Laser cutting has revolutionized manufacturing, offering unparalleled precision and intricate detailing across various materials. To truly harness the power of this technology, businesses require the perfect software to complement their laser-cutting needs.

This article will delve into the top 8 software solutions for laser cutting, helping you make an informed decision for your manufacturing endeavors.

Whether you’re a small business or a large corporation, this guide will help you choose the right software to take your laser-cutting projects to the next level.

How Does a Laser Cutting Machine Work?

A laser machine features a high-intensity laser beam, which can cut through most materials. The beam is generated through a focused laser head. The laser head is controlled by a computer program that takes input from design software and guides the beam along the desired cutting path, creating precise cuts with high accuracy.

Why Is Laser Cutting Software Important?

Laser-cutting software is a package designed specifically to create intricate models and cutting patterns for laser-cutting machines. This software allows manufacturers to create customized designs on PCs without manual input, ensuring all work is done precisely.

Design is the heart of laser cutting. The laser cutter cannot cut according to desired dimensions without the right design. So, design software is very important when performing laser engraving or cutting.

Here are five key benefits of laser engraving software:

Improved Precision and Accuracy

With the use of software, all the manual design processes get eliminated. The software carefully creates a cutting path and ensures that each part is cut precisely according to the created drawings.

Reduced Material Waster

Another important aspect of laser-cutting software is its ability to reduce material waste. By optimizing the cutting path, the software can minimize the material needed to create a specific design, which helps reduce costs and environmental impact.

Design Freedom

With CAD software, manufacturers can create complex designs, generate cutting paths, and precisely control the laser beam, resulting in faster production times and higher-quality cuts.

Automation

A design, once created, can be used multiple times for creating products in batches. This can help to automate the cutting process, which reduces the need for manual labor and increases productivity.

Insightful Design Parameters

The laser design software can also provide valuable insights into the laser cutting process, such as cutting times, material usage, and overall efficiency. These insights can be used to identify areas for improvement and optimize the laser-cutting process over time.

What Are the Different File Formats Used in Laser Cutting?

The laser patterns can be designed in all imaging software available, and nowadays, they can be converted to any format supported by laser cutting machines. However, laser-cutting machine directly supports vector image formats. Some of those are listed below:

DXF (Drawing Exchange Format)

This file format is most generated by CAD software. DXF files have 2D vector graphics that can be easily converted into cutting paths for laser-cutting machines.

AI (Adobe Illustrator)

AI is a vector graphics file format generated by Adobe Illustrator. It can contain vector graphics with solid lines, making them useful for creating complex laser-cutting designs.

SVG (Scalable Vector Graphics)

SVG is an XML-based file format usually used for creating compact website images. However, it is compatible with some laser engraving machines.

EPS (Encapsulated PostScript)

EPS file is used for storing vector graphics and is based on the PostScript language. It is also created with Adobe Illustrator and is supported by multiple laser machines.

CDR (CorelDRAW)

CDR is the native file format of CorelDRAW. CDR files are vector-based and can be scaled without losing quality or sharpness.

BMP (Bitmap image)

Bitmap images are not commonly used in laser-cutting machines as they are not vector graphics. However, some laser-cutting software may support bitmap images for use in engraving or etching applications.

8 Best Laser Cutting Software

Multiple CAD and graphic design software are available on the market. However, not all are well-suited for laser machines.

So, to make your search easier, we have shortlisted a few best laser engraving software on the market.

Adobe Illustrator

Adobe Illustrator is a widely used graphic design software on the market. It is used for creating 2D vector diagrams, which can be imported to any laser cutting machine.

Designers can create complex shapes with pen and line tools. The adobe illustrator files generally have the standard AI format. However, they can be exported in other compatible image formats like SVG, EPS, and PDF.

The software is paid and comes with a monthly and yearly subscription model, and you can sync your files on Adobe Cloud with an active internet connection. Illustrator 2022 application is only available for use in two operating systems, Windows (10 and 11) and Mac (10.15 or later).

Inkscape

Inkscape is an open-source vector graphics editor that is also popular among laser cutter designers. It offers a user-friendly interface, and its site’s information section explains how the software works.

Its local format is SVG. However, installing a few add-on packages can achieve other file formats, SVG, PNG, and JPG.

Inkscape has advanced design tools, such as object manipulation, layer management, and path operations, to help you manage complex drawings. In addition, it has an XML editor for experienced designers and various drawing tools to facilitate vector management.

