If you’re looking to make your business more efficient and streamlined, laser cutting can help you. Compared to mechanical cutting, it can save your business a significant amount of time due to its high cutting speed.

On the contrary, compared to other cutting methods, this process can hold some downsides, like a required skill set to operate. Therefore, it can be beneficial and a hindrance to you if you’re in the automotive, medical, woodwork, painting, HVAC, packaging, and electronic industries.

These aren’t the only industries that adopt laser cutting technology; there are a lot more due to the advantages laser cutting offers.

Laser cutting is gaining major attraction, and it’s forecasted to be around $6.44 billion by 2026. This figure is a massive example of why laser cutters are taking the lead over more traditional methods.

But to know if you should adopt this approach for your business over other types, you must look at laser technology more in-depth. Therefore, this post will cover more about what it is, its advantages and disadvantages, and how to choose the right one.

What is Laser Cutting?

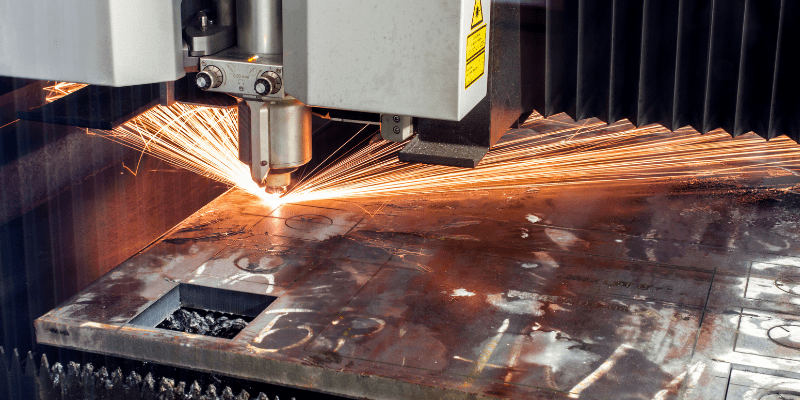

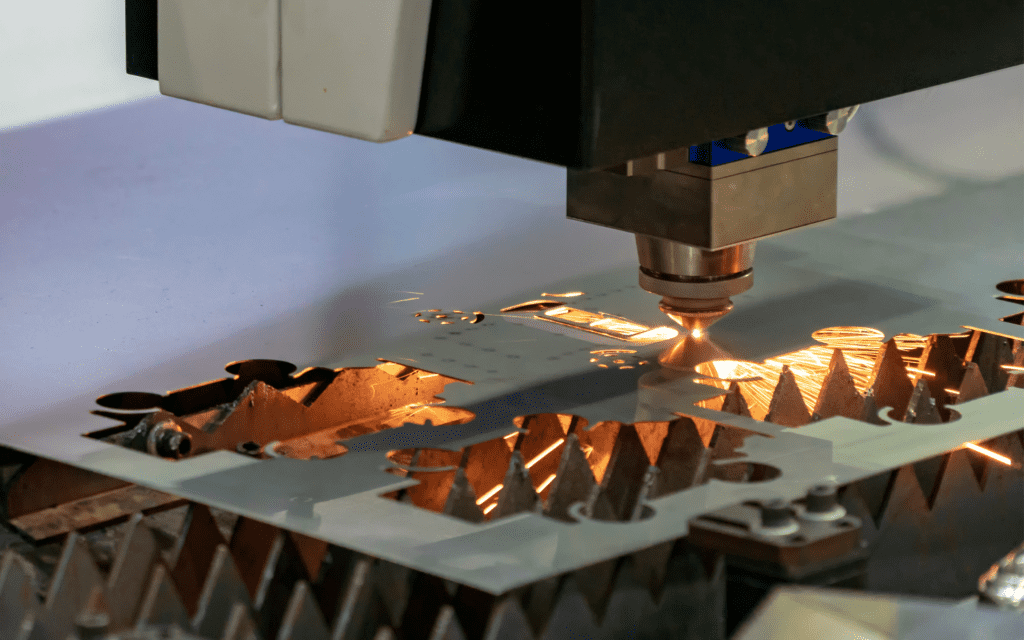

Laser cutting is a process that uses laser technology to cut materials. The laser produces a focused beam of intense light, which cuts through the material at very high temperatures.

