According to the report by Market Research Future, the global market of laser cutting machines is expected to increase by $5.96 billion at the rate of 8.46% CAGR by 2023.

The market for laser cutting machines is expanding due to the rising need for automation and high-quality cutting solutions across various sectors.

This write-up has useful information about tube laser cutting machines’ working, types, and applications.

What Is Laser Tube Cutting Machine?

A laser tube cutting machine is an industrial machinery that uses a powerful laser beam to precisely and accurately shape and cut hollow pipes and metal tubes. It can cut tubes of variable metals like:

These round tubes are used for multiple purposes, for instance, in the furniture industry, fitness equipment, sports, and industrial material.

Laser-cutting technology is rapidly developing in numerous industries. You can use it to cut tubes and structural shapes, long pieces (channels), or sectional hole cutting in metal tubes.

Furthermore, the fiber laser cutting machines fiber laser has the added capabilities of material drilling, labeling, and cleaning with high precision and accuracy.

How Does Laser Tube Cutting Machine Work?

Laser tube cutting machines employ a high-energy laser beam to precisely and accurately cut through metal tubes and pipes. The laser beam vaporizes the metal and provides you with a clean cut.

For a clear and better understanding, we have mentioned the step-by-step working of a laser pipe-cutting machine below.

Step 1: Install the pipe on the laser cutting machine. The pipe should be tightly fastened to keep it in place while cutting.

Step 2: Using a lens, the machine’s laser beam is focused on the metal’s surface. The machine uses this information to calculate the breadth and thickness of the surface it must cut through.

Step 3: The laser cuts through the metal wall after analyzing the dimensions.

Step 4: You don’t need many post-cutting treatments due to the high cutting efficiency and processing accuracy.

What Are the Advantages of Laser Tube Cutting Machines?

Some of the advantages of laser tube-cutting machines over traditional processing methods are as follows:

- Laser tube cutting machines provide exceptional precision and accuracy, making them an excellent alternative for companies that demand excellence in their cutting operations.

- You can also get complex shapes and designs faster simply with a narrow laser beam, saving time and enhancing efficiency.

- One of the primary advantages of laser cutting is the material savings it provides. The laser beam creates a clean, tiny slit with no burrs, reducing material loss and saving money.

- Furthermore, because of their high-speed capabilities, laser tube-cutting machines are ideal for enterprises that demand huge quantities of metal components and products.

- The most significant advantage of laser cutting is the high-quality cuts it generates. These precision cuts eliminate the need for extra finishing procedures, lowering manufacturing costs and enhancing overall efficiency.

