Laser technology has made our lives much easier than before. One example is CO2 laser technology. CO2 lasers blend gases to make a precise invisible beam. They’re known for accuracy and work well with various materials and in different industries.

In this blog post, you’ll learn all the simple details, from how they work to the things they can do. Find out why CO2 lasers are handy for different jobs and how they compare to other laser technology. Let’s get started!

What is CO2 Laser Technology?

The CO2 laser is an innovative technology that creates a precise invisible beam by employing a mixture of gases. According to DermNet, the gas mixture comprises carbon dioxide, nitrogen, and helium. The electric discharge results in laser beam emission.

CO2 laser technology is renowned for its accuracy. It’s widely used in cutting, joining materials, and laser treatments in medicine and research. It is also acknowledged for its versatility. It efficiently works across diverse materials and industries.

How Do CO2 Lasers Work?

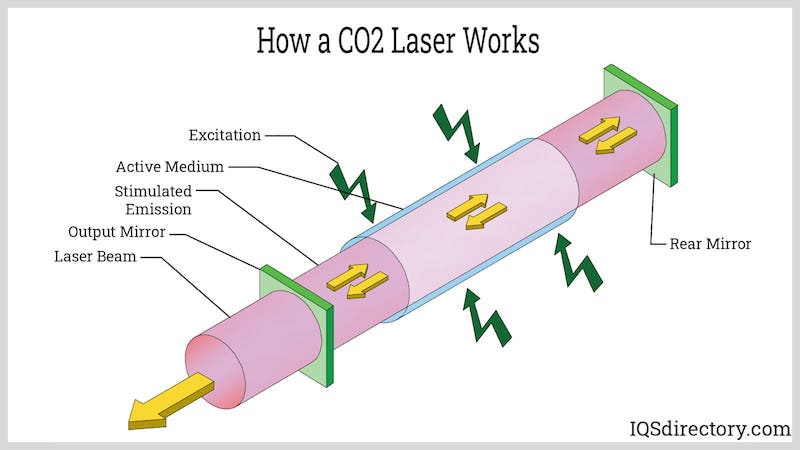

The operational sequence of a CO2 laser involves distinct stages, commencing with the inception of the laser beam within the resonator.

A resonator is a cylindrical glass tube housing carbon dioxide, nitrogen, and helium. This resonator features a reflective mirror at one end and a semi-reflective mirror at the opposite end. Ionization of the gas in the resonator is achieved through an electric field, energizing the nitrogen molecules and subsequently transferring this energy to the CO2 molecules, prompting electron movement to higher energy levels.

According to the Defence Technical Information Center, as these excited CO2 molecules undergo a transition to lower energy levels, they emit photons. The emitted photons induce a chain reaction, compelling nearby excited CO2 molecules to release photons in the same direction.

This cascade of photons is perpetuated as they bounce between the mirrors, prompting the emission of additional photons from adjacent CO2 molecules. This process persists until a critical mass of reflected photons generates a coherent beam of light that penetrates the semi-reflective mirror. The resultant light is then channeled through a lens, concentrating it into a high-energy intensity point for utilization in industrial or medical applications.

6 Types of CO2 Laser

There are 6 main types of CO2 laser, have a look at them:

1. Longitudinal-Flow Laser

These lasers contain a long, thin tube that carries the laser beam along its length. They are commonly used for actions such as cutting, engraving, and marking due to their ability to transmit focused energy across great distances properly. Longitudinal mode provide predictable results by continually eliminating laser gas from the tube using a vacuum pump.

2. Transverse-flow Laser

In contrast to longitudinal-flow lasers, the laser beam in transverse-flow systems travels across the width of the tube. This configuration is effective and appropriate for high-power workloads. Using this technology, the laser may handle greater gas flow, improving cooling and making the laser more robust in harsh environments.

3. Sealed-off CO2 Lasers

Seal CO2 lasers limit the laser gas mixture inside a sealed tube, making them compact and efficient. To prevent CO2 molecules from breaking down, modest quantities of hydrogen, water vapor, and oxygen are added to the gas mixture rather than replacing it entirely. Nickel cathodes heated to 300°C catalyze this process. Mirrors at either end provide a resonant cavity, increasing the laser’s operational life by several thousand hours.

