But fear not! As we delve into the world of wood laser cutters and CNC machines, you’ll gain all the knowledge needed to make an informed decision and create stunning workpieces.

What is a Wood Laser Cutter?

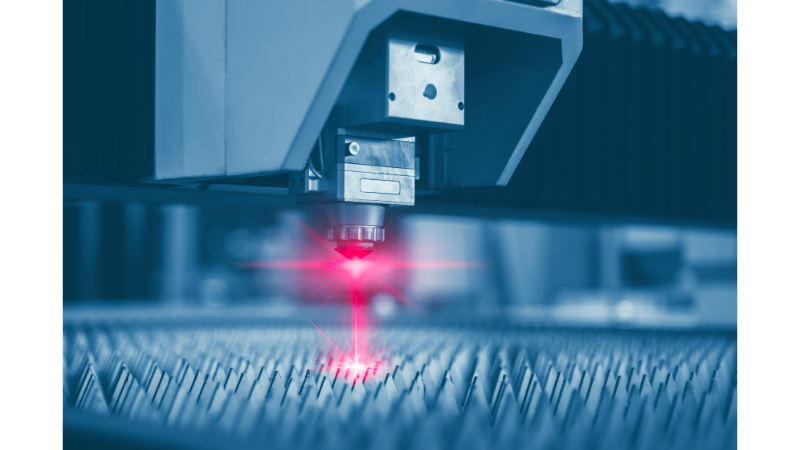

A wood laser cutting machine is an essential tool in the machinery manufacturing industry that utilizes laser technology to precisely cut and engrave materials in various. This advanced machine operates by emitting a high-powered laser beam that vaporizes or melts the workpiece, creating clean and accurate cuts with minimal waste. Wood laser cutting machines are often used in combination with CNC cutting technology for even more precise results.

Wood laser cutters are equipped with computer numerical control (CNC) systems, which allow operators to program intricate designs and patterns for cutting or engraving onto the wood surface. These cutters offer immense versatility, enabling manufacturers to produce intricate wooden components, furniture pieces, decorative items, and signage with great precision and higher energy efficiency.

With their ability to handle complex designs and produce high-quality finishes, wood laser cutters have become an indispensable tool for modern machinery manufacturing. The laser’s work area is where the workpiece is placed for cutting and engraving.

Understanding Laser Cutting

A laser cutting machine is a device that uses a concentrated beam of light to cut or engrave materials. An optic laser’s focused beam of light makes up a laser cutting machine. When it comes into contact with the materials and workpiece, the high-power laser from the laser engraving machine causes that substance to heat up and melt quickly.

Laser cutting machines come in various forms to cater to different needs and requirements. One common type is the CO2 laser cutter, which uses a carbon dioxide laser beam to cut through wood materials. Click here for details. CO2 laser cutters are versatile and can handle a wide range of wood thicknesses and densities. Another type is the fiber laser cutter, which uses a fiber laser beam called an infrared beam to cut through wood. Fiber laser cutters are known for their high cutting speeds and are often used for industrial applications.

Laser cutting machines have gained widespread popularity and are extensively utilized in various sectors. These highly efficient machines utilize a laser beam to achieve precise and clean cuts on a wide range of workpiece materials, including steel, aluminum, plastic, and wood. The accuracy and precision of these machines make them a preferred choice for engineers when cutting components. Additionally, small business owners can benefit from laser cutters as they enable them to offer excellent services at cost savings. With their ability to deliver exact and accurate cuts, laser cutting machines have become an indispensable tool across industries.

Applications in Woodworking

Wood laser cutters have a wide range of applications in the woodworking industry, offering precise and intricate cutting capabilities that traditional tools may struggle to achieve. Here are some key applications where wood laser cutters shine:

Custom Furniture: Wood laser cutters enable the creation of intricate and unique designs for custom furniture pieces. From intricate patterns and decorative details to personalized engravings, laser cutting can add a touch of elegance and individuality to furniture pieces.

Decorative Woodwork: Laser cutters excel at creating intricate and detailed designs for decorative woodwork. Whether it’s intricate patterns for wall panels, decorative screens, or ornamental accents, laser cutting allows for precise and consistent results.

Signage and Branding: Wood laser cutters can be used to create custom signage and branding elements for businesses. From company logos and names to intricate lettering and designs, laser cutting offers precise cuts and professional results for creating eye-catching signage.