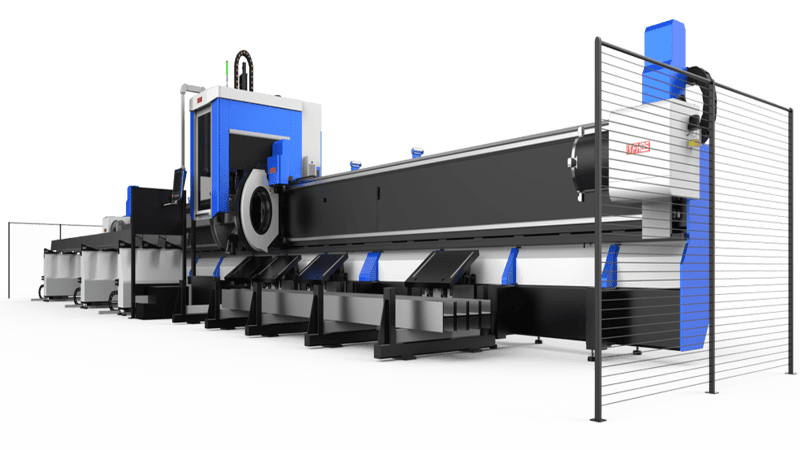

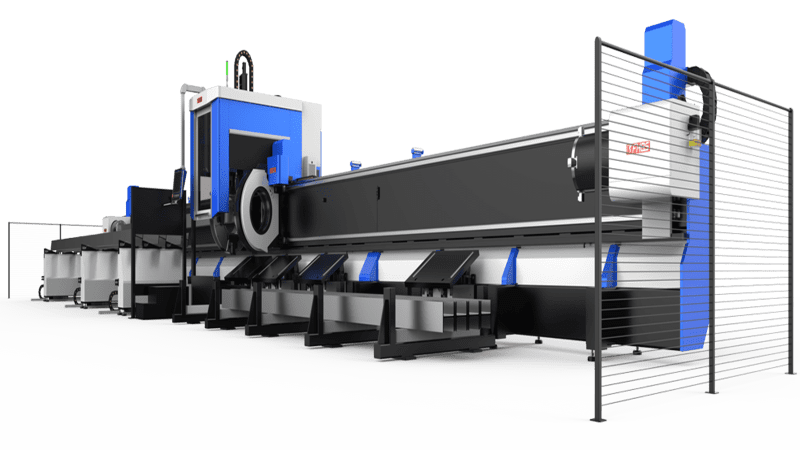

What Are the Three Main Types of Laser Tube Cutting Machines?

There are three main types of laser tube-cutting machines. Every type has its own capabilities and applications.

Laser tube cutting machines vary in size, power output, and cutting capabilities, distinguishing them from one another. Each laser tube cutting machine is intended to perform a unique cutting operation.

All-round tube laser cutting machines are adaptable and can handle various tube-cutting tasks. On the other hand, small tube laser cutting machines are ideal for cutting smaller diameter and thinner gauge materials.

Heavy-duty tube laser cutting machines are excellent for heavy-duty applications such as cutting large-diameter and thicker gauge metal tubes.

In further detail, let’s go through the fundamental distinctions between all three types of laser tube-cutting devices.

You may pick the proper laser tube cutting machine to optimize your production and boost your bottom line by carefully examining your company’s demands and the requirements of your individual cutting operations.

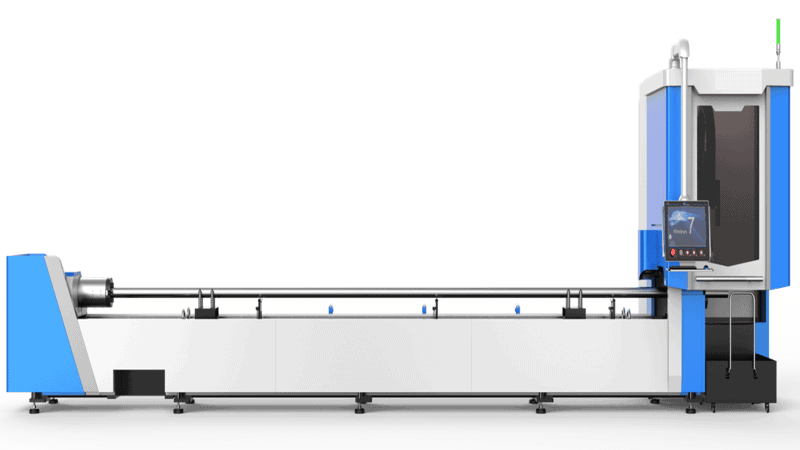

Small Tube Laser Cutting Machine

Small tube laser cutting machines are typically used for cutting smaller metal tubes. These devices create high-quality end products by making accurate cuts on thinner gauge materials with great precision using a concentrated laser beam.

They generally produce between 1500 and 3000 watts of power, which is ideal for cutting small-diameter tubes but less power than other kinds of laser tube-cutting machines. Small tube laser cutting machines are the best option for organizations with limited space since they have a smaller footprint than other types of equipment due to their smaller size.

Here are the advantages and disadvantages of small tube laser cutting machines.

Advantages:

- Cuts thinner gauge materials with extreme accuracy and precision.

- It has a limited footprint due to its smaller size.

- It is cheaper than other kinds of laser tube-cutting machines in terms of prices.

Disadvantages:

- Only able to cut tubes with smaller diameters

- Its limited power output is not suitable for heavy-duty applications.