4. Waveguide Lasers

Waveguide lasers employ a waveguide structure to guide the laser beam, resulting in high beam quality. They effectively absorb heat loss in their smaller lasing volume and larger resonator surface area. This makes them ideal for scientific research and medical operations where precise beam control is required.

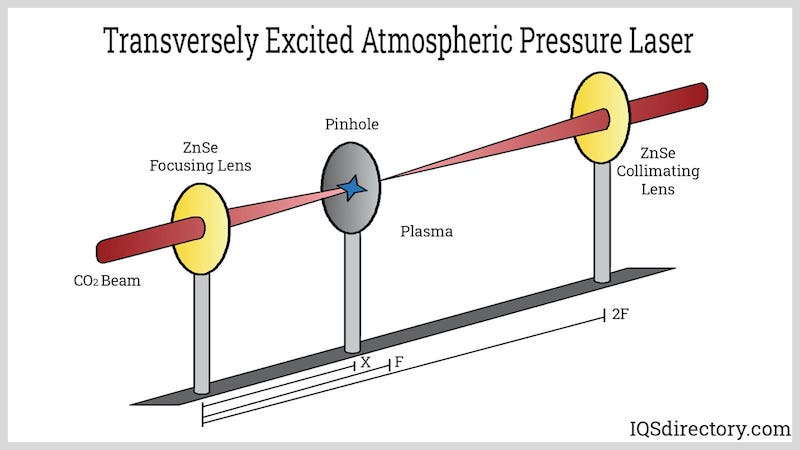

5. Tea (Transversely Excited Atmospheric) Laser

TEA lasers are ideal for pulsed laser applications such as material removal and spectroscopy due to their high pulse rate. Short pulses of discharge voltage across the gas flow lessen the probability of arcing.

Electrodes connected in series along the discharge tube provide steady functioning even at high pressures. While they normally have average output powers of below 100 W, TEA lasers can generate tens of kilowatts of power with high pulse repetition rates.

6. 300W CO2 Laser Cutting Machine

The Baison 300W CO2 laser cutting machine stands out as a pinnacle of precision and seamless finishing in the realm of cutting and engraving diverse materials. Its versatility extends to various mediums, including wood, plastic, leather, and more, showcasing a broad spectrum of applications. Renowned for its ability to engrave surfaces with remarkable accuracy, this cutting-edge machine ensures meticulous detailing in every project.

What sets it apart is not only its exceptional performance but also its user-friendly operation, eliminating the need for dangerous blades. With the Baison 300W CO2 laser cutting machine, precision meets simplicity, making it an ideal choice for a wide range of creative and industrial endeavors.

5 Key Benefits of CO2 Laser Machines for Your Business

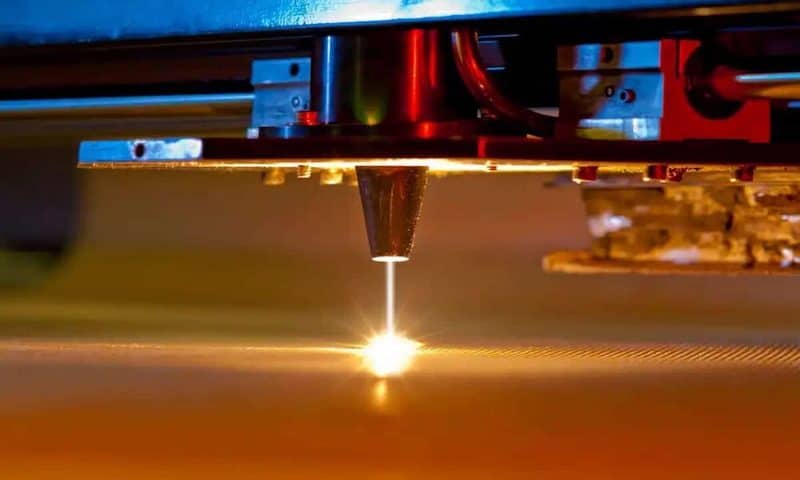

CO2 laser cutting machines provide several advantages to businesses across different sectors, becoming essential instruments for various jobs. CO2 lasers are ideal for precise cutting and engraving of materials such as wood, acrylic, leather, and metals.