Model Making and Prototyping: Wood laser cutters are commonly used in model-making and prototyping applications. They allow for the precision of wood to create detailed models, architectural prototypes, and product mock-ups, enabling designers and manufacturers to visualize and refine their concepts.

Art and Craft Projects: Wood laser cutters are a favorite tool for artists and crafters. They can be used to create intricate wooden artwork, jewelry, ornaments, and other craft projects. The high precision and versatility of laser cutting allow artists to push the boundaries of their creativity and produce stunning and unique pieces.

Inlay and Marquetry: Laser cutting machines can cut intricate shapes and designs in wood, allowing for the creation of inlays and marquetry. This technique involves inserting contrasting wood or other materials into the cutouts, resulting in stunning decorative patterns and designs.

Features to Consider when Buying a Wood Laser Cutter

When purchasing wood laser cutting equipment, there are several factors to take into account. These features will ensure that you select a machine that meets your specific needs and requirements.

Power of the Laser

The laser power of a wood laser cutting machine determines its cutting speed and cutting capabilities. Higher-wattage lasers can efficiently cut through thicker and denser plywood materials. Opt for a wood laser cutting machine with sufficient power output to achieve your desired cutting depth and high speeds in the work area, ensuring efficient and precise results.

Size and Workspace

Consider the dimensions of the machine’s work area, to ensure it can accommodate your project sizes. A larger engraving area provides more flexibility in terms of the size of materials you can work with.

Software and Compatibility

Check if the wood laser cutting machines support popular design software programs like LightBurn. This compatibility ensures seamless integration between your design software and the laser cutter, making it easier to transfer and execute your designs accurately.

Laser cutters vary in size and power, and some are specifically designed for certain materials. Researching and comparing different models will help you find the perfect match for your needs.

Safety Features

When using CNC cutting machines, it is crucial to prioritize safety. Make sure the machine is equipped with safety features such as emergency stop buttons, protective enclosures, and safety interlocks to protect operators in the work area.

Top 5 Wood Laser Cutting Machines Reviewed

The CNC laser engraver and cutter are known for their efficiency in cutting and engraving different types of wood materials. Whether you’re a hobbyist or a professional, these desktop laser cutters provide reliable performance and the highest quality results. Let’s dive into the details of each machine, including the output laser cutting machines.

CO2 Laser Cutting Machine

- Suitable for use with wood, plastic, metal, and many more materials

- Able to engrave surfaces with incredible accuracy

- The user-friendly interface simplifies operation, making it suitable for beginners.

Entry-level Sheet Metal Laser Cutting Machine

- Up to 140m/min cutting speed can guarantee your productivity.

- This machine provides perfect results and is sturdy and durable.

- The compact design allows you to save more space or place more machines.

Single Platform Sheet Metal & Tube Laser Cutting Machine

- You can use one machine for multiple uses.

- Requiring minimal space for the machine improves process and production flow.

- Cutting speed and effectiveness go hand in hand with this machine.

Dual Platforms Sheet Metal & Tube Laser Cutting Machine

- Guaranteed cutting accuracy without sacrificing cutting speed.

- A fully enclosed design with an advanced ventilation system makes it cleaner.

- Energy consumption can be reduced by 15-20% compared to similar products.

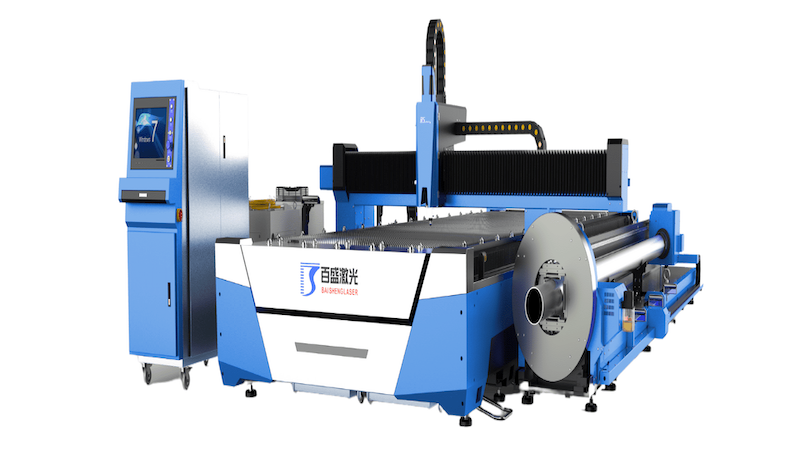

Coil-fed Laser Blanking System

- Removing time-latent material transport processes with direct-from-coil cutting.

