Whether operating the cooling in a fridge or scaffolding for a renovation project of an old building, cutting metal pipes or tubes is required for too many purposes. Steel and other metals are hard to cut, especially if you need to know what tool to use.

This article is about guiding you on cutting metal pipes and tubes for various purposes. It can be a fixing job, a new DIY project, or simply for industrial use. We will not only share which power tools to use for different metal pipes and tubing but also will show how to use them safely. So stick along, as we have much to share when cutting metal pipes.

The Importance of Choosing the Right Tool to Cut Metal Pipe and Tubing

Metal pipes and tubings are hard to cut. The choice of tool depends on the thickness and diameter of the pipe, as well as the type of cut you need to make.

Tube and pipe manufacturing parts are widely used in small industrial sectors such as aircraft manufacturing, engineering machinery, transportation, petrochemical, guardrail processing industry, and farm and animal husbandry.

Why Choosing the Right Tool to Cut Metal Pipes and Tubes Is Important?

Safety: Using the wrong tool for steel and plastic pipes can be dangerous. It increases the risk of injury, and choosing the right tools for the right material minimizes accidents.

Speed: Again, the right tools for the right material speed up the process. A mechanical hand saw will take an hour to cut the steel or any metal file, while a laser cutter can cut the same within a few minutes.

Accuracy: Cutting steel pipes and tubing with the wrong tool does not give accuracy. The right tool gives a precise cut that makes a better finish in the end product.

Efficiency: The right tool saves energy and time and ensures precise and even cuts.

Cost: Using the right tool can save a lot of material, time, and labor costs.

How to Cut Precise and Even Metal Cutting?

- Choose the appropriate tool depending on the type and thickness of the metal, and ensure the blades are sharp and in good condition.

- Use a measuring tool, like a ruler, and a marker to draw the cut line on the metal. Make sure the line is straight and even.

- Clamp the metal down to prevent it from moving during cutting.

- Follow the instructions for your chosen cutting tool, and cut along the marked line.

- After cutting, use sandpaper or a file to smooth out rough or uneven edges to create a clean, even edge.

Things to Consider While Choosing a Tool for Pipe Cutting

Below is a list of some of the factors you should pay attention to when choosing a pipe laser cutting machine.

- Different tools are better suited for cutting various types of metal. For example, a small pipe cutter may be better for softer metals, while a hacksaw or reciprocating saw may be better for cutting steel pipe.

- The tool you choose can handle the size and shape of the pipe or tube you need to cut. For example, a pipe cutter may not be suitable for cutting pipes with large diameters, and a hacksaw may not be suitable for cutting tubing with irregular shapes.

- The thickness of the metal also affects the tool you should use. Thicker metal may require a more heavy-duty tool, such as a band saw and tube laser cutting machine, while thinner metal may be cut with a simple handheld cutter or a circular saw.

- Some power tools, like a pipe cutter or tubing cutter, provide more precise cuts than others, like a hacksaw or angle grinder. Depending on the application, precision may be necessary.

- Always consider safety when selecting a tool to cut metal pipes and tubing. Some tools may be more dangerous, and some may require safety equipment like gloves or safety goggles.

- Some tools are more expensive, so you should consider your budget when selecting.

Here, we have mentioned several ways to cut metal pipes and tubing. We will specify which tool works for which material, how to use it, and some safety recommendations.