All-round Tube Laser Cutting Machine

All-round tube laser cutting machines are also known as universal tube laser cutting machines. They are a wonderful option for companies that need adaptation and flexibility in their metal manufacturing processes since they may be used for a range of tube-cutting operations.

They have the ability to cut tubes of any shape, size, diameter, and thickness. With power outputs ranging from 1500 watts to 6000 watts, all-round tube laser cutting machines can often cut through thicker and wider diameter tubes than small tube laser cutting machines.

Here are the pros and cons of All-round tube laser cutting machines

Advantages:

- They are highly versatile and capable of handling a variety of tube-cutting applications.

- All-round laser tube cutting machines boost productivity while maintaining high levels of accuracy and precision.

- They are also appropriate for companies requiring flexible metal fabrication processes.

Disadvantages:

- More expensive in comparison to a small tube laser cutting machine.

- They require more room in the manufacturing plant due to their larger footprint.

- They are not appropriate for really heavy-duty applications.

Heavy Duty Tube Laser Cutting Machine

As heavy-duty tube laser cutting machines are made for cutting large diameter and thicker gauge metal tubes, they are highly suitable for heavy-duty applications in sectors like construction, oil and gas, and shipbuilding.

These machines can cut through thicker and bigger diameter tubes since they have a higher power output than small tube and all-round tube laser cutting machines, ranging from 3000 watts to 12000 watts.

Here are some pros and cons of heavy-duty tube laser-cutting machines

Advantages:

- They have high power output for cutting thick gauge and large diameter tubes

- They are suitable for really heavy-duty applications

- They are the best option for providing high-precision cuts

Disadvantages:

- More expensive in comparison to other laser tube-cutting equipment.

- They require more room in the manufacturing plant due to their larger footprint.

- They might not process small-diameter tubes or thinner gauge materials.

The Applications of Laser Tube Cutting Machines in Different Industries

Laser tube-cutting machines are becoming popular in a variety of sectors due to their excellent accuracy, flexibility, and efficiency.

They successfully accelerate production and can cut a range of materials, including metals, with high accuracy. Their automation also lowers the possibility of mistakes and raises worker safety.

Here are some different industries that use laser tube-cutting machines.

Gym Equipment

Laser tube cutting machinery has become a preferred cutting method in the gym equipment industry due to its precision, speed, and efficiency. Metal tubes for a variety of equipment, including weightlifting machines, exercise cycles, and treadmills, may be cut using laser tube cutting machines.

Furniture

Laser tube cutting machinery is a reliable and high-precision tool for cutting metal tubes used in furniture manufacturing, including tables, chairs, shelves, and more. This technology offers several advantages over traditional cutting methods, such as improved accuracy, speed, and cost-effectiveness.

Storage Racks

Highly efficient for cutting metal tubes for storage racks that are mostly used in warehouses, factories, and retail stores. This non-contact processing technology provides high-precision cutting, reduces processing costs, and achieves complete automation for mass production.

Agricultural Machinery

Laser tube cutting machines are essential in the agricultural machinery sector by cutting metal tubes for numerous applications. Frames, brackets, and supports, which are crucial sections of agricultural machinery, including tractors, cultivators, and harvesters, are made using these machines.

Handrail

Laser tube cutting machines are highly applicable in cutting handrails for buildings, bridges, and other structures. Laser cutting’s accuracy and precision guarantee that the metal tubes are cut to precise lengths and forms, enabling quick and secure railings installation.

Along with producing aesthetically beautiful railings, the high-quality cuts enhance the structure’s overall design. Also, laser cutting is a quicker and more affordable way to make handrails, making it a great choice for companies in this sector.

Transportation Pipeline

Laser pipe-cutting machines have revolutionized the oil and gas industry by simplifying the construction of transportation pipes. Laser cutting technology’s precision and accuracy ensure that the pipes are cut to the exact size and form, resulting in a safe and dependable pipeline system that delivers oil and gas across long distances.

Laser tube-cutting machines provide faster production times than traditional technology, satisfying the needs of the oil and gas sectors. This translates to enhanced efficiency and production, helping firms to simplify processes and satisfy client needs.

