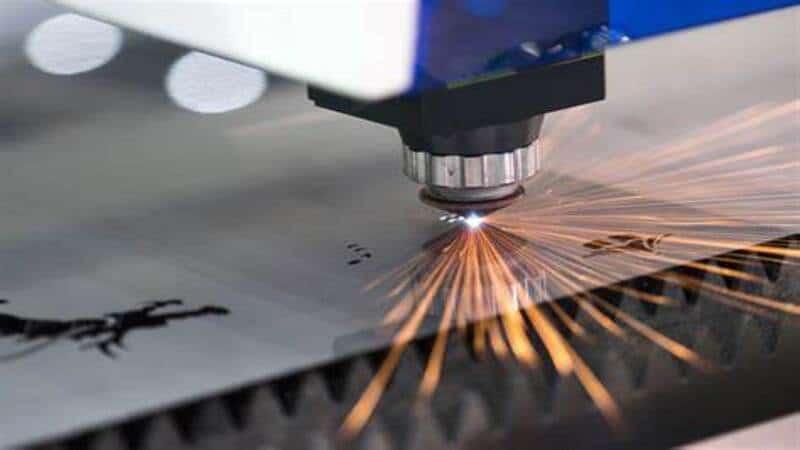

Laser cutters are considered one of the most efficient means of cutting and engraving. They also allow for cutting various materials (metal & non-metal), making them one of the most versatile cutting tools. However, people often ask if it is possible to cut at an angle using laser cutters.

So today, we will look at how laser cutting works and whether cutting at an angle is possible!

Laser Cutting at an Angle – Is It Possible?

By default, laser cutting machines work by cutting the material surface at 90 degrees (perpendicular). But depending on the user settings and the material, the cutting edge can slightly deviate away from the 90 degrees.

So in most cases, the laser cutters will cut at an angle close to 90 degrees (a slight angle). But if we talk about cutting at angles such as 45 degrees, that’s a different story altogether.

We have listed some of the ways through which laser cutters can cut at an angle:

1. Position the Material

To cut at an angle such as 45 degrees, you will have to position the material at 45 degrees. So when the laser beam hits the material in a straight line, the result will be a cut of 45 degrees.

You can use this method to cut at any angle (it can be anything, such as 45, 60, and so on). Positioning the material changes the beam path from 90 degrees to the angle defined by the user.

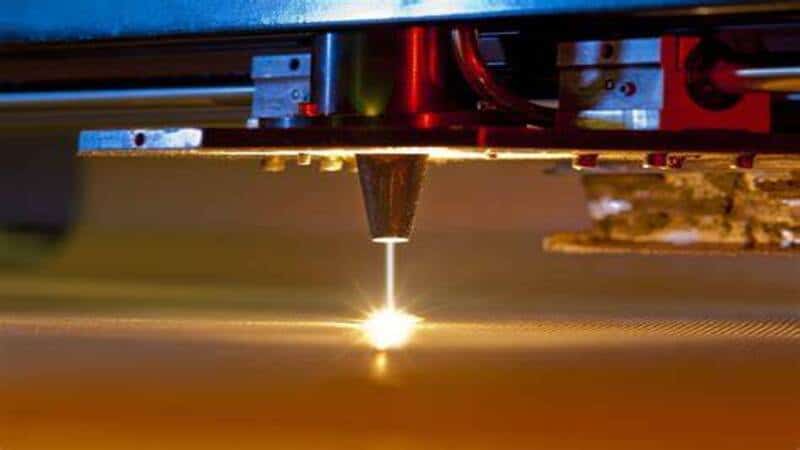

2. Position the Laser Cutter

Another solution is to position the laser cutter at a slant so that the beam alignment is at 45 degrees. This can also help you to achieve an angled cut with the help of a laser beam.

However, cutting at an angle is not an exact science and will require trial and error. As mentioned earlier, laser beam-powered cutting machines are not designed to cut at an angle. Instead, they are designed to cut in a straight line (90 degrees)!

So trying to do something such as cutting at an angle (45 degrees) means that you will have to use some additional tools or make some improvisions.

For laser cutting at an angle, we have prepared an article on bevel cutting.

3. Incorrect Settings

Sometimes, the angle of the laser head, mirrors, focus lens, focal point, and nozzles can also lead to cutting at a slight angle. However, you can’t get precision with this method as it is more related to wrong settings rather than doing it on purpose.

Such problems can lead to very poor cutting edges and even total failure to cut. That’s why we do not recommend you mess with the focus lens or any other parts, as it could affect the cutting ability of your laser cutter.

4. Material Thickness

The thickness of the material can also dictate the cutting angle of laser cutters. Generally, the cutting edge of thinner materials is slightly angled because the top of the material is exposed to more concentrated heat. Furthermore, the cutting process also leads to the removal of a lot of material which can cause a slight angle as well.

You will notice this slightly angled cut in less than 3mm thick materials. However, the cutting angle is usually unnoticeable and only deviates slightly from 90 degrees.

However, thicker materials can be cut more precisely due to the focal distance of the laser cutter’s lens. The top material is not as exposed to heat as the thinner materials. For bevel cutting thick materials, refer to this article.

Applications of Laser Cutting at an Angle

Now that we know that it is possible to cut at an angle through different tools and improvisations. The next question is, what are the uses/applications of cutting at an angle?

Laser cutting at an angle is used in various applications where workpiece edges need to be prepared for joining, especially welding. Some of the typical uses involve making promotional stands, store construction, exhibition stands, model making, mounts, and displays.

- Promotional Stands: Laser cutting allows for the precise cutting of logos, intricate designs, and custom shapes necessary for brand promotion. Beveled edges can add a dimensional aspect to stands, enhancing visual appeal.

- Store Construction: In retail store construction, angled laser cuts can be used to create unique shelving units, signage, and decorative elements that require precise fitting and assembly.

- Exhibition Stands: For exhibition stands that often require quick assembly and disassembly, beveled cuts ensure pieces fit together perfectly, providing structural integrity and aesthetic quality.

- Model Making: Precision is crucial in model making, and angled cuts can help in accurately replicating parts that need to join at specific angles.

As for the materials suitable for cutting at an angle, some of the suitable materials are acrylic, solid board, foam board, sandwich board, wood, and other solid materials.

Conclusion

As you can see, you can technically cut at an angle with the help of a laser cutter. However, you will need to improvise by changing the angle of the machine/material or tweaking the settings.

By default, a laser cutter can only result in optimal cuts if the laser beam is making contact with the material at 90 degrees. Any deviation from this angle can lower the cutting power of these machines and even lead to uneven cuts.

Many people try to adjust their laser cutters to make perpendicular cuts. Because if you think about it, laser cutters are famous for making precise, smooth, and straight cuts. However, keep in mind that you can still achieve angled cuts if that’s what you want. But it will require some trial and error.

Experience Precision Angled Cutting with Baison Laser!

At Baison Laser, we offer all types of laser cutters at competitive market rates. We know that your manufacturing projects are essential and thus require nothing short of reliable and high-quality cutting equipment. So if you want to experience quality laser cutting and get a good and efficient alternative, contact us today to get a quote!