It is free to use, and the best part is that you don’t need to pay up any monthly or yearly fee for purchases or upgrades. Inkscape runs on all operating systems, Linux, Windows, and Mac OS (13. 1 and later.)

CorelDRAW

CorelDRAW is another good option for designing projects for laser cutting machines. You can create complex shapes and patterns with its simplest user interface and array of design tools.

CorelDRAW allows for various settings to be adjusted, such as line width, color, and fill, which can help define cut lines, engraving areas, and other elements of a laser cutting project.

With this program, you can export designs to other file formats compatible with laser cutting software.

It can be downloaded freely on your Windows or on a Mac device, but you will have to pay monthly for regular use.

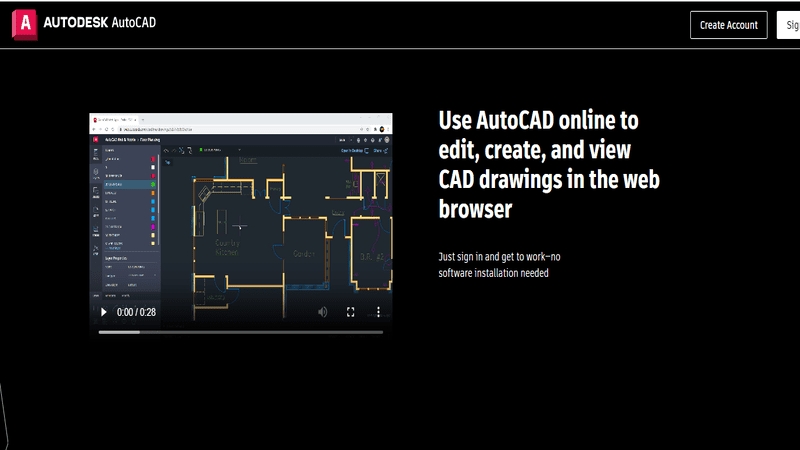

AutoCAD

AutoCAD is a computer-aided design software developed by AutoDesk. Its major use case is architecture, but it can be a helpful tool for crafting simpler laser patterns.

It has an intuitive interface, and you can import other files like DXF and DWG into its canvas. With AutoCAD, users can create and manage layers, blocks, and other design elements. This makes it much easier for designers to handle and manage complex projects.

It works on a subscription-based model but also offers a free 30-day trial. AutoCAD’s web app allows the software to be freely accessed via the browser on all operating systems.

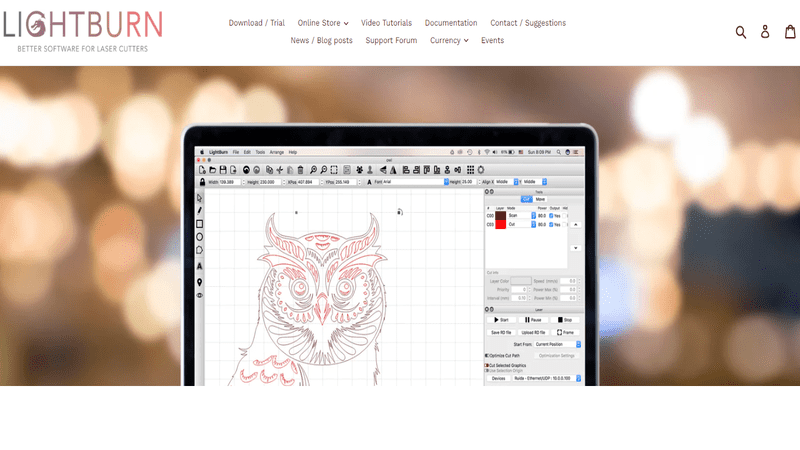

Lightburn

LightBurn is the best laser engraving software designed to work with a wide range of laser cutter machines, such as CO2, diode, and fiber. It is compatible with most machines, controllers, and firmware, including Ruida, Trocen, TopWisdom, GRBL, Smoothieware, and Marlin.

One of its advanced features is camera support, which lets users capture the work area to align and position their designs on the material to be cut.

With its built-in material library, users can save and manage settings for different materials, such as laser power, cutting speed, etc.

Lightburn is a paid software that runs on all three operating systems, Windows, Linux, and Mac. However, you can use it for free for its 30-day trial.

