This blog post delves into the 10 Best Laser Cutters of 2024 offering a comprehensive guide to help you make an informed choice. We aim to assist you in navigating the expansive market of laser cutters by focusing on their key features. It will illustrate how the right laser cutting machine can enhance your business’s productivity and quality of work. Let’s dive in.

Types of Laser Cutter

Understanding the differences between CO2 laser cutters, fiber laser cutters, and diode laser cutters is essential when considering laser cutting machines in 2024. Each laser type offers distinct advantages and limitations that can impact your specific needs.

I. CO2 Laser Cutters

The CO2 laser cutter uses a carbon dioxide gas mixture as the laser medium to generate a laser beam. The versatile laser cutter is widely used for cutting and engraving various materials such as wood, acrylic, fabric, anodized aluminum, and paper. These CO2 laser cutters are versatile and widely used in various industries due to their precision and affordability.

II. Fiber Laser Cutters

Fiber lasers deliver laser beams from the laser tube to the laser head using optical fibers, which are doped with rare-earth elements like erbium, ytterbium, or neodymium. They are highly efficient and primarily used for metal fabrication applications, including stainless steel, aluminum, brass, and copper. Deliver exceptional speed and accuracy, making them popular in industrial manufacturing applications.

You may want to learn about the differences between CO2 and fiber laser technology.

III. Diode Laser Cutters

Diode lasers use semiconductor diodes as the active medium. The laser beam is generated from the laser tube when an electric current passes through the diode, causing the release of photons. They are compact, energy-efficient, and commonly used for small-scale cutting, engraving, and marking applications, especially in industries like electronics and signage.

Here is an article for you to understand the difference between a fiber laser and a diode laser.

To determine which type of laser cutter is best suited for your needs, consider factors such as the materials you will be working with and the desired level of precision. Think about whether you require desktop laser cutters or the best portable laser cutter like a mini laser engraver.

It’s worth noting that different laser cutters support various file formats. Ensure compatibility with your preferred software by checking if the machine accepts common file formats such as SVG or DXF.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Application of Laser Cutting Machine

Discover the wide range of cut materials that can be cut using a laser cutter. Laser cutting machines are incredibly versatile, allowing you to work with various materials such as wood, metal, plastic, fabric, and leather.

Learn about various industries that benefit from laser cutting technology. Laser machines have revolutionized many industries, including:

- In the automotive manufacturing industry, diode lasers are commonly used for laser cutting to create precise components for cars and trucks. This metal processing technique is essential for efficient production and ensures accuracy in the manufacturing process. Laser cutters play a crucial role in the automotive manufacturing sector.

- Fashion: Designers use laser cutters to add intricate patterns and details to clothing and accessories.

- Architecture: Laser cutting with diode and CO2 lasers enables architects to create intricate models and prototypes by using engraving techniques with an engraver.

- Electronics manufacturing relies on laser cutting technology to produce circuit boards and other electronic components using diodes and CO2 lasers.

Explore real-world examples showcasing the versatility of laser cutting machines. Here are some instances where laser cutters have proven their worth.

- Custom Signage: Laser cutting allows for precise lettering and intricate designs on signs. Laser engravers use engraving techniques and cutters to achieve desired results.

- Jewelry Making: Fine jewelry designers use the diode laser engraver and cutter for engraving to create delicate pieces with precision. The engraver is an essential tool in the manufacturing process.

- Prototyping: Engineers utilize laser technology for rapid prototyping in product development.

- Packaging Design: Diode lasers in manufacturing are used to create unique packaging designs for products that stand out on store shelves. Laser cutters are particularly effective in creating these designs, making them an essential tool for engravers.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Factors to Consider When Choosing a Laser Cutting Machine

There are several key factors that should be taken into consideration. From machine power requirements to software compatibility, each aspect plays a crucial role in making an informed choice. Here are some important points to keep in mind:

- Evaluate laser power requirements and wattage options: Laser power is crucial for the cutting capability of laser cutters. The powerful laser cutter can effortlessly cut through thicker and tougher materials, thanks to its ability to melt or vaporize the material. This results in precise and clean cuts. If you frequently work with a wide range of materials or need to cut through thick ones, choosing a laser cutter with higher power will expand your capabilities and allow you to handle a greater variety of applications. About how to choose among different laser powers, you can refer to this article.

- Bed Size and Work Area: The size of the cutting bed and work area is an important consideration, as it determines the maximum size of the materials you can work with. Choose a machine with a spacious enough bed size that accommodates the largest size of the materials you typically work with.

- Software and Control System: The software and control system of a laser cutting machine plays a crucial role in its usability and functionality. Look for machines with user-friendly software interfaces and advanced control systems that allow for easy programming, design import, and customization of cutting parameters. Here is more about laser cutter software.

- Material Compatibility: Different laser cutting machines are designed to work with specific materials. Consider the types of materials you will be working with and ensure that the machine you choose is compatible with those materials. For example, if you primarily work with metals, a fiber laser cutter may be the best choice, while a CO2 laser cutter may be more suitable for working with non-metallic materials like wood, acrylic, or fabric.

