Stainless steel is one of the few materials with industry-wide applications. According to Eurometal, the body responsible for all EU metal distribution, stainless steel production is expected to reach 60 mn tonnes. You might think laser engraving on different stainless steel grades is identical, but from our professional experience, there are a few things that can differentiate their applications.

In this 5-minute read, we’ll delve into laser engraving stainless steel 304 and 316 grades. How their unique properties affect the laser marking, laser parameters, and a little insight into the best practices for optimal laser marking.

The Basics of Laser Marking

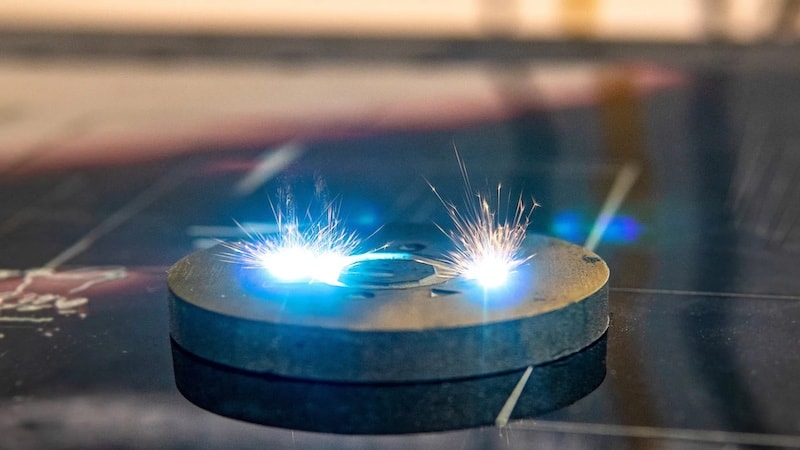

Laser marking is a contactless process of marking a surface using an intense high-energy laser beam. The main principle of a laser marking machine is reflecting emitted high-energy photons onto metal materials producing a controlled heat emission that can produce various markings on the surface.

Depending on the intensity of the laser beam and material properties, the laser marking process can be engraving, etching, annealing, or ablation. For coated materials, it can produce a discoloration effect.

Types of Laser Marking Processes For Stainless Steel

Before we delve into laser marking stainless steel, here’s some crucial insight into the different types of laser markings that are possible on different materials including stainless steel.

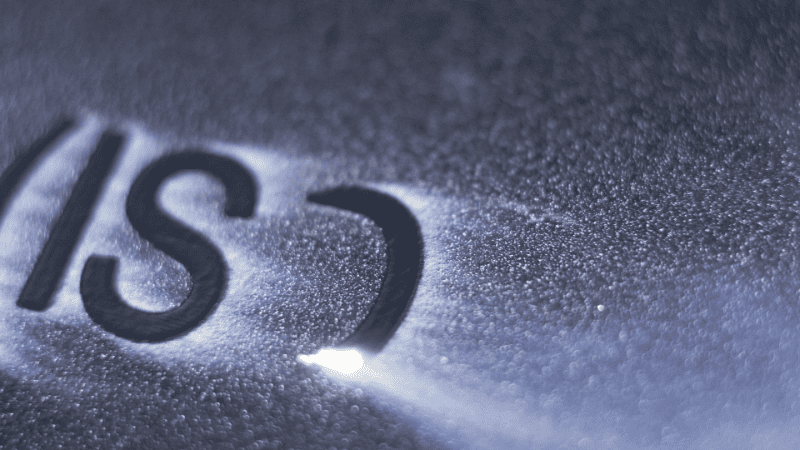

1. Laser Engraving

Laser engraving produces some of the most durable markings on stainless steel. A high-level beam is focused on the metal surface where heat melts and vaporizes metal materials creating a tiny cavity along the path of the laser beam. At high temperatures, oxidation also occurs discoloring the metals and making the engravings more prominent.

Laser engraving involves material removal and it is a subtractive manufacturing process. Click here to learn more about the laser engraving and laser marking differences. Laser engraving stainless steel is particularly useful when performing surface treatment processes like shot blasting as the stainless steel engraving can withstand abrasions and is more durable against rust.

2. Laser Etching

Laser etching is more common, fast, and repetitive. Laser etching relies on the same laser to mark stainless steel but here no significant material is removed. Instead, laser-etched steel is lighter in contrast to the surrounding steel which produces a permanent mark on the surface.

Laser etching reaches a depth of less than 0.001” and creates high-contrast black and white marks which are ideal for bar codes, QR codes, data matrix codes, and part identification codes.

3. Laser Annealing

To mark stainless steel without affecting its surface finish, we often use laser annealing. In laser annealing, there’s no material removal and the mark is achieved with a smooth surface.

Laser annealing involves localized heating just below the melting point and crystallization which produces discoloration depending on the temperature. Laser annealed mark is resilient to wear and abrasion damage.

Your choice for annealing, etching, or engraving will depend on your application. For instance, creating tough logos on parts that can last years or laser marking materials in a certain cycle time. Laser marking on soft surfaces is also possible on textiles and fabrics.

Characteristics Of Stainless Steel

Stainless steel gets its name from being rust-resistant, but there are many other properties of stainless steel and a few unique characteristics and advantages that divide stainless steel between different grades.

We’ll discuss stainless steel 316 and 304 grades, but first a few common properties of both steels.

By composition stainless steel has 10.5% chromium, small amounts of nickel, and desired carbon for strength approximately in the 1% range. This alloy has great corrosion resistance due to its chromium oxide layer (a thin protective layer) and often is the preferred option in metals for humid work environments.

The chromium oxide is also the reason for stainless steel’s durability. Chromium oxide slows down the deteriorating process and adds to the shiny aesthetic of steel. Furthermore, the chromium oxide layer can regenerate by an oxidation reaction with air making it suitable for heavy-duty and industrial applications.