Oil Refinery Equipment

Oil refineries require complicated gear such as heat exchangers, boilers, and pressure vessels to transform crude oil into various products. Metal tubes used in various equipment must be cut precisely to provide a perfect fit and safe functioning.

Laser pipe-cutting devices have become essential instruments in the oil refinery sector due to their extraordinary precision and accuracy in cutting metal tubes.

Laser tube cutting equipment, with its capacity to create clean, precise cuts with no material loss or burrs, has revolutionized the way metal tubes are cut and processed, allowing for better efficiency and safety in oil refineries.

Bridge Construction

Construction companies that construct bridges use laser tube-cutting machines to cut the metal tubes needed to build bridges. This involves precisely shaping and slicing bridge beams and supports to match each project’s particular requirements.

Heavy Equipment

Laser tube cutting machines are extensively used in heavy equipment industries such as mining, forestry, and construction to precisely and accurately cut metal tubes.

This high-quality cutting carves intricate designs and forms into metal tubes, enhancing the equipment’s overall usefulness and aesthetic.

Overhead Bridge Cranes

The manufacturing and construction industries frequently cut metal tubes for overhead bridge cranes using laser tube-cutting machines. These cranes are essential for transferring bulky supplies and machinery across factories and construction sites.

Automotive Industry

Laser pipe-cutting machine has completely transformed the automobile industry by making it possible to produce high-quality exhaust systems, chassis, and roll cages.

Due to the high accuracy and precision of laser cutting, the metal tubes are cut to precise dimensions. However, it also improves the cars’ safety and performance.

Aerospace Industry

The aerospace industry relies heavily on laser tube cutting equipment because they make it possible to precisely cut metal tubes for a variety of uses, including aircraft frames, landing gear, and engine parts.

Additionally, the adaptability of laser-cutting machines enables the creation of intricate forms and shapes that are frequently needed in the aerospace sector.

Energy Industry

The energy industry also uses laser tube-cutting machines to cut metal tubes for energy sector applications like solar panel frames, wind turbine parts, and machinery for power plants.

So, are you looking for precision and efficiency in your metal tube-cutting process? Look no further than the pipe laser cutting machine, a top-of-the-line professional laser tube cutter that can replace mechanical drilling and other outdated methods.

With its advanced technology and precise cutting capabilities, the pipe laser cutting machine is the perfect solution for any project that requires accurate and efficient metal tube cutting.

Whether you’re working in a manufacturing facility or a small fabrication shop, this tube laser-cutting machine will help you easily achieve your goals.

What Should You Consider While Choosing a Laser Tube Cutting Machine?

There are several things to consider when selecting a laser tube cutting machine for your company.

- The thickness of the materials you need to cut and the manufacturing quantity are two examples of the individual demands and requirements you should first evaluate.

- The machine’s power output, cutting speed, and precision should be considered next.

- You should also assess the machine’s software, automation capabilities, upkeep, and support options.

Non-contact processing has revolutionized the way we cut and shape metal tubes. With a small heat-affected zone, this cutting principle is highly efficient and can achieve complete automation, significantly reducing processing costs and time.

This technology has made mass production of standard metal tubes a reality, replacing the traditional processing methods that were once slow and costly.

You may choose the best laser tube-cutting machine by considering these factors, eventually improving production, efficiency, and profitability.

Conclusion

Laser tube cutting machines are highly adaptable in a variety of industries like construction, automotive, furniture, fitness, and sport.

This machine is a popular option for companies that need accurate and high-quality cuts since it can cut through various metals, including aluminum, brass, stainless steel, and carbon steel.

Moreover, the three primary categories for the laser tube cutting machine can provide you the great results according to your requirements.

We hope you find the best laser-cutting machine for your company.

Discover the Perfect Solution for Your Business with Baison

Baison offers a solution for you whether you’re searching for a laser-cutting machine for metallurgy, woodworking, textiles, or other industries. Modern technology in their equipment enables precise cuts and quick manufacture, enhancing productivity.

To guarantee that its clients get the most out of their equipment, Baison also offers first-rate customer care and technical support.

So, what are you waiting for? Contact us today!