By considering these factors when choosing a laser cutting machine, you can make an informed decision that meets your specific needs and ensures optimal results for your projects.

The Top 10 Laser Cutting Machines

In 2024, several laser cutter and engraver machines are expected to emerge as popular choices in the market. Here’s a comprehensive buyer’s guide to help you make an informed decision when purchasing laser cutting and engraving equipment.

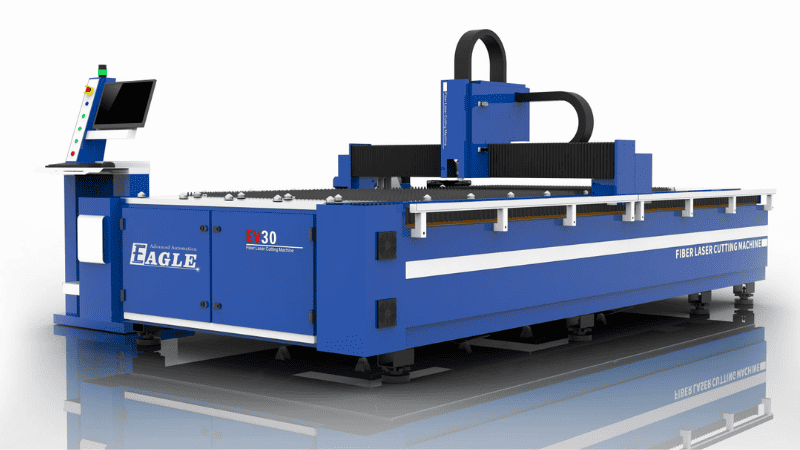

1. Baison High Power Sheet Metal Laser Cutting Machine

The Baison High Power Sheet Metal Laser Cutting Machine offers high cutting power and precision for industrial-grade sheet metal cutting. With advanced features, such as automatic nesting and intelligent cutting paths, it is ideal for large-scale manufacturing and fabrication operations.

With the help of this machine, you can save time delays by instantly inputting instructions for operation changes with responsive technology. The laser equipment can cut any pattern or shape on the go with a fast-cutting speed. It has functions and features such as “traceless micro linking,” “lightning perforation,” “five-level perforation,” “slag removal from perforation,” and “confer process,” raising the quality of thick plating processing.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

2. Glowforge Pro

Consider the Glowforge Pro, it offers excellent build quality and has become a popular choice for both beginners and professionals.

The Glowforge Laser cutter is a versatile machine that uses lasers to provide precise cutting and engraving. It features a red light positioning system for accurate positioning and compatibility with various design software. With its high-quality diode laser output and user-friendly interface, the Glowforge Pro is suitable for a wide range of applications.

3. Ortur Laser Master

The Ortur Laser Master is a compact laser cutter and engraver known for its affordability and versatility. Offers adjustable laser power and high precision, making this the best laser cutter for small businesses and hobbyists overall.

The Ortur Laser Master is also compatible with various operating systems, adding to its convenience. Whether you need a laser cutter or engraver, the Ortur Laser Master is a reliable choice. It’s the perfect tool for anyone looking to create precise designs with lasers. Upgrade your workspace with the Ortur Laser Master from Glowforge today.

4. Full Spectrum Laser Muse

The Full Spectrum Laser Muse is a compact and user-friendly laser cutter. It offers high precision and is compatible with various file formats. Its versatile capabilities make it a suitable choice for both professional and hobbyist use.

5. Bodor Laser P Series

The Bodor Laser P series boasts high-speed cutting and impressive performance. With a variety of power options and bed sizes, these machines offer flexibility in terms of application. Their user-friendly interface and advanced control features enhance their functionality.

6. xTool D1 Pro Laser Cutter

The xTool D1 Pro is a versatile laser cutting machine suitable for various applications. It provides high-powered laser cutting and engraving capabilities. With its user-friendly design and advanced features, it is a popular choice for industrial and professional use. The maximum speed of the xTool D1 Pro is 24,000 mm/min. You can also choose xTool P2 laser cutter to get more versatility in engraving and cutting.

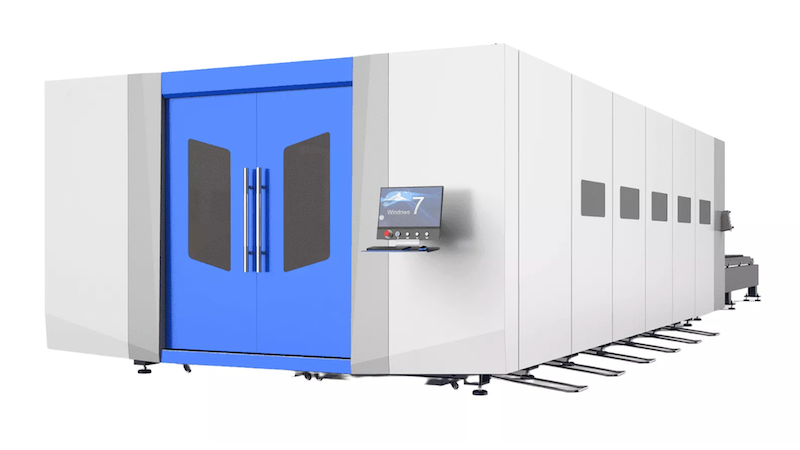

7. Trotec Speedy Series

Trotec’s Speedy series is renowned for its precision and high speed. These laser cutting machines offer a variety of power options and cutting bed sizes to accommodate different needs. They boast advanced software that enables efficient workflow management.

