In the ever-evolving industry of metal fabrication, laser-cutting has become a revolution in the way structural components are transformed. This sophisticated technique offers accuracy, efficiency, and versatility. However, this process might seem a bit complex and confusing.

According to The Business Research Company, the laser cutting machine market was valued at USD 5.03 billion in 2023 internationally at a CAGR of 10.2% from 2023 to 2032.

In this post, we will introduce you to the basics of laser-cutting in structural metalwork, providing a detailed overview of its principles, applications, and benefits. We will also explore the factors that contribute to its exceptional performance and streamline your production processes using Baison laser machines.

Metal Laser Cutting Machine Overview

The metal laser cutting method is a precise manufacturing process for building complex structures of construction and many other structural metalwork. It works by utilizing a concentrated beam of light energy to cut through a wide range of metal structures. It has many advantages over the traditional metal cutting methods, including precision, flexibility, and an automated process.

A laser cutter may operate by directing a focused laser beam onto the metal surface. Then it causes the material to melt or vaporize at the point of contact. The intense heat generated by the laser beam ultimately cuts the metal sheet.

They are categorized into fiber lasers, CO2 lasers, and YAG lasers. Many industries use these devices to build their required structures. These may include automotive, aerospace, electronics, medical devices, industrial applications, and many more.

Advantages of Laser Cutting in Structural Metalwork

Laser cutting in structural metalwork comes with a wide range of benefits. The structural metalwork production process has been revolutionized with the help of this laser-cutting technology. This cutting process has become more versatile and efficient over time. Some of the major benefits of laser-cutting in structural metalwork are given as follows.

1. Precision

The laser-cutting process is known for its exceptional precision capacity. In the production process of structural metalwork, laser cutters can initiate cuts with high tolerance and absolute precision. Maintaining precision in structural metalwork is very important to ensure the ultimate structural integrity of different structures, such as buildings.

2. Versatility

The laser-cutting process can cut a wide range of materials, such as aluminum, brass, stainless steel, copper, and many more. This versatility of the fiber laser is used greatly for the production process of structural metalwork.

3. Speed

Laser cutting is a fast process. The laser power has the ability to cut through the thick metal sheets of a structural metal in a few seconds, leading to reduced production time and cost.

4. Automation

One of the unique features of this cutting process is that it can be used efficiently without the constant intervention of a human being. Being automated means, this laser can further reduce the production cost and duration.

5. Reduced Finishing Requirements

The laser system can easily produce a cut edge with few burrs. By doing that, the laser cutter makes sure that there is no need for any secondary finishing operations.

6. Contactless Cutting

This process offers contactless cutting thanks to its cutting head. It ensures that there is no physical contact between the subject and the laser beam. Because of this feature, this process includes less wear and tear compared to other traditional cutting methods.

Laser Cutting in Heavy Structural Metalwork

Structural metalwork is an important element of modern architecture which involves large-scale engineering. Structural metalwork can be of two types: heavy structural metalwork and light structural metalwork. Heavy structural metalwork involves the construction of complex large steel elements. These components that are used to make heavy structural metalwork can easily weigh several tons.

Heavy structural metalwork is used to make:

- High-rise buildings

- Bridges

- Industrial plants

- Offshore structures

Functions of Heavy Structural Metalwork

The functions of heavy structural metalwork can involve a wide range of activities. Some of the main functions of heavy structural metalwork are given below:

- Heavy structural metalwork helps to form the basic layer and the skeleton of large-scale buildings, complex bridges, and other structures. Thus, they play an important role in modern construction and metal cutting.

- Heavy structural metalwork helps to support loads. They also help to transfer them.

- The heavy structural metalwork helps to support the weight of the bridge deck. Besides, they support the cars, trucks, and other vehicles that travel on the bridges.

- They can be easily recycled and reused as a versatile range of construction materials.

Materials Used

There are various ranges of materials that are used in this process in heavy structural metalwork. Some of the main elements are discussed below:

Effects of Laser Cutting on Heavy Structural Metalwork

Laser cutting can have a significant effect on heavy structural metalwork. Some of the effects are:

1. Edge Quality

By using laser cutting, heavy structural metalwork can have the smoothness of the edge. The edge quality depends on the cutting speed, laser beam, and the type of cut material.

2. Heat-Affected Zone (HAZ)

By heat-affected zone, we mean the area that is affected by the laser beam’s heat. It is important to minimize the heat. To do that, a low-power beam should be incorporated with a device that is used to cut at a high speed. This feature is applicable to an industrial laser.

3. Warping

The heat or the stress of the laser beam is responsible for causing warping. So, to minimize this warping, a lower power lease beam must be used. Some other effects also involve laser drilling and laser fusion cutting of heavy structural metalwork.