This technology has been around since the mid-1960s, offering an incredibly precise and efficient method to work with various materials, even those that are very delicate. To use laser cutters, operators must load pre-programmed instructions into the machines. Hence, it knows where and how to accurately direct laser beams for maximum efficiency for each material type.

Today’s laser cutting machines offer higher speeds and capabilities than ever before, allowing them to produce highly sophisticated designs with near perfection. High accuracy and repeatability levels make it easy to see why Laser Cutting has become so popular across many industries.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

How Does Laser Cutting Work?

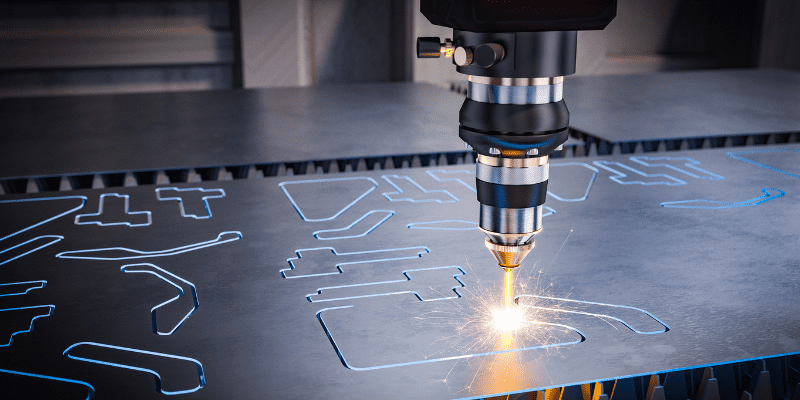

The main way laser technology operates is its extremely precise high-power laser distributed through an optic. It then strictly follows a CNC or C-code of the required design or pattern that needs to be cut onto the materials.

The laser beam at its narrowest is under 0.0125 inches/0.32 mm in diameter and has key widths as little as 0.004 inches/0.10mm depending on the cutting materials. As soon as it focuses on the material, it burns through it. After that, the material melts and vaporizes, creating a premium cut and smooth edge.

Once a laser cutting machine starts, it typically follows a set computer program. Computer programs on these machines will go into specific details, requesting the person to input information about the type of metal or material and the pattern it needs to cut.

Laser beams differ slightly due to the material and intended result. Based on the pattern you require, the laser beam will move around at different points and change based on its focal length. It does this to achieve different cutting layers and depths of the material. This is especially beneficial if you’re in the medical industry, as it has a lot of precision.

What are the Different Types of Laser Cutters?

There are three different types of laser cutters that you can use for your business:

1. CO2 Laser Cutter

The CO2 laser cutter is one of the most popular types as they’re the most cost-effective to buy. Their primary use is for cutting metals due to their ability to cut through strong materials. A Co2 laser has a long vacuum-sealed tube containing gas, most carbon dioxide, and nitrogen mixed in. As soon as the tube comes into contact with electricity, the molecular gas becomes stimulated, and intense light is emitted.

Once the light exits the tube, it’s redirected by mirrors through a lens onto the material. By this point, the material it’s focused on becomes very hot, causing the laser to cut through the material due to thermal separation.

2. Crystal Laser Cutter

These laser cutters generate different light beams and tend to cut through much stronger and thicker metals using smaller wavelengths. They tend to have a higher intensity than others and have higher power.

3. Fiber Laser Cutter

Fiber laser cutters operate in a similar way to fiber optic lights. This is because light enters a glass tube with different types of glass with reflective properties. The light tends to bounce down the tube, gaining strength as it moves.

Moreover, the fiber optics cause the laser to reduce down to a smaller yet finer diameter creating greater details and precision when cutting and engraving. Today, fiber lasers can cut up to 2″ of material. As fiber lasers tend to have high precision, they’re much bigger and more expensive. Compared to other cutters, they don’t need as much maintenance or replacement parts.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

What are the Advantages of Laser Cutters?

This cutting method boasts lots of advantages, such as:

- They provide clear and precise cuts.

These laser cutters offer more precision than other thermal cutters on the market. On average, an efficient laser cutter has an accuracy of +/-0.1 mm, providing opportunities for high precision without having to intervene during the process or afterward. This means a laser cutting machine can consistently produce good replicas if required.

