In the fast-evolving world of welding technology, handheld laser welders have become one of the most convenient and reliable solutions. Whether you are a professional welder seeking the perfect tool for your trade or a DIY enthusiast looking to take your projects to the next level, there is a handheld laser welding machine that’s perfect for you.

This article delves into the details of the handheld laser welder world and its benefits. Finally, we have narrowed down the top five handheld laser welders you should consider for your business.

What is a Handheld Laser Welder?

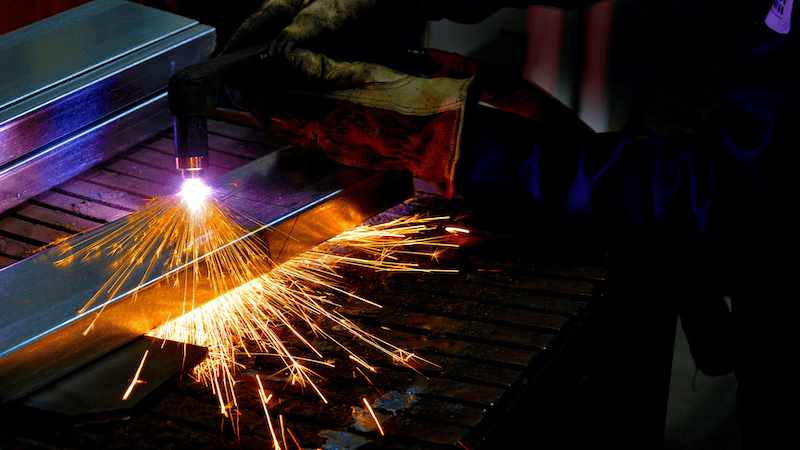

Handheld laser welders are portable fiber laser delivery machines capable of welding various metal materials within seconds. They comprise a main unit that houses the laser source and amplifier, connected to a handheld gun-like unit called the laser welding head.

Handheld laser welding machines are compact and roughly the size of a desktop PC. Almost all commercially available machines come with wheels at the bottom of the machine for more effortless mobility.

The handheld unit is considerably more lightweight than traditional welding methods, providing operators with a high degree of freedom and control when welding.

Additionally, the exit nozzle on the gun is interchangeable, further adding to the flexibility provided by the machine. Nozzle shapes direct the laser beam and ensure only the desired part gets welded.

Handheld laser welding machines are compatible with several metals, including titanium and stainless steel. Research has also shown that fiber laser welding is compatible with rare metals like Vanadium, Tantalum, and tougher Stainless Steel Alloys.

6 Major Benefits of Handheld Laser Welders

Hand held laser welding offers all the benefits of fiber lasers and more. Here are some of the many benefits of a handheld laser welding machine.

1 – No Filler Metal Required

Traditional MIG/TIG welding equipment necessitates using a filler metal rod. As the metal is heated, the filler metal melts between the two surfaces and bonds them together.

Laser welding doesn’t need a filler metal, as it selectively melts two metal surfaces together. The lack of filler metal reduces the operator’s welding complexity and the overhead costs of buying and storing filler metal rods.

A handheld laser welding machine is a one-stop solution compared to the complex and cumbersome MIG welding.

For wider gaps between metal surfaces (>0.2mm), a filler metal is also required for the laser welding machine.

2 – Cleaner Welds

Laser welding provides a nice and clean weld finish that is otherwise impossible with traditional welding methods.

Traditional means of metal welding (TIG/MIG/Arc Welding) result in a strong weld with an undesirable seam weld. The extra mass of the filler metal ends up as a thick line on the final product.

Post-processing equipment becomes necessary to clean up these weld beads. Laser welding forgoes all this by making a clean weld in the first place, saving you time and money in the post-processing stage.

