When we think of robots, our minds often conjure sci-fi characters from the movies. However, industrial robots are very much a reality and play an active role in modern-day manufacturing. Among them are multi-axis laser-cutting robots renowned for their precision, speed, and accuracy in handling complex machining tasks.

This guide delves into what laser-cutting robots are, their types, and their applications across various industries.

What Is a Laser Cutting Robot?

Laser cutting robots are machines numerically controlled by computers (CNC), reprogrammable, and can move in three or more axes. These are multi-purpose machines featuring a high level of automation and the capability to mimic complex motion in space. Just to be clear, a “Multi-Axis Laser Cutting Robotic Arm” and a “Multi-Axis Flatbed Laser Cutter” both fall into the category of ‘Industrial Robots.

Laser cutting robots are advanced machines that can create complex designs at extremely high speeds without compromising quality. Their precise guidance system, driven by high-processing computers, offers accuracy far superior to traditional 2-axis laser cutting, multi-axis mechanical, and plasma cutting machines.

Motion in multiple axes refers to the following:

- X-Axis: Moves horizontally from left to right.

- Y-Axis: Moves horizontally from front to back.

- Z-Axis: Moves vertically, up and down.

- A-Axis: Rotates horizontally around the X-Axis.

- B-Axis: Rotates horizontally around the Y-Axis.

- C-Axis: Rotates horizontally around the Z-Axis.

A robotic laser cutter with degrees of freedom in all six motions described above is referred to as a “Six-Axis Laser Cutting Robot”.

Applications of Laser Cutting Robots

Laser-cutting robots have unique characteristics, making them highly applicable to specific industries.

1. Automotive and Aerospace

Manufacturing cars and aircraft requires intricate components that are difficult to make using traditional means. That’s why multi-axis laser cutting robots are used in such industries for better accuracy, streamlined production, and continuous innovation.

2. Medical Industry

Medical equipment manufacturing requires extreme precision, which is easily achieved by multi-axes laser cutters.

3. Electronics

Electronics like PCBs and semiconductors require machining at a very small scale, so it’s hard to achieve a high level of control using mechanical cutters. That’s why laser-cutting robots are prevalent in this industry.

4. Industries Requiring Multiple Tasks

Laser-cutting robots can also be modified by replacing the laser cutting head to perform laser welding, cleaning, and marking. Such a high level of flexibility makes it an extremely economical and versatile machine for any industry.

How Laser Cutting Robots Work?

You might be intrigued by how laser-cutting robots can mimic human-like motion during machining. Here’s a brief sneak peek into the inner workings of a laser-cutting robot. For easier understanding, we’ve divided the machine into three components.

1. Laser Source

Every laser cutting robot has a separate laser source, like CO2 laser and Fiber laser system. The laser beam’s power, wavelength, and intensity affect factors like cutting speed, cutting depth, finish, and material compatibility. Fume extraction and assisted gas operation also play a vital part in machining.

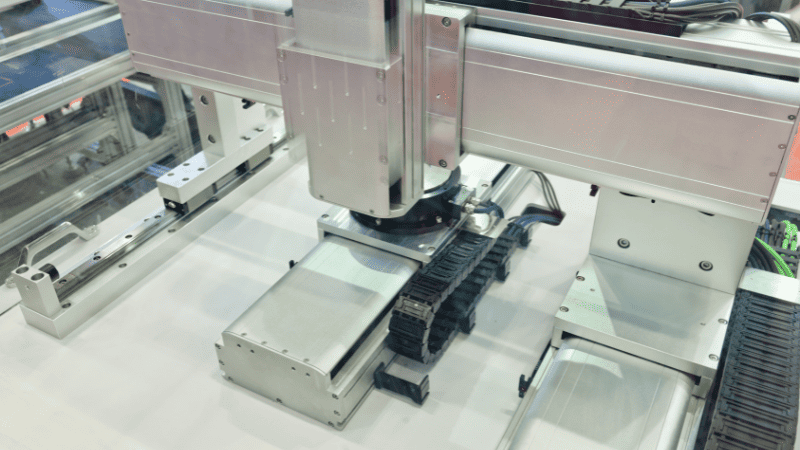

2. Assembly and Components

A laser robot can be a 3-, 4-, 5-, or 6-axis laser cutting machine, thanks to its complex components and assembly. Typically, cutting-edge stepper motors, laser scanners, servo motors, smooth guiding rails, and pneumatic and hydraulic systems, all working in unison, provide a complete 360-degree range of motion to the machine. It’s truly an engineering marvel.