Their concentrated beams produce exact forms and elaborate designs, making them useful in sectors like signage, jewelry, and manufacturing.

1. Versatility

These machines can deal with a variety of materials, including metals, plastics, wood, and glass. This versatility allows businesses to experiment with different applications, ranging from creating unique signs to producing complicated parts to fulfill the demands of different industries. In the medical field, it is employed to treat various skin concerns, including uneven skin tone, acne scars, sun damage, and wrinkles.

2. High Speed And Efficiency

CO2 laser machines are well-known for their ability to complete cutting, engraving, and marking operations fast. This efficiency increases productivity and lowers production costs, making them a good choice for businesses seeking to optimize manufacturing processes.

3. Non-contact Processing

Unlike previous procedures, CO2 lasers function without touching the material. This means that the material is less distorted and the equipment damaged less. It also guarantees that cuts are clean and precise, minimizing the need for additional finishing stages.

3. Customization and Personalization

CO2 laser machines enable businesses to customize items by engraving names, logos, or unique designs on various surfaces. This customized option increases client satisfaction and loyalty and edge over their competitors.

4. Minimal Material Waste

CO2 laser devices produce relatively little waste since they cut with high accuracy. The laser beam focuses closely, allowing resources to be used more efficiently, decreasing waste, and promoting sustainable practices.

5. Automation and Integration

Many CO2 lasers offer extensive automation features and may fit easily into current manufacturing lines. This indicates that organizations may automate repetitive processes, increase efficiency, and decrease labor expenses, resulting in higher total production.

5 Amazing Applications of CO2 Lasers

CO2 laser resurfacing has many applications, a few of which are mentioned below:

1. Material Processing

CO2 lasers are excellent at cutting through different materials, including metal, plastic, wood, ceramics, and composites. Their intense light allows for accurate cuts in different forms and patterns.

They are also good at writing or drawing on surfaces like metal, glass, or stone, making them perfect for adding details like serial numbers or logos.

CO2 lasers are used extensively in large-scale such as automotive, airplane, and electronics manufacturing units. They help to create exact cuts, holes, and forms in materials, which is necessary for generating the large number of pieces required. Furthermore, they are used in the textile sector to cut and decorate textiles, leather, and other materials, resulting in greater efficiency and precision as compared to manual processes.

2. Medical Usage

CO2 lasers are used by doctors in operations to cut through tissues or treat skin concerns like scars and wrinkles. Skin resurfacing is an advanced treatment that employs a CO2 laser. The laser beam penetrates the skin’s surface, and the fluid in skin cells absorbs it.

These lasers are extremely accurate, allowing tissue removal without causing significant damage to the surrounding skin cells. However, you need to keep your skin moisturized and prevent prolonged sun exposure after the laser treatment.

3. Laser Processing

CO2 lasers are used to do delicate operations such as generating small patterns or cutting tiny holes in ceramics and semiconductors. They excel at precision work without causing significant damage to materials. They are also used in sectors like automotive and electronics to create strong, long-lasting connections between metals.

4. Uses by Artists and Designers

Artists and designers choose CO2 lasers because they can create detailed artwork or decorations. These lasers can cut, carve, or engrave materials such as wood or acrylic with incredible precision, bringing creative ideas to life. They’re also great for making prototypes or models in design studios, which allows designers to test ideas quickly and efficiently.

5. Scientific Usage

Scientists use CO2 lasers for various tasks, such as examining small molecules and evaluating materials. These lasers produce clear pictures and data, assisting researchers in understanding processes at the microscopic level.

They also play an important role in the development of new technologies, such as improved communication devices and advanced optical tools, which contribute to our knowledge of the world.

Detailed Comparison with Other Lasers

When comparing CO2 lasers to other common types, we analyzed the light they produce, their versatility, cost, efficiency, and beam quality.

| Criteria | CO2 Lasers | Fiber Lasers | Nd: YAG Lasers |

|---|

What Type of CO2 Laser Machine is Best for Your Needs?

