Pipe-cutter tools range from the machines expert plumbers use to simple hand-held devices. This guide will explain the various types of pipe cutters, which machine is best, and why you should go for them.

What Is Pipe Cutting?

Pipe cutting can be defined as the process of cutting pipes with a machine without spoiling their shapes or distorting their features. This is because a tube that has had its form distorted or deformed is useless for use as it may or can fit appropriately into what it was cut for with other fittings or pipes.

Home improvement enthusiasts, construction workers, and plumbers use several hand tools and larger machines to cut pipes. You may have heard of pipe cutting as pipe profiling.

This process also involves removing a targeted portion of a pipe to ensure that it is joined with another fitting or pipe. This process is usually done by welding. Tube cutting usually employs pipe cutters that rotate and cut around the pipe’s radial point.

The pipe cutter machine is clamped on the pipe at the desired cut location of the tube while a screw control continues to apply pressure on the blade. After several turns and revolutions, the tube is cut to produce dished ends without being crushed and having their shape still together.

For larger pipes, they may be cut by automated pipe-cutting machines.

Pipe cutters are machines used to cut or slice pipes and are commonly used by plumbers for efficiency and reliability.

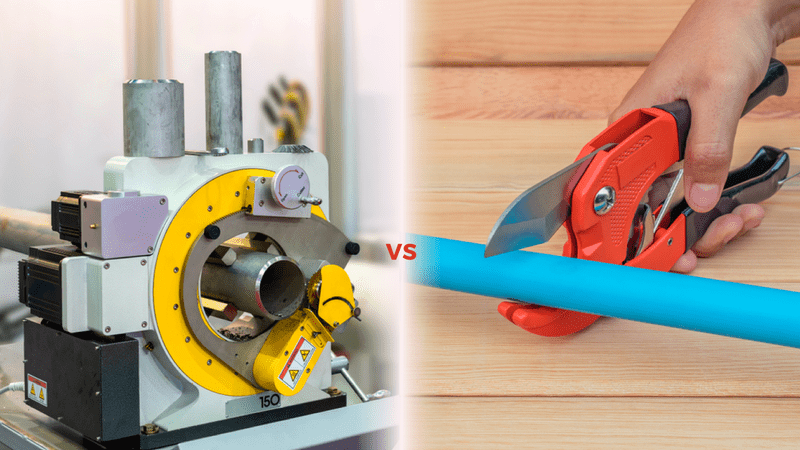

Not only do pipe cutters give efficient, professional-quality, and clean cuts, but they are also much easier, faster, and more convenient than blades, saws, and hacksaws. There are two major types of pipe-cutting machines, namely, manual and automated pipe-cutters.

What Is a Manual Pipe Cutting Machine?

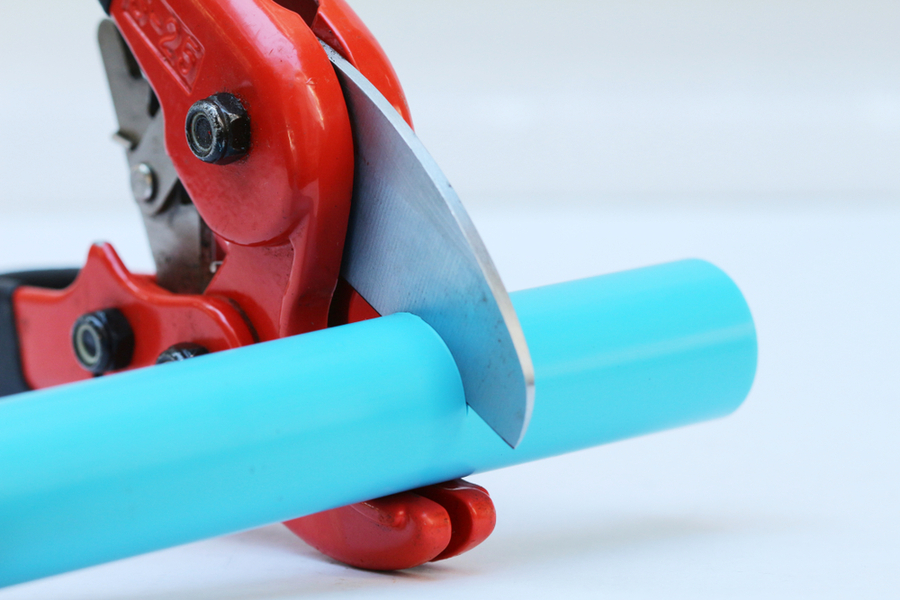

Manual pipe-cutting machines, also known as manual pipe cutters, are simple operational, and easy to use. They are cutters with high hardness, long service life, and are durable.

