We aim to help businesses find a machine that optimizes their manufacturing process without straining budget or compromising on quality, speed, and precision. So, let’s buckle up as we delve into the intricacies of CNC laser cutting machines, their features, and how to make an informed purchasing decision.

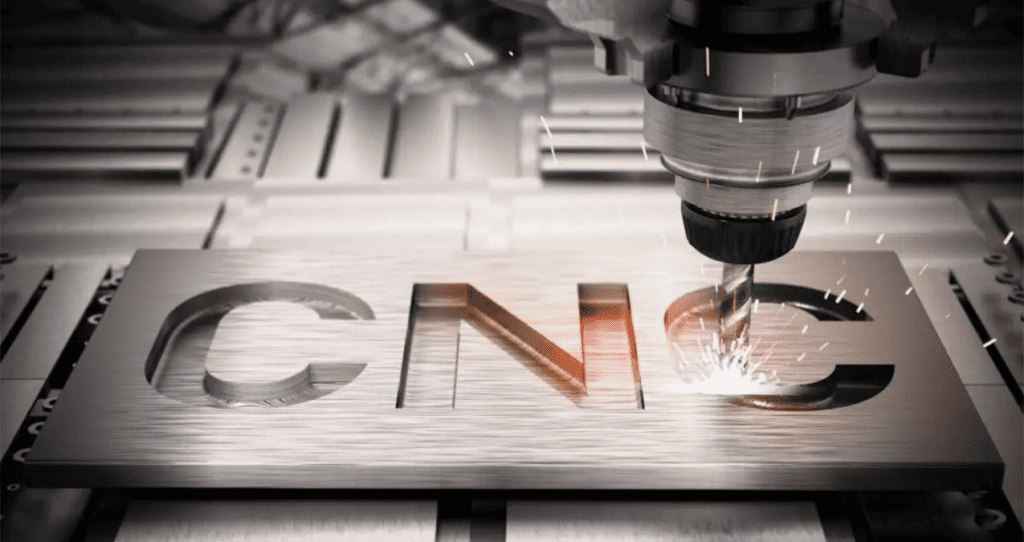

What Is CNC Cutting Machine?

A CNC (Computer Numerical Control) cutting machine is a power-driven device that cuts and shapes various materials like metal, wood, and plastic. It operates under a computer-controlled system, ensuring high precision, speed, and consistency in manufacturing.

These machines come in various forms, such as milling, laser, and plasma cutters. Among these, CNC laser cutting machines have become particularly popular due to their ability to cut complex shapes with high precision and speed, making them a top choice in many industries. As a result, manufacturers tend to cash on these modern machines’ high speeds and efficiencies.

How Do CNC Cutting Machines Work?

As we have established how CNC cutting machines became popular, it is also important to understand their working mechanism. However, understanding their operation can often be a hard-to-follow task for many business owners. But worry not even if you are not an expert in the field because we will break down this complexity into manageable steps:

- Design Phase: The process begins with designing the desired part or component using CAD (Computer-Aided Design) software. Depending on the requirements, the design can be as simple as a basic 2D shape or as complex as a 3D model. This phase is crucial as it directly impacts the precision of the final product.

- Conversion to CNC Language: Once the design is ready, it is converted into a language that the CNC machine understands – typically G-code. This language provides the machine with detailed instructions on what cuts to make, where to make them, and the speed at which to operate.