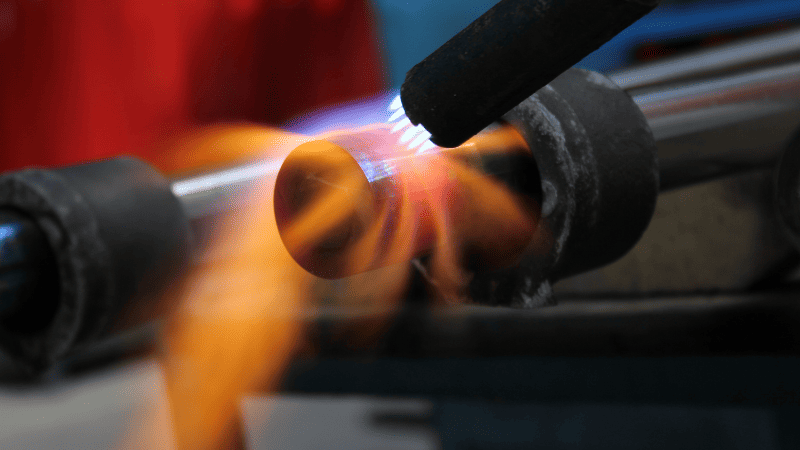

3 – Less Heat Input

Laser welding is a highly efficient process, utilizing a fraction of the energy of traditional methods while delivering the same quality results.

Laser welding equipment is designed for pinpoint heat input. Therefore, the laser welding machine can avoid a lower energy deposit.

Less energy input into the metal materials means negligible post-weld warping.

4 – Finer Welding Control

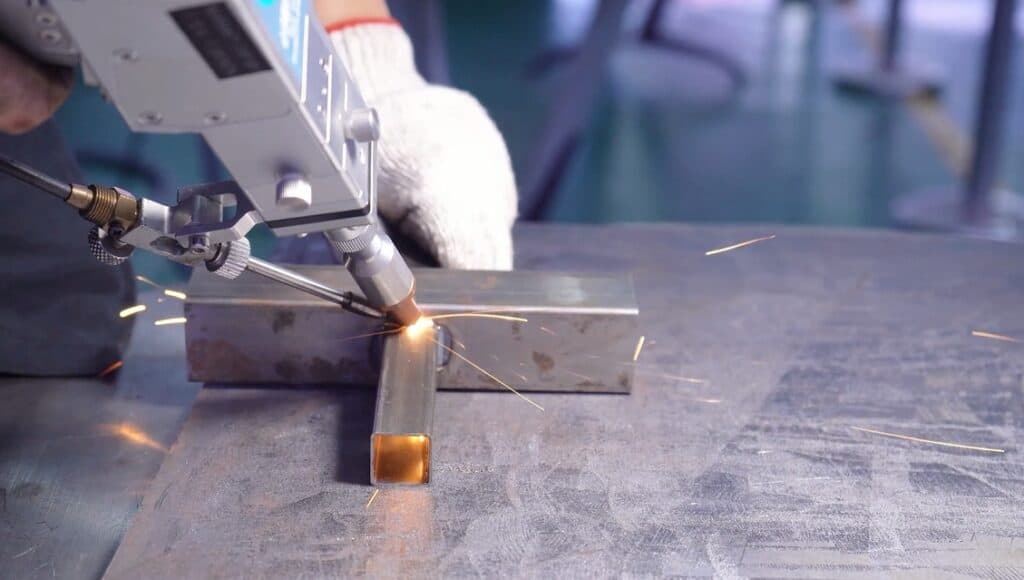

A good and robust weld requires an experienced operator and quality welding equipment. Studies have shown poor welding control can lead to larger weld pools, resulting in welding defects.

Experienced welders can compensate for the instability in the welding equipment, but the solution is never perfect. A handheld laser welding machine is lighter and more flexible, allowing welders to hone their skills further.

An experienced welder can match the quality and precision of an entry-level welding robot. Additionally, laser welding is more forgiving to novices and minimizes chances of operator error. You can learn about ways to improve welding control in this process.

5 – Wider Material Compatibility

Laser welding is quite versatile when it comes to material compatibility. It can weld all the usual metals and even some uncommon other metal materials like volatile magnesium, unstable vanadium, and tough titanium.

Additionally, due to its low heat input, it can easily weld thin materials. One big problem in welding thin materials is that traditional arc welding deforms thin materials.

You can even weld some thermoset plastics using a handheld laser welding machine.

A standard laser welding machine is compatible with the following materials and their alloys.

- Steel (High Carbon & Galvanized)

- Stainless Steel

- Copper

- Aluminum

- Magnesium

- Titanium

- Nickel

- Plastics

- etc.

