Welding has been an essential part of metal fabrication. It is used to join two metal pieces together. A fiber laser machine uses laser power to weld, and a handheld laser machine is a compact, portable welding machine that you can carry on-site.

It’s a smart option for no-contact welding. It can work from long distances, and you can work on large workpieces conveniently. As it’s a handheld device, you don’t need to lay the workpiece on the work table.

In this article, we will discuss handheld fiber welding machines. We will discuss its different parts, how it is used, benefits, applications, and all there is to know about these smart machines. Let’s open the discussion with what is a handheld fiber laser welding machine.

What Is a Handheld Fiber Laser Welding Machine?

These latest handheld welding machines offer no-contact welding. No contact welding means a machine weld metal parts without physically touching them. Handheld welding does not require any pressure or requires you to touch the physical parts with your hands.

The welding machine uses fiber laser technology to melt the surface material that vaporizes and crystallizes to form the weld.

Click the button below to get a professional handheld welding machine.

Do You Have Any Questions?

Let Us Solve Your Problem

How Does a Handheld Fiber Laser Welding Machine Work?

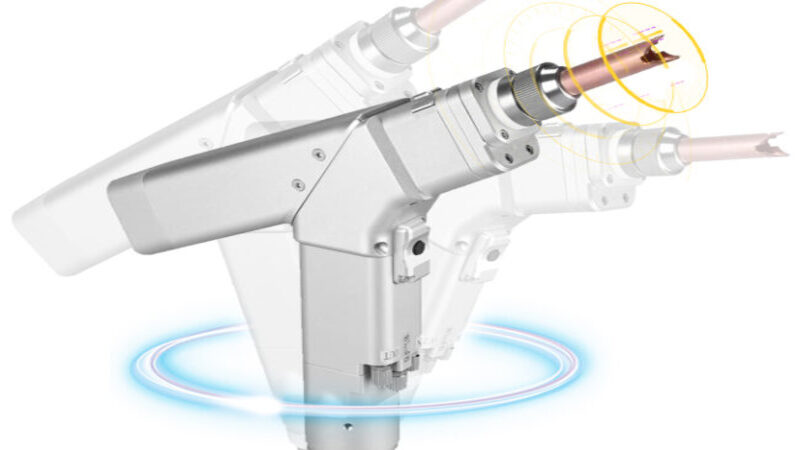

A handheld welding machine works with a fiber laser system. The first process is to generate the laser power. A fiber laser source comprises a laser diode, fiber optical cables, and optical resonators. The laser source produces light that runs through fiber optic cables and passes through lenses or mirrors. The light is reflected back and forth until amplified as required for the job.

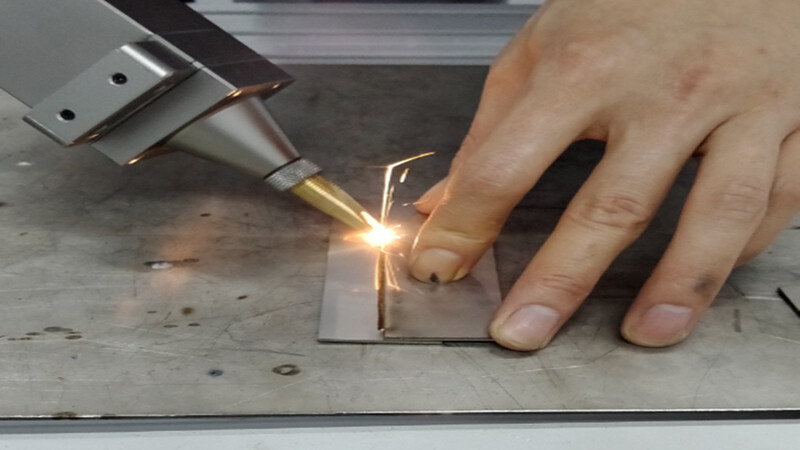

The laser beam is focused on the workpiece through a laser head. The welding head usually has a lens control to adjust the size and power of the laser beam. Once the beam touches the exact spot, it melts the material and joins the two parts together.

The molten matter solidifies and forms the weld. Some handheld welding machines have a cooling system to dissipate the heat and prevent overheating.

