The thriving improvement of the construction industry owes a lot of its success to laser cutting. With the increased use of laser cutting techniques, the job can be more focused, smooth, and easy.

In this article, we will give you answers to all your questions about what is laser cutting and how it can be used in the construction industry. We will go through the various uses of laser cutters in construction and the best laser-cutting machine to choose from.

Processing Situation of the Construction Industry

According to market research by Global Construction Market, with a compound annual growth rate (CAGR) of 4.6%, the value of the global construction industry is predicted to reach USD 10.9 trillion by 2023. The largest market is anticipated to be in the Asia Pacific region because of infrastructural development and urbanization.

1. Market Situation

As laser technology can increase accuracy, productivity, and safety, the construction sector is predicted to thrive. Per the report published by Reports Insight, the Green Building Materials Market is to grow at a compound annual growth rate (CAGR) of 12.4%. Nonetheless, there are some obstacles facing the construction sector, such as a lack of qualified workers, growing material prices, and environmental laws.

2. Labor Issues

The lack of skilled workers is one of the major issues facing the construction sector. By 2023, the industry is predicted to add 2 million jobs, but there is a lack of competent candidates to fill these roles. A portion of this can be attributed to the aging workforce and the drop in the number of individuals pursuing careers in construction.

3. Growing Expenses

Growing material costs are another issue the construction sector is dealing with. Recent years have seen an increase in the price of resources like steel, lumber, and concrete because of things like tariffs and supply chain disruptions. This has increased the cost of developing new ventures and strained business margins.

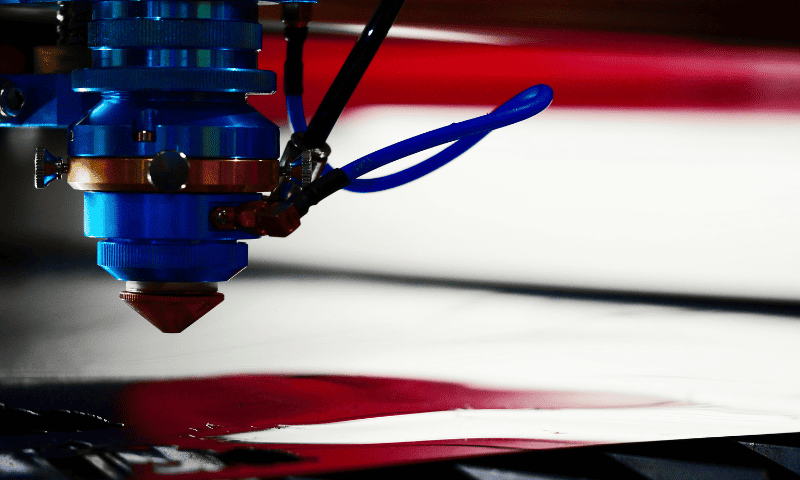

Overview of Laser Cutting

Laser cutting is used for cutting metal and non-metal materials by the use of highly focused laser beams. The compressed heat of the laser hits the surface and melts the material in the position of contact. After very little time, the material is completely separated, making the cut complete. It can also be used to engrave designs and writings.

Mostly used in complex jobs like the automotive industry, a vast range of forms and features can be produced using the flexible technique of laser cutting. It may be used to cut incredibly thin materials with a very precise operation. Furthermore, as laser cutting does not create any friction, it is subject to a lot less wear and damage to the tools and the materials.

Advantages of Laser Cutting for the Construction Industry

Laser cutting has gained immense popularity in recent years because of the features that it adds to a job. There are a lot of advantages of laser cutting, and most of them can be positively applied to the construction industry.

1. High Efficiency and Waste Reduction

Laser cutting saves a lot of time from the whole process because of the way it can bring out the best result each time. It differs a lot from other traditional processes, where you need to go over the same piece a few times to get the right cut and angle.

But that is not the case with laser cutting. It can give you the required result with a single stroke including angle cuts. For this reason, the job is more accurate and reduces a lot of material waste.

2. Enhanced Accuracy and Precision

The precision and reliability of the finished product are guaranteed with the help of laser cutting. Because of the highly accurate cuts that laser cutting equipment can make with the least amount of heat-affected zones (HAZ), there is much less damage to the material.

