Quick Answer: 2026 Market Price Ranges

In 2026, the cost of a fiber laser cutting machine typically falls into these ranges based on power and configuration:

- Entry-Level (1kW – 3kW): $15,000 – $40,000 USD (Ideal for thin sheets & startups)

- Industrial Standard (6kW – 12kW): $50,000 – $90,000 USD (The Baison Sweet Spot for production)

- High-Power Heavy Duty (12kW – 30kW+): $100,000 – $350,000+ USD (For thick plate processing)

Note: Prices vary by brand, exchange rates, and shipping costs.

Detailed Breakdown: Fiber Laser Cutting Machine Cost by Power

Power is the #1 factor influencing price. Here is a realistic estimate for Chinese-manufactured premium machines (like Baison) versus Western brands in 2026.

| Laser Power | Estimated Price (China Premium) | Estimated Price (European/USA) | Max Cutting Thickness (CS) |

|---|---|---|---|

| 1500W – 3000W | $15k – $35k | $80k – $150k | Up to 22mm |

| 6000W (Market Favorite) | $45k – $65k | $200k – $300k | Up to 25mm (Clean Cut) |

| 12kW – 20kW | $80k – $150k | $400k – $800k+ | 40mm – 60mm+ |

| Tube Laser Cutters | $50k – $120k | $300k+ | Variable Profiles |

>> Don’t guess. Get an exact quote for your specific configuration here.

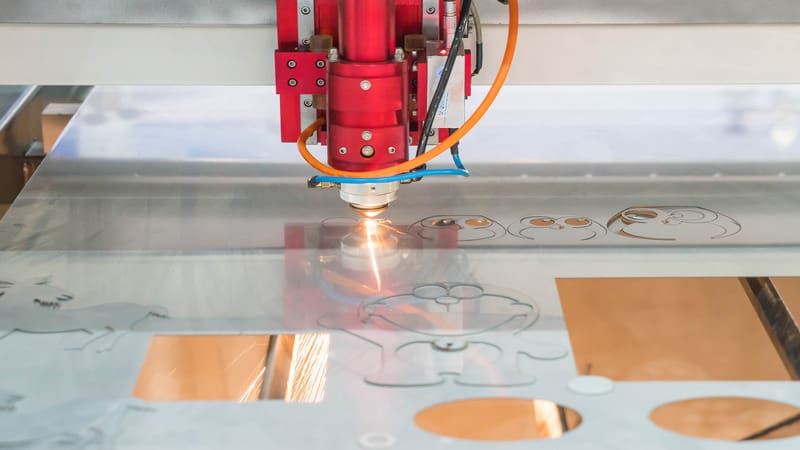

Today metal laser cutters are not limited to large industrial complexes, and many small to medium-sized businesses have adopted these machines into their workflow. Their versatility and ease of use have allowed them to gain widespread adoption.

How much does a laser cutter cost, and what type of machine best suits your production needs? This article explains the costs associated with laser cutters and gives a detailed price breakdown from small businesses to large industrial operations.

Types of Laser Cutting Machines

Laser-cutting machines come in several varieties based on size, power, application, and cost. However, the biggest differentiating factor between laser cutting machines is the type of laser used for the cutting process. There are 4 major types of lasers used in modern metal laser cutting machines.

- CO2 Lasers

- Nd: YAG Lasers

- Fiber Lasers

- Diode Lasers

Figure out what type of laser is best for cutting metal.

I. CO2 Laser Cutting Machines

CO2 (Carbon Dioxide) laser cutting machines consist of a glass tube filled with a gas mixture. A high-voltage current flows through the glass tube, exciting the gas molecules. The excited molecules radiate low-energy photons, amplified by reflectors at the edge of a glass tube. Photons repeatedly bounce across the reflectors until a powerful laser beam is formed.

The gas mixture of the CO2 laser cutter consists of several elements, including helium, hydrogen, carbon dioxide, nitrogen, oxygen, and xenon, with CO2 making up the bulk of the gas mixture.

II. ND: YAG Laser Cutting Machines

ND: YAG stands for neodymium-doped yttrium aluminum garnet. It is a complex crystal specially designed to act as a laser medium. The neodymium crystal is excited by an external source, usually a high-wattage lamp. Then similar to CO2 lasers, it is amplified using surrounding reflectors until a desired intensity is achieved.

The power output of an Nd: YAG laser cutter is primarily determined by the size of the neodymium crystal rod used as the gain medium. ND: YAG lasers are less common in industrial cutting operations and are primarily limited to skin care work.

