Are you interested in getting started with laser cutting but don’t know the ins and outs of what files are needed? Many people who haven’t worked with lasers before may be intimidated by all the technical terminology, but it doesn’t have to be so complex.

In this post, we will discuss everything related to what files go into making a successful laser cut and how they can help you create exceptional projects.

Lasers are used in a lot of things. This includes laser printers, chip manufacturing, barcode scanners, creating 3D graphics, and so on. Among the different uses of laser, there is laser-cutting, through which different materials can be cut precisely.

Laser-cutting requires a laser cutter, material, and laser-cutting file. The laser cutter machine is used to vaporize (cut) materials such as wood, plastic, acrylic…, etc. Then, we need the laser cut files, which tells the machine how to engrave designs or make the desired cut. There are different options for laser-cutting files, such as vector files, CAD files, and raster files.

So today, we will look at laser-cutting in complete detail, along with different laser files used in the industry. By the end of this article, I hope all your questions related to laser engraving and different file types will be answered!

So let’s get started!

What Is Laser Cutting?

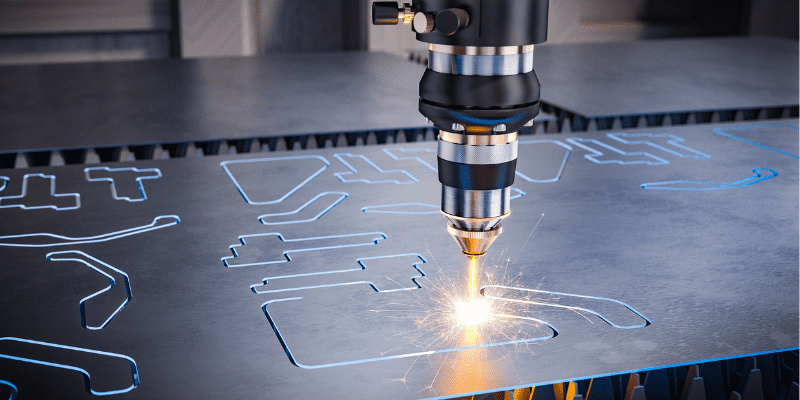

Laser cutting is a process that utilizes a powerful laser to cut through a material. You can compare laser cutting with any other type of cutting. The only difference lies in the precision and smooth finish.

If you are told to cut down a piece of wood with a saw, the result will not be 100% accurate. But if the same piece of wood is cut with laser cutting, it produces a highly precise cut! On top of that, if you have to create 1000 similar designs on a material. Then laser cutting can help you with that as well!

You may ask how laser cutting can achieve such high precision and accuracy. The first reason is a powerful laser beam that can vaporize or burn the material. And the 2nd reason lies in the use of laser-cutting files. But what’s that?

Well, Laser-cutting files give exact instructions to the laser machine on how to do its job! And this is what makes laser-cutting so accurate, precise, and smooth.

Laser cutting machines can be used for cutting a lot of different materials, such as:

- Wood

- Plastic

- Gemstone

- Metal

- Glass

- Paper

And so on…

What Are The Benefits of Using Laser Cutting?

Now that you understand how laser cutting machines work, it leads us to the next question. What are the benefits of using a laser cutting machine instead of other solutions?

Some of the most obvious benefits include flexibility, speed, repeatability, contactless cutting, automation, and cost-effectiveness!

Let’s look at each of these benefits in more detail:

1. Flexibility

Normally, one would need a lot of different tools to make different cuts. But when using laser cutters, just using the same setup is beyond enough to make different shapes!

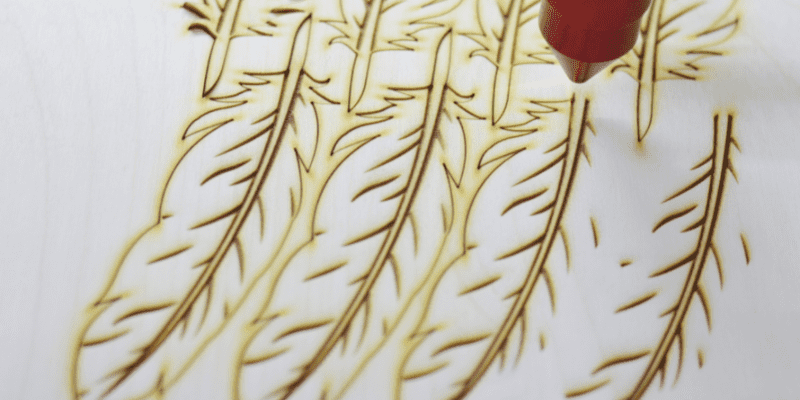

An additional benefit is that even the most intricate cuts are made easily with laser engraving. On the other hand, it would require hiring a highly skilled craftsman to make a moderate to advanced design!