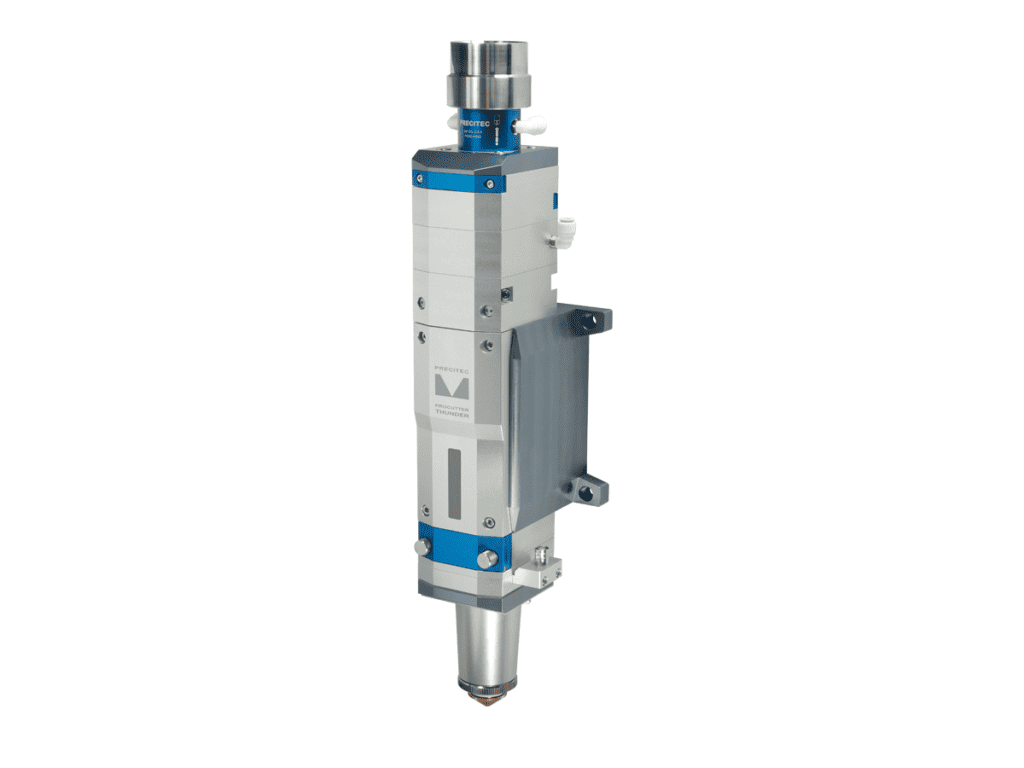

- Preparation of the Machine: This step involves setting up the machine for the cutting process. It includes selecting the right cutting tool or laser cutting head, adjusting the laser power, and ensuring that the workpiece is positioned correctly on the CNC machine.

- Cutting Process: The CNC machine now starts the cutting process as per the instructions you have given. It optimizes the cutting speed to ensure a balance between efficiency and quality. Moreover, for a CNC laser cutting machine, the laser beam precisely cuts or engraves the material, providing high precision and clean edges.

- Quality Check: After the cutting process is complete, the finished product undergoes a quality check. This step is essential to ensure that the cutting process has been successful and the product matches the initial design.

- Maintenance: Regular maintenance is necessary to ensure the machine’s longevity and consistent performance. This includes cleaning, part replacement, and checking for any potential issues that could impact the machine’s operation.

Factors to Consider When Selecting Economic CNC Cutting Machines

We always recommend business owners consider all vital factors when investing in a CNC cutting machine. It’s an investment that can significantly impact your production efficiency and overall profitability. However, the sheer number of options available in the market can make this considerably difficult. To aid you in this decision-making process, here are key factors to consider when selecting an economical CNC cutting machine:

Size

The size of your CNC machine should align with the scale of your production. Large machines are ideal for mass production but may not be the most cost-effective solution for smaller projects. Hence, always consider the size of the machine relative to your space and production volume.

Material Compatibility

CNC machines also vary in their ability to cut different materials. For example, while most CNC machines can easily cut soft metals and wood, cutting harder materials like steel may require a high-power laser cutter. Always ensure the machine you choose is compatible with the materials you commonly use.

Accuracy and Precision

The quality of your final product depends heavily on the accuracy and precision of your CNC machine. High-precision machines offer excellent quality but often come at an additional cost. Balance your need for precision with your budget constraints.

Speed and Productivity

Speed plays a crucial role in determining your production efficiency. A machine that cuts at high speed can significantly boost your production volume and reduce your turnaround time. However, don’t sacrifice quality for speed. The ideal machine offers a balance of both.

Maintenance and Repair

Maintenance costs can significantly impact the total cost of ownership of your machine. Consider machines that are known for their durability and have readily available and affordable replacement parts.

Service and Support

After-sales service, including technical support and warranty terms, is crucial. Good service can save you time, money, and potential downtime. Therefore, always check the manufacturer’s reputation for customer service.

Safety

Last but not least, the safety features of a CNC machine are paramount. Ensure the machine has adequate safety measures in place, such as emergency stop buttons and protective guards, to safeguard your workforce.

Pros and Cons of Different Types of CNC Cutting Machines

Moving on, understanding the strengths and weaknesses of different types of machines can help guide your decision-making process. Let’s delve into the pros and cons of two of the commonly used CNC cutting machines.

