and Proactive Maintenance

Operating industrial machinery, such as the 4 Chucks Heavy-Load Tube Laser Cutting Machine, demands a strong focus on safety. The machine incorporates safety features like protective enclosures and emergency stop buttons to reduce the likelihood of accidents during operation.

The machine’s software also includes safety protocols, ensuring it functions within specified parameters to avoid potential damage or hazards.

Consistent performance and extended machine life depend on regular maintenance. By adhering to the manufacturer’s suggested maintenance schedule, businesses can ensure optimal performance, prevent unexpected breakdowns, and prolong the machine’s service life.

Proactive maintenance tasks may involve cleaning and lubricating moving parts, inspecting and replacing worn components, and applying software updates as needed. This approach can lead to significant cost savings by minimizing the need for expensive repairs and downtime.

Tailoring the Machine with Customization Options and Accessories

The 4 Chucks Heavy-Load Tube Laser Cutting Machine offers a variety of customization options and accessories, allowing businesses to enhance the machine’s functionality and versatility to suit their specific needs. These adjustments enable the machine to cater to broader applications and industries.

Customization options can include specialized laser heads for certain materials or cutting demands, extra chucks for improved clamping capabilities, and software upgrades for enhanced control and monitoring. Accessories like tube lifting systems, rotary attachments, and air filtration units can further refine the machine’s performance and expand its capabilities.

By selecting the appropriate combination of customization options and accessories, businesses can optimize the 4 Chucks Heavy-Load Tube Laser Cutting Machine for their unique requirements, ensuring they can take on a diverse range of projects and stay ahead of the competition in a rapidly evolving industry landscape.

What Should You Consider While Choosing a 4 Chucks Heavy-load Laser Tube Cutting Machine?

When selecting a 4 Chucks Heavy-Load Tube Laser Cutting Machine, consider the following factors:

1. Cutting capacity: Evaluate the machine’s ability to handle the required range of tube sizes, shapes, and materials for your specific applications.

2. Software compatibility: Verify the compatibility of the machine’s control software with your existing design and production tools to ensure seamless integration.

3. Machine quality: Ensure the machine is built with high-quality components for durability, stability, and long-term reliability.

4. Ease of use: Choose a machine with user-friendly interfaces and features that simplify operation, minimizing the learning curve for your team.

5. After-sales support: Opt for a machine supplier that offers reliable after-sales support, including training, maintenance, and prompt customer service.

Conclusion

In conclusion, the 4 Chucks Heavy-Load Laser Tube Cutting Machine is a game-changing solution for businesses aiming to optimize their tube-cutting process. You can find the perfect machine tailored to your unique needs by considering the essential factors mentioned above.

As you delve into this advanced technology, we encourage you to explore other resources on our website to broaden your understanding of tube laser cutting and welding machinery. Discover how our products and services can help elevate your business operations.

Unlock the Future of Tube Cutting with Baison’s Help!

At Baison, we specialize in providing cutting-edge laser cutting and welding machinery tailored to your specific needs. Our 4 Chucks Heavy-Load Laser Tube Cutting Machine delivers unparalleled precision, efficiency, and versatility to help your business thrive in today’s competitive market.

Trust Baison to be your partner in achieving superior production outcomes and creating a sustainable, technologically advanced future for your business. Request Instant Quote.