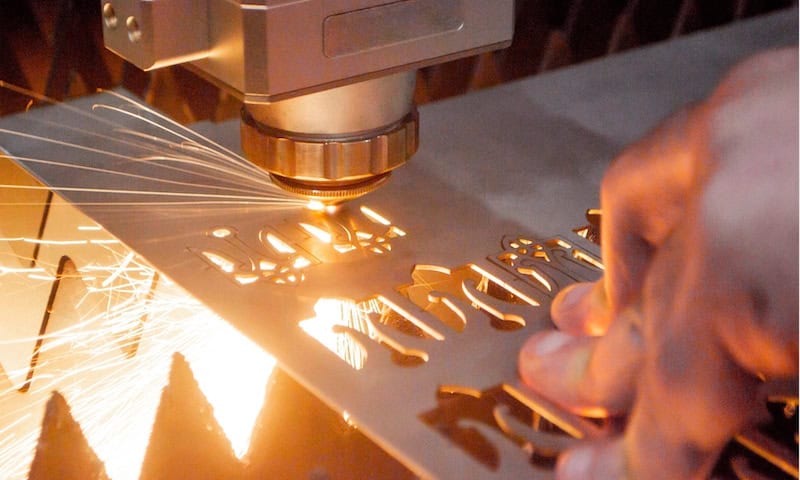

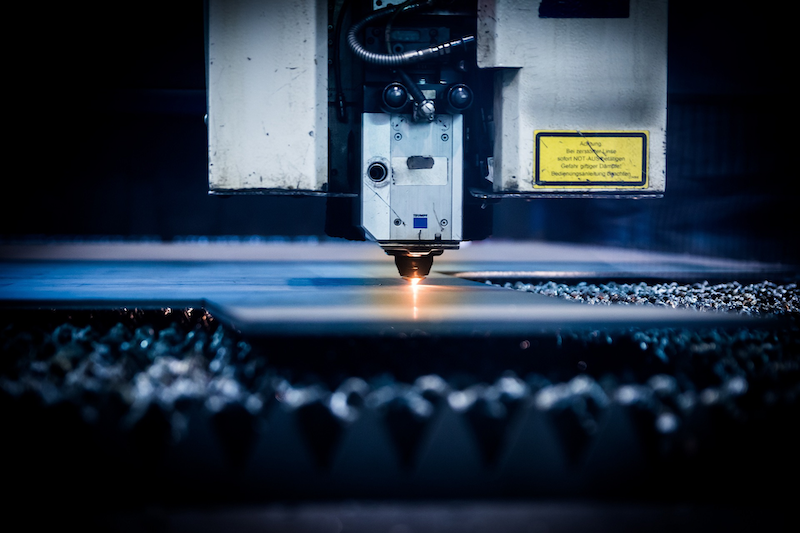

Laser cutting uses an intense laser beam to make detailed designs on materials by melting or burning them. It’s fast and creates intricate patterns quickly. Laser cutting is gaining popularity among small business owners and urban manufacturers.

In this article, we’ll find out how long a laser cutter can last, the different lifetimes of various types, and if the laser tubes wear out over time.

Why Should The Lifespan of A Laser Cutter Be A Concern?

According to LinkedIn, the US laser cutting is expected to be worth $6973.3 million by 2028. There is no doubt that laser cutting will create a huge market and profits.

However, laser tube damage with time, and their output wattage decreases. In addition, if the mirrors and lens have degenerated, a 25-watt rated tube that initially generates 32 watts may have reduced to 20 watts within five years or less. As a result of the power deterioration, you will have to lower the speed setting to compensate for the lower wattage. It will take longer to engrave a particular work than if the laser tube is new.

(You may want to understand the connection between laser cutting speed and power.)

Typically, the lifespan of these laser cutters is 10,000 to 15,000 hours. After that period, the pump diodes must be replaced so the laser cutter can work. The laser tube, power supply, and motherboard are three critical components that might fail.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Signs of Aging In Laser Cutting Machines

Aging in laser cutting machines shows some signs. Below are some of the note-worthy signs of aging in laser machines:

1. Cutting Precision Decline

Laser cutters lose accuracy over time, leading to less precise cuts due to worn components and misalignment.

2. Component Failures Increase

Older machines experience more breakdowns caused by worn parts and electronic degradation, leading to production disruptions.

(Here are the 5 main laser cutting machine accessories you need to focus on.)

3. Overall Performance Reduction

With age, machines become less efficient, resulting in slower processing and decreased output due to wear and calibration issues.

4. Visible Wear and Tear

Signs of wear become evident, including worn cutting beds, nozzles, and mechanical parts, requiring regular maintenance.

5. Increased Noise and Vibrations

Aging machines produce more noise and vibrations, signaling potential mechanical problems that need attention.

Factors Affecting The Life of A Laser Cutter

Many factors influence the life of laser cutting machines, including laser generator quality, material quality, operating circumstances, maintenance, and cleaning. These factors are explained in further detail below:

1. Laser Generator Quality

The laser generator stands as the pivotal component of the laser engraving machine. Its caliber profoundly influences the machine’s overall stability and lifespan. Top-tier laser generators often integrate superior chips and undergo stringent quality assurance measures. Such generators typically boast extended lifespans and demonstrate consistent performance during operation.

