Leather is a versatile material that is employed to fabricate clothes, shoes, and numerous accessories. Traditional methods for cutting leather are inefficient and require skillful artisans to cut out intricate patterns laboriously. However, the advanced laser technology allows you to cut and engrave leather more conveniently.

In this blog post, you’ll explore cutting leather with a laser machine. You’ll also learn about the benefits and types of leather you can cut with a laser.

Overview of Laser Cutting Technology

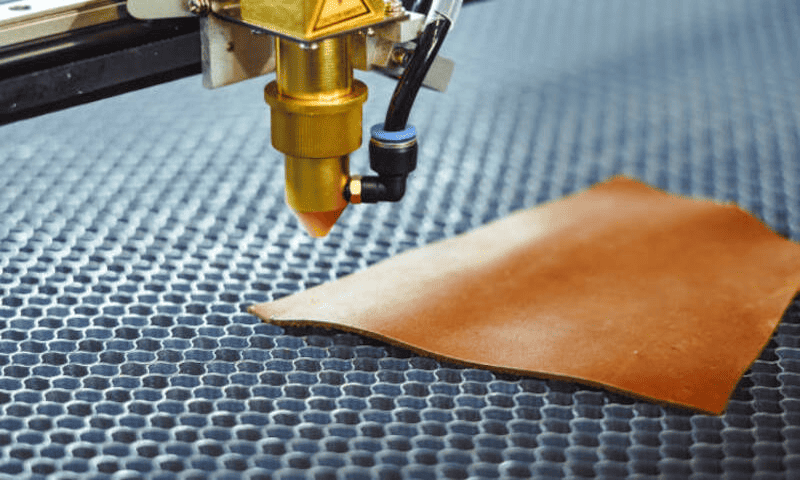

Laser cutting is a revolutionizing technology in the leather crafting industry. The laser-cutting machine generates a fine laser beam that instantly melts and vaporizes the materials. The beam is guided by various lenses and computer numerical control (CNC) technology to achieve precise and accurate cuts.

A laser source emits a laser beam that passes through several lenses that boost its energy. The laser beam also becomes monochromatic before leaving the laser container. According to the TWI, the diameter of a laser beam is 0.32 mm, and its kerf width is 0.10mm at the narrowest point.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Benefits of Laser Cutting Leather

Leather cutting with laser is a precise technique that benefits leather goods manufacturers. Here are some prominent advantages of employing laser cutting for crafting leather products:

1. Improved Quality

Laser technology offers you precise control over the cutting process. Unlike traditional methods that rely on the skills of crafters, laser cutters are guided by computer software. The software lets you create a design you want to cut or engrave on the leather. The computer-aided laser beam follows the path and curves created in the software. It allows you to cut intricate patterns and detailings without any hassle.

Moreover, leather laser engraving and cutting use the contactless approach. It limits the physical contact of the laser cutter with the material. It minimizes the risks of damage to the material, giving you fine edges and clean cuts.

2. Customized Designing

Creating designs and intricate details over leather is a daunting task. A slight mistake can leave you with an imperfect finish.

However, computer-aided laser cutting can help you diversify your projects. You can create customized designs, patterns, and even logos with a laser beam. You can also engrave names or personalized details on wallets or purses. This customization is a valuable selling point for fashion brands.

3. Efficient Material Usage

Laser cutting significantly minimizes leather wastage during the manufacturing of various products. Unlike traditional techniques, where craftsmen manually cut every piece of leather, laser cutters employ computer software.

The software design cuts the required area, limiting the risks of human errors. You can efficiently utilize the material without any flaws or damage to the final product. It also boosts your productivity and saves your time and effort.

4. Versatility in Material Thickness

Laser cutting allows you to cut various types of leather. You can accurately cut delicate as well as thick leather. This versatility enables you to fabricate multiple products by using a single equipment. Moreover, it allows you to maintain the high quality of the products irrespective of the thickness of the leather you employ for manufacturing.