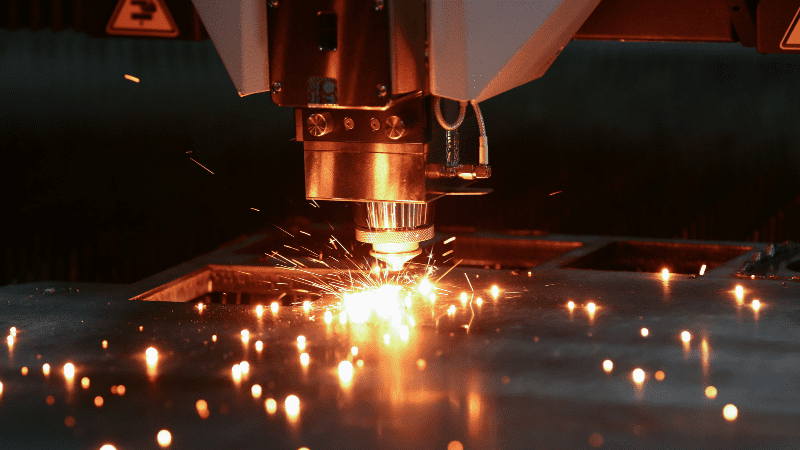

I. Laser Cutters

Nothing beats laser cutters when cutting steel and other hard materials for manufacturing industries. These high-end machines use laser beams to cut materials from small pipes to massive metal sheets for manufacturing purposes. These laser tube cutting machines have robust cutting power and reduce production time.

Laser cutters may be overkill for DIY projects, but their power, efficiency, and finesse are the best for small to big industrial or manufacturing purposes. These are specialized tools widely used in the sheet metal industry.

Optics and computer numerical controls directly these high-powered cutting machines to direct beams on the material. This process cuts the material to the required length and size. These machines can also cut out holes or designs in tubing for assembly. These high-powered machines can cut through any hard material, including steel or copper pipe.

Laser cutting machines also come in different varieties, such as fiber laser cutting or CO2 laser cutting machines depending on different industrial and manufacturer needs.

These are also easy-to-use and environmentally friendly machines suitable for a range of materials. These laser pipe cutting machines work for small and big industries depending on the nature of the work.

Things to Consider While Selecting Laser Cutting Machines

Here are a few things you should consider before selecting a laser-cutting machine:

- Laser power as it determines the speed and quality of the cutting process

- Type of metal pipes and tubing you will be cutting

- The thickness of the metal pipes and tubing

- The cutting speed of the machine

- Consider the size of the metal pipes and tubing

- The machine’s capacity, including the maximum size and weight of metal pipes and tubing

- Maintenance requirements to ensure that you can carry out the required maintenance without any difficulty

- Appropriate safety features, such as a protective enclosure, to protect the operator from potential hazards

II. Cutoff Wheels

Cutoff wheels are commonly used in metalworking, construction, or automotive repair sectors to cut metal pipes and tubes, especially those made of ferrous metals such as steel, iron, and stainless steel. They can also cut non-ferrous metals such as aluminum and copper. These wheels are made of abrasive materials that can cut through tough materials, including steel pipes and tubings.

Cutoff wheels are often used in applications that require precise, controlled cuts, such as metal fabrication, automotive repair, and construction. They are available in various sizes and thicknesses to accommodate different materials and cutting needs.

The Cutoff wheel consists of a thin, circular disc-shaped wheel made of abrasive material, such as aluminum oxide or silicon carbide, bonded with a resin or vitrified material.

A cutoff wheel is typically mounted onto a rotary tool, such as a hand-held angle grinder or a stationary chop saw. As the tool is turned on and the cutoff wheel begins to spin, the abrasive material on the edge of the wheel comes into contact with the material being cut, gradually grinding through it and producing a clean, precise cut.

It is essential to use the appropriate cutoff wheel for the material being cut and to follow safety precautions, such as wearing eye protection and avoiding excessive pressure that could cause the wheel to break.

How to Use a Cutoff Wheel?

- Clamp the workpiece securely, or hold it steady with a vise.

- Hold the cutoff wheel perpendicular to the workpiece and at a 90-degree angle to the cutting surface.

- Turn on the power tool and allow the cutoff wheel to reach maximum speed before contacting the workpiece.

- Gently lower the cutoff wheel onto the workpiece and slowly push it forward while applying light pressure. Please do not force the wheel or apply too much pressure, as this could cause it to break. Once you have cut through the material, please turn off the power tool and wait for the cutoff wheel to come to a complete stop before removing it from the workpiece.

- Clean up any debris or dust left from cutting, and put away your tools.

Advantages

- Precise cutting as it creates clean, accurate cuts without damaging the surrounding material.