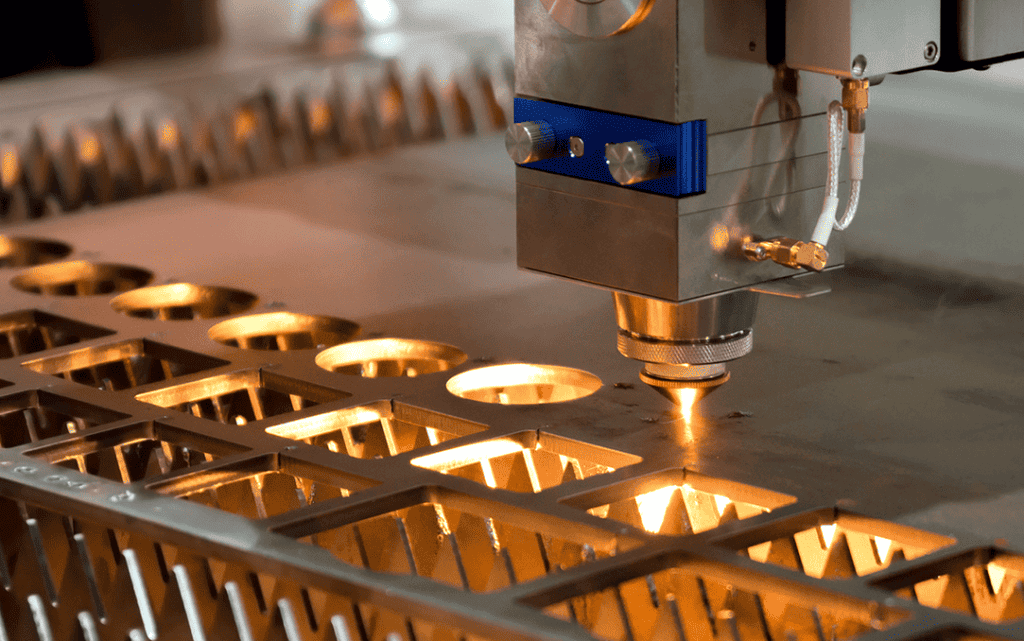

CNC Laser Cutting Machines

CNC laser cutting machines utilize high-power laser beams to cut highly precise materials. They are highly versatile and commonly used in industries such as automotive and aerospace due to their ability to accurately produce complex shapes.

Pros:

- High precision: Laser-cutting machines offer superior accuracy, able to cut intricate designs with high precision.

- Versatility: They are capable of cutting a wide range of materials, from soft metals to harder substances like steel.

- Speed: These machines often provide high cutting speeds, enhancing production efficiency.

Cons:

- Initial investment: CNC laser cutting machines can be more costly upfront than other types of CNC machines.

- Maintenance costs: The high-power laser head needs regular maintenance, which can add to the operational costs.

- Power consumption: These machines typically consume more power due to their high-speed laser equipment.

CNC Plasma Cutting Machines

CNC plasma cutting machines use a plasma torch to cut through materials like steel, aluminum, and other conductive metals. They are often used in fabrication shops, industrial construction, and automotive repair.

Pros:

- High cutting speed: Plasma cutters can cut through metal quickly, increasing production efficiency.

- Cuts thick materials: They can easily cut through thick metals, which can be challenging for other types of cutting machines.

- Lower initial cost: Plasma cutters are generally cheaper than laser cutters, making them a cost-effective choice for many businesses.

Cons:

- Lower precision: Plasma cutters typically do not offer the same level of precision as laser cutters.

- Limited material compatibility: They are best suited for cutting conductive metals and are not as versatile as laser cutters.

- Safety considerations: Plasma cutters require careful handling due to the high temperatures of the plasma beam.

CNC Water Jet Cutting Machines

CNC water jet cutting machines are a type of cutting machine that uses high-pressure water to cut materials such as metal, stone, and composites.

Pros:

- High precision and accuracy: CNC water jet cutters can cut materials with high precision and accuracy, making them ideal for cutting precise shapes and patterns.

- Versatility: CNC water jet cutters can cut a wide variety of materials, including metal, plastic, glass, stone, and composites.

- Speed: CNC water jet cutters can cut materials quickly, making them suitable for high-volume production.

- Low cost: CNC water jet cutters are often less expensive than other cutting technologies, such as laser cutting or CNC routers, making them a cost-effective solution for many industries.

Cons:

- High installation cost: CNC water jet cutters require specialized equipment and setup, which can be expensive to install.

- Messy operation: CNC water jet cutters use high-pressure water jets to cut materials, which can create a lot of mess and potential for water damage.

- Limited by size: CNC water jet cutters may be limited by the size of the cutting area, which can limit their usefulness for cutting large materials.

- Safety concerns: CNC water jet cutters use high-pressure jets of water and high-speed cutters, which can pose safety risks to operators.

Considering the pros and cons of different CNC cutting machines based on your business requirements will guide you to make a more informed decision.

Find the Way of Economical CNC Cutting Machine

Want an economical CNC Machine solution for your business? Not sure where to start?

To make the process more manageable, we’ve compiled a few strategies to help you find a CNC-cutting machine that meets your operational needs and budget constraints. Here’s what you need to do:

Online Research:

The internet is an abundant source of information, reviews, and comparisons for CNC machines. This vast resource is used to research various manufacturers, models, and specifications. Many customers have found this method useful in identifying machines that best balance cost and functionality.

