Have you ever looked at the intricate details of a laser-cut stone and wondered how creative the process is? This innovative technology is transforming the way we shape and utilize stones in various industries. Beyond its aesthetic appeal, laser cutting offers unparalleled precision, speed, and versatility.

This guide will talk about the A to Z of the process of laser cutting stones. It will equip you with the knowledge to successfully laser cut stones and take it as the new integration to your business. We’ll delve into the intricacies of the process, its benefits, uses, and so on.

Understanding Laser Cut Stone

Stones are often cut to improve the shine, structure, and reflection surface. In all types of industries, from construction to jewelry making, laser cutting stones and stone engraving is very popular.

A laser cutting machine utilizes a high-powered beam of light to melt or vaporize material along a pre-programmed path. This controlled process allows for precise and intricate cuts in various thicknesses and shapes.

For stone, the laser interacts with the minerals, creating clean edges and minimal dust. You can laser engrave stone and metals as it is becoming a revolutionary approach in architecture.

Benefits of Laser Cutting Stone

Compared to traditional cutting methods, laser cutting offers distinct advantages when it comes to stones. For stones, the cutting becomes more of an aesthetic inclusion than a functional one. So perfect and symmetrical cutting improves the quality of the stone.

1. Precision and detail: You can achieve intricate designs and sharp edges with minimal chipping or cracking. In traditional sawing methods, the surface of the stones gets damaged and loses its luster.

2. Versatility: When cutting stones with laser cutting machines, the possibilities are endless. You can cut a wide range of stone types and thicknesses, from delicate marble to robust granite without bringing any change to the machine configuration.

3. Speed and efficiency: When cutting with a laser, stones get additional allure and almost all the strokes are perfectly planned and executed. You can minimize production time and material waste compared to manual or waterjet cutting because of the high speed and accuracy of the laser beam.

4. Safety: The traditional ways of cutting rocks and stones pose huge risks for the operators. On the other hand, because of the high rate of mistakes and subpar output, raw materials are wasted as well. You can eliminate the risk of operator injury associated with traditional cutting tools because of laser cutting technology.

For more safety articles related to laser cutting, click on the two below: Selecting the Right Laser Class & Ensuring Safety, Laser Cutter Exhaust Systems Guide.

What is the Best Type of Laser Cutter for Cutting Stone?

The ideal laser cutter for stone depends on the specific type and thickness of the material you’ll be working with. Choosing the ideal laser cutter for stone or even a stone laser engraving machine depends on a delicate balance between stone type, material thickness, budget, and desired outcome.

1. Carbon Dioxide Laser: Carbon dioxide laser machines are ideal for cutting softer stones like marble, limestone, and slate.

2. Fiber Laser: This type of laser cutting machine is more powerful and versatile, suitable for cutting harder stones like granite and basalt.

Perhaps you’d like to know the difference between CO2 and fiber laser technology.

3. Pulsed Laser: Offers high peak power for precise, crack-free cuts in thick materials.

Types of Stone Suitable for Laser Cutting

Not all stones are created equal when it comes to laser cutting. Some, like marble and granite, are readily cut with excellent results. Others, like sandstone and limestone, require more careful consideration due to their porosity or susceptibility to heat. A laser engraver requires a certain stone porosity for the best result.

In most cases, the construction industry uses materials like marble and granite. These stones are polished, given shape, and engraved according to requirements.

Other more luxurious mineral stones like diamonds, emeralds, and rubies are used in jewelry making. These need even more careful and intricate processes. Research the specific stone you plan to use and consult with a laser-cutting expert for optimal results.

4 Steps in Laser Cutting Stone

Laser cut stones are very lucrative and a few steadfast steps need to be followed for laser cutting stones.

Step 1: Prepare the Stone

All types of stones first need to be prepared before taking to the cutting block. Ensure the stone is clean, dry, and free of cracks or imperfections. If there are any issues in the preparation process, the final laser-cut stones will have imperfections.

Step 2: Design Your Project

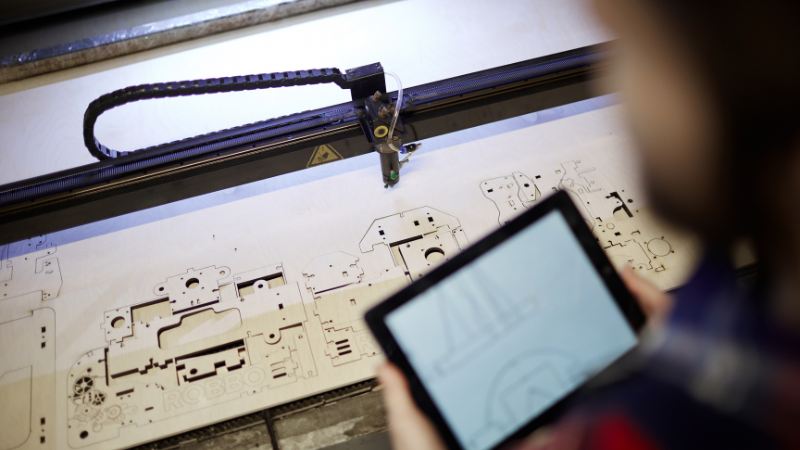

It is important to approach the whole cutting process in a systematic manner. As laser cut and laser engraved stones mainly have a lot of appeal for visual attraction, designing the project properly is a must. Create a digital file for the desired cut pattern using CAD software.

