Laser-cutting machines are a revolutionary tool for efficiently cutting various materials. Its extraordinary precision allows you to achieve perfection in your designs. Despite its effective cutting, several misconceptions are hindering its extensive usage. Addressing these myths enables businesses and cutting shops to add this advanced technology to their cutting floors.

In this blog post, we’ll uncover some common myths about laser-cutting machines. So, let’s dive into it.

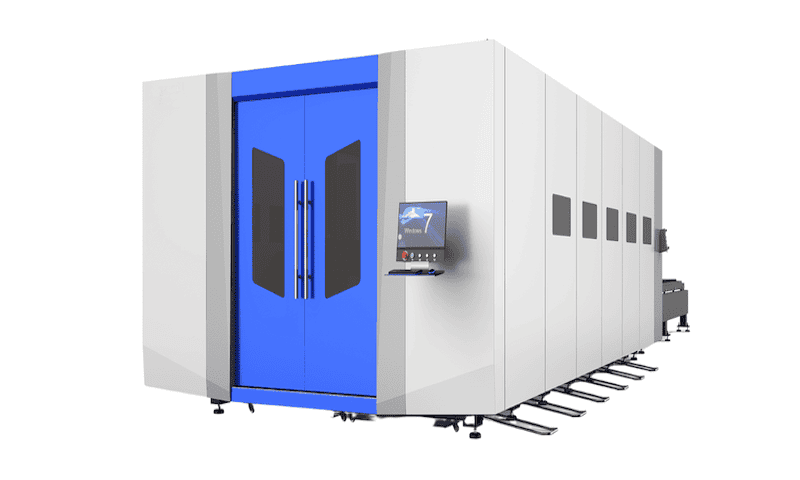

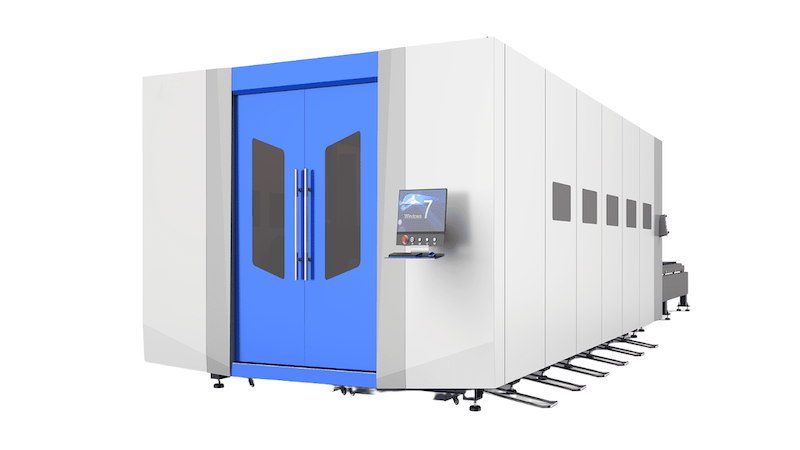

What is a Laser Cutting Machine?

A laser cutting machine is a specially designed instrument that employs high-intensity laser beams for cutting various materials, including wood, leather, acrylic, and metals.

According to the TWI, the laser beam is generated due to the stimulated emission of a lasing material via an electric discharge or lamps in an enclosed container. This laser beam melts and vaporizes the material, creating a clean and smooth cut.

Computer-aided design (CAD) programs allow you to create your desired pattern. These designs are fed to a computer numeric control (CNC) system. CNC system, along with laser optics, directs a laser beam according to your design path. It allows you to create intricate designs with smooth edges accurately.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Myth 1: Laser Cutting Machines are Difficult to Operate

