Laser cut labels offer a fresh and distinctive way to elevate your products. With the precision and intricacy of laser cutting technology, these labels stand out from the crowd. Whether you need labels for packaging, branding, or crafts, laser cutting allows for endless design possibilities.

From paper and cardstock to wood, these materials can be transformed into stunning labels that make a lasting impression. Say goodbye to ordinary print stickers and embrace the beauty of laser cut labels that add a touch of sophistication to any project or product.

Basics of Laser Cutting

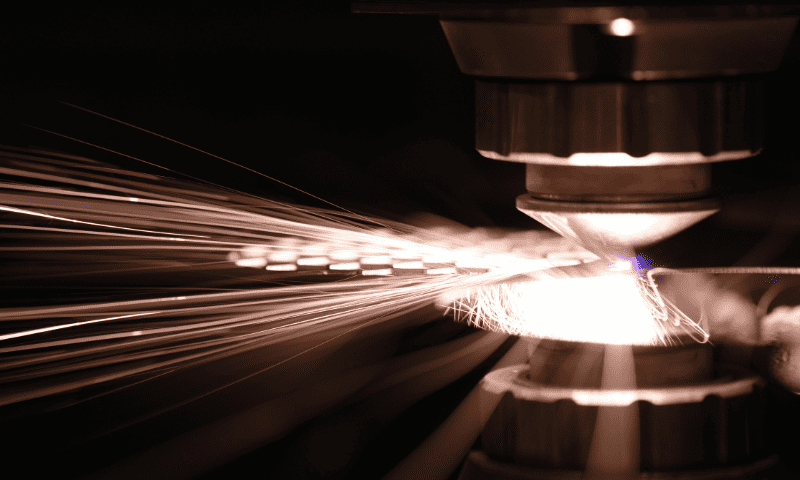

Laser cutting is a fascinating non-contact process that utilizes a high-powered laser beam to effortlessly cut through various materials. This technology has gained immense popularity due to its accuracy, precision, and versatility. Let’s delve into the basics of laser cutting and explore its incredible capabilities as a cutter.

Laser Beam Precision

One of the key advantages of laser cutting is its ability to achieve precise cuts with clean edges. The laser beam used in this process is controlled by sophisticated computer software, ensuring exceptional accuracy and eliminating any room for error. Whether you need intricate designs or simple shapes, laser cutting can deliver remarkable results.

Types of Lasers

Different types of lasers are employed for cutting various materials. CO2 lasers are commonly used for organic materials like wood, acrylic, fabric, and paper. On the other hand, fiber lasers are ideal for metals and other reflective surfaces. Each type offers unique benefits depending on the material being cut.

Intricate Designs and Minimal Waste

Laser cutting allows for the creation of intricate designs that would be challenging or impossible with traditional methods. The precision of the laser beam enables delicate detailing and complex patterns with ease in print, artwork, div, and sticker. This process minimizes material waste since it cuts precisely along the desired path without unnecessary excess.

Do You Have Any Questions?

Let Us Solve Your Problem

The Benefits of Laser Cutting Labels

Laser-cut labels offer a range of advantages compared to traditional methods. Let’s explore the benefits of using laser cutting technology for creating labels.

1. Precise and Intricate Designs

With laser cutting, you can achieve precise and intricate designs that are difficult to replicate with conventional methods. The laser beam is incredibly accurate, allowing for intricate details and fine lines on your labels. This level of precision helps create visually appealing designs that stand out, especially when using a wood cut line.

2. Minimal Risk of Damage or Distortion

One significant advantage of laser cutting is that it doesn’t require physical contact with the material being cut. This means there’s minimal risk of damage or distortion to the cut line during the process.

Unlike other cutting techniques that may involve pressure or friction, laser cutting ensures clean and sharp edges without compromising the integrity of the label material.

3. Quick Production Turnaround Times

Whether you’re working on a small-scale project or a large-scale production run, laser cutting offers quick production turnaround times. The automated nature of the laser system allows for efficient processing, reducing production time significantly. This makes it ideal for businesses looking to meet tight deadlines without sacrificing quality.

4. Professional Appearance

Laser-cut labels have a professional appearance that can enhance product packaging or branding efforts. The clean edges achieved through laser cutting give labels a polished look that conveys professionalism and attention to detail. This can help elevate your brand image and make your products more visually appealing to consumers.