III. Fiber Laser Cutting Machines

A fiber laser cutting machine is an industrial laser cutting equipment that uses a high-powered fiber laser to cut through various materials with high precision and accuracy. Fiber cutting machines suit thin, mild, and thick metal sheets and tubes. They are specifically good for cutting stainless steel and non-ferrous materials. With 500W plus laser power, they can cut through very thick materials.

You may want to know the difference between fiber laser and CO2 laser technology.

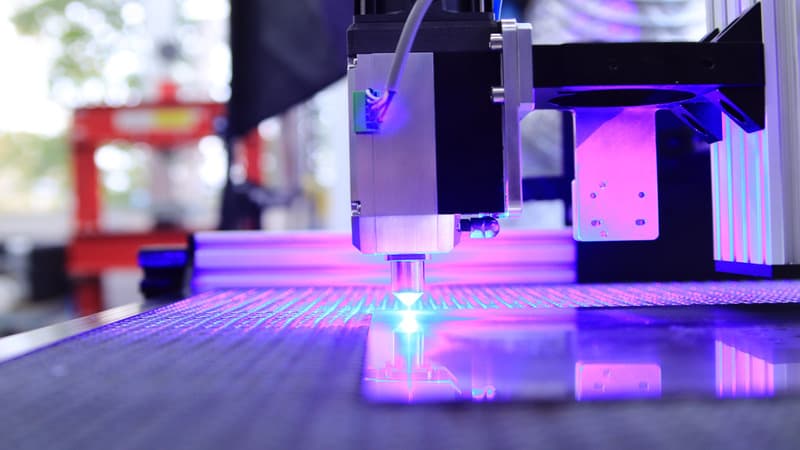

IV. Diode Laser Cutting Machines

Diode lasers are solid-state lasers using semiconductor material as a laser gain medium. They work and operate similarly to fiber and neodymium options and share many design elements.

A typical diode laser cutter is much smaller and often used by hobbyists for marking, engraving, and occasionally cutting soft materials like plywood and acrylics. Such laser cutters are not intended for heavy use and typically use cheaper optical lenses, resulting in lower cutting precision.

You can also click on this article to learn about the differences between fiber laser and diode laser.

Which Laser Cutting Machine Is Best for Your Needs?

The biggest deciding factor is material compatibility. You should choose a laser-cutting machine based on your specific material-cutting needs. Not all laser cutting systems support plastic or wood cutting, but they are still nice to have features.

CO2 laser cutter systems are designed to cut metal and non-metal options and are only incompatible with reflective metal surfaces like brass or copper. Neodymium laser cutters work best on metals and are compatible with some non-metal materials like ceramics and glass.

A standard fiber laser cutting machine is primarily aimed at metal cutting, but can also be used for laser engraving and marking plastics, rubbers, leather, etc.

Next, you must consider the long-term power cost of laser-cutting machines. Gas-powered laser cutters are generally larger, bulkier, and less efficient than solid-state metal laser cutter systems. On average, the energy efficiency of CO2 laser-cutting machines ranges between 5% to 20%.

Solid-state laser cutters like neodymium and fiber laser machines are considerably more energy efficient, typically ranging between 20% to 35%. If you’re worried about the power consumption costs of your laser cutting machines, it is strongly recommended that you pick an energy-efficient model.

Shockingly diode-based laser cutter systems are the most efficient going all the way up to 65% energy efficiency for 12-15W lasers. However, it should be noted that these systems are typically sold as laser engravers with minor cutting capabilities.

It is important to note that even the best diode laser cutter on the market is not designed to cut sheet metal. You may be able to force it to cut through very thin sheets of metal (under 0.04 in.) at a slow cutting speed, but even then, the results would be disappointing.

Use the detailed comparison table below to narrow down the most suitable laser metal cutter option for your needs.

| Laser Technology | CO2 | Fiber | Nd: YAG | Diode |

| Energy Efficiency | Lowest | Medium | Medium | Highest |

| Pricing | Low | High | High | Very Low |

| Life Span | Short | Very Long | Long | Medium |

| Precision | Low | Very High | High | Medium |

| Power Output | Medium to High | Very High | Medium | Very Low |

| Material Compatibility | Metals & Non-Metals | Mostly Metals | Mostly Metals | Non-Metals |

| Versatility | Medium | High | Low | Low |

| Applications | Metal Cutting, Metal Engraving, Non-Metal Cutting | Metal Cutting, Metal Engraving, Non-Metal Engraving, Metal Marking, Metal Cleaning | Metal Cutting, Ceramic Cutting, Medical Use | Wood Cutting, Wood Engraving, Thin Material Cutting |

Average Cost of Metal Laser Cutting Machines

A metal laser cutter can cost as little as a few hundred dollars for small hobbyist machines and go upwards of a million for industrial-grade laser machines. However, their automation and multi-axis motion are huge cost contributors for those extremely expensive machines.

