Basic Principles of Laser Wavelengths

Laser wavelengths refer to the distance between two successive peaks of a light wave emitted by the laser, and this determines its color or position in the electromagnetic spectrum. Wavelength is directly linked to the energy of the light, with shorter wavelengths representing higher energy and longer ones indicating lower energy.

The human eye can perceive wavelengths from about 400 nm (violet) to 700 nm (red), which is the visible spectrum. However, lasers can operate outside this range, in the ultraviolet or infrared regions, for example.

The specific wavelength a laser emits depends on its medium (gas, crystal, or semiconductor), and different wavelengths have various applications, from medical procedures to communication, and interact differently with materials. Safety considerations also vary based on wavelength, especially concerning potential harm to eyes and skin.

Common Laser Types and Their Wavelengths for Different Materials

The suitable wavelength needed for laser engraving and cutting materials mainly depends on the type of materials. The nature of workpiece materials will respond differently while interacting with these wavelengths. Here are some common laser types and their wavelengths.

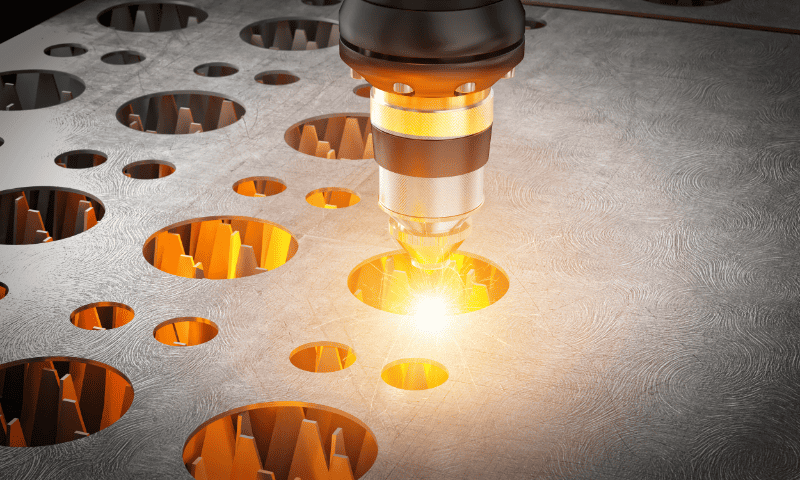

1. CO2 Lasers (10.6 µm wavelength): CO2 lasers are one of the most prevalent types in the industry. Ideal for cutting materials like rubber, plastics, paper, and wood, CO2 lasers excel in both cutting and engraving these materials with precision. CO2 laser cutters offer high power output, ensuring localized heating, which means the structure and texture of the materials remain uncompromised.

A significant portion of this wavelength penetrates the materials, enhancing absorption. As a result, the material surface heats up, leading to vaporization, making CO2 lasers a popular choice for delivering precise engraving solutions. From intricate details to full cuts, their versatility is unmatched. However, their higher reflectivity can pose challenges in specific applications, necessitating careful attention for optimal results.

2. Fiber Lasers (1.06 µm wavelength): Fiber lasers are also common for engraving and cutting. These work best on metals like copper, brass, aluminum, and steel. The effectiveness of fiber lasers in cutting materials is due to their strong absorption and deep penetration into these metals.

Due to this, fast melting takes place, and the users can cut and shape these materials as they want. Besides, precise engraving takes place as a result of laser cutting machines. Other than this, there is no harm in using these lasers for cutting and engraving even non-metals with the same precision.  Here is an article on the comparison of CO2 laser and fiber laser technology.

Here is an article on the comparison of CO2 laser and fiber laser technology.

3. Nd: YAG Lasers (1.064 µm wavelength): Nd: YAG lasers are one of the pulsed lasers. These are good for ceramics and metals. They create a similar influence to fiber lasers on the materials and can be a great alternative for CO2 lasers as well. Their wavelength is different from the other common types of lasers available for usage. These are crucial for precise metalworking when needed.

We have also prepared an article to help you choose between YAG lasers and fiber lasers.