Several types of CO2 laser machines are available in the market for different purposes. The type of CO2 machine that is best for your needs depends on the following steps:

Step 1: Assess Your Needs and Requirements

When you’re choosing CO2 laser cutting machine gear for your business, take your time to choose wisely. Here’s a simple step to help you out.

Think about the materials you’ll work with, how thick they are, and how precise you need to be with cutting and engraving. You can also use particular CO2 lasers for improving the healing process, accelerating collagen production, or treating skin cancer. However, some lasers are meant for lighter skin tones. Treating darker skin tones with such CO2 lasers will result in hyperpigmentation issues.

Knowing exactly what you need will help you pick the right CO2 laser equipment. Take your time with each step, and don’t rush into any decisions. It’s important to get it right from the start to make sure your business runs smoothly.

Step 2: Select A Reputable Brand

Look for one that’s famous for making good, reliable machines. Check out what customers say in reviews and testimonials, and see how long the manufacturer has been around. Price matters, but it’s not everything.

Aim for a brand that gives you a mix of quality, reliability, and good value for money. You should research and find the best brand for your needs. It’ll pay off in the long run by ensuring you get a CO2 laser that meets your business requirements perfectly.

With 20+ years of laser cutting expertise, Baison Laser provides custom solutions through an in-house R&D team. We handle everything from manufacturing to installation and after-service, ensuring top-notch quality. Trusted globally by millions of businesses, Baison offers versatile machines to suit various needs.

Step 3: Set A Realistic Budget

Now, it’s time to plan your budget. Make sure it fits what you can afford, but also think about how much you’ll get back from your investment. Look at the prices of CO2 laser equipment and remember to include other costs like maintenance, training, and software.

Your budget should match what your business needs and goals are. it’s important to get it right. With a realistic budget in place, you can make sure you’re investing wisely and getting the most out of your CO2 laser equipment.

Step 4: Clearly Define Your Needs

Next, it’s essential to know exactly what you need from your CO2 laser equipment. Think about what your business requires, like the size and power of the machine and any special features. Decide if you’ll use it for big jobs or smaller ones, as this affects what size and power you’ll need.

Also, consider if you need CNC technology to make the machine more efficient. Make sure you’re clear about what you need. It’ll help you choose the right CO2 laser equipment for your business’s specific tasks and goals.

Step 5: Check Your Workspace

Now, take a look at your workspace to ensure it can accommodate the CO2 laser equipment you plan to buy. Check things like ventilation, available space, and the size of the machine. Proper ventilation is important for keeping the equipment safe and working well.

Measure your space to make sure the CO2 laser machine fits comfortably without overcrowding. It’s important to avoid cramming too much into your workspace to prevent safety issues. By ensuring your workspace is suitable, you can create a safe and efficient environment for operating your CO2 laser equipment.

Maintenance and Troubleshooting of CO2 Laser

Here are some common problems that may arise during the use of CO2 lasers, some solutions, and maintenance tips:

1. Cleaning

It’s common for CO2 lasers to gather dirt and dust, which can impact how well they work. To fix this, simply clean the laser lens and optics regularly using a soft cloth or brush to remove any dirt buildup.

This routine maintenance will keep your laser running smoothly and prevent problems like inconsistent cutting or engraving. By taking care of these simple cleaning tasks, you can ensure that your CO2 laser performs at its best and continues to deliver reliable results for your projects.

2. Checking the Cooling System

If your CO2 laser starts acting up, it could be due to issues with the cooling system. To troubleshoot, inspect the water lines for leaks or blockages to make sure they’re working properly. If you spot any problems, clean or refill the coolant as needed.

This helps prevent the laser tube from getting too hot and potentially getting damaged. By staying on top of maintenance like this, you can keep your CO2 laser in top shape and ensure it continues to operate smoothly for your projects.

3. Alignment

If your laser seems off, it could be due to the beam not being focused right. To fix this, check if the mirrors and optics are aligned properly to make sure the beam goes where it’s supposed to. If needed, tweak the mirrors a bit to make sure the laser works better.