All prices listed below are in USD and are subject to change after publishing this article. But overall, these numbers should give customers all the necessary information for making a good purchasing decision.

- The cheapest laser cutter is a diode-based machine at <$500. Don’t be taken in by the attractive pricing. These models are designed for plywood engraving and cutting and not for metalwork industries.

- Going up, you can find a beginner-friendly hobbyist CO2 metal laser cutter between $2,000-3,000.

- Entry-level fiber metal laser cutting machines cost $15,000. These machines are equipped with a low-power laser and will struggle when cutting metal plates (>6mm).

- At $30K-100K you are slowly moving toward professional factory equipment. A CO2-powered laser cutter, generally speaking, will be under $50k. While a fiber laser cutting machine costs upwards of that $50K mark.

- Going above $200K, you will find specialized fiber laser machines for large-scale productions or robotic arm-assisted fiber lasers for detailed custom production.

CO2 VS. Fiber Lasers

Knowing to choose whether CO2 or fiber laser technology is important. Fiber lasers are a newer technology with several key benefits, like the compact size and higher precision. A standard $15-20k Fiber laser will have a lifespan of over 30,000 hours. Contrarily a $2,500 CO2 model will only last around 2,000 hours before you need to change the laser tube.

For small business owners looking for an affordable laser cutter, a CO2-powered machine would be a decent option.

Small Machine VS. Industrial Options

A smaller metal laser cutting machine (<$50K) is designed to run occasionally for no more than a few hours a day. Such laser machines typically last a couple of years before serious maintenance is required.

Industrial laser machines (>$100K) are meant for large factories that run the machines all day without a break. The increased cost here is mostly due to the better reliability and construction of the machine that enables its extensive use.

Customized Pricing Options

All major brands offer custom quotes for their laser-cutting machines. The price for these machines will vary based on the number of units, shipping location, and additional parts requested by the buyer. You will be able to get a significant discount based on your needs.

Factors that Affect the Price of Laser Cutting Machines

Laser cutters are complex machines that can be configured and tuned to a specific production style. Following is a short list of factors that impact machine costs most.

1. Type of Laser

The importance of a good laser source in your metal laser cutter should not be underestimated. A fiber laser cutting machine is approximately ten times more expensive than a CO2 one. But it is also more energy efficient and has a higher laser power configuration in a smaller size.

2. Power Output of Laser

As you increase the power output (wattage), Lasers become increasingly difficult to manufacture. Hence, you will see an exponential increase in price as you move from low-power laser cutters to higher ones.

Laser engravers start at the lower power option, around 1-5W. For sheet metal fabrication, you need at least 50W, irrespective of the laser source. You will need to move to kilowatt lasers to cut different materials like thick stainless steel.

3. The precision of Laser

The precision of a laser is measured as spot diameter. A smaller laser spot will lead to precise cuts and higher cutting speeds. CO2 lasers have a spot diameter between 0.01 in. (~250 microns), while fiber lasers can go as low as 0.001 in. (~25 microns). Higher precision lasers require robust and expensive optical components.

4. Machine Size

Like all machines, larger ones are more expensive. The size of their work bed limits all laser cutters. You can process large metal sheets and cut more parts with larger beds. Another big cost contributor for larger machines is their shipping costs due to the increased size and weight.

5. After Sale Services

Once you buy a complex machine like a laser cutter, you can run into various operational issues. Your machine could be damaged in shipping or have a defective servo motor. You need a trustworthy and reliable after-sales service to help you get your machine up and running during those critical moments.

It is important to buy from a reputable seller willing to help you even after making a sale. After-sales services can include some of the following options.

- Customer Support for Initial Machine Setup

- Machine Operator Training

- Diagnostic Help

- Sale of Replacement Parts

- etc.

Most manufacturers offer after-sales services for free. However, some might charge you extra.

Benefits of Owning a Metal Laser Cutting Machine

The price of a good laser cutting machine can seem a lot at first glance. And many of you might opt for a metal-cutting service provider instead of buying your own machine.

Although metal cutting services can be a viable option for some, most people should consider buying their own metal laser cutter as it offers significant benefits for their business.