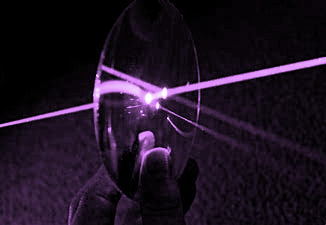

4. UV Lasers (355 nm wavelength): UV lasers work on different wavelengths, and these are common for engraving. Glass, ceramics, and some special forms of plastic are easier to engrave with UV lasers. But for cutting, these are not recommendable at all. Their wavelength is short, and therefore, professionals can achieve better precision and accuracy from them. For The choice of fiber laser and UV marking machine, you can refer to this blog.

For The choice of fiber laser and UV marking machine, you can refer to this blog.

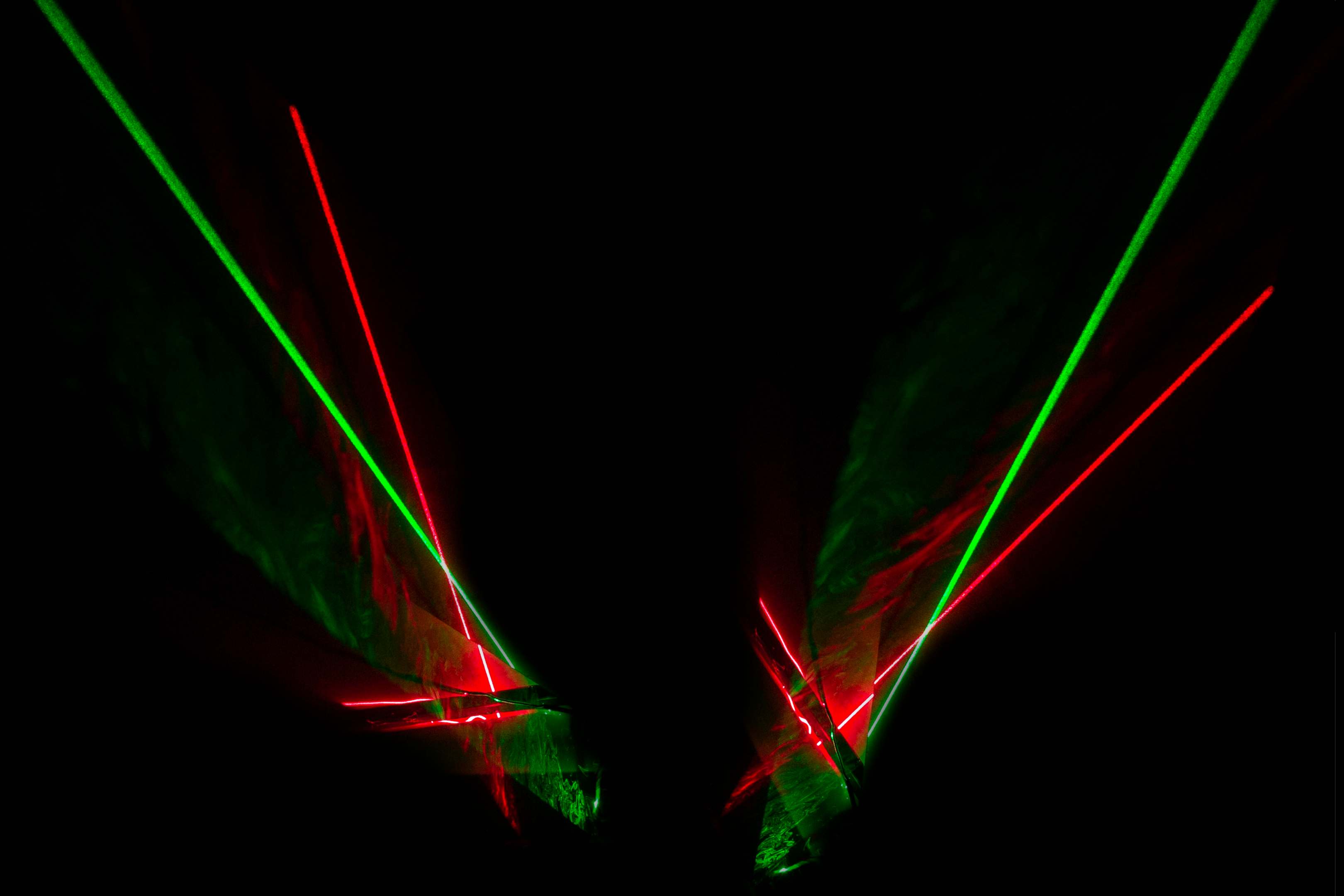

5. Green Laser (532 nm wavelength): Green lasers are good for ceramics and plastics. They have a higher wavelength than UV lasers, which makes them highly specific in their functions. These are not useful for cutting, but for engraving, they can promise great results. For visible and precise details and engraved impressions, green lasers are totally unmatchable in their performance.

We have an article about fiber laser and green laser marking machine selection.

6. Diode Lasers (various wavelengths): Diode lasers are adaptable and versatile because they contain different types of diodes. The type of diode laser determines the performance of these lasers. Therefore, while using diode lasers, we need to be highly clear and specific.

Because different diodes respond differently to specific materials, one mistake can ruin the entire workpiece in seconds; these are useful for engraving metals and ceramics. It is important to adjust them as per the nature of the material to derive desired results from them.

You may be interested in the difference between fiber lasers and diode lasers.

Do You Have Any Questions?

Let Us Solve Your Problem

How Does Wavelength Affect Laser Cutting and Engraving?

The role of laser wavelength in laser systems cannot be understated. It dictates how the laser interacts with materials, influencing the depth, precision, and safety of the operation. Here’s a structured breakdown of how wavelength plays a pivotal role:

1. Material Absorption

- The wavelength determines how a material will absorb the laser beam from the laser head.

- Different materials absorb wavelengths differently. For instance, organic materials like acrylics and wood readily absorb the 10.6 micrometer wavelength emitted by CO2 lasers.

- Higher absorption rates are conducive to effective cutting and engraving.

2. Engraving Depth and Penetration