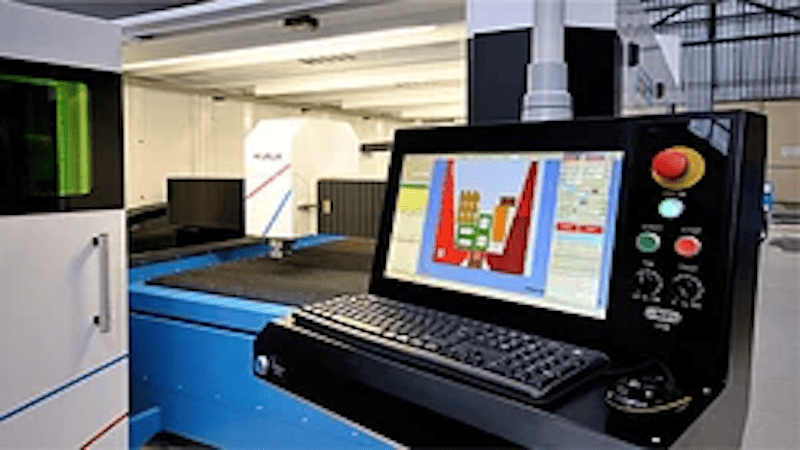

Many people consider laser cutters a complicated machine that requires technical skills and extensive training for operation. However, this is not true. Modern laser-cutting machines come with a simplified user interface. Their intuitive controls and automated features are user-friendly, allowing you to streamline the cutting process.

Moreover, tutorials and online training programs are available. These tutorials assist beginners in understanding the features of laser cutters. They can conveniently learn to operate this machine and become adept in cutting various materials with it quickly.

Myth 2: Laser Cutting is Expensive

Another common notion about laser cutters is that they are way too expensive and require considerable investment. However, modern laser cutters have high purchase and installation costs. However, they are cost-effective and offer you several benefits in the long run. They offer precise results with minimal material wastage that traditional cutting machines can’t provide.

In addition, a laser cutter’s high power and speed contribute to boosting productivity with minimum labor. Moreover, advancements in laser technology are leading to the manufacture of affordable laser cutters accessible to small businesses and industries.

Myth 3: Laser Cutters Require Constant, Expensive Maintenance

It is another prevailing misconception about laser cutters. Many people think that laser cutters require a lot of effort for maintenance. However, technological advancement has made laser-cutting machines easy to maintain.

Unlike traditional machines and tools that require frequent maintenance or replacement, a laser cutter can be maintained with a few manual adjustments. Its computer control also allows you to program and operate the machine conveniently.

Modern laser systems come with internal sensors that constantly monitor the temperature, fluid level, and output power. Its motion systems offer internal lubrication, preventing frictional damage. The pressurized beam below monitors the leakage in the system.

In addition, a modern PC attached to the laser cutter comes with numerous sensors and controls to assist you in troubleshooting. The PC also conveys information about faults in simple English instead of complex codes. It allows anyone to understand the defect and fix it instantly. Moreover, routine maintenance of laser machines doesn’t require hours. Your in-house technicians can easily handle those maintenance tasks.

Myth 4: Fiber Lasers are Better Than CO2 Lasers

Many believe a fiber laser is superior to a CO2 laser cutter. People have this notion as fiber lasers are the latest technology and are rated at higher wattages than CO2 lasers. However, this is just a misconception.

Both laser cutters are designed for a particular purpose. The high wattages of fiber lasers make them a suitable tool for cutting metal sheets in metal fabrication. However, they are not the best option for cutting organic materials like acrylic or wood.

A CO2 laser cutter enables you to cut organic materials without damaging them. The flexible application of CO2 lasers makes them a better option. So, Don’t focus on the wattage rating while picking the right laser cutter for your needs. Instead, focus on the intended purpose and power efficiency of the laser.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

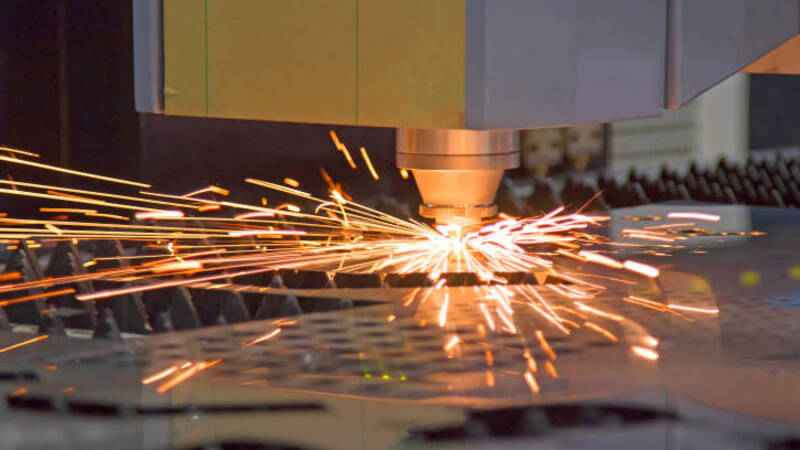

Myth 5: Laser Cutting Machines are Dangerous

Many operators new to laser cutting are concerned about its hazards. Fire and injury risks are among the primary concerns of most people opting for laser cutters. However, lasers generate a controlled amount of heat, focusing on a specific area. It is unlikely to cause ignition. Unlike other traditional methods, laser cutters also prevent the charring of several materials. It leads to smooth and clean cuts.