- Leveraging a high-accuracy leveling system to ensure precise cuts, every time.

- Saving time that would have been spent transporting materials, sorting, and more.

How to Use a Wood Laser Cutting Machine Safely

When using a wood laser cutting machine, it is crucial to prioritize safety precautions to ensure the well-being of the operator and prevent accidents. Additionally, regular maintenance of the machine is essential to keep it functioning optimally and extend its lifespan.

Safety Precautions

Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, gloves, and closed-toe shoes, when operating the wood laser cutting machines.

Ventilation: Ensure proper ventilation in the workspace when using laser cutting machines or laser engraver machines to remove fumes and smoke generated during the cutting process. Use exhaust systems or ensure the workspace has good airflow for the right laser cutter experience.

Fire Safety: Keep a fire extinguisher nearby and familiarize yourself with its usage. Regularly clean the machine and workspace to remove any flammable debris or dust that could potentially ignite the laser tube.

Operator Training: Only trained and authorized personnel should operate the wood laser cutter. Familiarize yourself with the machine’s operation manual and safety guidelines.

Material Compatibility: Ensure that the wood material being cut is suitable for laser cutting. Some woods may release toxic fumes or produce excessive smoke when laser cut.

Maintenance Tips

Regular Cleaning: Clean the machine regularly to remove dust, debris, and residue. Use a soft brush or compressed air to clean the lens, mirrors, and other components.

Lens Inspection: Inspect the laser cutter machine lens regularly for any damage, scratches, or debris buildup. Clean or replace the machine’s laser lens as necessary to maintain optimal cutting quality.

Alignment Check: Periodically check and adjust the alignment of the cutter’s laser beam to ensure precise and accurate cutting. Follow the manufacturer’s instructions for alignment procedures.

Cooling System Maintenance: Maintain the cooling system of the laser machine by regularly checking and cleaning the water reservoir, replacing the coolant, and ensuring proper water flow and temperature for optimal delivery performance.

Software and Firmware Updates: Stay updated with the latest software and firmware versions provided by the manufacturer. These updates may include performance improvements and bug fixes.

FAQs

Can I use wood laser cutting machines for other materials?

Yes! While primarily designed for wood cutting applications, many wood laser cutters are also capable of engraving or cutting other materials like acrylics or plastics. However, it’s important to check the specifications of each machine to ensure compatibility with your desired materials.

What safety precautions should I take when using a wood laser cutter?

When operating a wood laser cutter, always wear protective eyewear to shield your eyes from the focused laser beam. Ensure proper ventilation in your workspace and avoid leaving the machine unattended while it is in use.

How do I choose the right power output for my wood laser cutter?

The power output of a wood laser cutting machine determines its cutting ability. Consider the thickness and type of materials you plan to work with when selecting a machine. Higher power outputs are generally better suited for thicker materials or denser woods, while lower power outputs may be sufficient for thinner materials.

What kind of software is needed to operate a wood laser cutter?

Most wood laser cutters come with their own proprietary software for controlling and manipulating designs before sending them to the machine for cutting. Familiarize yourself with this software and its capabilities to fully utilize your wood laser cutter’s features. Ensure efficient delivery by understanding the software.

Conclusion

We’ve journeyed through the landscape of wood laser cutting machines, exploring their features, benefits, and the top models currently on the market. So, which feature of a wood laser cutting machine seems most important to you? By knowing that we provide you with valuable insights into its features and performance, you can make informed decisions based on your budget and requirements.

Baison Laser Provides The Best Laser Cutting Solutions

If you still can’t decide, contact us! Baison is one of the leading companies that can help you choose the best laser cutter for your needs, whether CO2 laser cutters or fiber laser cutting machines. A free application evaluation is provided by industry experts to help you understand your laser system investment before you even make a purchase. If you’re ready to elevate your woodworking skills, don’t hesitate to dive deeper into our detailed reviews and choose the best laser cutter today for fast delivery.