Laser Cutting in Light Structural Metalwork

In recent times, light structural metalwork has become increasingly popular. These are lighter and more durable. Light structural metalwork can be easily converted into complex shapes and structures because of their light weight and flexibility.

Light structural metalwork is used to make:

- Furniture and fixtures, such as tabletops, shelving, and signage.

- Architectural metalwork, such as railings, balustrades, and cladding panels.

- Industrial components, such as brackets, housings, and enclosures.

- Aerospace, such as wing spars and engine housings.

- Medical devices, such as surgical implants and prosthetics.

Functions of Light Structural Metalwork

Light structural metalwork can be used to create various types of structural components. Some of them are:

- Because of its lightweight and flexibility, light structural metalwork can be easily incorporated into complex structures.

- These structures are incredibly durable. Besides, they are also capable of withstanding different adverse environmental conditions.

- Light structural metalwork can last for a long time, making it a more reliable choice.

- These structures can be customized into a wide range of shapes and forms.

Materials Used

The materials that are commonly used in the production process of light structural metalwork are given below:

- Carbon steel

- Aluminium

- Stainless steel

Effects of Laser Cutting Machine on Light Structural Metalwork

There are some issues that you may face while manufacturing the structures of light structural metalwork. The main issue may be the thickness. The type of material being cut may also cause some difficulty while working. The thicker the material, the more power it will need for cutting. Other than that, limited thickness and reflectivity may make the process a bit more complicated.

Some of the main effects of laser cutting on light structural metalwork are given below:

1. High Precision

The process can make very accurate and precise cuts, up to 0.001 inches, on the light metalwork.

2. Smooth Edges

To make a smooth and burr-free light structural metalwork, you need to use these devices. These devices also help you eliminate the use of any other devices for finishing.

3. Automation

Laser-cutting devices can be easily automated leading to reduced labor cost and production time.

What Type of Laser is Suitable for Cutting Structural Metalwork?

There are some lasers that are more suitable for structural metalwork. These lasers come with their own advantages and disadvantages; the suitability of the selection of laser will depend on the requirements and type of job that the laser will be used for. Some of the popular lasers that are used for cutting structural metalwork are discussed below:

I. Fiber Laser Cutting Machine

Fiber Lasers are the most common types of lasers known for their precision and speed. They are faster, which makes them the perfect candidate for high-volume production requirements. They come with minimal heat-affected zones (HAZ) and relatively low maintenance requirements.

Fiber laser cutting machines can cut various types of materials, including steel, stainless steel, aluminum, titanium, nickel alloys, copper, and brass. They are proven to be more energy-efficient and economical.

II. CO2 Lasers

CO2 lasers can be used to make some unique structural metalwork. Although they are not as widely used as the fiber ones, they are quite popular in the market. These lasers need regular gas refills and resonator cleaning, leading to increased maintenance costs.

The CO2 laser cutter is mainly used for sheet metal processing. It includes an electricity-driven gas laser technique. Materials like steel, stainless steel, or aluminum can be easily cut through it. This laser can be a bit slower than the fiber laser.

Besides these two, there are also plasma cutting and flame cutting machines. We have also prepared articles to give you a more in-depth understanding of laser cutting versus plasma cutting and flame cutting.

Applications of Laser Cutting in Structural Metalwork

Laser cutting offers a wide range of advantages over traditional cutting methods, making it a preferable choice. The applications can not be described in simple words. There are vast applications and uses of this in the production process of structural metalwork.

I. Common Products

While discussing the application, it would make more sense if we first discuss the common products that can be cute with lasers.

- Beams

- Girders

- Columns

- Plates and sheets

- Tubes and pipes

- Brackets

- Trusses

II. Industries That Need Structural Metalwork

There are some industries that are completely useless without metalwork structures. And there is no easier and more effective way than laser cutting to make these structures more reliable, durable, and aesthetic. Some of these industries are:

- Construction industry

- Industrial machinery industry

- Oil and gas industry

- Transportation industry

- Agricultural industry

- Aerospace industry

- Shipbuilding industry

- Consumer goods Industry

- Automotive industry

Precautions for Laser Cutting in Structural Metalwork

Laser cutting is the name of a versatile and precise metalworking process. However, it is very important to take necessary precautions when working with laser power to ensure the safety of both the operator and the environment.

Some of the precautionary steps of using a laser are given below:

- The cutting device must be properly grounded so that it can avoid any kind of electrical shock.

- To avoid eye damage, never look directly into the laser beam.

- Flammable materials must be kept away from the cutting area.

- Appropriate ventilation must be used in the working area to remove the fumes and gases released.

- Unauthorized personnel should not be in the cutting area.

- Waste materials disposal techniques need to be followed.

- All local and environmental regulations must be complied with.

- Appropriate air quality must be maintained to ensure a good working environment for the operators.