- You can create a lot of different cuts. Laser cutting machines are highly adaptive. You can change cuts and materials through simple software changes. You can use this machine on acrylic, wood, plastic, paper, and more. You don’t constantly need to change tools to achieve this; you can do it with a button click.

- Speed

When comparing laser cutting services next to other methods, it’s a lot faster, especially when you wish to create more complex cuts. It is also quicker to cut thick materials than a typical plasma or flame cutter.

One of the major advantages of this machine is that it requires less manpower to operate it. You only need an experienced machine operator to oversee the machine, the product’s final quality, and the cutting seed. In comparison, it needs less labor and upfront costs to intervene at each stage. Similarly, some machines also have feeding systems and follow-up conveyors, making them operate more quickly.

- Superior cuts

With laser cutting, there’s no need to worry about quality. They often produce cuts of a higher standard compared to other machines. They often don’t need additional processing, and materials are less likely to be damaged or deformed. This is because these machines have a small heat-affected zone, which allows you to produce more reliable and consistent parts.

- Less wear and tear

These cutting tools are often contactless, making them subject to less wear and tear. Because of this, you don’t need to replace the tools quickly, as they don’t wear out easily. This saves you time, and the materials you cut into are consistent with quality.

- Short set-up time

Due to the efficient technology in laser cutters, you don’t need to worry about your system going down. The technology is straightforward and high-end; you can set up the machine and use the program immediately. With this machine, you don’t need to worry about significant backups or delays.

- Don’t need to clean materials

Unlike typical processes with laser cutting technology, there’s little mess behind the production process. There’s no deburr or sanding at the end, as the laser produces a smooth finish when it comes to the cut. The products often have such high quality at the end that you can send them straight off to shipping (if you wish).

- Quickly change mid-production

If you find you have a sudden change in design or want to make changes during the middle of production, you can do. These machines can quickly pivot and adapt to your changes as soon as you input them into the software.

What are the Disadvantages of Laser Cutting?

When purchasing a laser cutter, you should also consider the disadvantages. They are:

- High power consumption

Depending on the laser used, the machine may need more energy to operate it. Moreover, a thicker material like metal could take up a lot of power and resources to cut into.

- Expertise is required

While these machines have less manpower to operate them, they still need skilled and experienced operators. Experienced operators running these machines are quite costly to hire. These professionals must know how to utilize them properly, looking at the efficiency, cut, and quality. However, hiring the right one can save you time and headaches during the entire process.

- Purchasing fees when thinking about the downsides linked to laser cutting, one of the main ones is their upfront price. The initial investment can be quite expensive compared to other cutting tools. On average, these lasers can cost twice as much as a plasma or water jet. While this cost might be a lot at first, they save you on investment in the long term due to their low running costs and high-efficiency rate.

- Restrictions on metal thickness

Compared to other cutting, and thermal methods, it’s difficult for this machine to cut thick plates. The amount of thickness it can cut into is all based on the machine type and operator using it. If you do use thick materials with this machine, its speed can be reduced drastically.

- Toxic fumes

Sometimes the fumes this machine produces can be dangerous if you inhale them. Depending on the material the machine is cutting, toxic fumes can occur, which may require good ventilation to get rid of them. Therefore if you’re cutting plastic, you’ll need to invest in a good ventilation system to eliminate the fumes.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

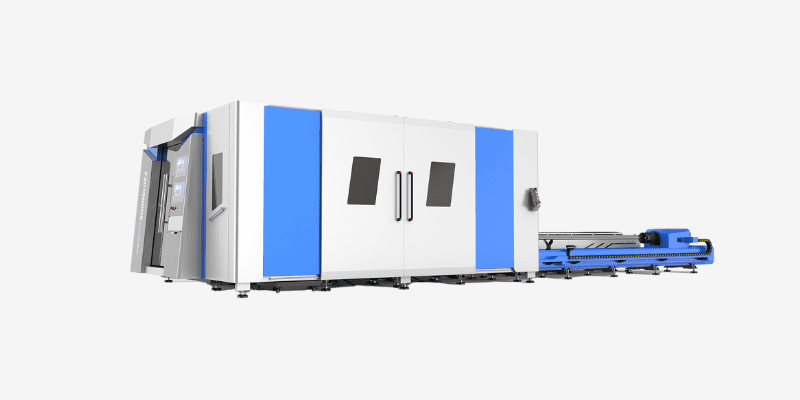

How to Choose the Right Machine for Your Business?