Modern laser cutters are also designed to prevent hazardous effects. Safety features like interlocks, protective housing, and fume extraction systems significantly reduce the potential risks. Safety measures can also prevent injury, fire, and other potential hazards. Moreover, adhering to the manufacturer’s guidelines ensures safe operations.

Myth 6: Laser Cutters Can Cut Any Thickness of Material

It is another common notion about laser cutters that mislead people. Many people purchase laser cutters with this belief, but it’s incorrect. Laser cutting machines are designed to cut thicker materials that traditional cutters can’t slice. However, laser cutters also come with some limitations. The thickness a laser cutter can handle depends on laser power.

The cutting capacity of a laser cutter also depends on the material type of your workpiece. Laser cutters can be used for several materials, including wood, acrylic, leather, and metals. However, some materials release hazardous fumes when interacting with laser beams. Fiberglass, epoxy, and some types of plastic are not suitable for laser cutting.

Moreover, thick materials are often hard to cut. According to the Defense Technical Information Center, laser cutters can conveniently cut thinner materials. Most laser cutters come with a range of thicknesses they can cut. Thick stainless steel sheets can’t be cut through all types of laser cutters. You need a high-power laser cutter to cut intricate designs and patterns in the stainless steel.

Myth 7: All Laser Cutting Machines are the Same

Consumers who are new to laser cutting technology and lack knowledge of laser machines consider all laser cutters to be the same. It makes them choose the wrong cutter for their business.

Laser-cutting machines come with different features. Variations in features of a laser machine vary the quality of the beam it creates. Power, speed, and focus of the laser are prominent features affecting the quality of the laser it offers and impacting the results it produces.

In addition, you also need to pay attention to the ease of operation it offers. Some laser cutters have complicated operating systems, requiring technical skills for troubleshooting. You need to hire experts for smooth operations. So, choose the laser cutter wisely to achieve the desired outcomes.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

FAQs

1. What are the problems with laser-cutting machines?

Operating laser-cutting machines can be challenging. You might experience poor cutting if you have not adjusted the laser parameters. It might leave a burr on the workpiece, which are hard to eliminate. It results from the improper focus of the laser cutter on the workpiece. Moreover, sometimes, the laser machine fails to emit light due to malfunctioning of the machine.

2. What is the main disadvantage of laser cutting?

Laser cutting has some downsides. One is the thickness limitation. Laser cutters can cut materials up to a particular thickness. In addition, laser cutters can’t cut all materials. Some materials generate harmful fumes when they come in contact with a laser beam. Moreover, laser cutters require considerable upfront costs.

3. Which material should never be cut by laser?

Not all materials are suitable for laser cutting. Polypropylene, polystyrene, fiberglass, coated carbon fiber, and ABS shouldn’t be cut through a laser beam. Polypropylene and polystyrene catch fire, while fiberglass, coated carbon fiber, and ABS release harmful fumes when interacting with a laser beam.

Conclusion

Laser-cutting machines are revolutionizing technology that can boost your business. Its unique features and precise cutting process allow you to fabricate desired products with clean cuts. Misconceptions about laser systems are the major reason numerous businesses can’t adopt this innovative technology. Addressing the myths and determining the truth behind them can help you make the right decision.

Understanding the capacity and operations of this machine enables you to leverage it to boost productivity and reduce material wastage. Moreover, having the right laser cutter is also necessary.

Unleash the Potential of Laser Cutting Machine with Baison Laser!

Laser cutting is an extensive industry, with several brands advertising their laser cutters. Choosing the right tool is necessary to achieve the best results. Baison Laser is one of the top laser cutter providers. Its durable laser-cutting machines enable you to cut various materials quickly. Contact us today to get a new laser-cutting machine. Our experts will guide you in getting the right laser cutter for your needs.