This article breaks down the basics of custom laser cutting services and compares their benefits to buying your own laser cutter.

Understanding the Custom Laser Cutting Services

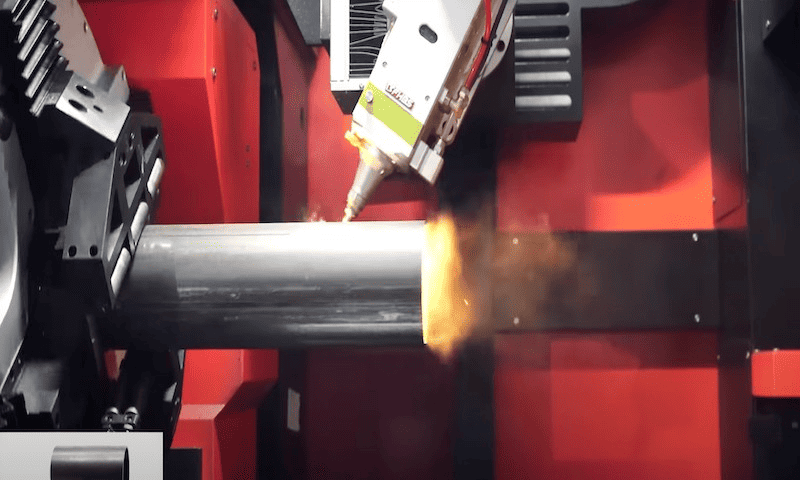

Custom laser cutting services refer to the use of a CNC laser machine to cut, engrave, and mark custom-designed parts. Traditional manufacturing services require a new set of expensive dies or molds for each design iteration. In comparison, laser cutters can quickly cut a complex design without such restrictions.

Laser cutting services are usually a business-to-business solution, where a business uses its laser cutting machines to cut and process parts for others.

Not everyone needs a fancy state-of-the-art laser-cutting machine. For most individuals and small businesses, having another company laser-cut their designs is the best option.

Benefits of Custom Laser Cutting Services

Custom laser cutting services offer a multitude of advantages to businesses, small and large. Making them a versatile and cost-effective solution for various industries. Perhaps, that’s the reason why the laser cutting market is expected to increase by USD 1.25 billion from 2021 to 2026.

From rapid prototyping to accommodating unique design requirements, the benefits of these services are substantial. Here is a short list of the many advantages of laser-cutting services.

1. Rapid Prototyping

Rapid prototyping refers to techniques used during the product development phase that result in the quick fabrication of designs and scale models. CNC is a major part of rapid prototyping, as it can swiftly transform computer designs into real, usable prototypes.

The speed, accuracy, and precision of laser cutting allow for quick design iterations and a clean surface finish, saving time on the post process.

2. Quick Turn Around

Laser cutting is a fast process. The automated high precision of a laser beam makes quick work of all materials, ranging from tough stainless steel to soft acrylic.

Traditional manufacturing limits the production turnaround times with their prerequisites. Some old processes require an investment in a die and punch before cutting starts, while others need to calibrate their machines for each material.

Laser cutting’s quick turnaround is advantageous for businesses facing tight deadlines or those requiring on-demand production. Sometimes, it takes less than an hour to go from digital design to the finished part.

3. Versatility and Flexibility

Laser cutting is a remarkably versatile technology capable of handling almost any manufacturing task. The laser beam isn’t just limited to cutting. It can engrave, mark, clean, and even weld. Most laser machines come with at least two or more of these features.

Moving on to high-end industrial solutions, premium 5-axis laser cutting machines are fully automatic and can cut even the most complex designs with relative ease.

The incredible versatility of laser cutting makes custom laser cutting services suitable for a broad spectrum of applications, from industrial manufacturing to artistic creations.

4. Wider Material Choice

What’s the point of custom laser cut parts if you are only limited to a handful of material choices? Fiber laser cutters are at the forefront of metal laser cutting but are just as good at non-metal materials like leather, wood, or plastic.

Wood laser cutting has recently become a major part of custom furniture design. From the humble plywood to the more premium birch or maple, laser cutting machines have you covered.

