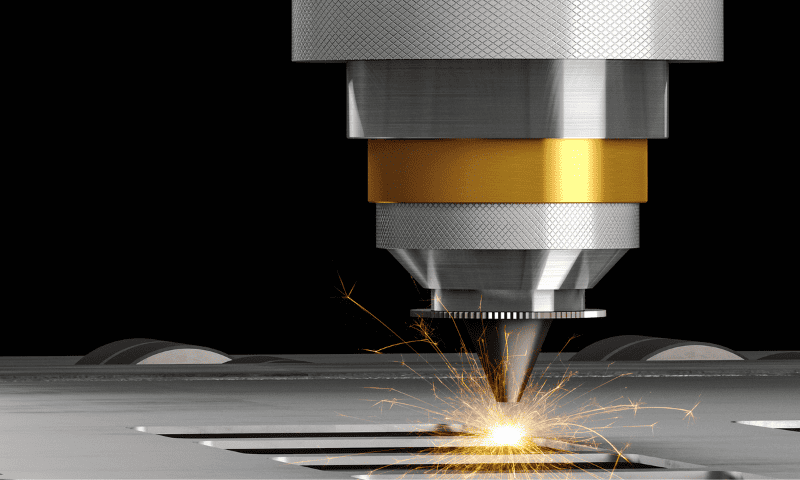

Precision Focusing Lens: Enhancing Cutting Accuracy

In the intricate world of laser cutting, precision is paramount. At the heart of achieving precise and detailed cuts lies the indispensable precision-focusing laser lens—a key component that elevates laser cutting to an art form. A different focus lens is crucial for accurately directing the laser beam onto the workpiece, ensuring perfect engraving by the laser engraver machine.

- Understanding the Precision Focusing Lens: The precision focusing lens, often referred to as a “focus lens,” is a core element of laser cutting machines. Its purpose is to converge the laser beam into an incredibly fine point, ensuring pinpoint accuracy during the cutting or engraving process. It guarantees endurance and an incredibly fine point for precision. This lens acts as the eyes of the laser machines, allowing the laser head to create intricate designs with unparalleled detail using the laser beam.

- Optimizing Accuracy with Different Focus Lenses: Laser cutting isn’t a one-size-fits-all endeavor. Different projects demand varying levels of precision. This is where different focus lenses come into play. These lenses, also known as “pinpoint lenses,” allow laser cutters to adjust the focus point for specific tasks. For those working with slightly thicker materials, pinpoint lenses become invaluable. They ensure that even intricate designs on these materials are executed flawlessly.

Pinpoint Lenses: Navigating thicker materials with finesse using laser cutter accessories to cutting slightly thicker materials presents a challenge that pinpoint lenses, and laser accessories, are uniquely equipped to overcome. These lenses enable laser cutters to maintain their precision even when working with materials that are outside the norm. With pinpoint lenses, the laser beam remains focused and accurate, ensuring clean cuts and detailed engravings on these materials.

In the intricate dance of laser cutting, the precision focusing lens takes center stage, fine-tuning every detail and ensuring that every cut is a masterpiece. With pinpoint accuracy and the ability to navigate different materials, these lenses are the embodiment of precision in the world of laser cutting.

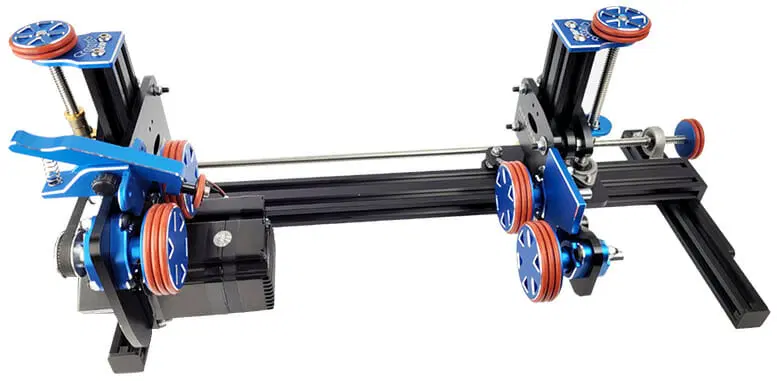

Rotary Attachment for Expanding Possibilities

Expand your creative horizons by adding a rotary attachment to your laser machine. A rotary attachment is a must-have laser cutter accessory opening up whole new shapes of material to laser engrave upon.

By incorporating a rotary attachment into your laser cutting workflow, you can increase versatility and maximize productivity. Here’s why the rotary attachment is a must-have for any laser machine enthusiast.

- Engrave cylindrical objects: The rotary attachment allows you to engrave on rolling pins, bottles, tumblers, and more. Say goodbye to flat surfaces only, as now you can add intricate designs to curved shapes effortlessly.

- Create 360-degree designs: With the rotary attachment, you can design patterns that wrap around the entire circumference of an object. Imagine personalized tumblers with names or logos seamlessly engraved all around.

- Unlock new applications: By adding a rotary attachment to your laser cutter, you open up a range of new applications. Personalized bottles, custom-shaped boxes, and even unique enclosures are just some examples of what you can achieve.