- Works fast, saving time and increasing productivity

- It can be used on various materials, including steel, stainless steel, aluminum, and copper

- Easy to use and requires minimal setup

- Affordable

Disadvantages

- Generates a lot of heat, which can cause the metal to warp or change its properties

- Difficult to control, leading to inaccurate cuts

- Have thin blades with a limited cutting depth

- Wear down quickly, requiring frequent replacements

- Cutting with a cutoff wheel can produce a lot of dust and debris

- Loud and noisy

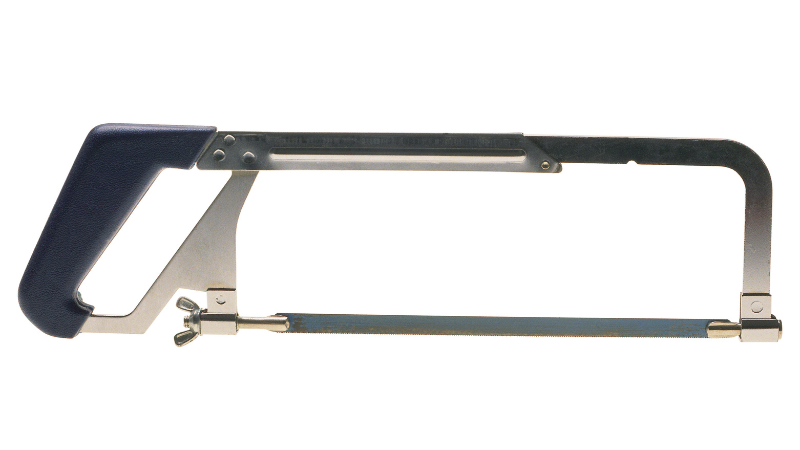

III. Hacksaw

Almost every workshop needs a hacksaw. Nothing beats it for basic plumbing pipes and construction. It’s easy to use, cheap, and cuts steel, aluminum, or other metals. They are also durable and long-lasting, so you can use them for multiple projects without replacing them.

Hacksaws are portable tools that can be used in almost any location. That makes them ideal for DIY projects that require you to cut metal pipes and tubing in hard-to-reach areas. Hacksaws allow for a high degree of control when cutting, which is particularly important when working with metal pipes and tubing. You can cut slowly and steadily with a hacksaw, making accurate, clean cuts without damaging the material.

If manual power and time consumption are the issues, then a power hacksaw speeds up the work and comes with a lot of power. A hacksaw comes in handy when cutting or repairing already-built things. Click to learn the difference between manual and automated pipe cutting.

When selecting a hacksaw for your project, consider the size and thickness of the material you will be cutting. The teeth-per-inch (TPI) of the hacksaw blade will also affect the type of cut you can make. A higher TPI will produce a smoother cut but take longer, while a lower TPI will cut faster but leave a rougher edge.

How to Use a Hacksaw?

- Secure the material to a workbench or other sturdy surface.

- Measure and mark the line you want to cut on the material.

- Hold the saw with both hands, one at each end of the frame. The blade should be pointing away from you.

- Apply light pressure to the blade and cut with long, even strokes. Short strokes will make the cut uneven and may cause the blade to bend or break.

- Once you have cut through the material, release the tension on the blade and remove it from the cut.

Advantages

- Relatively inexpensive compared to other cutting tools

- Versatile for cutting a wide range of materials, including plastic, wood, and other metal materials.

- Requires minimal setup time

Disadvantages

- Time-consuming and slow

- May produce uneven or inconsistent cuts

- Limited cutting capacity and may not be suitable for cutting thicker or larger diameter pipes and tubes.

- Pose a risk of injury if not used properly.

IV. Steel Pipe Cutter

Pipe or tube cutter steel pipes or tubes are common to cut steel pipes or tubes in workshops. A PVC cutter is also available in the market and specializes in cutting PVC or plastic pipe. It’s a handheld tool used for personal DIY projects and professional workstations.

The C-shaped tool with a hardened steel cutting blade to cut metal pipes. The hard metal blade makes it different from other power tools. Steel pipe cutters make a square cut and leave a smooth finish. They may work slower than other power tools.