6 – Competitive Pricing

Perhaps the most significant benefit of handheld laser welding comes from its affordable pricing. Generally speaking, the price of a handheld laser welding machine is determined by the wattage of its laser.

A low-wattage laser welding machine can cost as little as $2000 (USD). For an industrial-grade laser welding machine, that is a very reasonable starting price, especially considering its many benefits.

Top 5 Handheld Laser Welders

Although hundreds of laser welding solutions are available to consumers, choosing the right one can be a chore.

We have simplified this step and compiled a slit of the best handheld laser welding machine.

Criteria for Choosing the Best Laser Welding Machine

When selecting these five handheld laser welders, we mainly referred to the following criteria:

1. Product Performance: We examined the basic performance of each machine, including welding speed, accuracy, stability, etc.

2. User Experience: We also considered the user experience of these machines, such as ease of operation, learning curve, and after-sales service, etc.

3. Market Feedback: We refer to the feedback and reviews in the market to ensure that the products we recommend can be recognized by users.

4. Price: We also considered the price of each machine to ensure that the products we recommend can provide value for money to users.

1 – LightWELD XR Handheld Laser Welding Machine

LightWELD XR is a fiber laser welding system from IPG Photonics and an experienced player in the laser solutions industry.

The XR model reaches 2500W of peak laser power, has changeable nozzles, an impressive 60-micron spot size, and higher metal penetration.

IPG Photonics also sells a lower-end model called the LightWELD XC that performs similarly but lacks many quality-of-life improvements.

2 – Han’s Handheld Laser Welder HW-D

Next, we have the compact handheld laser welding machine, the HW-D from Han’s Laser Corporation.

This versatile laser welder can be configured with three laser power settings (1kW, 1.5kW, and 2kW). Han’s claim to fame is its impressive 3-in-1 laser functionality. It has metal welding, cutting, and cleaning capabilities that tempt any business owner.

Han’s Laser isn’t out to replace laser cutting machines. Instead, it offers a versatile machine that can also be used for simple cutting operations.

This all-in-one handheld laser welding system comes in at a massive weight of 600 lbs. (275 kg). Although it is still mobile, with wheels at the bottom of the machine, the weight might be too much for a single operator to push around.

3 – Baison Laser FSC Handheld Welding Machine

Baison Laser is a long-term manufacturer of fiber laser systems. With over 20 years of industry experience, they do not compromise welding quality and machine versatility.

Their handheld laser welding machines are built from the ground to ensure a simple, hassle-free welding process. Its robust cooling system enables low-noise continuous operation. The Baison laser welder also comes with a comprehensive set of safety features.

Baison stands out because of its high-quality laser optics and motor system. A good laser beam directly indicates quality in any welding equipment.

Baison also offers automatic laser welding machines (robots) for those looking for something premium.

4 – HS Laser HW-1500 LightWelder

HS Laser’s HW-1500 is a miniature fiber laser welding machine with an impressive 1500W of laser power. Standing tall at just 21 inches with a length of 26 inches. It’s a sleek, straightforward laser welding machine with an ergonomic design and comfortable weld gun grip.

The HW-1500 produces one of the cleanest welds. The laser beam in handheld laser welding machines truly shines when welding metals. It supports vertical welding, overhead welding, butt welding, and more.

HS Laser has designed its handheld laser welder to improve the advantages of laser welding further. This has resulted in exceptional weld quality that is just as good, if not better, than the competition.

Due to its smaller size, the phase change cooling system can’t fully stretch its legs. The mini size limits its operating temperature to just 104°F (40°C). This temperature limitation will hurt welding operations in the summer, especially for regions closer to the equator.

5 – PhotonWeld-A1600

The PhotonWeld A1600 is a very middle-of-the-road laser welding machine. It’s compact but not too small, has adequate cooling but can get a little loud, and lacks the laser power its competitors offer.

To be clear, at 1600W of power, the A1600 is a decent performer, and considering the power density of laser welding machines, it will perform admirably in most operations.

But one thing that pushes PhotonWeld into the top five is its simple and easy-to-navigate control panel. This is a no-frills laser welding machine meant to get you up and running in the shortest amount of time.

Additionally, the A1600 comes with pre-programmed weld settings for quick setup. You can save the frequently used settings and conveniently switch to them with a few clicks.

