Laser technology is crucial in various industries, from manufacturing to medical applications. As businesses strive to improve efficiency and precision, understanding the differences between different types of laser systems becomes essential.

This post will discuss the critical distinctions between fiber and diode lasers, exploring their advantages and limitations. We’ll also help you determine which laser technology best suits your industry or application.

What Are Fiber Lasers

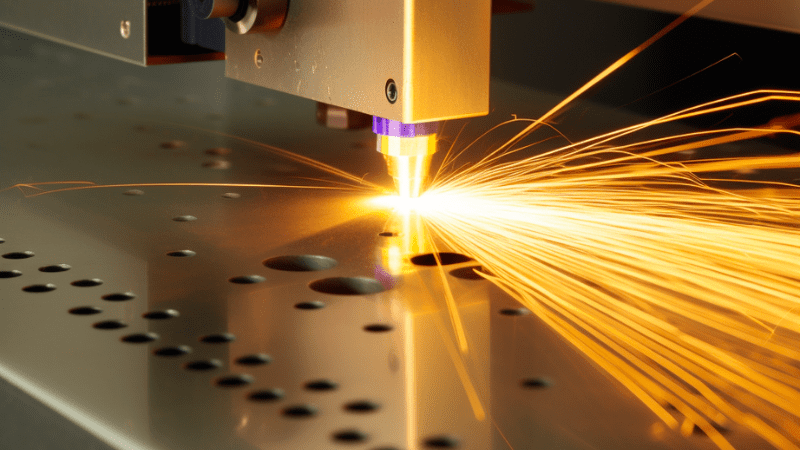

Fiber lasers are a solid-state laser technology that utilizes optical fiber as the active medium, doped with rare-earth elements such as erbium, ytterbium, neodymium, etc. The laser beam is generated within the fiber itself and transmitted through flexible optical fibers, providing superior beam quality and stability.

1. Advantages of Fiber Lasers

Some key benefits of fiber lasers include:

- High efficiency: Fiber lasers are known for their high wall-plug efficiency, which converts a larger percentage of input electrical power into laser output.

- Excellent beam quality: Fiber lasers produce a high-quality, near-diffraction-limited beam, resulting in improved precision and processing capabilities.

- Compact design: The fiber-based design allows for a smaller, more compact system that is easier to integrate into existing manufacturing processes.

- Low maintenance: Fiber lasers have fewer components and require minimal maintenance, reducing long-term operational costs.

2. High Output Power and Thin Materials Capability

Fiber lasers can produce high output power, allowing them to cut, weld, or process a wide range of materials, including thin sheets and reflective metals. Their high power density enables faster processing speeds and improved productivity.

3. Applications of Fiber Laser Machines

Fiber laser machines are used in various industries and applications, such as:

- Metal cutting and welding: Fiber lasers are ideal for cutting and welding metals, including stainless steel, aluminum, and copper alloys.

- Marking and engraving: Fiber lasers provide precise, high-resolution marking and engraving for various materials, including plastics, metals, and ceramics.

- Medical applications: Fiber lasers are used in various medical applications, such as tissue cutting, dental procedures, and ophthalmic surgeries.

- Micromachining: Fiber lasers are well-suited for micromachining tasks, such as micro-drilling, micro-cutting, and micro-welding.

What Are Diode Lasers?

Diode lasers are semiconductor lasers that use a diode, typically made of gallium arsenide or other semiconductor materials, as the active medium. When an electric current is applied to the diode, electrons, and holes, recombine, resulting in the emission of photons and the generation of a laser beam.

1. How Do Diode Lasers Work

The diode laser operation involves:

- Forward-biased p-n junction: The diode is forward-biased, creating a p-n junction where electrons and holes accumulate.

- Recombination process: When electrons and holes recombine, they release energy in the form of photons.

- Optical cavity: The photons are trapped within the optical cavity formed by the diode’s reflective surfaces, stimulating further electron-hole recombinations and generating more photons.