2. Speed

Laser engraving is also a lot faster than other cutting methods! Especially when it comes to intricate cuts that can take days to finish through mechanical cutting.

And even if we compare laser engraving with flame or plasma cutting, the laser still beats them in speed!

Now you may ask how long it takes to cut through a specific thickness of, say, 10 mm… Well, it all depends on the laser cutter’s power – A more powerful laser beam will cut way faster than a normal one!

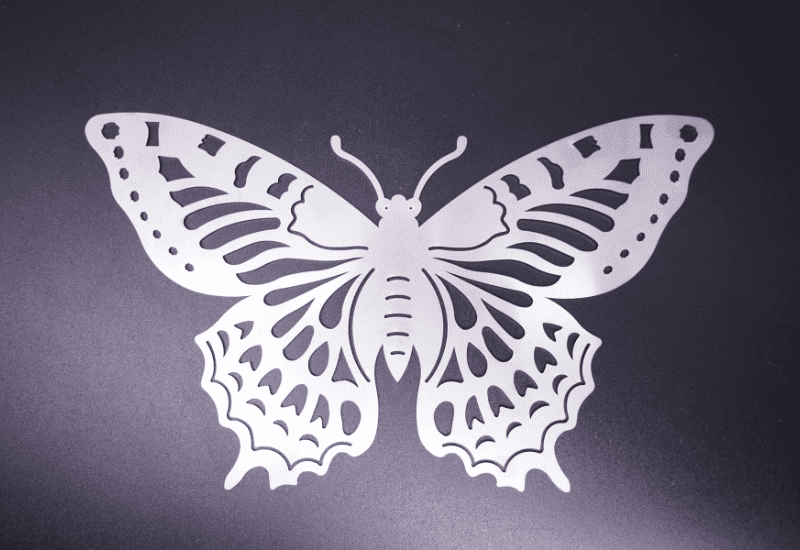

3. Repeatability

Do you need to make 100 pieces of the same design that look 100% similar? You can do that with laser engraving!

As mentioned earlier, laser machines utilize specific files for cutting and engraving. This ensures 100% repeatability of the design patterns!

If you compare laser cuts with mechanical or other methods, the engraving results show a clear difference… Despite the number of copies made of a single design, the different copies will look alike with high accuracy!

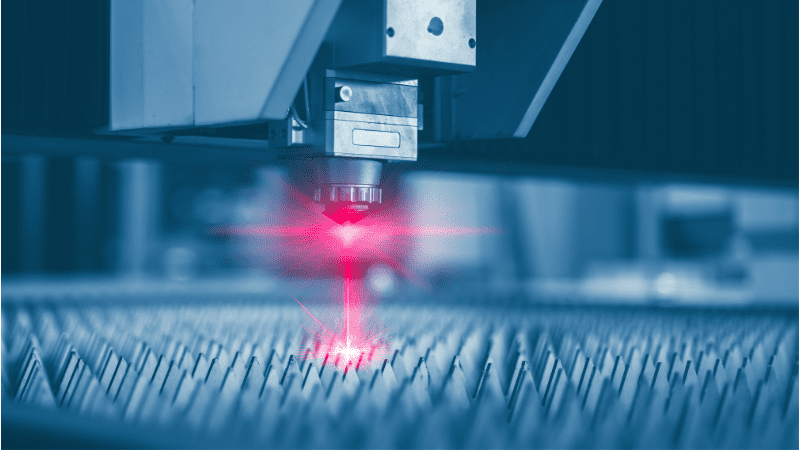

4. Contactless Cutting

Laser machines do not require any physical contact with the material for cutting. As long as the beam can come into contact with the required material, it will cut through!

This contactless cutting removes all the perils that come with mechanical friction, such as the wearing down of tools.

It also makes the cutting process safe and prevents any potential injuries.

5. Automation

Laser cutting and engraving don’t require a lot of manpower since it is fully automated. It only requires an operator who knows how the machine works to produce thousands of designs efficiently.

And with the automation of laser cutting and engraving, there is no loss of quality and accuracy, which makes it even better!

6. Cost Effectiveness

Last but not least, laser cutting and engraving are highly cost-effective solutions. That’s because you only need limited manpower to produce designs at scale!

In contrast, mechanical methods usually require a bigger team of craftsmen and thus can easily drive up the costs!

What Files Are Used For Laser Cutting, and How Do They Work?

Some of the popular file formats used in laser cutting and engraving include:

- Vector files

- Raster Files

- CAD & 3D files

- Compound files

All these files can be used for successful laser-cutting depending on the requirements and access to the relevant software.

Let’s take a closer look at each file format in more detail!