This feature is even more highly appreciated in the construction industry, as even a small error can create huge hazards. Human error is completely eliminated with laser cutting, which also guarantees that each component is cut precisely to specification.

3. Flexibility and Material Equality

Many materials that are frequently used in construction, including materials such as metals, polymers, wood, and even some other types of composites, can be processed using laser cutting technology. Because of its adaptability, laser cutting can be used by construction workers and contractors for a wide range of applications involving different materials.

4. Robotics and Labor Expenses

Laser-cutting devices allow for accurate and complex cutting patterns and repetitive jobs. In the construction industry, engineers can lower labor costs by implementing better-suited machines that can increase production rates. Click to learn how laser cutters save costs.

5. Security and Decreased Risks

Workers are put in danger by traditional cutting procedures, which frequently entail spinning blades, embers, and flying debris. However, these hazards are eliminated by the non-contact nature of laser cutting. The equipment contains a laser beam, and there is very little dust or fume produced during the cutting operation.

6. Sustainable Practices

When considering cutting techniques, laser cutting is comparatively less harmful to the environment than other methods. It uses less energy, generates less trash, and doesn’t need coolants or dangerous chemicals. This is consistent with the building industry’s increasing focus on sustainability.

Laser Cutting of Architectural Panels

When we talk about the role of laser cutting in the construction industry, we also mean the more design elements of architecture as well. Architectural panels refer to the panels used indoors to create partitions, to put up temporary walls, etc. In this case, laser cutting can have a huge impact. Have you noticed the trendy architectural panels with beautiful cutouts and patterns? That is only possible with laser cutting.

- Laser cutting has made it possible to create intricate designs on architectural panels that would otherwise never be possible manually.

- It can create smooth and sharp designs.

- Now, it has become possible to create perfectly duplicate pieces of panels that can be used as decor items in the construction industry.

- Laser cutting has made decorative room particles possible for architects and interior decorators.

Laser Cutting of Architectural Tubes

Architectural tubes are used in multiple spaces for various purposes. These can be used as scaffolding, staircase handrails, designer structures, and even work platforms. These tubes need to be cut precisely to be used. Sometimes, the design and plans demand small and well-adjusted pieces that can only be possible with the help of laser cutting machines.

For constructing industrial buildings and pipeline routes, architectural tubes are a must. These often add functional values to the infrastructure as well as a unique design value indoors. Many well-known architectural firms are now using these tubes innovatively with the use of laser cutters.

What Laser Cutting Machine is Suitable for the Construction Industry?

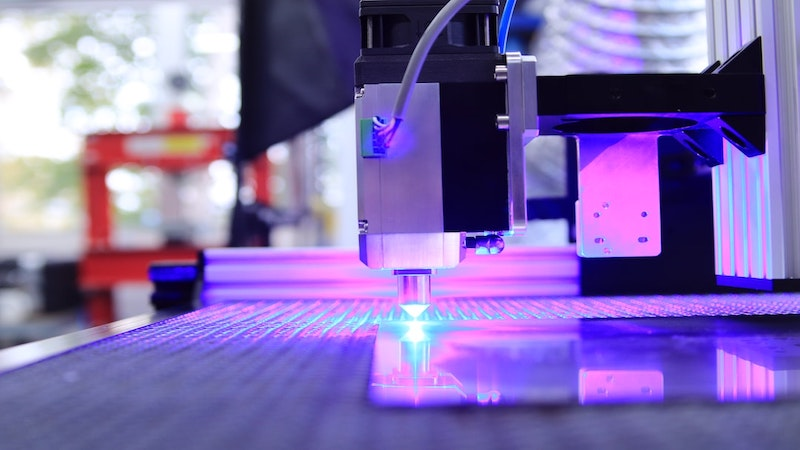

Among various types of options for laser cutting machines, the most common are Carbon Dioxide Laser Cutters, Fiber Laser Cutters, and Crystal Laser Cutters. Even though almost all types of laser cutters can be used on various sides of a construction job, the best choice for construction purposes is a fiber laser cutting machine.