While there is no material that a laser cannot cut. Some require a lot of care and consideration so the material being cut doesn’t melt, burn, or release unwanted fumes.

| Material Choices for Laser Cutting | |||||

| Plastics | Metals | Foams | Rubbers | Wood | Others |

| ABS | Aluminum | Silicone | Neoprene | Softwoods | Paper/ Cardstock |

| Acrylic | Brass | Nylon | Silicon | Hardwoods | Cardboard |

| Delrin | Steel | Neoprene | Viton | Plywood | Fabrics |

| HDPE | Stainless Steel | Polyurethane | Polyethylene | MDF | Leather |

| Mylar | Titanium | Polyethylene | Natural Rubber | etc. | Carbon Fiber |

| Nylon | Tungsten | etc. | etc. | N/A | etc. |

| Polyethylene | etc. | N/A | N/A | N/A | N/A |

| Styrene | N/A | N/A | N/A | N/A | N/A |

| etc. | N/A | N/A | N/A | N/A | N/A |

Laser cut acrylic is particularly popular among product designers as it is a low-cost, lightweight material that is hard to cut with traditional solutions.

Additionally, laser cutting is preferred for materials like carbon fiber since the process doesn’t warp or destroy the sensitive fibers.

5. Low MOQ Requirements

One of the most underrated benefits of custom laser cutting is the low MOQ (minimum order requirement). Most manufacturing processes are designed for large-volume productions. This means if you only want one or two parts fabricated, you will pay through the nose.

The cost per part decreases significantly once your orders are in the range of thousands with the same design. For example, stamping sheet metal parts requires an expensive punch and die investment, paying for the machine run time and the labor cost of all workers involved.

With laser cutting, a single operator can quickly set up the laser cutter, and the machine will automatically cut up your desired designs in minutes. Thus, laser-cutting service providers have significantly lower MOQs compared to traditional manufacturing.

6. Custom Part Dimensions

No custom laser cutting service is complete without some custom, non-standard designs. Whether it’s intricate patterns, fine details, or specific part dimensions, laser cutting can achieve accuracy down to fractions of a millimeter.

Industries that deal with low-volume custom designs benefit the most from laser cutting and engraving services. The automotive industry, in particular, has so many intricate parts that can only be cut using a high-precision laser machine.

7. Online Laser Cutting Services

A big part of today’s custom manufacturing industry is online laser cutting. Users can simply upload their designs to the service provider’s website and get an instant quote. Most online laser cutting ventures also offer design insights and help new users refine their designs for free.

Upon payment, the online laser cutting services provider will cut, post-process, and ship the parts to the requested address, usually within a work week.

The lower overhead cost of laser cutting enables more flexible business practices. Contrarily, traditional manufacturing, like waterjet cutting or die casting, rarely offers online services.

Elements of Customize Laser Cutting Services

All custom laser cutting services follow the same procedure and practices.

Step 1- Verifying Vector Designs

Manufacturers first verify your provided designs and see if they are compatible with laser cutting. Errors in the design are reported back to the customer. Afterward, the customer can modify their design or ask the manufacturer for help.

Step 2- Selecting Laser Cutting Materials

Next, the customer indicates their desired material for the design. Material plays an important role in the cost of the final part. Thicker metal and plastic materials are on the expensive side, while wood materials like birch plywood are considerably cheaper.

Step 3- Tolerance for Custom Laser Cut Parts

When selecting custom laser cutting services, always be sure to specify your geometric tolerances. Even minor issues with tolerances can run your final part.

Step 4- Laser Cutting and Engraving

Next, specify if you need additional laser services like making or engraving. Manufacturers usually don’t charge a lot for extra services like engraving a company logo on your custom parts.

Step 5- Production Volume

Manufacturers offer significant discounts on larger volume production runs. Try consolidating your fabrication needs and getting multiple parts cut from the same custom laser cutting place to get the best deal.

You will receive your estimated laser cutting quote after the manufacturer approves your design and you outline all of the desired variables.

Custom Laser Cutting Services vs. Buying Your Own Laser Cutter

Custom laser cutting services are generally a good option for most individuals and small business owners. But for many, the cost of buying their own laser cutter is a better solution than relying on someone else for their fabrication needs.

Reasons to Use Custom Laser Cutting Services

Not sure if you want to customize your laser cutting service? Keep reading.

1. Professional Expertise

Custom laser cutting services are managed by professionals with expertise in handling various materials and intricate designs. They understand the nuances of the laser cutting process and can provide high-quality results.