Manual pipe cutters are pipe cutters that can cut all kinds of pipes, such as plastic, soft metal, and pe pipes. The manual pipe-cutting machines are suitable for efficiently cutting thin-walled steel pipes, aluminum tubes, and copper pipes.

What Is Automated Pipe Cutting?

Automated pipe-cutter distinguish from a manual pipe-cutter with a much better and professional-quality cut and higher cutting speed.

The automated pipe-cutting machines are available in different sizes depending on the electric drive versions, integrated process chain, cam modules, material costs, isolated elements, manual drive versions, and pipe diameters. An automated pipe cutter can cut more than one pipe simultaneously.

Advantages and Disadvantages of Manual Pipe-Cutting Machines

Advantages

- It saves time and does not require professional help, as it is easy to use.

- It helps save money as you do not need to pay professionals to help with the automated pipe-cutters.

- It is very safe to use, and it is created for easy use.

Disadvantages

Manual cutter machines have numerous advantages, but that does not mean any disadvantages. Compared to automated pipe cutters, there are several disadvantages to manual pipe-cutters.

- It cannot cut considerable lengths of tubes, huge ones.

- It cannot be customized to fit any size and shape.

- It is not that versatile and is not that flexible.

- It is expensive and can bring inconvenience to future maintenance.

Advantages and Disadvantages of Automated Pipe-Cutting Machines

Advantages

There are several benefits to an automated pipe cutter

- It can cut through any length of tubing, especially the larger ones.

- It can also be customized to fit any shape and size.

- It is flexible and more versatile than a manual pipe-cutter.

- It gives professionally accurate and clean cuts to all pipes.

Disadvantages

Although there are numerous advantages of automated pipe-cutters, there are also disadvantages. Some of these disadvantages include the following:

- Expertise is needed as specialized and professional operators are necessarily required to carry out any task related to the cutting of tubes.

- There is exposure to dangerous fumes. This is due to the thermal cutting method that makes the materials cut faster.

Applications of a Manual Pipe-Cutter

Select the model according to the pipe diameter that must be cut. When fixing the manual pipe cutters, you should consider the tightness moderate and the four cutting knives in good contact with the pipe’s outer wall. The applications of a manual pipe-cutter include the following:

- It is used for industrial applications.

- The machine is used to cut plastic tubes.

- The device is quite helpful for small and medium-scale businesses.

- It is also used for repairing and maintaining tubes around the house or companies and for DIY projects.

Applications of Automated Tube Cutting machines

Everyone can benefit from the numerous applications of automated pipe cutters, from large-scale manufacturing industries to small businesses. Areas of application include the following:

- High-volume production of professionally cut pipes in industries that require the cutting of different tubular materials.

- Consistency, accuracy, and safety of pipes in large quantities for upstream and downstream workflows.

- Micro-cutting and clear-cutting of complex tube sizes and shapes.

- Accurate and high-precision cutting of metal parts.

- Micro-cutting in the manufacturing of high-tech products.

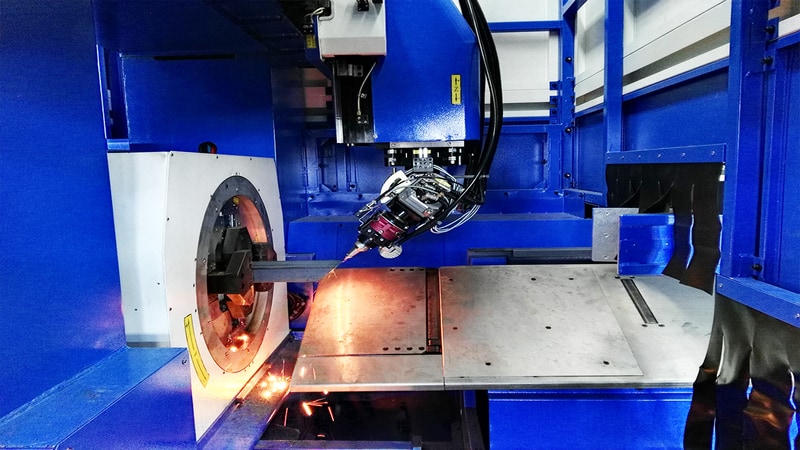

- Thermal cutting machines help laser pipe cutters do their work with efficiency.

- Compatibility with numerous materials.

- Suitable for bulk production, and no tool replacement is required.

The Differences Between Manual and Automated Tube Cutters

| Manual Pipe-cutting Machine | Automated Pipe-cutting Machine | |

| Cost | In the short-run manual pipe-cutting machines are cost-effective | In the long-run manual pipe-cutting machines are cost-effective |

| Accuracy | There is a threat of operator error | Automation gives better accuracy |

| Time | With bulk manufacturing or production, more time is used | Lesser time is needed for more production of cutting pipes |

| Safety | Pretty safe to use | Professionals have to be trained on how to use them better |

Before one can choose between a manual and an automated pipe-cutter for their use, certain factors should be considered. These factors include cost, accuracy, efficiency, and safety differences.