- Coherent light output: The photons travel coherently in the same direction and phase, forming the laser beam that exits the diode.

2. Advantages of Diode Lasers

Some key benefits of diode lasers include the following:

- Compact size: Diode lasers are small and lightweight, making them suitable for portable applications or integration into existing systems.

- High electrical-to-optical efficiency: Diode lasers can efficiently convert electrical energy into laser output, reducing power consumption and operational costs.

- Wide wavelength range: Diode lasers can produce a broad range of wavelengths, allowing for diverse applications and customization.

- Long operational life: Diode lasers have a long operational life, typically exceeding 10,000 hours, which reduces the need for frequent replacement.

3. Applications of Diode Lasers

Diode lasers are used in a variety of industries and applications, such as:

- Laser pointers: Diode lasers are commonly used in laser pointers due to their compact size and low power consumption.

- Optical communication: Diode lasers are widely used for data transmission in fiber optic communication systems.

- Medical applications: Diode lasers are utilized in various medical procedures, including dermatology, hair removal, and photodynamic therapy.

- Material processing: Diode lasers are employed in material processing tasks, such as soldering, welding, and cutting thin materials.

Fiber Laser vs. Diode Laser

| Feature | Fiber Laser | Diode Laser |

| Laser Beam Quality | Excellent, near-diffraction-limited beam | Good, but typically lower than fiber lasers |

| Light Source | Optical fiber doped with rare-earth elements | Semiconductor diode |

| Cutting Efficiency | High efficiency, suitable for a wide range of materials | Lower efficiency, suitable for thin materials |

| Laser Modules | Compact design, easy to integrate into existing systems | Very compact, ideal for portable applications |

| System Maintenance | Low maintenance due to fewer components | Low maintenance, long operational life |

| Power Output | High output power, suitable for heavy-duty applications | Lower output power, suitable for less demanding tasks |

This table highlights the key differences between fiber lasers and diode lasers, including laser beam quality, light source, cutting efficiency, laser modules, system maintenance, and power output. By comparing these features, you can better understand which type of laser technology is more suitable for your specific needs and applications.

Other Laser Types

When comparing fiber lasers with other laser types, it’s essential to understand the basic principles and working mechanisms to determine which technology best suits your needs. Below are brief comparisons of fiber lasers with CO2, disk, solid-state, and laser pointers.

1. CO2 Laser Machine

CO2 laser cutters utilize a gas mixture as the active medium, primarily consisting of carbon dioxide, and generate an infrared laser beam. CO2 lasers are widely used in material processing, cutting, and engraving applications.

- Is fiber laser better than CO2 machine? The answer depends on the specific application. Fiber lasers offer higher efficiency, better beam quality, and lower maintenance, making them ideal for metal cutting and processing tasks. On the other hand, CO2 lasers excel in processing non-metal materials like acrylic, wood, and plastic.

2. Disk Laser

Disk lasers are a type of solid-state laser that employs a thin disk made from ytterbium-doped yttrium aluminum garnet (YAG) or other materials as the active medium. Disk lasers deliver high output power and excellent beam quality, making them suitable for various material processing tasks.

- Fiber lasers and disk lasers share many similarities, but fiber lasers generally offer better efficiency and a more compact design, making them more suitable for integration into existing systems.

3. Solid-State Lasers

Solid-state lasers use a solid, crystalline, or glass material doped with ions as the active medium, and the laser beam is generated through the process of stimulated emission. Examples of solid-state lasers include Nd: YAG, ruby, and Ti: sapphire lasers.

- Fiber lasers are a type of solid-state laser, and they generally offer better efficiency, beam quality, and system compactness compared to other solid-state lasers.

4. Laser Pointers

Laser pointers are handheld devices that emit a low-power laser beam, often used for presentations or recreational purposes. Most laser pointers use diode lasers as their light source due to their compact size and low power consumption.

- Fiber lasers are not typically used in laser pointers, as their main advantages (high power output, efficiency, and beam quality) are not necessary for such applications. Diode lasers are more suitable for laser pointers due to their small size and low power requirements.