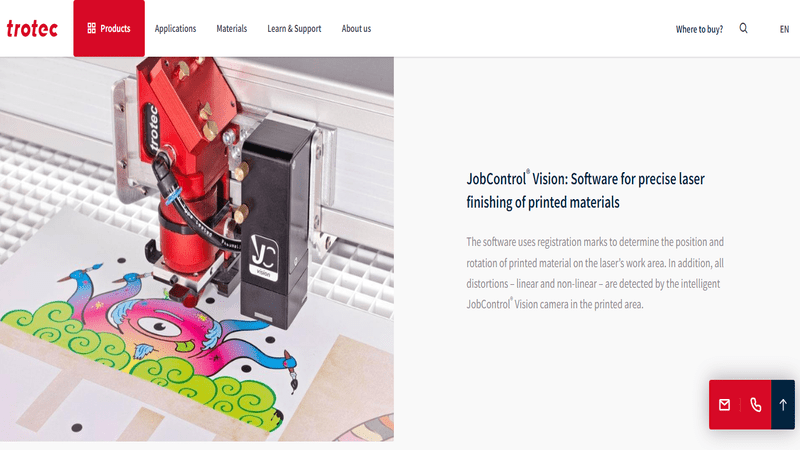

Trotec JobControl

Trotec JobControl is developed by Trotec, a popular laser machine manufacturer, allowing users to control their laser cutters and optimize their cutting process.

Trotec JobControl provides advanced design tools such as nesting and tiling, material database, and color mapping.

The pricing for Trotec JobControl is often included with the purchase of a Trotec laser cutting machine, and it helps create precise and accurate designs for laser cutting.

TurboCAD

TurboCAD is another popular option that will meet your design needs. It creates not only 2D drawings but also complex 3D models, making it an excellent option for engineers, architects, and manufacturers.

The feature that is helpful for laser pattern designers is its “overkill tool,” which makes it easier to delete overlapping lines in detailed drawings, ensuring the final is accurate.

Its “underlay tool” makes line tracing much easier. You can easily snap the endpoints and create a vector file from any given image.

TurboCAD 2023 is available for both Windows and Mac users. You can either choose an annual subscription model or a permanent license, which may not be a viable option for small businesses.

DraftSight

Draftsight is a product of SolidWorks’ developer, Dassault Systemes. It is one of the most powerful tools for creating vector images from bitmap images. Users can use its trace function to recreate vector lines from a bitmap image.

Draftsight replicates the laser with size with its “hairline” option. This feature lets users know the exact thickness that a laser beam would cut on its single pass. When your design involves lines and sharp edges, this is the perfect software to get desired results.

The package is paid, but you can test it out on your Windows PC or Macbook with its 30-day trial.

The Same Software Runs on Different Laser Cutting Machines-Can It Works?

Yes, the same software can work with different laser-cutting machines as long as the software is compatible with the specific machine controllers and firmware.

However, when you are using the same software with different laser-cutting machines, you might need to adjust settings like cutting speed, laser power, and material settings to account for differences in machine specifications.

What Should You Consider When Choosing Laser Cutter Software?

The right laser engraving software is the key to gaining desired results from a laser cutting machine. Here’s a list of things to keep in mind when choosing design software:

Compatibility

One of the most important factors to consider is compatibility with your laser machine and cutter. Not all laser cutter software is compatible with all machines, so choosing software that works with your specific model is important. To be very sure, you will need to check your machine’s user manual.

Similarly, some software needs the use of external hardware. So, make sure your existing hardware supports the software needs.

Features

Each software offers the user its own set of features. Choose one that fulfills your project needs. For instance, some software is better for simple designs or patterns, while some bear advanced features like a simulation of the laser cut model.

Ease of Use

Choosing software that is easy to use and learn is important, especially if you are new to laser cutting. Look for software that offers a user-friendly interface and clear instructions.

File Formats

Ensure the software supports the file formats you need for your project. Common file formats used in laser cutting include DXF, AI, SVG, and DWG.

Price

The cost of laser cutter software can vary widely, so choosing software that fits your budget is important.

Some software programs offer free trials or demos, which can be a good way to test the software before purchasing. There are also a few free-to-use; small businesses can take advantage of that.

Customer Support

When choosing software, look for one with dedicated technical support and user discussion forums. This will be helpful in case you encounter any issues or have questions about the software.

Conclusion

Laser-cutting software is crucial for designers and manufacturers looking to optimize their laser-cutting process. It can help create high-quality, intricate designs with ease and efficiency.

Make sure to check compatibility, advanced features, supported file formats, and customer support material before you choose laser-cutting software for your machine.

Discover the Perfect Solution for Your Business with Baison

We at Baison Laser develop state-of-the-art laser cutting machines that are compatible with most software listed there.

You can contact our team today if you’re having trouble finding the right software for your laser machine. Or, if you’re interested in one of our laser machines, you can freely request a quote.