Getting a professional to cut and ship your designs to your doorstep is easier than investing in your own laser cutter and training new employees.

2. No Upfront Investment Cost

You only pay a small convenience fee to the laser cutting service provider. They take your drawings (EPS, DWF, DXF, and other vector formats), cut materials, verify the part dimensions, and ship them to you.

If you decide to buy your own laser cutting machine, it will come with a hefty upfront cost, which includes machine cost, shipping, and installation costs.

3. Wider Range of Materials

A great thing about having someone else laser-cut your designs is the wider range of materials. You don’t have to worry about material thickness, availability, or properties.

Custom laser cutting places often keep a diverse range of materials on hand for customers. If you have a particularly rare material in mind, it is the service provider’s responsibility to source the desired materials.

4. Operational Convivence

When you don’t own the laser cutting machine, you are also not responsible for its operational costs, staff training, and maintenance. Leaving you free to focus on your work creating and optimizing part designs.

With custom laser cutting, you don’t even have to worry about fabrication challenges like laser kerf management or material warping.

5. Flexibility

There is just an incredible level of flexibility involved in custom laser cutting services. You can order as few or as many parts as you want whenever it’s convenient, and you can easily switch suppliers if you are unsatisfied with the final results.

Reasons to Buy Your Own Laser Cutter

Want to buy your own laser cutting equipment? Consider these 5 reasons.

1. Cost Efficient

If your business needs include frequent and high-volume laser cut parts, investing in your own laser cutter may be more cost-effective in the long run. You can save on per-unit costs associated with outsourcing.

Sheet metal fabrication using laser cutters is particularly more cost-effective for high-volume productions.

2. Even Faster Turnaround

While online custom laser cutting services offer quick turnaround times, you still have to wait for parts to be shipped to your location. With an in-house laser cutting setup, instead of waiting 3-5 business days, you only have to wait 3-5 hours for your parts to be in your hand.

3. Business Growth

Laser cutters are an investment in the long-term success of our business. You can vertically integrate your business elements, where you control the designs, materials, and cutting services.

Additionally, if you have spare production capacity, you can offer laser cutting services to other businesses.

4. In-House Prototyping

For those looking to innovate and engineer new product designs, in-house prototyping is necessary. You can quickly and conveniently fabricate new product iterations and revisions using your laser cutter.

You also don’t risk sharing your sensitive proprietary designs with third parties. Keeping your plans confidential and safe.

5. Versatility

Having your own laser cutting machine enables a more versatile approach to business. You can cut metal and non-metal parts, get your brand logo laser engraved on the product, and better manage your production rate. All while working in your own factory and not relying on other companies.

FAQs

FAQ 1: Are Laser Cutters a type of CNC Machine?

Yes, Laser cutters use the same computer numerical control (CNC) system as any other CNC milling machine. All laser cutters except handheld laser cutting machines fall under the category of CNC.

FAQ 2: What Type of Materials Can You Cut with Custom Laser Cutting?

Custom laser cutting services aren’t limited to a specific material. You can request metals, plastics, and even wood for your designs.

FAQ 3: How Fast Are Custom Laser Cutting Services for Sheet Metal?

Custom laser cutting places generally take 1-2 days to laser cut the parts. Shipping times are dependent on your location relative to the manufacturer.

FAQ 4: How to Reduce Your Custom Laser Cutting Quote?

You can reduce your quote by choosing low-cost materials like plastics or cheaper metals like aluminum. Additional savings can be had by lowering your geometric tolerances and using simpler designs.

Conclusion

Custom laser-cutting services are great for getting laser-cut parts without investing in expensive laser cutters. With the rise in instant online commerce, customers can now send their designs to a manufacturer and have the finished part at their doorstep within a week.

However, even with its many benefits, laser cutting services can’t replace the versatility of having your own laser cutter.

Transform Your Ideas into Reality with Baison Laser!

Baison is one of the biggest fiber laser systems manufacturers in China. We serve a diverse clientele from over a hundred countries across the globe.

Our products are built on a commitment to quality, attention to detail, and decades of experience in the manufacturing sector. At Baison, we value customer experience above all else. We built our FREE Sample Proofing and Application Evaluation program solely for the benefit of our loyal customers.

Experience the best-in-class laser cutting solutions with Baison. Contact Us Today!