Cost

A manual pipe cutter is cost-effective if you require it to be completed in the short term. However, if your part is complex and needs other parts, it may require custom tooling as it is an advanced manual machine.

The efficiency of automated pipe-cutter results in shorter running times and saves production costs. For example, the ability to take several production steps at once keeps one from the costs of transitions reducing labor costs and others.

Accuracy

Operator errors are a significant threat when cutting with a manual pipe cutter. This is because producing quality and accurate cuts depends on the operator’s skill level. With an automated pipe-cutter, you get better accuracy as it is automated.

Time

Undoubtedly, an automated pipe-cutter reduces the time and improves lightning-fast efficiency, such as quick setup, shorter cycle times, faster throughput, and fast changeovers to produce so much in so little time compared to manual pipe cutters.

Safety

The automated process not only helps save time and cost, but it is also much more accurate when compared to manual cutting, making the repeatability and reusability faster and making the process safer.

How to Choose the Right Pipe-Cutting Method?

Pipe cutters are easy to use and can be used to cut whatever pipe you have to cut.

Factors to Consider

Factors to consider when choosing the right pipe-cutting method to use are the cost, the efficiency, the quality of the cuts, the safety, how it is significantly reducing production time, and the accuracy at which it cuts. Considering all these would help you choose the right pipe-cutting method to use.

Customer’s Specific Needs

In choosing the suitable pipe-cutting method, your specific customer needs should also be considered.

Fiber Laser Cutting: This is one of the best ways to cut pipes and tubes. A focused laser beam helps to cut the tubes or pipes accurately by producing heat. This method is best used for shape, pipe-through, and angular cutting.

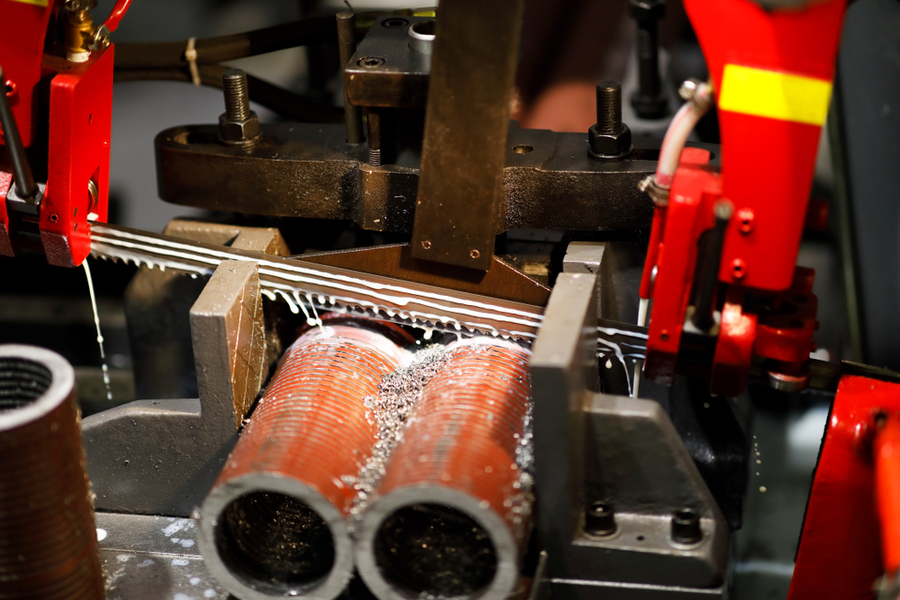

Cold Saw Cutting: In this method, the tubes and pipes are cut with the help of rotating cold saws.

Bandsaw Cutting: The pipes are cut using a perfect band blade with sharp teeth.

Abrasive Cutting: Here, pipes are cut with the help of an abrasive pipe cutter and abrasive saw equipment. The friction and shearing force will enable the rotary abrasive saw cut the tube to the length desired.

All you need to do is look into the basics of the processes of pipe-cutter machines, the types of pipes you need to cut and the different pipe-cutting methods, the advantages and disadvantages of both, and their differences.

Conclusion

Depending on the texture of the pipe, the size, the shape, and the environment in which the pipe cutter must be carried out, you can select the tube cutter you need. In addition, it is also essential to consider the safety and health of the operators in your services and the surrounding.

Baison has more than twenty years of experience in this industry. The products are cost-effective, and the after-sales service is perfect. If you need free application evaluation services, contact us today!