3. Software

The automation and complex movement in the three-dimensional space of laser-cutting robots are all possible due to sophisticated software running on high-performance computers. Cypcut and Cypone are examples of laser-cutting software. With continuous advancement, we are also witnessing the incorporation of Artificial Intelligence in the numerical control systems of these machines. So, the potential is unlimited.

5 Common Robot Types Used for Laser Cutting

After understanding the basics, let’s look at the types of laser cutting robots.

I. Cartesian Robot

These are CNC machines that move in x, y, and z Cartesian coordinates. The capability to move in forward, backward, sideways, upward, or downward position is the minimum criteria needed to qualify as an industrial robot. The 3-axis laser cutting machine is excellent for repetitive tasks and high-volume part production.

There are also 4-, 5- and 6-axis laser cutting robots that can spin horizontally around the x-, y- and z-axis, further enhancing the motion capability of the machine. Multi-axis laser cutting robots are excellent for complex designs and tube-cutting processes.

You’ll also get the most precise cuts in these machines as this arrangement allows maximum control. Besides laser cutting and welding, these robots are also good for material handling.

CNC laser cutting machines come in all shapes and sizes, but they usually don’t go beyond a 2 by 6-meter flatbed size. That’s good enough for small to medium-scale production.

II. Gantry Laser Cutting Robots

Gantry robotic laser cutting machines are similar to automatic CNC machines but have large gantry beams that drive the laser cutter. They follow the same cartesian coordinates systems, but the gantry system allows machining at a much larger scale. There is no upper limit to machine size per se, so it depends on the project requirement. You’ll see such machines in industries with large-scale production.

The 3d five-axis gantry laser cutting machines are one of the most versatile, high-tech, and efficient cutting systems and are the epitome of precision, accuracy, and speed. Gantry laser cutters have open construction, which makes maintenance and material handling much easier.

However, with large and open gantry laser cutting machines, caution and regular maintenance are necessary to protect it from the external environment.

III. Articulated Laser Cutting Robotic Arm

Articulated Robots is just the scientific name for Robotic Arms. Though, they are much rarer than the industrial robots we discussed. These robotic arm laser cutters are extremely versatile and can perform machining at angles, which are impossible for CNC laser cutting machines.

A six-axis laser-cutting robotic arm can cut highly complex designs much faster. The robotic arms are excellent for designs involving sharp angles and curves in 3d space. However, they aren’t that precise in comparison, so it’s a trade-off.

These machines have high upfront costs, so they are best suited for highly specialized manufacturing, which is otherwise impossible with traditional means. Automotive and Aerospace industries make the most use of such dynamic articulated laser-cutting robots.

IV. SCARA Robots

SCARA is short for Selective Compliance Assembly Robot Arm, essentially an articulated robotic arm, as we discussed before, but has some minor differences. They have less freedom of motion, usually 4-axis, unlike a full-fledge six-axis robotic arm.

However, they are specifically designed for tasks requiring high repeatability and precision. SCARA robots have fewer joints and linkages, making them easier to maintain and capable of handling tasks that involve high cyclic stresses.

V. Parallel Robots

Parallel links robots have 3 or 4 serial arms that move in unison to create different types of motion. This arrangement is pretty common in 3d printing machines. Such industrial robots are also extremely efficient in picking and handling goods. However, with laser cutting, their applications are limited.

Which Materials Can Laser Robots Cut?

Laser cutting robots are highly versatile and can perform machining on nearly any material available in the market. However, it’s no surprise that certain laser technologies are more compatible with specific materials. Therefore, there isn’t a single laser cutter out there capable of handling every task.

Modern CNC laser cutting systems are designed in such a way that it’s easier to change the laser source and laser head, increasing the adaptability of the machine to the maximum. Also, multiple-axis laser-cutting robots can move around material blocks, creating intricate and complex cuts.

Let’s discuss briefly some materials and the laser cutting robots that are compatible with them.