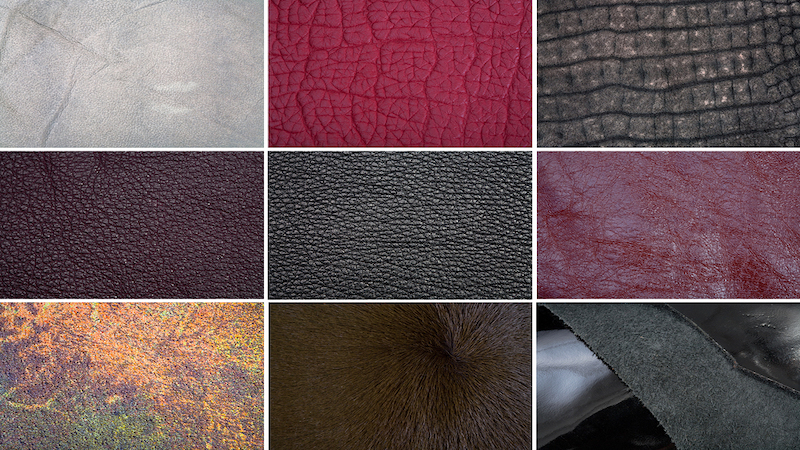

Types of Leather Suitable for Laser Cutting

You can use various types of leather for laser cutting. However, it doesn’t mean all its types are suitable for laser cutting. A few types of leather emit harmful fumes when in contact with a laser beam. The toxic fumes can deteriorate your health and damage the equipment. The following are some suitable types of leather you can laser cut:

1. Vegetable-Tanned Leather

Vegetable-tanned leather is tanned using plant-based materials like leaves, fruits, or bark. Although the process is quite slow, it doesn’t release toxic fumes or chemicals into the surroundings. It is one of the best choices for laser engraving and cutting. Its even surface allows it to absorb laser energy, leading to accurate cutting.

2. Chrome-Tanned Leather

Chrome-tanned leather is another choice for laser cutting. Chrome-tanned leather undergoes a specific tanning process using chromium salts. This process results in a more durable and flexible leather. However, chrome-tanned leather may not be the best choice when it comes to laser cutting as it contains acidic chromium salt and several chemicals. To get precise results, you need a high-end laser cutting machine.

3. Bonded Leather

This unique type of leather is manufactured by combining natural leather fibers with synthetic materials. This combination adds unique features to leather. Moreover, bonded leather is cheaper than other types of leather. It is also suitable for laser cutting and engraving processes, allowing you to create intricate designs and exclusive products.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

What is The Right Laser Cutting Machine for Leather?

Several types of laser-cutting machines allow you to cut different materials. However, you need to be cautious when dealing with the delicate nature of leather.

The size of your project, your budget, and the required precision level significantly impact the choice of laser cutting machine. The desired power of a fabric laser-cutting machine also influences this decision. Of various laser cutting machines, the wavelength and power of the CO2 laser cutting machine make it the most suitable option for laser cutting.