Used Machine:

Purchasing a used CNC cutting machine can be a great way to save money. Pre-owned machines are often priced significantly lower than new ones, and if properly maintained, they can still offer high precision and performance. Be sure to inspect the machine thoroughly and verify its service life, maintenance history, and operational efficiency before making a purchase.

Renting or Leasing Machines:

If your business has fluctuating production volumes or limited initial investment, renting or leasing a CNC machine might be the most economical choice. This option allows you to use high-quality, high-speed equipment without bearing the full cost of ownership. However, always consider the long-term costs and the terms of the agreement.

Look for Financing Options:

Several manufacturers offer financing options for purchasing CNC machines. These arrangements can make it more manageable to acquire high-quality cutting equipment by spreading the cost over a more extended period. Be sure to understand the terms of any financing agreement, including interest rates and payment schedules.

Look for Discounts and Specials:

Manufacturers often run promotions, offering discounts or value-added services for their CNC cutting machines. Keep an eye out for these specials, as they can significantly reduce your acquisition costs. Be sure to verify that any discounted machines meet your quality and production efficiency requirements.

How to Ensure the Longevity and Performance of CNC Cutting Machines

Keep your investment safe with regular maintenance. Here are some essential tips to keep your equipment running efficiently for an extended period:

- Regular Maintenance: Routine checks and replacements of the machine parts to maintain optimal performance.

- Appropriate Use: Use the machine as per the manufacturer’s instructions to prevent unnecessary wear and tear.

- Invest in Quality Tools and Materials: High-quality tools and materials enhance machine longevity and precision.

- Train Your Operators: Regular training ensures efficient machine operation and early detection of potential issues.

- Safety First: Safety measures protect both the operator and the machine, extending the machine’s lifespan.

- After-sales Service: Choosing manufacturers with reliable after-sales service helps with the timely detection and repair of potential issues, saving you costly repairs in the long run.

Q&A: Common Questions about Choosing Economic CNC Cutting Machines

Q: Is a more expensive CNC machine always better?

A: Not necessarily. The best CNC machine for your business depends on your specific needs and production volume. An expensive machine might offer features that you may not require.

Q: How important is the service and support from the manufacturer?

A: It’s very important. Reliable after-sales service ensures your machine’s longevity and helps maintain optimal performance.

Q: Can I cut any material using a CNC machine?

A: CNC machines can handle a wide range of materials, but compatibility varies. Always double-check the machine’s specifications before cutting new material.

Q: How can I prolong the lifespan of my CNC machine?

A: Regular maintenance, appropriate use, investing in quality tools, and following safety protocols can help prolong your CNC machine’s lifespan.

Q: Can CNC machines handle complex shapes?

A: Yes, CNC machines, especially CNC laser cutting machines, can handle intricate designs and complex shapes with high precision.

Conclusion

As we conclude, it’s important to remember that choosing an economical CNC machine is not just about price but also about quality, efficiency, and after-sales service. The right machine can boost your production efficiency, save costs, and give you a competitive edge in the market. Make sure to explore our other resources on CNC machines on our website to help you make an informed decision. Thank you for reading, and we look forward to assisting you further with your CNC needs.

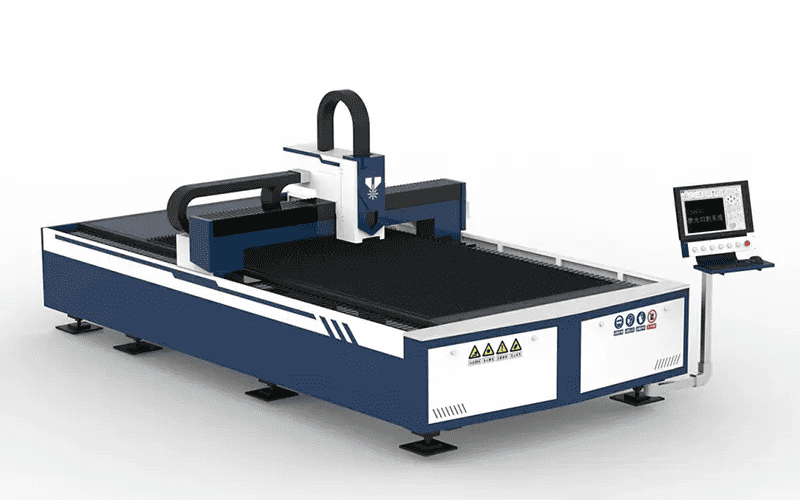

Baison Laser: Your Partner in Economical CNC Machine Solutions!

Ready to take the next step towards efficiency and cost-effectiveness? Visit our product page to explore our range of economical CNC cutting machines. Baison Laser, your trusted partner in precision and performance, is here to guide you on your manufacturing journey.