2. Machine Structural Design

The structural configuration of the laser cutting machine must be meticulously devised, considering factors such as thermal expansion and mechanical deformation during operation. For instance, the machine’s laser generator and optical components generate substantial heat during operation, necessitating an efficient cooling mechanism to maintain stable temperatures.

3. Cleaning and Maintenance

Regular maintenance and cleaning play a crucial role in prolonging the lifespan of your laser-cutting machine. Tasks such as cleaning optics, inspecting electrical connections, lubricating drive systems, and other routine maintenance activities are essential.

Identifying and addressing potential issues promptly can prevent problems from escalating and causing more severe damage. Ensuring smooth and consistent operation over time is imperative.

4. Material Quality and Cutting Process

The requirements for laser cutting machines vary depending on the processed materials. Some materials exhibit high reflectivity and absorption, leading to increased losses in optical components and compromising the laser’s focus and output quality. Therefore, adjustments to the cutting process settings may be necessary to optimize the machine’s longevity.

5. Conditions of Use

Regular exposure to high-intensity workloads imposes additional stress on the various components of the laser cutting machine, thereby reducing its overall service life. To mitigate this, users should strictly adhere to the manufacturer’s instructions, properly schedule workloads, and avoid prolonged overloading.

6. Operating Environment

The operating environment significantly influences the performance and durability of laser-cutting equipment. Factors like temperature, humidity, and dust levels can all affect machine functionality and lifespan. Elevated temperatures and humidity levels can cause damage and oxidation to electronic components, while excessive dust accumulation can obstruct optics and moving components.

7. Skills and Training

The proficiency and expertise of the operator play a pivotal role in extending the lifespan of laser-cutting equipment. Operators should undergo comprehensive training to acquire proficient machine operation and maintenance skills. This helps minimize the risk of machine damage resulting from incorrect operation.

Baison offers professional customer training, don’t miss this opportunity for professional advancement!

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

The Lifespan of Different Laser-Cutting Machines

Different laser cutters have varying service lifespans. In general, the life of a laser cutting machine is determined using the number of working hours, which is commonly expressed in hours. A high-quality laser cutter may endure tens of thousands of hours if adequately maintained.

Furthermore, lower-quality machines may break faster or deteriorate in performance. Laser cutters are commonly classified into three types. Their function and lifetime are discussed below:

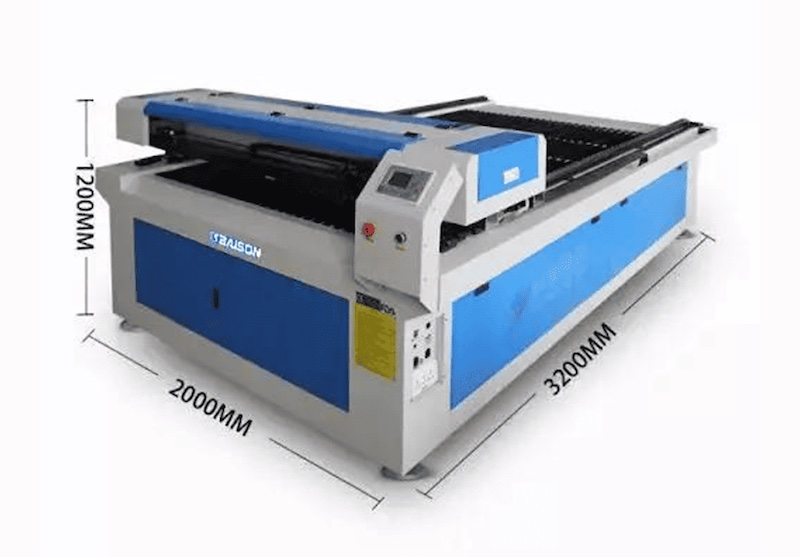

1. CO2 Laser Cutting Machine

The CO2 laser cutting machine stands out for its high efficiency and affordability. Operating at a wavelength of 10.6 micrometers, it emits a beam from a laser resonator. The longevity of the CO2 laser cutting machine’s laser tube varies from 3 months to 4 years. Overdriving the laser tube accelerates its aging process, leading to a shortened service life. Typically, a 100W laser tube under regular usage has a rated life of 3000-3500 hours.

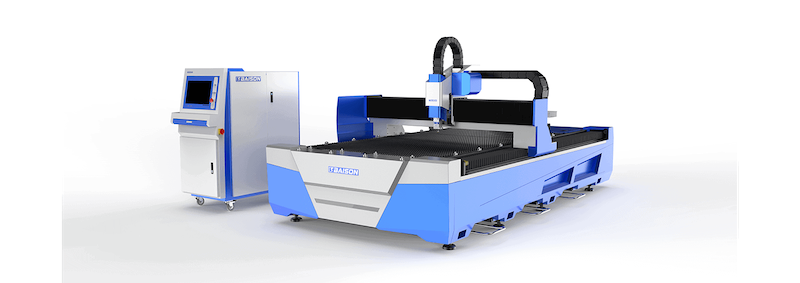

2. Fiber Laser Cutting Machine

The fiber laser technology emits a beam with a wavelength of 1.064 micrometers, boasting high energy density capable of effortlessly cutting through thick and sturdy materials such as copper, aluminum, steel, and other metals.