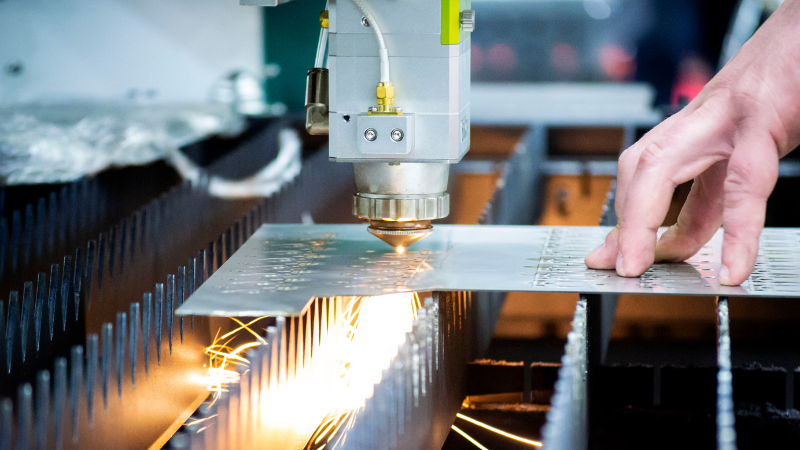

CO2 laser employs a mixture of carbon dioxide and some auxiliary gases in a gas tube to generate the laser beam. Auxillary gases include helium, hydrogen, and nitrogen. Light is emitted when electricity is passed through the gas tube. The light is transformed into a high-intensity laser beam as it passes through mirrors. According to SignMasterSystems, the laser emitted from the leather laser-cutting machine has enough heat to cut hard materials, including leather.

The wavelength of CO2 is around 10.6 micrometers. Organic materials readily absorb this wavelength. It enables you to manufacture multiple products from natural materials.

How to Laser Cut Leather?

Cutting leather by using laser cutters is a straightforward process. The following are the steps involved in leather laser cutting:

1. Create a Design

You need to prepare a design before operating a laser-cutting machine to cut leather. You can use a CAD program or graphic designing software, like Adobe Illustrator.

The design elements you prepare should be equal to or larger than the thickness of the leather piece. It prevents the leather piece from tearing. You can create intricate designs or simple geometric patterns for your laser-cutting process. After preparing the design, import your design to the laser cutter software.

2. Prepare Your Leather

Leather has several types, each with unique characteristics. Some leather types contain chemicals that can create toxic fumes when undergoing laser engraving or cutting.

After ensuring your workpiece is safe to laser cut, secure it with clamps on the cutting table. Avoid any wrinkles or folds in the leather that may cause uneven cuts or burns. Moreover, your leather should be aligned with the laser head and cutting table.

3. Adjust the Laser Settings

Perform a test run to learn about the right setting for your leather. It will help you identify the optimal settings for your workpiece. Adjust the focus, power, and speed of the laser cutter. These are crucial parameters and ensure clean and precise cuts. Test the laser settings on a small scrap piece before cutting the leather.

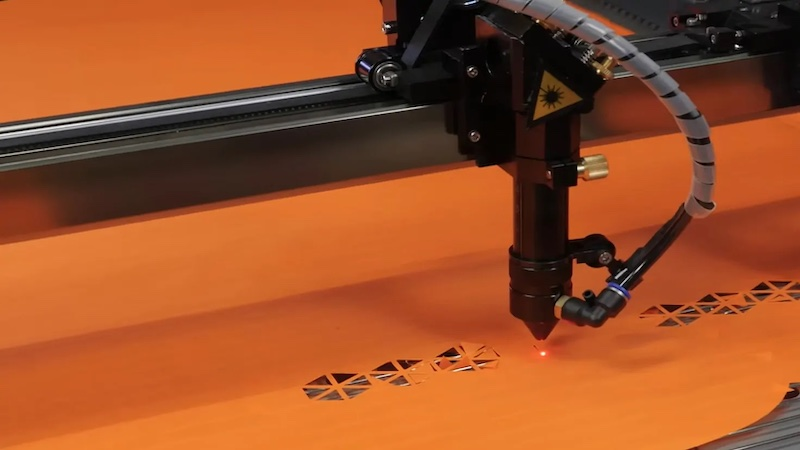

4. Cut Your Leather Workpiece

Once you have set the parameters, it’s time to cut the leather. Wear safety goggles and protective gear to avoid the hazardous effects of laser. Also, maintain a well-ventilated workstation to prevent the accumulation of toxic fumes. Operate the laser cutter, and the laser beam will follow the design you have created and cut the leather.

With regard to safety, we have prepared two articles for you to read: Selecting the Right Laser Class & Ensuring Safety, and Laser Cutting Exhaust Systems.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Optimal Settings for Laser Cutting of Leather

The test run can help you determine the right settings for your leather laser-cutting project. However, setting the following parameters can help you set the machine accurately.