Difference Between Stainless Steel 304 and 316

It is important to distinguish between both stainless steel before laser engraving, so you can decide which one is suitable for your application and project. Here are the characteristics of the two types of steel.

| Type 304 Stainless Steel | Types 316 Stainless Steel | |

| Composition | 18% Chromium 8% Nickel | 16% Chromium10% Nickel 2% Molybdenum |

| Resistance | Resistant to oxidation, and corrosion | Molybdenum gives it extra resistance to chemical corrosion |

| Application | Pressure vessels Pipes Utensils | Benches and equipment (medical labs) Chemical containers |

Laser Marking on 304 Stainless Steel

Laser engraving is one of the most precise ways to mark stainless steel. This gives you the freedom to choose any intricate design, logo, or information that you want to convey to the end user. Here’s how to laser engrave stainless steel type 304.

Step 1: Choose the best laser machine

There are a host of laser machines that can engrave steel depending on your production time, number of pieces, and quality of engraving. The industry standard for engraved stainless steel is fiber lasers. If you’re looking for more affordable options, you can also opt for a diode laser.

If you still don’t know how to choose between light lasers and diode lasers, read this blog post.

Step 2: Surface Preparation

To laser engrave stainless steel, the metal surface has to be free from any contamination. This not only means cleaning any rust but also removing any dust, grease, and lubricant. For best results, a laser marking spray is used before engraving.

Step 3: Preparing the Files

Most designs and logos are made in creative design software with files that are vectors, png, or raster images. Laser engravers do not read these formats, which means saving your designs in laser engravers’ formats like DXF, PDF, or JPG.

Step 4: Laser Beam Settings

Adjusting laser beam parameters will allow you to etch stainless steel, and engrave stainless steel, and this is where the process differentiates for engraving and etching stainless steel.

Type 304 stainless steel laser engraving happens at power levels above 50W and the pulse frequency is set to low for deep engraving stainless steel. The marking speed is decreased for best results.

Step 5: Engraving

After adjusting the settings, the laser engraver begins to engrave stainless steel.

Laser Marking on 316 Stainless Steel

Laser engraving stainless steel 316 follows the same steps from choosing the laser engraver to saving the files. Here’s a quick breakdown of all the steps to laser engrave stainless steel 316.

Step 1: Choose the best laser machine

Fiber laser engraving stainless steel is the most preferable method, which means choosing fiber lasers instead of infrared or CO2 lasers.

Step 2: Surface Preparation

The surface preparation method is identical involving degreasers and rust removal.

Step 3: Preparing the Files

Design files are saved in a laser machine-readable format such as PDF, JPG, or AI.

Step 4: Laser Beam Settings

Fiber laser engraving can produce different results based on the laser beam controller, focal length, wavelength, and a few other parameters.

When laser engraving type 316 stainless steel, the typical settings are as follows:

- Laser engraving above 50W for deep engraving stainless steel

- Laser beams focused below the surface depending on the laser mark depth

- Slow marking speed for more prominent marking

- Multiple passes for deeper engraving or when production time is not a concern.

Step 5: Engraving

Once these parameters are set in laser machines, they can begin engraving on the go.

The parameter settings of the laser beam when laser marking two kinds of stainless steel can be understood in detail in this article.

Comparison Of Laser Marking 304 And 316 Stainless Steel

In order to help you faster access laser marking two kinds of stainless steel comparison information, this table sums up the laser marking process based on fiber laser for both steel grades.

| 304 Stainless Steel | 316 Stainless Steel | |

| Laser Intensity | 20* – 100 W | 20* – 100 W |

| Marking Contrast and Quality | Good quality marks with decent contrast | Slightly darker and with a bit more contrast |

| Surface Finish Post-Marking | The surface is not as smooth and impacts quality and contrast | A smoother surface leads to a better finish |

| Passivation After Marking | Enhance corrosive resistivity | Enhanced corrosive resistivity, less alteration in finish |

| Cost Implications | Cost-effective to mark | More expensive due to higher nickel and molybdenum content |

| Applications | Kitchen and food grade items, automobile industry | Chemical containers, boats and marine uses, medical devices |

Application of Laser Marking 304 and 316 Stainless Steel

The real difference between stainless steel 304 and 316 is based on their applications

According to Kloechner Metals, 304 stainless steel has a higher melting point than 316, which means it may be more suitable for high-temperature environments. Stainless steel 304 is an FDA-approved material and is therefore used in cooking ware, storage tanks, fryers, etc. It is also a popular material for making steel countertops often used in restaurants.

Laser annealing is a great way to get an imprint on a smooth surface for such countertops without leaving any trace of depression and vaporized metals. Type 304 is also used in medical equipment due to its biocompatibility and resistance to cleansing agents.

Engraved type 316 stainless steel is useful as it resists rust, and abrasion and is ideal for demanding applications. Fiber laser is used to deeply engrave 316 stainless steel as it is used in boat fittings because of its high resistance to corrosion from salt water. Other uses include heat exchangers and corrosive chemical containers. Here’s a quick look at 100 W fiber laser machines capable of the toughest engraving with precise marking.

Conclusion

Laser engraving is by far the most economical option for impressioning logos, texts, and characters onto stainless steel that is long-lasting and represents quality. To understand, which laser engraver is best for your project, it is important to know the key differences between the applications of stainless steel, their properties, and which laser marking process is effective for stainless steel.

Get the Baison Laser Marking Craftsmanship!

Are you looking for precise laser marking on your stainless steel samples? At Baison Laser, we continue the trend of quality laser marking with our efficient, accurate, and versatile laser marking machines. We have a range of laser marking machines that are suitable for various industry standards. Get an instant quote from our helpful engineers!