Following are a few key benefits that owners of laser cutting machines enjoy.

- Flexibility

- Versatility

- Lower Production Costs

- Reliability

Having a laser cutter on hand will help run the production process more smoothly. You know the number of laser-cut parts that can be produced daily. And you don’t have to wait for someone else to start production. Additionally, the cost per part is significantly lower than metal cutting services.

Options like a fiber laser machine are small and compact enough to fit easily in your workshop. And the machine cost is low enough that you can get a return on your investment within a year.

Top 10 Metal Laser Cutting Machine Brands

Here is a brief list of the top metal laser machine brands that sell to a global market.

- TRUMPF – Trumpf is one of the industry’s leading laser and laser manufacturing tool providers. They offer several manufacturing tools but specialize in laser solutions and even offer automation services. Their catalog includes fiber and CO2 cutting solutions for medium to large-sized productions.

- Bystronic – They are a large-scale multi-national company primarily focused on sheet metal processing. Bystronic sells industrial-grade fiber laser cutters with smart features and a user-friendly design.

- Baison – Baison is a fiber laser systems manufacturer operating out of China. They serve clients in over 100 countries and have a diverse catalog of laser-cutting products. Baison offers CO2 and Fiber cutting options and laser welding, marking, and cleaning machines.

- TANAKA – Tanaka is one of the oldest manufacturers of metal cutting solutions, going all the way back to 1917. In 100 years, they have gone from small-scale operations in Japan to international shipping laser, plasma, and gas metal cutting machines.

- Prima Power – Prima is another fiber laser and sheet metal solutions provider with manufacturing facilities in four countries and ships to an international clientele in over 80 countries.

- Messer – Messer is a US-based metal-cutting solutions provider. They specialize in small to medium-sized laser and plasma-cutting machines. They also provide repair and retrofit services for older cutting machines.

- Mitsubishi – They are a globally known brand responsible for a wide range of products spanning many industries. Mitsubishi has one of the largest catalogs of laser cutting solutions on this list.

- Salvagnini – Salvagnini is an Italy-based company with products aimed at sheet metal work. They only offer fiber laser machines with some minor customization options.

- Mazak – Mazak Optics is a manufacturer of fiber laser cutters primarily working in the US, Canada, and Mexico. Their manufacturing facilities are located in Parts of Asia, the EU, and the US.

- AMADA – Amada is a relatively small fabrication services and products company based in the US and operating in North America. They offer high-performance metal laser cutting solutions in fiber and CO2 varieties.

Tips on Buying a Suitable Laser Cutter

After reviewing this entire article, you have all the information required to make a well-informed purchase. However, you can never be too careful, especially if you’re a first-time buyer.

Here are four tips that will help you finalize your purchase.

1 – Choose an Appropriate Machine Size

Laser cutters always need a little extra room in your workshop for peak operation. You need enough room for decent airflow so that the laser system won’t overheat and space for machine accessories. Choose a machine size that fits your workspace and leaves plenty of room to walk around.

2 – Consider Future Operational Costs

Laser cutters can be expensive to run, and small costs will start to add up. The two biggest cost factors are power consumption which leads to excessive energy bills, and maintenance, like replacing the laser tube of a gas laser cutter.

3 – Account for Shipping Costs in Your Budget

Shipping costs can often be greater than the price of the laser cutter. Large and heavy machines cost a lot to ship around the world. This can be mitigated by buying a modest-sized machine from a company with an established global shipping network.

4 – Production Capacity

Production capacity is controlled by the laser’s cutting speed and the machine’s bed size. Cutting speed further decreases when dealing with a thicker piece of metal. Consider your production needs before deciding on a machine.

5 – Post Processing Time

Lasers can generate a lot of heat, especially when cutting thick materials at low speeds. This can cause melted metal beads to form at the edges of the work.

For more tips on choosing a CNC laser cutting machine, check out this article.

Conclusion

Laser cutters are versatile metal and non-metal processing machines that are readily available at affordable prices. However, additional features and performance capabilities can cost quite a bit. Your ideal production capacity, material choice, and power draw targets will greatly influence the final price of your laser cutter.

You can often contact sellers directly and ask for necessary additional information.

Get Your Own Laser Cutting Machine Today!

Baison is an experienced manufacturer of laser cutting machines, operating globally. Our laser metal processing systems are designed to cater to all types of industries. Baison’s diverse catalog encompasses powerful and efficient fiber and CO2 laser options.

Additional services include application evaluation before purchase and a robust customer training program to help you get started. Take your business to new heights and contact us today!