1. Vector Files

Vector files are a collection of shapes and lines from different mathematical calculations. You can think of vector files as a map that provides the coordinates to the laser machine. Using these coordinates, a laser machine can cut based on the specification!

One of the major benefits of vector files is that it is bound by the resolution. A vector image file can be stretched infinitely without losing the quality of colors, shapes, and text.

Vector files are typically made in the following file types:

- Adobe Illustrator (AI) – With the help of Adobe Illustrator, vector files can be created easily. It is one of the most popular tools for this file format. This tool is normally used for making logos and graphics.

- Corel Draw (CDR) – Another popular option is Corel Draw which is very similar to Adobe Illustrator in terms of usability and functionality.

- Scalable Vector Graphics (SVG) – The SVG file format is similar to the AI and CDR and can be opened/changed in any popular vector software.

Using vector files is best if you want to use the same design for different sizes. As mentioned earlier, vector files ensure that your image doesn’t lose its clear quality despite the size of the design!

2. Raster Files

Raster files (bitmap images) are pixels containing information about the colors and tonality. A pixel on its own is nothing but a mere dot. However, when millions of pixels are combined, it creates an image that can be displayed on mobile, computer…, etc. Unlike the vector file formats, the raster files depend on the resolution. That’s why if you zoom in or stretch a raster image, it will become unclear and lose its quality.

If you already know the exact size of the design, then a raster file can be used without any problem. You can change a raster into a vector file if you need a different file for laser-cutting.

Most of the images you see on the web or even those present on your mobile are raster files! So yes, these are quite popular and are extensively used in laser-cutting machines! They are even more popular than vector files!

Some of the popular Raster file types are given below:

- JPEG – It is an acronym of the Joint Photographic Expert Group and utilizes compression technology to reduce image size.

- BMP – It stands for the Bitmap image file and is a popular raster file type.

- PNG – Stands for Portable Network Graphics and is normally used for web graphics.

- GIF – It stands for Graphics Interchange Format and is normally used for creating animations.

- TIFF – It stands for Tagged Image File Format and is extensively used in commercial printing.

3. CAD & 3D Files

CAD files are computer-aided designs with programs such as FreeCAD, AutoCAD, Fusion 360, and others.

A CAD file is a vector file but with one big difference: A CAD file can be used to create highly complex 2d and 3D designs.

Some of the popular CAD file formats are given below:

- DWG

- DXF (Drawing Exchange Format)

4. Compound Files

A compound file is more complex than the raster and vector file formats… Using a compound file, the raster and the vector images can be stored. This makes it a unique option for users.

Some of the popular compound file formats are given below:

- PDF (Portable Document Format)

- EPS (Encapsulated PostScript)

These files can be made in Adobe Illustrator, Corel Draw, or any other vector program. You can also use free laser cut files to create your artwork!

How Can You Create or Modify These Files to Get The Best Results From Your Laser Cutter?

A laser-cutting machine is only as good as the files you use for making the designs!

When creating or modifying these files, ensure that you keep the following in mind:

- The first and most important thing to remember is always to use the RGB color mode! If your image file uses a different color mode, you can easily change it into RGB through any image editor!

- Backgrounds and laser machines do not do well together! So make sure that your image files do not have any backgrounds! An image file with a white background can help you get the best results from your laser cutter!

- It is a good idea to view your image file in greyscale before cutting and engraving! In case you do not know, all the designs are made in greyscale by default – So it is a good idea to view how the final design will look!

So the next time you create vector files or raster images for your project, keep these tips in mind!

Other Considerations When Using Laser Cutting Technology in Your Business or Project Planning Process?

Some of the other things that you should consider when using this technology in your business include the following:

- Always choose a good quality laser-cutting machine.

- This is a mostly automatic process and thus requires a skilled machine operator.

- A laser-cutting machine will only produce what’s provided to it as input (in the form of a laser-cutting file). So make sure to select the right file type which meets all the requirements!

- If you are running short of creativity when creating designs, you should hire a graphic designer!

- Know beforehand what type of laser-cutting machine will meet your requirements!

Conclusion

If you are new to laser-cutting and engraving, all this information will help you start on the right track! When it comes to laser-cutting, one of the most important pieces of the puzzle is the laser-cutting file, without any doubt!

The file dictates whether your finished design or engraving will look spectacular or just a mistake! So make sure you read about all the different file formats mentioned above… And remember to read our tips on getting the best results for your next laser-cutting project!

Looking to Get Your Own Laser Cutting Machine?

If you are searching for a trusted manufacturer of laser-cutting machines, you can go with Baison Laser, a leading manufacturer from China. We offer different laser-cutting machines and have a history of offering reliable and high-quality equipment at affordable rates! Contact us to get a quote now!