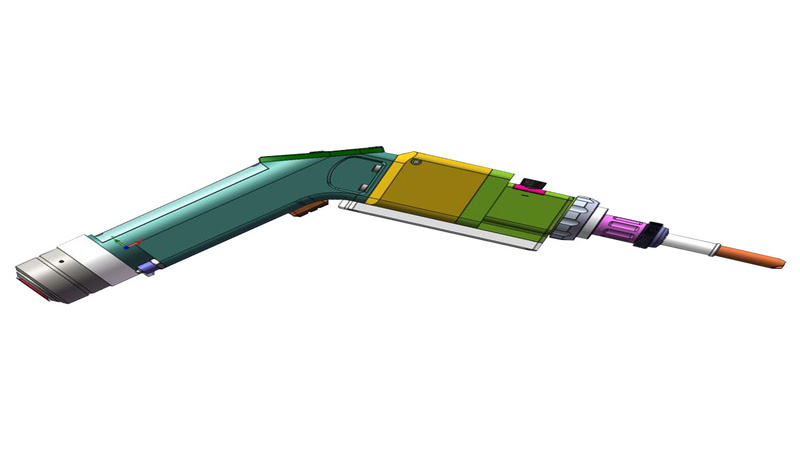

Some Basic Components of a Handheld Fiber Laser Welding Machine

Let’s inspect a handheld laser welder machine in detail.

1. Fiber Laser source

The fiber laser source is part of fiber laser delivery from where laser power is produced. It comprises laser diodes, fiber optic cable, and a laser resonator.

2. Welding Head

It’s the part from where a laser beam is generated. It focuses the beam on workpieces. The welding head generally has lenses and a control system to adjust the laser beam frequency, power, and shape.

3. Power Supply

A power supply component provides the electric power for the laser source and other components.

4. Control System

A control system consists of key parameters that should be adjusted before the welding machine starts. They can be the laser beam’s power, shape, and speed.

5. Cooling System

A cooling system dissipates the heat and cools down the machine and workpiece. The cooling system keeps the temperature of the machine in control as well. The device can use a water or air cooling system.

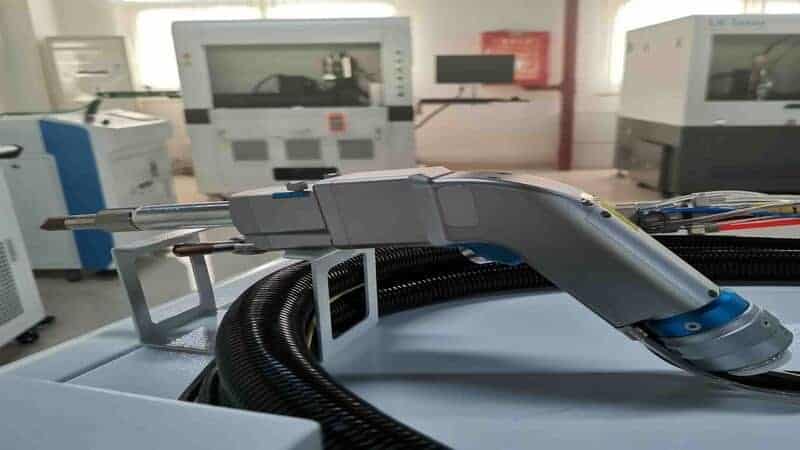

6. Handheld Device

A handheld device is part of the machine that the welder holds in hand and directs the laser beam on the workpiece. It has a trigger or button that the welder can press to activate the laser beam and start the welding process.

Types of Handheld Fiber Laser Welding Machines

Handheld welding machines can be different in their energy delivery. Here are two types:

I. Continuous Wave Fiber Laser Welding Machine

As the name suggests, a continuous wave fiber laser welding machine delivers a continuous outburst of energy for welding.

This type of machine has an upslope when it starts; it continuously sends laser power, and a downslope when turned off. It works non-stop and is suitable for high-volume production. This type of welding is suitable for heavy projects where deep penetration is required. It is also ideal for crack-sensitive materials like stainless steel.

II. Pulsed Fiber Laser Welding Machine

The pulse fiber laser welding machine works at small pulses instead of emitting continuous beams. A pulse laser welder can produce more energy than its average power. It is suitable for spot welding where high power is required.