Step 3: Set Laser Parameters

All the parameters of the cutting machines relate a lot to the cutting process. How well the job is getting done depends on how well the parameters are set. Adjust power, speed, and pulse frequency based on the stone type and thickness.

Step 4: Cut and Monitor

Load the material on top of the cutting block and make sure to input the correct design. Initiate the laser cutting process and keep an eye on the progress to ensure optimal results. If the design file is inserted well, the whole process can be done automatically.

Choosing the Right Parameters for Laser Cut Stone

We have already said how important it is to set the best balance of the laser cutting parameters. If you fail to do that, the output will not be adequate and the issues may increase the costs. Selecting the correct laser parameters is crucial for achieving clean cuts and preventing damage. Experimentation and consulting with experts are key.

- Power: Higher power settings are needed for thicker stones and harder materials. But if the power is too high for the thickness of the subject material, the material will be ruined.

- Speed: Slower speeds are necessary for intricate cuts and delicate materials.

- Pulse frequency: Higher pulse frequencies reduce heat buildup and minimize HAZ (Heat Affected Zone).

- Focus distance: Maintaining the correct focus distance ensures optimal beam intensity on the stone surface.

Maintenance and Care of Laser Cutting Equipment

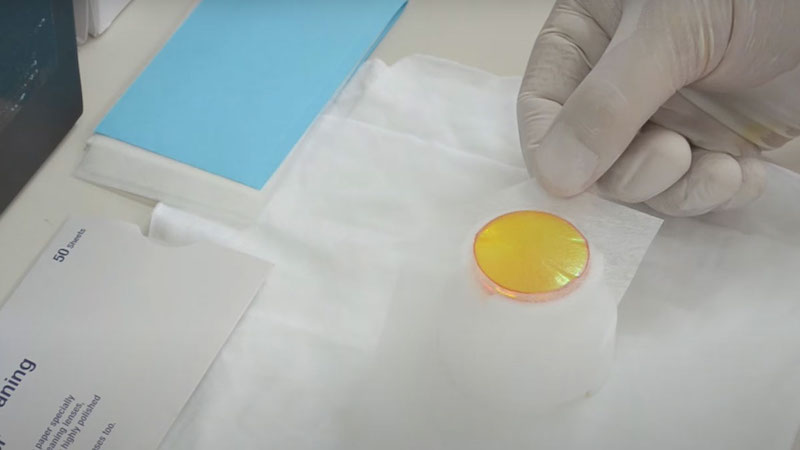

Regular maintenance is vital for optimal performance and longevity of your laser cutter. All laser engraving stones need the best-maintained laser engraving machines to find the optimum results.

- Cleaning: The lens and nozzle of the laser beam equipment need to be cleaned regularly. Remove dust and debris to maintain beam quality.

- Lubricating: All the moving parts need to be properly maintained to avoid any glitches and hiccups in the movements. Thus, the moving parts need to be lubricated. Ensure smooth operation and prevent wear and tear.

- Following recommendations: In most cases, the manufacturer provided a detailed manual on the maintenance of the laser machine. Refer to the specific manual for detailed instructions.

5 Project Ideas for Laser Cut Stone

- Decorative tiles and mosaics: Create unique and eye-catching patterns for walls, floors, or countertops.

- Jewelry and accessories: Craft personalized pendants, earrings, bracelets, and charms.

- Signage and plaques: Design elegant and durable signage for your home, business, or garden. Here, laser engraving stone is very popular.

- Sculptures and art installations: Explore the artistic possibilities of laser-cut stone with intricate designs and textures.

- Functional objects: Craft lampshades, coasters, plant holders, and other practical yet beautiful items.

FAQs

1. How much does laser cutting stone cost?

The cost of laser cutting stone depends on several factors, including the type and thickness of the stone, the complexity of the design, and the size of the project. Professional services typically charge per square inch or project basis.

2. What software is used for laser cutting stones?

CAD software like AutoCAD or CorelDRAW is commonly used to create digital designs for laser cutting. Many laser cutters also have dedicated software for importing and controlling the cutting process.

3. Are there any environmental concerns with laser cutting stone?

Laser cutting itself has minimal environmental impact. However, consider the source and lifecycle of the stone material and ensure proper disposal of any dust or debris generated during the process.

Conclusion

Cutting stones have been used since the beginning of the age when luxurious castles and mansions were being made. Marble stones, sandstones, and granite have been used widely to make buildings and add a beautiful element to any modern architectural design.

This guide has hopefully equipped you with the foundational understanding to navigate the world of laser-cut stone. At Baison, we have all the answers to your questions to help you begin. So, embrace the precision and increase your reach in the laser cutting business.

Embrace the Potential of Laser Cutting Stones with Baison Machines!

The laser technology has improved so much that there are more additions you can bring to your business. Join us today and ask any and all types of questions about laser-cutting stones. We at Baison always welcome you with all our available information and guidelines to help you become successful in this new venture.