Steel cutters work for pipes up to 50 diameters. Some larger steel cutters can cut lines 76 mm in diameter. Like Pip cutters, tube cutters work the same as pipe cutters with the difference that they are designed to cut the tubing.

How to Use a Steel Pipe Cutter?

- Place the pipe into the cutter: Insert the pipe into the cutter’s jaws and tighten the cutting wheel onto the pipe.

- Rotate the cutter: Turn the cutter around the pipe in a circular motion, tightening the cutting wheel slightly with each rotation.

- Continue cutting until the pipe is severed: Keep rotating the cutter until the cutting wheel severs the pipe.

- Remove the cut pipe: Release the cutter and remove the cut pipe.

Advantages

- Quick and Efficient

- Clean and Precise Cuts

- Easy to Use

- Cut a wide range of metal piping and tubes, including copper, steel, and PVC.

- Lightweight and portable

- Lightweight and portable

Disadvantages

- Limited cutting capacity

- A Pipe or tube cutter can be dangerous and cause injury

- Require regular maintenance, such as sharpening blades

- Can be Expensive

An angle grinder is another tool used to cut metal piping and tubing. It cuts through metal quickly. The power tool uses a spinning disc or abrasive wheel to cut through tough metal. The tool comes with various accessories like abrasive wheels that pin at the speed of thousands of RPMs, which is powerful enough to cut metal. However, choosing the right abrasive wheel for the type of tubing or pipes you are cutting is important.

How to Use an Angle Grinder?

- Attach the disc to the angle grinder, ensuring it is properly secured and tightened.

- The angle grinder’s guard must be adjusted to protect your hands and face from debris and sparks. Loosen the screws that hold the guard in place and move it to the desired position, then tighten the screws again.

- Plug in the angle grinder and turn it on.

- Use a steady hand and apply even pressure to the metal pipes.

- When you finish the angle grinder, please turn it off and unplug it from the power source.

Advantages

- It cuts through pipes and tubes quickly, making it an efficient tool for cutting large quantities of materials

- Available in different sizes and can be used with different types of cutting discs

- Can make precise cuts with a steady hand

- Small and portable

Disadvantages

- Dangerous if not used properly

- Lots of dust, noise, and vibration

- Limited cutting capacity not suitable for cutting very large or thick pipes and tubes

VI. Reciprocating Saw

A reciprocating saw is another powerful tool for cutting thin, medium, and thick metal piping and tubing. These are the most powerful saws; you can cut metal sheets and piping with proper blades. The power tool has a thin metal blade that can reach into tight spaces. The blade moves back and forth in rapid push-pull action to cut various materials.

Its aggressive power is more suitable for demolition and rough cutting than precise cuts. Besides metal piping, it can be used to cut multiple other tough materials of metal.

Reciprocating saw works in narrow, deep, and long spaces. Reciprocating saws can cut copper pipes, aluminum, cast iron, and high-strength alloys. A reciprocating saw comes with different blades, including:

- High carbon steel

- High-speed steel

- Bi-metal blades

- Carbide reinforced

Here are some advantages and disadvantages of using a reciprocating saw:

Advantages

- Quick-release clamp for quick blade change

- Variety of Blade that cuts through almost any hard material

- Easy to Carry

- Battery-powered and cord-powered versions

- Good for both straight cuts and curved cuts

Disadvantages

- Easily gets hot after prolonged use

- Exposed blades have the risk of injury or accidents

- Dust and water resistant

VII. Jigsaw

A jigsaw is a powerful tool commonly used to cut curves, shapes, and intricate designs in various plastic, metal, and ceramic materials. It consists of a reciprocating blade that moves up and down rapidly, allowing it to cut through the material quickly.

Jigsaws are suitable for cutting metal pipes and tubing, although the specific type of blade needed will depend on the thickness and hardness of the metal. Blades with more teeth per inch (TPI) are better suited for cutting thinner materials, while blades with fewer TPI are better for thicker and harder materials.

Jigsaws are like reciprocating saws with the difference in their blade thickness and how they move. Unlike the push-pull motion of the reciprocating saw blades, jigsaw blades move up and down. That gives precise curved cuts.