The welding machine runs for a smaller period, so it is suitable for heat-sensitive or very thin materials. It also works well on reflective material, as a power spike lasts a fraction of the pulse time.

For more details on the types of laser welding, refer to this article.

Do You Have Any Questions?

Let Us Solve Your Problem

Advantages of Handheld Welding Machine

Let’s look at some of the advantages of handheld fiber laser welding machines:

1. High Precision

A fiber laser welding machine uses a laser beam for welding metals. It is a very accurate and precise method of any kind of welding, including overlap welding, where long and continuous welding is needed. The movement of the fiber laser is controlled by computer software.

The chance of the laser beam missing or going wrong is almost zero. The beam is very narrow and affects only the material where it is directed. It is far more accurate and precise in welding than traditional methods.

2. Compact and Portable

Many welding projects require the machine to be taken on-site. A handheld laser welder is easier to carry and compact than other machines.

3. Easy to Use

Fiber laser welding machines are built on modern standards. They are user-friendly and easy to use. Compared to other welding methods, they are less hectic for the operators. These welding machines can even be automated and require less manual intervention than other welding methods.

4. Weld in Any Position

Welding requires joining two metal pieces. The welders sometimes need to reach for the nooks and crannies to fill the spots. A handheld welding head is easier to work even in difficult angles. Whether it is butt welding, vertical position flat fillet welding, or internal fillet welding, a handheld device works in all positions and can join even complex pieces together.

5. Better and Higher Strength Welding

The handheld welding machine provides a narrow beam with a precise welding bead. The beam heats the metal on the spot, giving a very fine weld seam. Compared to other welding methods, a laser welding machine focuses the beam on the spot, and a high-density power beam gives better welding results.

The welding seam strength is also better and requires no finishing at all. The welding seam of a handheld laser welder requires postprocessing.

6. Fast Welding Speed

Laser welding beam is more powerful than other welding methods. It also can finish the welding in less time than traditional welding methods.

7. No-consumables Are Required

The handheld laser machine does not require any consumables. It reduces production or repair costs as no consumables are required.

8. Energy Saving Machines

A handheld laser welding machine is built on modern lines. They are energy-saving machines that save 80%-90% of electricity. It further reduces the production cost.

9. Safe

These modern machines are user-friendly and easy to use. They can even be automated. They are safer for the welders than other welding methods. If proper safety measures are taken, there is also no environmental risk. The operator feels less fatigue and physical strain during the welding process.

Applicable Materials of Handheld Fiber Laser Welding Machines

Fiber laser welding machine works with high-density laser power. The high-power laser beam can melt any material, including thick and thin metals. It can work on the following metal materials.

1. Stainless Steel

It can work on any grade of stainless steel and may be useful in welding stainless steel utensils, furniture, or decoration pieces. Due to the narrow beam, the heat-affected zone is small, which means no defects in the surrounding material. You can weld thin plates as well.

2. Carbon Steel and Alloy Steel

Laser welding machines can handle carbon steel well. A fiber laser welding machine with equal precision can work well on carbon or alloy steel. The increased carbon content can risk pores or welding cracks, but the fiber laser welding machine’s focused high-power beam eliminates and avoids cracks.

3. Silicon Steel

Silicon steel is a common material for making electric equipment and has magnetic properties. It is difficult to weld with ordinary methods due to the risk of cracking due to high silicon content. A handheld fiber laser welding machine can offer effective welding with no distortion.

4. Spring Steel

Spring steel is used in making springs for different industries. It is high-carbon steel that is challenging to weld. It is also easy to deform or get cracks. It is also a thin material. A narrow laser beam gives precise control over the welding process and can give reliable weld quality.

5. Galvanized Sheet

Galvanized steel has a layer of zinc to protect it from corrosion. However, a handheld laser welding machine can give desired results.

6. Aluminum and Alloys

Aluminum and its alloys are used in many industries. They have high thermal conductivity and low melting points. It is a highly reflective material and can be challenging to weld. The highly focused laser beam ensures precise and effective welding of aluminum and its alloys.

Do You Have Any Questions?

Let Us Solve Your Problem

Applications of Handheld Fiber Laser Welding Machine

A handheld fiber laser welding machine is very convenient and can be used in multiple industries.