Below is a comprehensive comparison table of these 5 top handheld welding equipment to make it easy for you to quickly find and refer to them.

| Machine Model | Specifications | Advantages | Power | Suitability |

|---|

Factors to Consider When Buying a Handheld Laser Welder

Handheld laser welding machines have gotten so good over the past few years that you shouldn’t have any problems buying a capable welding machine from a reputable seller.

However, buyers should be well informed of the most important factors that contribute to laser welding machines’ performance.

1. Power and Performance

Laser welding machines shouldn’t be judged on their laser power alone. Due to the laser beam’s higher power density, a 1000W-2000W laser is more than enough for most metals.

Consider a handheld laser welding machine’s advertised continuous and peak power. Most lasers will only operate at their peak output for a few seconds. A 2500W peak power laser welder will revert to ~1500W afterward.

2. Portability and Design

Portability is a big selling point for laser welding equipment. Large projects mandate that the welder be moved around to accommodate the workpiece.

Choose a laser welder that can be easily moved around and is not too bulky or heavy. Next, you want a design with no protruding parts that can be easily damaged in transit.

3. Ease of Use

A laser welding machine should be treated as any other tool. It shouldn’t require a complex and tedious instruction manual to operate.

Choose a welding machine that comes with simple and intuitive controls.

4. Price and Value

When buying a laser welder, always consider your business needs. An expensive machine used regularly has more value than a low-cost option that doesn’t get frequent use.

The laser equipment industry is full of machines that offer several features at a premium price but ones that never get used by the customer.

Try to avoid marketing terms and look for practical value.

I’m sure you want to know exactly how much a welding machine will cost.

How Handheld Laser Welders Compare to Other Welding Machines

Laser welding is a newer technology compared to traditional welding methods. It still has a long way to go, but it already shows several benefits over its older brethren.

I. Handheld Laser Welders vs. TIG/MIG Welders

MIG/TIG welding is a decent all-rounder metal joining solution. However, this process is challenging to automate and lacks laser precision.

TIG welding generates more heat, requires filler material, and produces a less desirable finish.

However, it is a low-cost solution and has a short learning curve. Studies also show that the tensile strength of TIG-welded metals is slightly higher than laser-welded ones.

II. Handheld Laser Welders vs. CO2 Welders

Gas welding equipment is bulky, unreliable, and obsolete. It lacks fine-tune precision, is very inefficient, and has a fragile gas chamber made of glass.

Fiber lasers have a lifespan of 20,000 hours compared to the 2,000 hours of CO2 lasers. On long, complex welding projects, you run the risk of a failing CO2 gas chamber. The industrial sector doesn’t have two thousand hours of machine operation time.

The only saving grace for CO2 welding is its dirt-cheap pricing and broader availability.

For more about fiber lasers vs. CO2 lasers, read this article.

Safety Tips for Using Handheld Laser Welders

Before we wrap up this article, let’s review some basic safety guidelines for handheld laser welding.

1. Proper Storage

Laser welding machines are sensitive devices; moisture and dust ingress can hamper performance and damage internal components.

Additionally, on the factory floor, ensure that small metal chips and debris don’t enter the laser welding machine.

2. Cable Management

The optical fiber cable connecting the weld gun to the laser system is fragile. Bending at sharp angles or running over one will damage it beyond repair.

3. Hand & Eye Protection

Always wear proper hand and eye protection. Safety goggles and fire-resistant gloves are your friends.

Conclusion

Laser welding has slowly grown over the years, starting from CO2-based lasers and then shifting to optic fibers. Their compact size has paved the way for handheld laser welding machines that are just as capable as traditional methods. Additional benefits of laser welding include higher quality weld finish and excellent energy efficiency.

All top laser welders offer 1500-2500W of power and come with changeable welding heads (nozzles). Thus, buyers should focus more on ease of use and portability when getting a laser welder.

Empower Your Welding Journey with Baison Laser!

At Baison Laser, we’re committed to providing cutting-edge solutions tailored to your needs. Having read about the top 5 handheld laser welders, are you ready to make an informed decision? Elevate your welding projects with unparalleled precision and efficiency. For high-quality laser welding machines and excellent customer service, look no further than Baison Laser. Get started with our FREE application evaluation and customer training.