Fiber laser cutting machines have some added advantages over other types of laser cutting machines when it comes to the construction industry, including:

- Greater energy efficiency: Compared to carbon dioxide (CO2) lasers, fiber lasers use less energy to produce the same amount of power. This results in decreased operational expenses and a smaller environmental footprint.

- High power output: Compared to CO2 lasers, fiber lasers are able to provide power outputs that are more than adequate for cutting thicker materials like stainless steel, steel, and aluminum, which are frequently used in construction.

- Minimal maintenance: Compared to carbon dioxide lasers, fiber lasers have simpler designs and require less maintenance, which reduces downtime and boosts output.

- Improved beam quality: The smaller spot size and increased focusability of fiber lasers result in more accurate cuts and a reduction in heat-affected zones (HAZ). In construction projects, this accuracy is essential to preserving both structural integrity and aesthetic appeal.

- Compact size: Fiber laser equipment is usually smaller than CO2 equipment, which makes it ideal for building sites with possible space constraints.

We have prepared a detailed comparison of CO2 laser and fiber laser technologies.

Applications of Laser Cutting in the Construction Industry

Fabricating steel structures is one of the most common uses for laser cutting equipment. And most of the time, steel plays a big part in connecting the use of laser cutters in the construction sites. Construction projects can benefit greatly from the usage of laser-cutting machines since they can efficiently and precisely cut through thick steel plates.

1. Structural Steel Fabrication

Structural steel components are used for building a variety of buildings, bridges, and infrastructure improvements. These can be done using fiber laser cutting.

Because of its accuracy, steel beams, columns, and other structural components can be cut according to the needs of the project without any issues. These structures are often held as the barebones of a bigger project.

2. Architectural Metalwork

Architects always need to add metalworks such as railings, panels, balustrades, signs, etc. Fibre laser cutting has an important role in perfecting the creation of these pieces. Not only is it used to cut down pieces that would otherwise be difficult to cut to perfection, but laser cutters can carry out tasks that might not be possible in any other way.

3. Sheet Metal Cutting and Forming

Sheet metal components are cut and formed using laser cutting for a wide range of building applications. It is frequently used to make ductwork, cladding panels, roofing panels, and other building materials. Additional finishing steps are less necessary since laser cutting guarantees exact dimensions and smooth edges.

4. Plumbing and HVAC Components

For the production of plumbing and HVAC system components, laser cutting is an invaluable tool. Fiber laser cutters can be used in a much more accurate way with great finishing. With extreme precision, it cuts pipes, ducts, fittings, and other parts to guarantee correct fit and operation in intricate plumbing and HVAC systems.

5. Model Building and Prototyping

For building and architectural projects, laser cutting is frequently utilized in the prototype and model-making processes. It enables engineers and architects to produce very accurate and detailed physical models of their concepts, allowing them to assess and visualize their concepts prior to moving on with large-scale construction.

6. Interior Decorating and Renovation

Custom-designed furniture, ornamental accents, and signage can be produced using laser cutting in interior design and renovation projects. Its versatility in handling different materials such as wood, plastics, and acrylics makes it an ideal tool for crafting visually appealing and one-of-a-kind interior pieces.

7. Manufacturing of Displays and Signs

When creating displays and signage for indoor and outdoor use, laser cutting is a common method of production. It is perfect for producing eye-catching signage for establishments, institutions, and public areas because of its capacity to create complex forms and crisp edges.

How to Choose Laser Cutting Machine for the Construction Industry?

For your requirements, choosing a laser cutting machine wisely is very important. There are different types of machines and each also has various capacities, sizes, and other elements. You need to find the specifications that work the best for your needs. So, there are a few things you can do to ensure better decision-making.

- Speak with a laser-cutting specialist if you are making your first purchase and are unsure which laser-cutting equipment is best for you. They can assist you in determining your demands and make a recommendation for a machine that satisfies them.

- To learn about the benefits and drawbacks of various laser cutting devices, read internet evaluations.

- Before making a purchase, shop around and compare costs from other manufacturers.