- Shorter wavelengths, such as those of UV lasers, don’t penetrate materials as deeply as longer wavelengths.

- Longer wavelengths, like those of CO2 lasers, have better penetration, making them suitable for engraving and cutting thicker materials.

3. Material Suitability

Not all wavelengths are suitable for all materials. For example, shorter wavelengths may not be effective on metals, while CO2 lasers, due to their longer wavelengths, can handle larger workpieces with precision.

4. Thermal Effects

- The heat produced during engraving or cutting is influenced by the laser’s wavelength.

- Intense and penetrative wavelengths generate more heat, which can be harnessed effectively for cutting resistant materials.

5. Safety Considerations

Working with lasers necessitates safety, and the predictability of a laser’s interaction with a material can reduce risks like burns.

6. Reflectivity Concerns

- Some materials, especially metals, can reflect certain wavelengths.

- Shorter wavelengths might be reflected by highly reflective metals.

- Fiber lasers, often preferred for metalwork, produce less reflectivity compared to CO2 lasers.

7. Precision in Engraving

- Precision is paramount in cutting and engraving, and shorter wavelengths often deliver higher resolution.

- This enables workers to achieve intricate patterns and customization, meeting specific client demands.

If you want to further explore the physics behind laser technology, you can also watch free educational videos produced by MIT.

In summary, understanding the interplay between laser wavelength and material is fundamental to achieving optimal cutting and engraving results. It influences not just the quality of the outcome but also the safety and efficiency of the process.

Factors to Consider When Choosing Laser Wavelengths

The wavelength of the laser plays a pivotal role in determining how the laser interacts with different materials and thus affects the efficiency, quality, and safety of the cutting and engraving process. Here are the primary factors to consider when choosing laser wavelengths for cutting and engraving:

1 – Material Absorption

Different materials have specific absorption profiles. It’s vital to select a wavelength that is efficiently absorbed by the material for effective energy transfer. For instance, CO2 lasers (with wavelengths around 10.6 micrometers) are ideal for organic materials, while fiber lasers (around 1 micrometer) are better for metals.