Which Laser Cutter is Suitable for Cutting Labels?

Choosing the right machine is crucial. There are different types of laser machines available, each with its own unique capabilities and suitability for specific label materials. Let’s dive into which laser cutting machine is best for cutting labels.

1 – CO2 Laser Machines

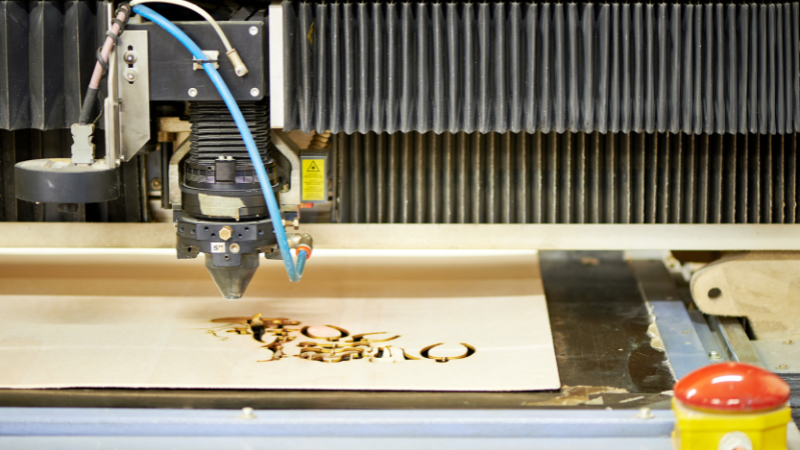

CO2 laser machines are widely used for cutting label materials like paper and cardstock. These machines are known for their versatility and ability to handle a variety of thicknesses. They work by emitting a high-powered CO2 laser beam that vaporizes the material it comes in contact with.

Pros:

- Versatile and can cut various label materials. Click here to understand the specific CO2 laser cutting machine cutting what material.

- Ideal for intricate designs and fine details

- Can handle different thicknesses of paper and cardstock

Cons:

- Not suitable for metallic label materials

- May require additional ventilation due to the production of fumes

2 – Fiber Lasers

Fiber lasers, on the other hand, are ideal for cutting thin metallic label materials such as aluminum or stainless steel. These lasers use a solid-state medium, typically an optical fiber doped with rare-earth elements, to generate a high-intensity laser beam.

Pros:

- Excellent precision when working with metallic label materials

- Fast and efficient cutting speed

- Minimal maintenance is required compared to other types of lasers

Cons:

- Limited versatility as they are primarily designed for metallic materials

- Higher initial cost compared to CO2 lasers

3 – Desktop Laser Cutters

Suitable for: These are ideal for small-scale operations, crafting, or small businesses. They can handle materials like paper, fabric, and thin plastic, which are often used for labels.

Why: Desktop models are more affordable and space-efficient. They’re great for producing labels in small quantities or for individual projects.

When selecting a laser cutter, it’s important to consider factors such as power output, bed size, and software compatibility. Assessing your specific requirements in terms of label design and material thickness will help determine which type of laser machine suits your needs best.

Do You Have Any Questions?

Let Us Solve Your Problem

The Process of Laser Cutting Labels

The process of laser cutting labels involves several steps that transition from the conceptual design of the labels to the actual physical cutting. This process utilizes the precision and efficiency of laser cutting technology to produce high-quality, durable labels. Here’s a breakdown of the process:

1. Design Creation

The first step involves creating a digital design of the label. This is usually done using graphic design software like Adobe Illustrator, CorelDRAW, or similar programs that can produce vector files. The design includes all elements of the label, such as text, logos, and any decorative elements.

It’s crucial that the design is precise, as the laser cutter will follow this blueprint exactly.