- Enhance productivity: The rotary attachment saves time and effort by allowing you to work on multiple items simultaneously. You no longer need to manually rotate objects; instead, let the machine do the work while you focus on other tasks.

To take advantage of these benefits, consider investing in popular rotary attachments like Rotoboss or Actuators. These accessories are designed for easy installation and compatibility with various laser cutter models.

Incorporating a rotary attachment into your laser cutting setup will expand your creative possibilities and streamline your workflow. Don’t miss out on the opportunity to explore new shapes and designs with this essential accessory!

Optimal Performance with an Air Compressor

Using an air compressor is crucial for achieving optimal performance with your laser machine. Here are some key reasons why:

- Consistent Cutting Results: An air compressor ensures consistent cutting results by providing a steady stream of air to the laser beam. This helps prevent flare-ups and maintains a smooth cutting process.

- Improved Efficiency: With an air compressor system, you can enhance material processing efficiency. The airflow generated by the compressor blows away particles and smoke residue, allowing for cleaner cuts and reducing the need for post-processing.

- Safety Measures: Proper ventilation is essential when working with a laser cutter. By utilizing an air compressor, you can maintain optimal airflow during the cutting process, minimizing the risk of heat damage to delicate materials and ensuring a safer working environment.

- Protect Delicate Materials: Delicate materials such as acrylic or wood can be prone to discoloration or warping due to excessive heat. An air compressor provides effective cooling that protects these materials from potential damage caused by high temperatures.

Water Chiller System: Temperature Control for Optimal Performance

In the realm of laser cutting, temperature control is a must. Keep your laser tube cool and extend its lifespan with a reliable water chiller system. The water chiller system takes the spotlight, ensuring laser machines stay cool and perform at their best.

- Cooling for Consistency The water chiller system is laser cutting’s temperature regulator. It keeps the laser tube—the machine’s core—at the perfect temperature, ensuring consistent cutting quality and preventing overheating.

- Stable Temperatures, Precise Cuts Stable temperatures are vital for precision. The water chiller system stabilizes temperature by dissipating excess heat from the cutting process. This stability ensures uniform cuts on various materials.

- Choosing the Right Fit Picking the right chiller system is crucial. Laser power, usage frequency, and compatibility with your setup should guide your choice. Easy installation and maintenance are also key factors to consider.

- Longevity and Performance The water chiller system not only enhances precision but also extends the laser tube’s lifespan. It prevents excessive wear, ensuring accurate and consistent performance across projects.

Exhaust System: Air Quality and Material Protection

In the realm of laser cutting and laser engraving, achieving precision goes hand in hand with ensuring a safe and clean working environment. The exhaust system emerges as a crucial accessory that addresses these needs through three fundamental aspects:

- Clearing the Air of Hazards: The exhaust system isn’t just an accessory—it’s a guardian of air quality. It swiftly removes fumes by fume extractor, smoke, and debris generated during laser cutting, preventing their accumulation and ensuring a healthier atmosphere for operators.

- Safeguarding Operator Well-being: Safety is paramount, and the exhaust system plays a pivotal role. By eliminating potentially harmful byproducts from the cutting process, it provides operators with a safer workspace, minimizing exposure to toxins and promoting overall well-being.

- Extending Equipment Longevity: Material protection is another facet of the exhaust system’s significance. By removing debris and particulates, it prevents these particles from settling on delicate internal components of the laser cutting machine. This protection extends the life of the equipment and ensures consistent performance over time.

In the ever-evolving landscape of laser cutting, the exhaust system remains an unsung hero, silently working to maintain air quality, protect operators, and enhance the longevity of equipment. It’s more than just an accessory—it’s a guarantee of precision, safety, and lasting performance.

FAQs

Can I use my laser cutter without an exhaust system?

While it is possible to use a laser cutting machine without an exhaust system in some cases, it is highly recommended to have one. An exhaust system helps remove harmful fumes and particles generated during the cutting process, ensuring better air quality in your workspace.

Are these laser cutter accessories compatible with all models?

While most laser cutter accessories are designed to be compatible with a wide range of machines, it’s always recommended to check the compatibility specifications before making a purchase. Different models may have specific requirements or limitations that you need to consider.

Can I retrofit these accessories to my existing laser cutter?

The feasibility of retrofitting accessories depends on the compatibility of your existing laser cutter. Consulting with a professional or manufacturer can help determine if the accessories are suitable for your machine.

Conclusion

Now you know the necessary accessories for laser cutting and engraving. As venture into the diverse world of laser cutting, these accessories stand as faithful companions, enabling manufacturers to push boundaries, explore new dimensions, and transform ideas into reality. The integration of these must-have accessories not only enhances the capabilities of laser cutters but also propels the entire industry forward, making precision, innovation, and excellence the hallmarks of every laser-cut creation.

Choose the Laser Cutter with Top-Quality Accessories

At Baison Laser, we believe that the right accessories can elevate your laser cutting projects to new heights. Our laser cutting machines come equipped with the best laser cutter accessories range from lenses to exhaust system, carefully selected to ensure optimal performance, accuracy, and creativity. Explore our collection today and elevate your laser cutting experience with Baison Laser.