Metals

Stainless steel, carbon steel, mild steel, aluminum, and its alloys are best cut by multi-axis fiber laser cutting robots. Similarly, copper and nickel alloys are compatible with these machines. With the right power and governing parameters, it can cut up to 22 mm in thickness.

Some advanced laser cutting machines are capable of machining titanium parts, too. The automotive industry uses six-axis fiber laser robot arms to create intricate curves and shapes.

Non-Metals

Non-reflective materials like wood, leather, glass, ceramic, and fabric are best cut by CO2 laser cutters. In addition, many industries are also using such machines for acrylic and plexiglass laser cutting.

Major Advantages of Using Laser Cutting Robots

Laser cutting robots are the future of the manufacturing industry, and rightly so. Here are the key benefits of laser-cutting robots over traditional CNC machinery.

1. Range of Motion and Reach

Multi-axis robots offer a wide range of motion, meaning the machine is no longer restricted to moving in conventional planes, like in mechanical or plasma cutting. Though traditional machining has its place in repetitive machining processes, high-tech laser robots excel in the rapid prototyping of complex geometries.

2. Complex Design at Rapid Speed

Industries like aerospace demand highly sophisticated manufacturing; if not executed properly, it can lead to critical issues. Hence, laser-cutting robots have become an excellent choice in such settings. Additionally, fast-processing CNC algorithms offer features like “Fly Cutting,” delivering unparalleled machining speeds.

3. Lesser Footprint

Laser-cutting robotic arms take considerably less space compared to conventional laser-cutting machines, making production cleaner and smoother. However, the arms do require unrestricted empty vertical space to move freely in any orientation necessary for the cutting path.

4. Autonomous Working

With the right programming software, laser-cutting robots can operate in auto mode, requiring minimal human intervention even for complex jobs.

Who Can Benefit from the Use of Laser Cutting Robots?

Even though laser-cutting robots appear perfect for machining processes, they may not be feasible for every project. CNC Laser cutting robots are feasible for high-speed machining of complex parts and rapid prototyping.

For simple and repetitive machining, conventional 2-axis machining will give better results. Also, medium to large-scale manufacturing industries reap the most benefits of laser cutting robots. That’s because the upfront cost of multi-axis machining is high, making it challenging for small-scale industries to cover the expenses.

How Much Does a Laser Cutting Robot Cost?

Laser-cutting robots are expensive compared to their traditional counterparts. Typically, multi-axis laser cutting machines cost within the range of $30,000 to $250,000. Make sure to find the right manufacturer and properly communicate your project needs so that you get a customized laser-cutting machine tailored specifically for your project.

FAQs

1. How Do Laser Cutting Robots Compare to Other Cutting Methods?

Compared to mechanical, plasma, water jet, and even traditional laser flatbed cutters, the laser cutting robots have the following advantages:

- Excel in precision and can achieve cleaner cuts and finer details.

- Can work on a wide range of materials.

- They operate faster than traditional cutting methods, enhancing production efficiency.

- Can handle complex tasks autonomously once programmed.

- The performance often outweighs the initial investment, especially in high-volume or intricate cutting applications.

2. What Is the Use Of Laser In Robotics?

The combination of robotics with laser technology has upgraded conventional laser cutters to the point that they can rapidly machine extremely complex designs. It has helped researchers and designers to create more dynamic and intricate designs, which was previously impossible.

3. Why Do People Use Laser Cutting?

Laser cutting is a fast, efficient, and effective cutting technology that attracts people from all fields of work. It offers minimum material waste, and cuts are much smoother than mechanical cutting. Laser-cutting machines are extremely adaptive to automation, resulting in lesser labor costs and better production.

Conclusion

Laser cutting robots are steadily improving, with industries investing millions in enhancing their practicality and economy. Our guide serves as a stepping stone into the realm of multi-axis laser-cutting robots, providing an overview of their potential and shedding light on the future of laser-cutting machines.

Precision Redefined: Discover Laser Cutting Robots at Baison Laser!

If you seek top-tier laser machines trusted by major industries, you’ve landed in the right place. Baison Laser has served global clients for over two decades. Our cutting-edge manufacturing plants produce the world’s finest Fiber laser and CO2 laser cutting robots, laser welding machines, and laser marking machines.

We customize our products to suit your project needs and offer market-competitive after-sales services. Still unsure? Why not experience our Free Sample Evaluation? Request your Quote Now!