2. Material Selection

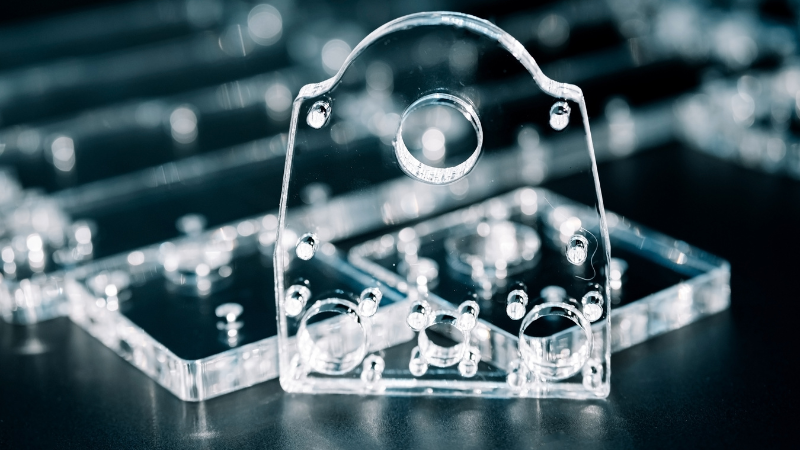

Based on the label’s intended use and the specifications of the laser machine, an appropriate material is chosen. Common materials include paper, plastic, acrylic, or even thin metal sheets.

The material’s thickness and color can also be selected at this stage, depending on the requirements of the design and the product to which it will be affixed.

3. Machine Preparation

The chosen material is placed in the laser cutter’s bed. The machine’s settings are adjusted based on the material’s thickness, the laser’s speed, and the power settings that dictate the cut’s depth and precision.

The vector design file is uploaded into the laser cutter’s software, ensuring the machine follows the exact design.

4. Laser Cutting Process

With everything set, the laser cutting process begins. The laser cutter follows the digital design, making precise cuts in the material. The laser cutter follows the path of your design and emits a high-powered laser beam that cuts through the material along the predetermined lines.

The laser either vaporizes the material or causes it to melt or burn, leaving behind the label’s shape and design. The process can be relatively quick for simple designs but might take longer for more intricate details. Each individual label takes at least 5 mins.

5. Quality Checks and Cleanup

After cutting, the labels undergo quality checks. Each label is inspected for accuracy, ensuring all details reflect the original design and meet quality standards.

Any residue from the cutting process, such as dust or burnt edges, is cleaned off the labels. Depending on the material, additional finishing processes like sealing or coating may be applied to enhance the label’s durability or appearance.

6. Application

The final labels are now ready for application. They can be affixed to products manually or using an automated system, depending on the volume.

This streamlined process allows for the mass production of labels with high precision, consistent quality, and detailed imagery or text, making laser cutting a preferred method for label creation in various industries.

Material Suitable for Laser Cutting Labels

The choice of material is crucial. Different materials offer varying levels of durability, customization options, and aesthetic appeal. Here are some popular materials suitable for laser-cut labels:

1. Paper and Cardstock

Paper and cardstock are versatile options for laser-cut labels. They are easy to work with and allow for intricate designs. With a wide range of colors and finishes available, paper and cardstock labels can be customized to suit any branding or packaging style.

2. Acrylic

Durable and weather-resistant, these materials are used for labels that might be exposed to the elements or require a longer lifespan. Acrylic can be cut cleanly with a laser, providing a smooth, polished edge that doesn’t require additional finishing. Wanna know how laser cut acrylic? Click here.

3. Wood

Thin sheets of wood can be laser cut for a rustic or unique look and are often used for premium labels, gift tags, or decorative pieces. The types of wood used include plywood, veneer, and solid woods like cherry or maple.

4. Metallic Materials

For a premium label finish, metallic materials like aluminum or stainless steel can be cut using fiber lasers. These materials add elegance and sophistication to any product or packaging design.

These are often seen in industrial or outdoor settings for signage, information plaques, or inventory tags. Fiber laser cutters are generally used for cutting metal materials.

By choosing the right material for your laser-cut labels, you can enhance their visual appeal while ensuring durability. Consider the specific requirements of your project, such as the desired aesthetic, budget constraints, and intended use.

Do You Have Any Questions?

Let Us Solve Your Problem

5 Ideas for Laser Cutting Labels

Laser-cut labels offer a unique way to express creativity and professionalism. They can be tailored for various purposes and audiences. Below are 5 ideas that can serve as inspiration for laser cutting labels.