Fiber lasers can last approximately 100,000 hours. The mean time between failures (MTBF) significantly influences the service life of various fiber laser cutters, with a higher MTBF indicating a longer-lasting laser machine.

3. YAG Laser Cutting Machine

YAG laser cutting machines surpass CO2 laser engraving machines in strength. According to CircuitGlobe, Nd:YAG (neodymium-doped yttrium aluminum garnet) cutters produce a robust laser beam with a wavelength of 1.064 micrometers. They enable you to cut significantly thicker and more resilient materials.

Due to their higher power, YAG lasers degrade more quickly. Typically, YAG laser cutting machines have a service life ranging from 10,000 to 15,000 hours, shorter than other laser cutters.

We have also prepared a comparison article of these three laser technologies for you to learn more about CO2 vs. fiber laser technology and YAG vs. fiber laser.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Maintenance Tips to Prolong Lifespan

Perform regular maintenance under the maintenance handbook and the manufacturer’s instructions. Regular maintenance of laser-cutting equipment primarily includes the following steps:

1. Regular Inspection

The laser-cutting machine consists of several key components. It includes the circuit, gearbox, cooling, light source, and dust extraction systems. Regular system checks are essential to prevent software crashes and prolong the machine’s lifespan.

2. Clean in Time

The intensity of the laser-cutting process continually produces fumes, smoke, and debris. Together, these cause a buildup of filth within your machine and its attachments (chiller, fume filter, etc.). This buildup can lead to system breakdowns and overheating. You surely do not want to postpone business due to a breakdown, especially one that might have been avoided.

Cleaning the laser engraving machine is the most straightforward way to extend its service life. Following each work, the operator must clean the equipment and its surroundings. Any clutter or garbage near the equipment poses a safety risk.

3. Timely Maintenance

If you want to keep the machine running steadily and for a long time, you must also perform preventive maintenance on the machine’s systems, which includes:

- The cooling system (to ensure a constant temperature effect)

- Dust removal system (to provide a dust removal effect)

- Light source system (to ensure laser beam quality)

- Gearbox system.

Preventive maintenance might help you avoid more problems with your laser beam. A laser cutter can survive for years if the components function correctly and the machine does not overheat.

When to Consider Replacing Your Laser Cutter?

The following signs indicate that it’s time for you to upgrade your laser cutter:

1. Frequent Breakdowns

If it keeps needing repairs often, even after you try to fix it, it might mean it’s getting too old or worn out. This can slow down your work and cost you more money.

2. Declining Precision

Laser cutters must be precise, especially for detailed work. If yours isn’t cutting as accurately as it used to, it might be a sign that it’s not working well anymore.

3. Slower and Less Efficient

Your current laser cutter needs to meet the demand as your business grows. If it’s taking longer to cut things or not working as efficiently, it could be time for a new one that can handle the workload better.

4. Missing Modern Features

Newer laser cutters have better technology to make your work easier and faster. If your current one doesn’t have the latest features like better software or safety measures, you might miss out on ways to improve your work.

Investing in a new laser cutter might be worth it if you notice any of these signs. Upgrading can help you work better and stay competitive in your industry. When it’s time to replace your laser cutter, it’s about weighing the costs of repairs versus the benefits of getting a new machine.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

FAQs

1. Do Lasers Weaken Over Time?

Laser beam size and power can fluctuate over time for a variety of causes, the majority of which stem from the second law of thermodynamics. When the laser beam size or power varies, so does how the laser light interacts with the substance being treated (power density).

2. What is the Downside of Lasers?

The downsides of laser cutting include material thickness restrictions, toxic gasses and fumes, excessive energy usage, and upfront expenses.

3. Why do Lasers Fail?

This failure mode is typically caused by utilizing too much die attachment material during assembly, and extremely high temperatures and pulse energy levels will hasten the failure process. Laser diodes can fail in progressive deterioration and catastrophic failure.

Conclusion

Recognizing signs of aging such as decreased precision, increased breakdowns, and inefficiencies is crucial for maintaining optimal performance. Regular maintenance and understanding when to upgrade are essential to avoid costly downtimes and to keep pace with technological advancements.

Ultimately, staying informed about your laser cutter’s condition and market innovations will help ensure your operations remain competitive and cost-effective. Investing in timely updates and replacements can save you time and resources in the long run.

Make Your Laser Cutting Better with Baison Laser!

As a trusted provider of cutting-edge laser cutting solutions, Baison Laser offers a range of high-quality laser machines tailored to meet diverse cutting needs.

We want to help you stay on top of the game! Ready to make your cutting process better? Start by asking for a quote from Baison Laser. Need personalized advice? Our experts will guide you to get the required fiber laser technology for precise cutting.