2 – Heat Affected Zone (HAZ)

The size of the HAZ can be influenced by the wavelength. Shorter wavelengths tend to have smaller HAZs, resulting in cleaner cuts and less thermal deformation, which can be crucial for precise applications. In addition, by adjusting the pulse width through the laser machine, users can optimize the engraving or cutting process.

3 – Cutting and Engraving Depth

Depending on your application, you might want shallow engraving or deep cuts with various laser power ratings. Some wavelengths penetrate deeper into specific materials than others, affecting the resulting depth.

4 – Surface Finish

Some wavelengths can produce smoother or rougher finishes on certain materials. Depending on the desired outcome, this can influence the choice of laser wavelength.

5 – Equipment Availability and Cost

Not all laser types are available in all wavelengths, and some might be more expensive than others. Ensure that the chosen wavelength aligns with available equipment and budget constraints.

5 – Beam Quality and Focusability

Some wavelengths allow for better focusing, resulting in sharper, finer laser beams. This can be crucial for detailed engraving or the precision laser cutting process.

6 – Environmental Considerations

Some laser wavelengths might require specific environmental conditions to operate efficiently, like particular cooling methods or ambient temperatures.

In summary, the choice of laser wavelength is a balance between the material being processed, the desired outcome, available equipment, safety considerations, and budget constraints. It’s essential to understand the needs of your specific application and to do thorough research or consult with experts when choosing the appropriate wavelength for cutting or engraving.

Do You Have Any Questions?

Let Us Solve Your Problem

Achieving Intricate Details with Specific Wavelengths

We can also achieve details and intricate patterns by using different types of wavelengths. However, professional knowledge is needed for this to happen without any complications. It is important to know that different wavelengths produce different results for this purpose. Below are the details that can prove to be helpful.

- Fine Art Engraving with UV Lasers (355 nm): UV lasers are beneficial for intricate engraving. It is also possible to use these lasers for glass and ceramics so that better details can be executed by using their small wavelength.

- Precision Marking with Green Lasers (532 nm): Green lasers have a different wavelength as compared to UV lasers, which are reliable for laser marking processes and intricate engravings. In the field of electronics, green lasers are important for working with microchips and PCBs, where accurate readability and accuracy are important.

- Intricate Woodwork with CO2 Lasers (10.6 µm): CO2 lasers are not for cutting with a laser cutter, but they are crucial for wood engravings. Sincere, these have a large wavelength. These lasers adapt well to the wood and develop intricate and complex patterns because of precision work. Due to this reason, different types of engraved wooden furniture designs are possible to achieve with these lasers.

- Metal Jewelry Crafting with Fiber Lasers (1.06 µm): Fiber laser is reliable for developing metallic jewelry. From cutting to engraving, these lasers are easy to work with for crafting different types of metallic ornaments. Such lasers are crucial because they add finesse and shine to the jewelry for men and women. Metallic jewelry is not affordable, and one major factor that adds to their pricing is the use of fiber lasers as well.

- Microscale Engraving with Diode Lasers (Various Wavelengths): Diode lasers are only reliable for engraving small workpieces since these contain different natures of diodes for working. For engraving impressions and markings on medical equipment and devices, these lasers are beneficial because of their outstanding results in this regard.

It is obvious that different wavelengths will give variable results while engraving and cutting the workpieces. Therefore, it is important to work with accurate lasers to get the desired results. A wrong choice of laser cannot only damage the workpiece but working with this laser can be dangerous as well. Experts recommend studying the laser type and material to work on, which is crucial before heading with the process later.

Conclusion

There are different laser types common in the cutting and engraving industry today. It is obvious that each laser type has its own benefits for various purposes. However, to ensure there are no complications during the process, relying on suitable lasers is crucial.

Also, it is beneficial to determine what wavelength you need for a particular workpiece. In this way, you will be able to get the desired results without struggling with results at all.

Explore the World of Laser Systems with Baison!

Baison, your reliable laser partner, meets your needs successfully with all-around equipment like laser cutters or laser marking machines. You can further learn about us by booking a one-on-one consultation with our experts as well. So there is no need to wait anymore. Tag along with us to bring your dreams into reality and streamline engraving for you today!