8. Kern Laser Systems

Kern Laser Systems offers high-quality engraving and cutting solutions for various industries. Their machines are recognized for their precision and reliability. Advanced features like cameras, rotary attachments, and autofocus are part of their offerings.

9. Thunder Laser Nova Series

Thunder Laser’s Nova series offers a range of laser cutting and engraving machines suitable for different needs. These machines are known for their ease of use and precision. They come with intuitive software and reliable after-sales support.

10. Boss Laser LS Series

The Boss Laser LS Series stands out for its robust construction and durability. These machines come in various power options and bed sizes to cater to different needs. They are equipped with user-friendly laser control software and provide reliable customer support.

It’s important to note that the popularity and availability of specific laser cutters may vary based on regional preferences and market demand. When purchasing a perfect laser cutter in 2024, keep the key points in mind to ensure you find the best machine that meets your requirements and budget.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

How to Use a Laser Cutting Machine

Using a laser cutting machine requires careful attention to safety and proper operation. Here is a general guide on how to use a laser machine.

1. Safety Precautions Before Operating a Laser Cutter

- Familiarize yourself with the safety features of laser equipment, including the emergency stop button, air assist, and safety interlocks. This is especially important when using home laser cutters, portable laser cutters, and mini laser engravers.

- Wear appropriate personal protective equipment (PPE) such as safety glasses and gloves when working with lasers or laser cutters.

- Ensure the work area is well-ventilated and free of flammable materials.

We have prepared two articles on safety: Selecting the Right Laser Class & Ensuring Safety, Laser Cutter Exhaust Systems.

2. Prepare the Material

- Choose the appropriate material for laser cutting, ensuring it is compatible with the machine’s power and capabilities.

- Clean the material’s surface to remove any dust, debris, or contaminants that could affect laser processing, laser cutters, laser engraving, or lasers.

3. Configure the Cutting Parameters

- Set the appropriate cutting parameters such as laser power, cutting speed, and focus depth.

- These laser cutters’ settings may vary depending on the material being cut with a laser engraving machine.

- Refer to the user manual or software interface of the laser engraver and cutter for guidance on selecting the correct parameters for laser engraving and laser cutting.

4. Start the Cutting Process

- Once everything is properly set up and tested, initiate the cutting process using the machine’s control panel or software interface.

- Observe the laser cutting process from a safe distance, ensuring there are no obstructions or issues with the laser cutters or laser engraver machine during operation.

5. Post-Cutting Care

- After the cutting process is complete, carefully remove the cut pieces from the cutting bed, taking care to avoid any sharp edges.

- Clean the cutting bed of laser cutters and remove any debris or residue left behind from the cutting process using a laser engraver machine.

- Properly store the material, turn off the machine, and disconnect it from the power source.

By following these steps, you can safely operate a laser cutting machine while optimizing its performance for different materials and thicknesses. Remember to always prioritize safety precautions throughout your work process.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

FAQs

1. How often should I clean my laser cutting machine?

It is recommended to clean your laser cutting machine after each use or at least once a week if used frequently. Regular cleaning helps prevent debris buildup and ensures consistent performance.

2. Can I use any cleaning solution on my laser cutter?

No, it is important to use cleaning solutions specifically designed for laser cutters. Using harsh chemicals or abrasive materials can damage the delicate components of the machine.

3. How do I know if my laser cutting machine needs servicing?

If you notice a decline in the performance of your laser cutting machine, such as decreased cutting quality or unusual noises, it may be time to schedule a service. Regular maintenance checks can help identify any potential issues with the lasers or laser engraver before they become major problems.

4. Can I cut any material with a laser cutting machine?

Laser cutting machines are designed for specific materials. Different machines have different capabilities, so it is essential to check the specifications and ensure that your desired material can be cut using the particular machine you own or plan to purchase.

Conclusion

In conclusion, knowing about the latest laser cutting machines will help you identify the best laser cutter for your projects. Having a capable laser cutter can significantly improve your workflow, accuracy, and productivity. Whether you’re working with the thin plastic board, copper, or other materials, dedicated laser cutting machines deliver clean, precise cuts while keeping users safe.

Start your journey with Baison Today!

At Baison Laser, we understand the importance of high-quality laser cutting solutions to meet the specific needs of your industry. Compared to other laser cutters, our lasers are top-of-the-line, whether you need to cut coils or sheets, you can find the perfect laser equipment in our product catalog.

Not only that, but we also offer the best laser engraver and laser marking machine. Request an instant quote or contact us for further assistance. We are eager to help you revolutionize your production process with our lasers and cutters.