1. Power

The laser power is a crucial parameter as it impacts the precision of cuts during laser cutting. Insufficient power of a laser machine leads to rough edges. Experts recommend getting a CO2 laser of a minimum of 40W power.

2. Speed

The optimal speed of the laser depends on the power of the laser-cutting machine. According to Artizono, you should maintain a speed of 12mm/s if your laser power is 40W. For a 60W laser cutter, the optimal speed is 17mm/s.

3. Focus

Laser focus is also imperative for the optimal working of a laser cutter. If you are dealing with a thick leather piece, perform multiple passes. You need to set the laser focus with each pass to encounter increased depth. Moreover, clean the focusing lens frequently to prevent the accumulation of heavy smoke.

7 Attractive Laser Cutting Leather Projects

Laser cutting is a widely adopted technique. It is employed for numerous customized projects. Here are some appealing laser-cutting leather projects you can start:

1. Personalized Leather Wallets

A leather wallet is a unique accessory. The laser cutting and engraving process allows you to add a name or a distinctive design that can make them more special. You can also engrave the interior of the wallet to make it more appealing.

2. Customize Leather Keychains

Leather keychains are stylish and versatile accessories. These elegant keychains are functional and keep your keys organized. Laser cutting allows you to create a logo or exclusive design on your keychain to add a personal touch to your accessory. You can also cut different patterns on the leather to make them more stylish.

3. Laser Cut Jewelry

Laser cutting allows you to create elegant leather jewelry pieces. With this method, you can create stunning earrings, bracelets, necklaces, and rings. The precise cutting enables you to manufacture fine pieces with smooth edges.

4. Leather Bags

Leather bags are a timeless fashion accessory used for centuries for their durability, versatility, and style. They are a staple in any wardrobe and can elevate your personality. You can accurately cut various leather panels and stitch them to create your bag. You can also engrave symbols or patterns to add uniqueness to your bag.

5. Leather Journal Covers

Many people cherish their journals. Customizing them with their name, favorite quote, or excellent design. This way, journaling becomes even more meaningful for you.

6. Custom Leather Dog Collars

Choosing a suitable collar for a dog is an essential decision for dog owners. Engraving your dog’s name, your contact details, or a design can make your dog’s ordinary collar into a memorable keepsake.

7. Engraved Leather Bookmarks

Laser-engraved leather bookmarks can be a special gift for a book lover. You can add a name, initials, or quote to make it look creative. Leather bookmarks are durable and elegant. You can use various colors and patterns to add a personal touch.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

FAQs

1. Can a 10-watt laser-cut leather?

You can use a 10-watt diode laser to cut leather. It enables you to create patterns and designs. However, a 10-watt CO2 laser machine can’t cut leather.

2. What is the best cut of leather?

Among various types of leather, full-grain leather is the best one. It is not separated from top-grain leather and split layers, which makes it the strongest and most durable.

3. Are There Any Limitations to the Colors or Textures of Leather for Laser Cutting?

Laser cutting works well on most colors and textures of leather. However, very dark leathers may not show intricate designs as clearly, and extremely textured leathers might result in uneven cuts or alterations in design visibility.

Conclusion

Cutting leather with a laser cutter is superior to crafting various products. You can start various exclusive projects with laser-cutting techniques.

Prepare a unique design for your product and use the right software to set each element. Check the manufacturer’s instructions to adjust the right settings. Also, pick up a suitable laser-cutting machine for your project. Baison Laser offers the best solutions. So, get a laser cutter for your leather cutting project and create something new.

Unleash the Potential of Leather Laser Cutting with Baison Laser!

A reliable laser cutter is necessary for cutting intricate designs and patterns on the leather. Baison Laser offers you durable laser-cutting machines. Contact us to learn about the ins and outs of the laser-cutting machines. Our experts will guide you to choose the right machine for your needs.