Cost and Return on Investment for Fiber Laser Systems

- Initial Investment and Setup Costs of Fiber Lasers: While the initial investment for a fiber laser system may be higher than some other types of lasers, their long-term benefits often outweigh the upfront costs. The advanced capabilities, higher efficiency, and lower maintenance requirements of fiber lasers make them a more cost-effective option in the long run.

- Operational and Maintenance Costs of Fiber Laser Systems: Fiber lasers have fewer consumables, require less frequent maintenance, and generally consume less energy than other laser types. This results in lower operational and maintenance costs over the lifetime of the system, contributing to a more favorable return on investment.

- Potential Savings and Increased Productivity with Fiber Lasers: The high precision, speed, and efficiency of fiber lasers can lead to significant savings in material waste, labor, and processing time. These factors, combined with lower operational costs, can increase productivity and profitability for businesses that invest in fiber laser technology.

What to Consider when Choosing a Laser

When selecting a laser for your specific needs and applications, evaluating various factors is crucial to ensure you choose the most suitable technology. Here are some important aspects to consider when selecting a laser:

1. Wall Plug Efficiency

Wall plug efficiency refers to the conversion of input electrical power into useful laser output. A higher wall plug efficiency means the laser can generate more output power with less input power, resulting in lower energy consumption and operational costs. Comparing the wall plug efficiency of different lasers can help you choose a more energy-efficient and cost-effective solution.

2. Output Coupler

The output coupler is a partially reflective mirror that forms one end of the laser cavity, allowing a portion of the laser beam to exit while reflecting the rest back into the cavity. The characteristics of the output coupler, such as reflectivity and transmission, can significantly impact the performance of the laser.

When selecting a laser, consider the output coupler’s type and specifications to ensure optimal application performance.

3. Beam Quality

Beam quality is a critical factor in determining a laser’s overall performance and capabilities. A high-quality laser beam will have a near-diffraction-limited profile, enabling better precision, cutting capabilities, and processing speeds. When comparing lasers, evaluate their beam quality to ensure you select a laser that can deliver the precision and performance required for your specific tasks.

4. Laser Engraving Capabilities

If you plan to use the laser for engraving purposes, it’s essential to consider the engraving capabilities of the laser system. These capabilities may include the type of materials that can be engraved, the engraving resolution, and the maximum engraving speed. Different laser systems’ engraving capabilities can help you select the most suitable technology for your engraving needs.

Customization and Scalability of Fiber Lasers

- Modular Design and Expandability in Fiber Laser Systems: Fiber laser systems often feature a modular design, allowing you to expand and adapt the system as your needs evolve. This makes integrating additional components or increasing the laser power easier without replacing the entire system, providing a more cost-effective and flexible solution.

- Customizable Features and Options for Fiber Lasers: Fiber lasers can be tailored to your specific needs by offering various customizable features, such as adjustable beam parameters, beam delivery systems, or specialized software. These options can help optimize the laser performance for your particular applications and industry requirements.

- Upgradability and Future-Proofing with Fiber Laser Technology: Fiber lasers can be upgraded more easily than many other types of lasers, ensuring they remain relevant as technology advances. This means that you can keep up with changing industry demands or take advantage of new technological developments without having to invest in a completely new system.

Conclusion

In conclusion, when comparing fiber lasers and diode lasers, it’s essential to consider factors such as performance, efficiency, customization, and return on investment. Fiber lasers tend to excel in areas like precision, speed, and adaptability, making them a popular choice for many industries.

However, the final decision should be based on your specific needs and applications. Explore other resources on our website to learn more about laser technology and how it can benefit your business.

Discover the Power of Baison’s Fiber Lasers Today

Experience unparalleled efficiency and precision with Baison‘s cutting-edge fiber laser technology. Our commitment to quality, innovation, and customer satisfaction ensures you receive the best solutions for your business needs. Contact our experts to find the perfect laser system tailored to your requirements.