Here is a comparison table of jigsaw and reciprocating saws to help you understand how both work.

Safety Tips to Use Hand and Power Tools to Cut Metal Pipes and Tubes

Working with metal pipes and tubing can be hazardous if safety precautions are not taken. Here are some comprehensive safety tips for using power and hand tools to cut metal pipes and tubing:

- Wear Personal Protective Equipment (PPE): Always wear appropriate PPE such as safety glasses, gloves, hearing protection, and a respirator mask. It will protect you from flying debris, sparks, noise, and harmful fumes.

- Choose the Right Tool: Select the right tool for the job. Different cutting tools, such as saws, cutters, and grinders, are used for different purposes. Use the tool that is most appropriate for the material and task at hand.

- Check Your Equipment: Inspect your equipment for damage or defects before starting any job. Ensure the metal cutting blade or wheel is sharp and in good condition. Replace any damaged or worn-out parts before use.

- Secure the Workpiece: Ensure the workpiece is securely clamped in place before cutting. This will prevent it from moving or shifting during the cutting process.

- Clear the Workspace: Clear any clutter or debris before starting. This will prevent any tripping hazards or interference with the workpiece.

- Follow Safe Cutting Procedures: Always follow safe-cutting procedures. Keep your hands and fingers away from the cutting area. Never force the tool through the material. Let the tool do the work.

- Control the Cutting Tool: Always keep control of the cutting tool. Maintain a firm grip and always keep both hands on the tool.

- Watch for Sparks: Sparks are common when cutting metal. Be aware of where the sparks are flying, and ensure they are not igniting any flammable materials in the workspace.

- Use Proper Dust Collection: Metal dust and debris can be harmful if inhaled. Use proper dust collection methods such as a vacuum or exhaust system to remove dust and debris from the workspace.

- Know What to Do in Emergency: Always be prepared for emergencies. Keep a first aid kit nearby and know how to use it. Know the location of emergency exits and fire extinguishers in case of a fire.

Benefits of Laser Cutting Machines

Precision cutting: Laser cutting machines use computer-controlled precision to cut through metal pipes and tubes. It means that the cuts are incredibly accurate, which reduces the need for additional finishing work and produces higher-quality end products.

Speed: Laser-cutting machines can cut through metal pipes and tubing much faster than power tools. It reduces production time and can increase output, which is particularly important in industries with high demand and tight deadlines.

Versatility: Laser cutting machines can cut various shapes and designs into metal pipes and tubing. It means they can be used for various applications, from simple cuts to complex designs.

Safety: Laser-cutting machines are designed with safety features that minimize the risk of injury to the operator. Unlike power tools, the operator does not need to come into direct contact with the cutting surface, which reduces the risk of accidents.

Cost-effectiveness: Although laser cutting machines are generally more expensive than power tools, they can be more cost-effective in the long run. That’s because they require less maintenance and produce less waste than power tools, which can save money on repair and disposal costs.

Final Words

In conclusion, cutting metal pipes and tubes can be challenging, but it can be done easily and efficiently with the right tools and techniques. Power tools such as saws and grinders can provide a cost-effective solution for cutting metal pipes and tubes for home projects or small workshops.

Laser cutters offer a more advanced solution for cutting metal pipes and tubes, with the ability to create intricate cuts and designs easily. However, laser cutters can be more expensive and require specialized training to operate safely.

Boost Your Metal Cutting Capabilities with Our State-of-the-Art Laser Cutting Machines!

Baison offers state-of-the-art laser cutting machines that utilize advanced laser technology to precisely and efficiently cut metal pipes and tubing, providing superior results with minimal waste. Whether you’re working on a small-scale project or a large-scale production line, our laser-cutting machines are designed to meet your demands and streamline your workflow.

Don’t settle for less-than-perfect results and wasted resources. Invest in our reliable and efficient laser-cutting machines today and take your metal-cutting capabilities to the next level. Contact us today for a free evaluation of your needs, and let our expert team recommend the perfect laser system.