By doing this regularly, you can make sure your laser cuts and engraves just the way you want, ensuring your projects turn out great every time. Keeping an eye on these things helps maintain your laser’s performance and keeps your work top-notch.

4. Checking the Power Supply

If your laser suddenly acts up, it could be the power supply causing trouble. To prevent this, check the power supply unit often for any signs of damage, like worn wires or burnt parts. If you spot anything broken, replace it to keep your laser working smoothly.

By doing this regularly, you can avoid power issues that might mess with your laser’s performance. Keeping an eye on the power supply helps ensure your laser keeps running smoothly, so you can focus on your projects without any interruptions.

5. Updating Software

If you’re having trouble with your laser, it could be because of the software. Keep your laser running smoothly by updating its control software regularly. This ensures you get the latest bug fixes and improvements.

Before updating, make sure to save your settings and preferences. This way, you won’t lose any important data. By staying on top of software updates, you can avoid potential issues and keep your laser working like new. Updating your software is an easy way to maintain your laser’s performance and ensure it meets your needs

6. Regular Maintenance

Aside from fixing specific problems, it’s crucial to regularly maintain your CO2 laser to keep it in good condition. This includes tasks like lubricating moving parts, inspecting for loose connections, and ensuring everything appears in good shape.

Regular maintenance helps prevent unexpected issues and prolongs the lifespan of your CO2 laser. By taking care of routine maintenance tasks, you can keep your laser operating smoothly and avoid costly repairs down the line. Make it a habit to perform regular checks and maintenance to ensure your CO2 laser remains in fresh condition for years to come.

The Future of CO2 Lasers

As we look ahead, the trajectory of CO2 laser technology suggests a transformative evolution characterized by trends such as miniaturization, enhanced efficiency, and seamless integration with other cutting-edge technologies.

Anticipating a future where CO2 lasers become smaller and more efficient, their expanded capabilities will allow for a broader spectrum of tasks to be executed with reduced energy consumption. This versatility is particularly advantageous, facilitating their utilization across diverse settings such as factories and hospitals.

A noteworthy development on the horizon involves the integration of CO2 lasers with robotics, computers, and smart technologies. Envision lasers equipped with autonomous decision-making capabilities, adapting their operations based on real-time environmental cues.

As CO2 lasers keep getting better, we might discover new jobs for them. They could be used for less invasive surgeries, creating things with 3D printing, and maybe even helping out in space exploration.

Discovering New Uses for Lasers

As CO2 lasers improve, we will find new uses for them. They might be utilized for less invasive surgery, 3D printing, and possibly space exploration. So, the future of CO2 lasers is more than simply making them stronger; it’s also about discovering new ways they may aid us in our daily lives.

FAQs

1. How does CO2 laser technology function?

CO2 laser technology operates by stimulating carbon dioxide molecules with energy, causing them to emit light when hit by photons.

2. Is it possible for a CO2 laser to cut metal?

Yes, CO2 lasers can cut metal by focusing a high-energy beam onto the material, making precise cuts with minimal heat damage.

3. What is the maximum thickness that a CO2 laser can cut?

The maximum thickness a CO2 laser can cut depends on its power and the type of metal, typically up to several millimeters

Conclusion

In short, CO2 lasers have amazing potential and versatility across various sectors and fields of study. CO2 lasers play an essential role in advancing technology and new ideas, from ultra-precise cutting and design to medicinal treatments and scientific investigation.

As we look to the future, continued developments in CO2 laser technology promise even greater efficiency, compatibility with other technologies, and new uses. With their ability to change and fit in, CO2 lasers stay as very useful tools, pushing forward improvements and opening up lots of possibilities in making things, healthcare, studying, and more. Try Baison Laser to get the best results.

Unlock the Power of CO2 Laser with Baison Laser!

Discover the world of precision cutting, engraving, and more with Baison Laser! Unlock your creativity today and bring your ideas to life with our state-of-the-art laser-cutting solutions. Don’t wait any longer to make your projects shine. Contact Baison Laser now and let’s turn your visions into reality using the best laser technology available.