1 – Custom Branding Labels

Create unique and eye-catching labels to showcase your brand identity. Laser cutting allows you to design labels with intricate patterns, logos, or typography that will make your products stand out on store shelves. Whether it’s for packaging, bottles, or promotional materials, custom branding labels add a professional touch to your products.

2 – Personalized Gift Labels

Make your gifts extra special by adding personalized laser-cut labels. From birthdays to weddings, you can create labels with the recipient’s name or a heartfelt message. These labels not only enhance the presentation of your gift but also show the thought and effort you put into making it truly one-of-a-kind.

3 – Informative Content Labels

Labels are not just about aesthetics; they can also provide important information about a product. Laser cutting enables you to create informative content labels that include QR codes, instructions, ingredients, or product details in a visually appealing way.

By incorporating clear and concise information on your labels, you ensure that customers have all the necessary details at their fingertips.

4 – Decorative Stickers for Home Decor

Laser-cut stickers can be used as decorative elements in home decor projects. Whether it’s adding a personal touch to furniture, walls, or accessories like mirrors and frames, laser-cut stickers offer endless possibilities for customization. You can choose from various designs and sizes to match your style and create a unique look for any space.

5 – Safety and Warning Labels

Laser cutting is an ideal method for creating safety and warning labels that adhere to industry standards. These labels can be applied to machinery, equipment, or hazardous materials containers to ensure proper usage and minimize risks. With laser-cutting precision, you can produce durable labels that effectively communicate crucial safety information.

By utilizing laser cutting techniques for label production, you unlock endless creative possibilities while ensuring high-quality results. From custom branding labels that elevate your brand image to informative content labels that provide essential details, laser-cut labels offer both style and substance. So, let your imagination run wild and explore the exciting world of laser cutting for labels.

Tips for Successfully Making Labels by Laser Cutting

Armed with this knowledge, you’re ready to dive into creating your own laser-cut labels. But before you do, here are a few final tips to ensure your success.

- Correct Machine Settings: Adjust the laser’s parameters like speed and power settings based on your material. For example, thicker materials require slower cuts at higher power, while thinner materials need faster cuts at lower power.Focus the laser correctly. The machine’s focal point should be precisely adjusted to the surface of your material for a clean cut.

- Material Handling: Flat materials are key. Make sure the material is completely flat on the cutting bed; even minor warps can affect cut quality. Use masking tape on the surface of materials to reduce scorch marks. This is especially useful for transparent materials like acrylic.

- Post-Processing: Clean the labels after cutting to remove any residues or particles. If necessary, apply any post-processing treatments like painting, sealing, or attaching adhesive backings.

By following these tips, you can enhance the quality of your laser-cut labels and ensure a more efficient, productive, and safe working process.

Do You Have Any Questions?

Let Us Solve Your Problem

FAQs

FAQ 1: Can I use any type of material for laser cutting labels?

Yes and no. While many materials can be used for laser cutting labels, some work better than others. Generally, thin materials like paper or cardstock are ideal because they allow for precise cuts without excessive burning or scorching. However, certain plastics or wood veneers can also be used successfully depending on the specific requirements of your project.

FAQ 2: How long does it take to laser cut labels?

The time required for laser cutting labels varies depending on factors such as the complexity of the design, the size of the labels, and the speed setting of the machine. In general, smaller projects may take just a few minutes, while larger or more intricate designs can take several hours.

FAQ 3: Can I use laser-cut labels for outdoor applications?

Absolutely! With materials like UV-resistant plastics or laminated papers, laser-cut labels can endure outdoor conditions, maintaining their quality against elements such as sunlight or moisture. Ensure your material choice aligns with your outdoor durability requirements.

Conclusion

You now have a solid understanding of the basics of laser cutting, the benefits it brings to label making, the suitable machines for this process, and the materials that work best.

Now it’s time for you to unleash your creativity and bring your label designs to life! Whether it’s for personal use or business purposes, laser-cut labels can add a touch of uniqueness and sophistication to any project. Start experimenting with different materials and designs today – who knows what amazing creations await? Happy label making!

Elevate Your Brand with Baison Laser!

Ready to distinguish your products with precision-cut, standout labels? Partner with Baison Laser, where technology meets craftsmanship. With our state-of-the-art technology and laser equipments, we will ensure that your vision is realized with precision and quality. Reach out today for an unparalleled branding transformation!