- The device must be inspected regularly for any damage and to check if it is free from dust and debris.

Product Solutions of Laser System

Laser-cutting machines can help you expedite productivity while reducing both production costs and time. These machines are designed in such a way that not only offers precision and accuracy but also provides customized solutions to many construction problems.

There are many machines available in the market that are popular for cutting lasers for structural metalwork. Two of the most popular models in the market are given below:

I. Coil-fed Laser Blanking System

Coil-fed Laser Blanking System is the name of a flexible solution for building structural metalwork of any size and shape. This system of Baisan offers more productivity, reduced cost, and production time.

The machine comes with a laser power of 1500W-6000W and a max moving speed of 100m/min. It has a positioning accuracy of approximately ±0.03mm/m and a repositioning accuracy of ±0.03mm. Some of the unique features of the Coil-fed Laser Blanking System are:

- Zero-Delay Cutting

- Precision and automation

- Easy and Flexible Changes

- Cost Savings

Applications of Coil-fed Laser Blanking System

There are many applications of Coil-fed Laser Blanking System. Some of them are:

- Aluminum Curtain Walls

- Billboards

- File Cabinets

- Fire Equipment

- Showcase

- Ventilation ducts

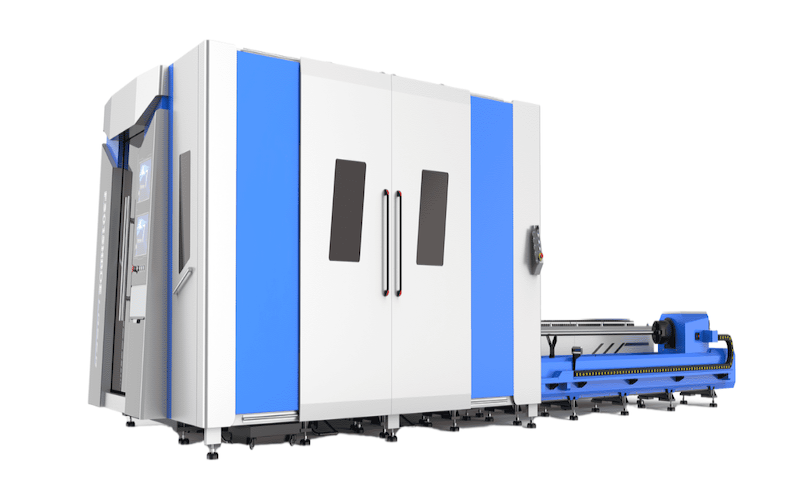

II. Dual Platforms Sheet Metal & Tube Laser Cutting Machine

Dual platforms sheet metal & tube laser cutting machine is designed in the most unique way to cut through tubes and sheet metal with the most precise and accurate sizes. This device is more suitable for complex structures and industries.

It has a laser power of 1500W-12000W and a maximum moving speed of 80m/min. It comes with a positioning accuracy of ±0.03mm/m and a repositioning accuracy of ±0.03mm. The device has two processing sizes, which are 3000mm×1500mm and 4000mm×2000mm. Some of the unique features of dual platforms sheet metal & tube machines are given below:

- Fully enclosed unique design

- Easy to operate

- Patented climbing exchange platform

- Quality cutting results

- Energy-saving tech

Applications of Dual Platforms Sheet Metal & Tub Cutting Machine

This device comes with the most advanced and widely used technology. It can be used in the production of both metal and vehicles. If you want the most accurate and precise cuts, this is the best choice for you. Some of the major applications of this device are:

- Furniture

- Gym Equipment

- Storage racks

- Handrail

- Medical equipment

- Agricultural machinery

FAQs

1. How thick of metal can a laser cut?

The thickness a laser can cut varies by type and power. CO2 lasers typically cut up to 25mm of steel, while fiber lasers can handle up to 30mm. Specific capabilities depend on the machine and metal type.

2. Which Are the Most Important Parameters to Control in Laser-Cutting?

There are some important parameters that can influence how a laser-cutting device will work. These include wavelength, power, pulse width, and spot size. The maximum power rating of the device can control the power, and the other parameters can be controlled as well.

Conclusion

Laser cutting in structural metalwork is easier, more innovative, and more efficient with the help of the perfect laser-cutting devices. As technology advances, laser cutting is set to become even more integral in shaping the future of structural metalwork. A deep understanding of laser cutting’s capabilities is crucial for ensuring not just the structural integrity of projects but also their aesthetic excellence and time efficiency.

The Precision that’s Above and Beyond with Baison Laser!

Compromising on quality is never an option. Baison Laser‘s technology is engineered with precision in mind. Our state-of-the-art fiber lasers deliver exceptional cutting performance, ensuring clean, burr-free edges on even the most intricate designs. Contact us today, and let us embark on a journey of manufacturing excellence together.