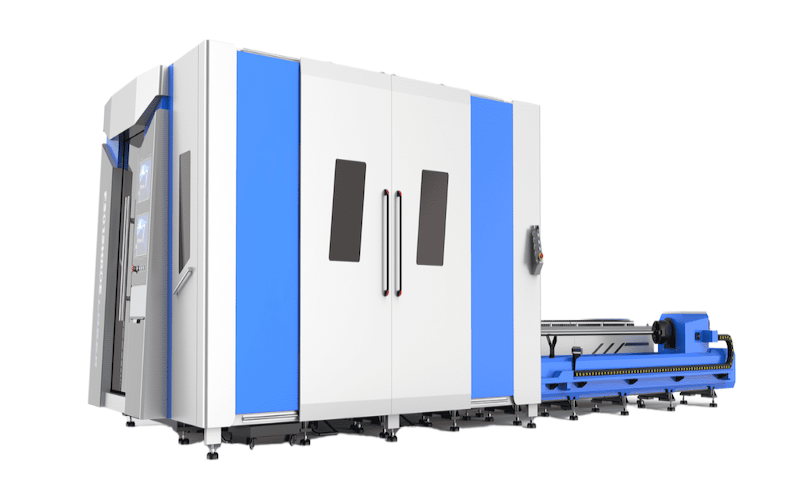

A Probable Choice: Multi-function Fiber Laser Cutting Machine

Baison multi-function fiber laser cutting machine promises the precise cutting of metal sheets and tubes in complex environments. This can be the one-stop solution to your laser-cutting machine choices. As it can be used to cut both pipes and sheets, you can do the job of two machines with just this one.

Baison multi-functional fiber cutter has dual functionalities and precise bevel angles, helping you save much-needed time and increasing your production efficiency and cost. It offers automation in control of the cutter, with advanced system monitoring. It can cut through any type of surface and gives shapes to anything you need, no matter the shape, angles, and design.

Common Problems and Solutions

You might face some issues while working with laser cutters in your line of work. However, these issues may arise because of the lack of skills and/or a piece of damaged equipment. Here are some of the possible problems and their solutions.

| Problems | Possible Solutions |

| Uneven cutting | This issue might be an indicator that there is something wrong with the power supply. Also, you can adjust the graphics that is input to a higher resolution. |

| Deformation in the cases of smaller holes | You need to use smaller nozzles when working with smaller designs and tight spaces. |

| Unwanted burrs | Increase the speed of the laser, or you can try to solve it by reducing the power. |

| Insufficient depth of the cut | Make sure to advance slowly when cutting through thicker pieces. If it still is not solved, you need to change the equipment. |

| Safety issues | This is quite a difficult and dangerous job. You must always wear personal protective gear and make sure that the cutting workshop is well-ventilated. |

FAQs

1. Is the laser cutting business profitable?

If you are looking to start your own laser cutting business, the initial cost is quite high. But you you are skilled or you have access to skilled labor, it can become profitable relatively sooner than you would expect. If you can tackle a wide range of different technical tasks successfully, then the business has a greater potential for profit.

2. What software can be used for laser cutting?

There are a number of software that you can use as a more intricate laser cutting technology. Automatic laser cutting machines all require software where the directions are pre-programmed. Among them, the most popular ones are AutoCAD, SheetCAM, and LightBurn.

3. What is the cost of a laser-cutting machine?

An ordinary small-scale laser cutter can be purchased for $400 to $5000. However, the price can increase and become up to $200,000 for high-value and durable cutters used for industrial purposes.

Conclusion

With its ability to cut a wide variety of materials precisely, efficiently, and versatilely, laser cutting has completely changed the construction sector. Its influence may be seen in the creative interior element designs, the incredible details of architectural metalwork, and the accuracy with which structural steel is fabricated.

Building design and construction will undoubtedly change in the future as laser cutting technology develops and finds more uses. The role of laser cutting in the construction industry is quite enormous.

Elevate Your Construction Company with the Use of Laser Cutting Machines!

Whether you have a related business in the construction industry or want to learn more about laser cutting machines and how they work, Baison can answer all your questions.

Contact us now with your inquiries. With the speed of industrialization all over the world, using more advanced elements in your factory is a must. And in the case of a construction company, there can be no better alternatives!