I. Kitchen and Bathroom Industry

Kitchen and bathroom accessories are used in everyday life. There is a diverse utensil-making industry. Then there are accessories for cabinets, cooking ranges, hoods, sinks, and multiple other products that require welding of stainless steel and other metals.

Handheld laser welding machines can be used in shops, and workers can take them on-site for fitting or on-spot repair jobs.

II. Home Appliances

Home appliances are a big industry that requires small to big parts for various home appliance machines. These parts need to be cut and welded accurately, and a handheld fiber laser welding machine is accurate and precise enough for the job.

III. Metal Furniture

Metal furniture is a big industry that is booming with smart options. Standing desks, lifting desks, and ergonomic chairs must join metals with complex shapes and at difficult angles. A handheld laser welding machine can meet their requirements and combine complex shapes and designs with finesse.

IV. Doors and Windows Industry

As modern designs become more complex, so does the need to weld with more precision and strength. A handheld laser welding machine can be an excellent addition to the door and window industry. It can give speedy results and help workers install the stainless steel door, cabinet, window, and guardrail precisely and quickly.

V. Handicraft Industry

The handicraft and jewelry-making industry needs a better option than our traditional welding techniques. The narrow laser welder beam focuses on spot and heat and perfectly joins even very delicate and thin material. The jewellery-making industry requires joining small and delicate parts with precision.

VI. Automotive Industry

A handheld laser welding machine can significantly benefit the automotive industry. It can be used for welding body panels, exhaust systems, engine components, and several small to big parts. It can be ideal to work in high-stress areas.

Besides these, a handheld fiber laser welding machine can be useful in any industry that requires welding parts. It can be a great addition to workshops and small-scale industries as well.

Factors to Consider When Choosing a Handheld Fiber Laser Welder

You should consider a few things while selecting a handheld fiber laser welder.

1. Power Output

Power output determines the capacity of your machine. A higher-power machine can work on thick and tough metals. But for jewelry making and welding delicate parts, you may not need a higher power. So select the power output depending on your welding needs.

2. Welding Speed

Laser welding machines work much faster than traditional argon arc welding, TIG welding, or MIG welding techniques. However, make sure you check the welding speed to suit your production needs.

3. Spot Size

It is the maximum size of the laser beam that a machine can generate. The spot size is important to understand the heat the laser machine produces and how deep it can penetrate into the material. It can also be helpful to check before selecting the machine, as selecting too narrow a spot size for larger parts may take a long time to weld.

4. Laser Beam Quality

Beam quality refers to the shape and distribution of the laser beam. A good quality beam will give a smooth weld without any distortion. Ask your suppliers for the laser machine specifications to check the parameters.

5. Cooling System

A cooling system of a laser welding machine is essential to check. It dissipates the heat that prevents the material from overheating. It is also essential for the protection of the laser machine itself. Two types of cooling systems can be used in laser welding machines, which are water cooling systems and air cooling systems.

6. Ergonomics and Usability

The size of the handheld laser welding machine should also be considered. When you are buying a handheld device, it’s ergonomic. Size and portability are important, so check the technical specs and see if they suit your needs.

7. Cost

The last and most important is cost. The cost of a handheld laser welding machine depends on the power and other features. Select one that suits your needs while staying within the budget.

A laser welding machine may cost you more than other welding options, but it will justify its price by giving you more speed and high-volume production and also help you cut the production cost in the long run.

Do You Have Any Questions?

Let Us Solve Your Problem

Conclusion

A handheld laser welding machine is an excellent addition to the laser equipment industry. Unlink bulky welding machines that give irregular welding processes and give inconsistent results. A handheld device is more portable and helps you weld in tight spaces and difficult angles with precision.

Handheld laser welding machines are also cheaper than other fiber laser welding machines.

Invest in Baison’s Laser Welding Machine for Speed, Power, and Precision

Baison offers the latest technology in handheld laser welding machines suitable for welding stainless steel, carbon steel, aluminum, alloys, silicon steel, spring steel, and almost all types of thick and difficult-to-weld metals. They are available in 1000W, 1500W, and 2000W.

Our handheld devices offer more power, speed, and accuracy than other welding machines. You don’t have to be an expert to use these machines; by following some basic safety measures, anyone can weld with precision.