If you’re looking to buy a good laser cutter, you’ll want to consider the following before purchasing:

- Power

One of the first things to consider is the power output of the cutter. By knowing the power, you’ll be able to determine the number of materials it can cut and the thickness of the material. Therefore, knowing the power will give you a good indicator of the machine’s suitability for your manufacturing process.

- Cost

Another heavy influence over your choice of laser cutting machine is your budget. You’ll want to look at the overall cost of the machine to help you decide. Some companies also provide options to customize your machine based on your requirements.

- Ventilation

When using a good laser cutting machine, you’ll want it to run as long as possible to maximize your business’s efficiency. Depending on the machine, excessive heat can be generated due to the current and friction from moving parts. To avoid overheating, you should see if the machine has a built-in cooling system or a high-quality chiller to stop the machine from overheating and breaking.

- Quality

To ensure consistent and well-cut materials, you should buy machines of the highest quality. Yet, when it comes to this industry, there are many counterfeit ones causing difficulties with operations. To avoid this, you should buy certified ones from well-known companies.

- Software requirements

While many laser cutting machines come with a variety of software, you’ll want to pick the one that is easier for you and your staff to use. Alongside this, you should look for software that includes the features you need for your machine, i.e., units to save you from conversions, materials, etc.

- Bed size

Another vital factor to take into account is the bed size the machine can handle. This term covers the dimensions of the area where the material you’re using to cut sits. The larger the bed size, the more room the machine will have to cut bigger materials in one go. Therefore, you’ll want to pay close attention to the bed size based on the model of the laser cutting machine.

- Floor space

Before buying any machine, you’ll want to see how much room you have in your factory or production area. Once you have an idea, you should know the floor size of the machine to give you further insight if it fits well easily.

- Accessories

Some laser cutting machines come with add-ons to enhance your cutting. For instance, some have rotary tools to help engrave round objects more easily. Others come with additional software features and more.

- Maintenance

Ideally, the best cutters are the ones that don’t need much maintenance. However, every machine requires some care to function correctly. To know the scope of work involved, you’ll want to read the manual before buying.

Tips for Getting the Most Out of Your Laser Cutter

To ensure you get the most out of your laser cutter, you may want to do the following:

1. Select an Appropriate Material

Before using any laser cutter, you must have the right material. Material qualities can be opaque, translucent, rigid, flexible, etc. Therefore you’ll want to know the properties of the material first. Think about the design guidelines, the thickness of the material, and the color. Then once you’ve selected the suitable material, look at the machine to see if it works well with it.

2. Look Closely at the Dimensions

While many laser cutting machines can allow you to cut through thick materials and large quantities, you’ll want to know the size of the laser cutting material. After all, the size of the material can dedicate the size and scope of the project. Therefore you’ll want to look at the dimensions suggested in the materials design guidelines first.

3. Think About the Spacing

You’ll want to consider the minimum spacing required when using the machine. Spacing is important as it can reduce the likelihood of errors and help you achieve the best results in laser cutting. It’s essential to know the minimum spacing in the middle of two paths must be equal to your material thickness. Following this will make your object more resistant and less likely to break under the machine.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Conclusion

Laser cutting has many advantages and disadvantages; however, the benefits outweigh the downsides. While laser cutters can be expensive for your business initially, they’re a worthwhile investment as they require less manpower.

Other laser cutting advantages exist. These machines are responsive and come with some of the world’s best technology built into them. Due to the software they use, there’s little setup time required, and they are easy to use by a skilled operator.

The software these machines use makes them highly versatile, allowing you to change mid-production if needed. They can also run independently with little supervision, so these machines are less subject to wear and tear than other cutting methods. Moreover, they’re highly accurate and provide clean cuts with smooth edges compared to other machines.

Like all machines, they have a few downsides like the cost to buy, toxic fumes, expertise involved to run, and high power used. However, these are cons that you can easily solve in the long run.

Get Top-of-the-line Laser Cutting Machines at Baison Laser!

When buying a laser cutter, you’ll want to consider the price, floor space, ventilation, maintenance, software requirements, and more. At Baison Laser, we can help find the right laser based on your needs; contact us for an application evaluation.