When it comes to choosing the right materials for laser cutting technology, there are a few things you need to keep in mind. The thickness limit is one of them. In this blog post, we’ll take a look at the thickness limit for different materials and what that means for your project. Stay tuned!

Basics of Laser Cutting

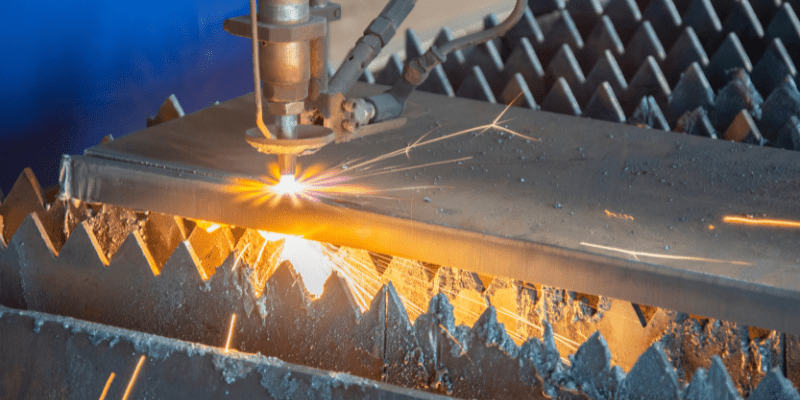

Laser cutting is a cutting-edge machining technology gaining popularity for its cutting ability of materials through laser, thus creating a different cutting environment. It allows welders to cut metals of maximum thickness accurately. Increasing laser technology makes it possible to develop high-power CNC metal sheet machines.

Proper laser cutting depends on different factors, such as:

- Material & quality of cutting machine

- Laser type

- The maximum thickness

- The cutting environment

- Cutting speed

Understanding these factors is critical for proper laser cutting.

The Maximum Cutting Thickness of Laser for Different Materials

The cutting thickness of the laser for different materials is shown in the table. Maximum laser cutting thickness depends on material and laser type.

| Maximum cutting thickness | Carbon steel maximum thickness | Stainless steel maximum thickness | AluminumPlate maximum thickness | Copperplate maximum thickness |

|---|

Working on Laser Cutting Machines

Laser machines can cut various materials, such as carbon steel, stainless steel, aluminum plate, copper plate, and metal sheet. This cutting also includes metals with high accuracy and maximum thickness. These machines use different lasers to cut materials of varying thicknesses but show similar fabrication processes.

Laser cutting machines produce a consistent, intense light to cut even thicker materials accurately that can adjust according to the requirement.

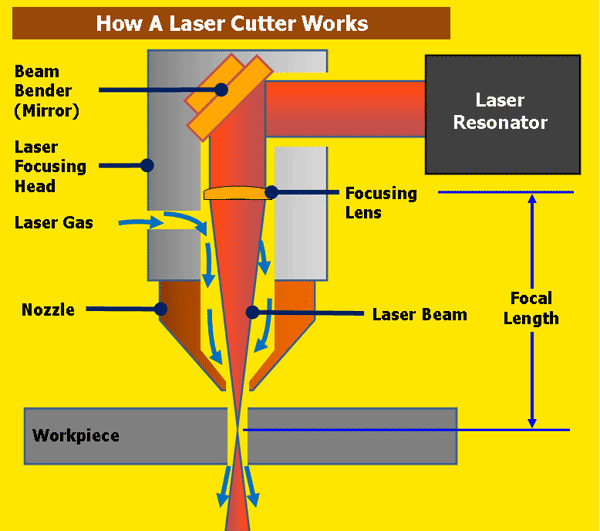

Laser machines work by focusing and redirecting the light to a targeted material. The light becomes much hotter once it is concentrated. The light heating results in the cutting of material.

Moreover, a gantry system mounts the laser during laser cutting. It allows movement of the laser on the XY axis. Thus, it can cut the materials with even maximum thickness at varying angles and curves with higher accuracy.

Types of Laser Cutting Machines

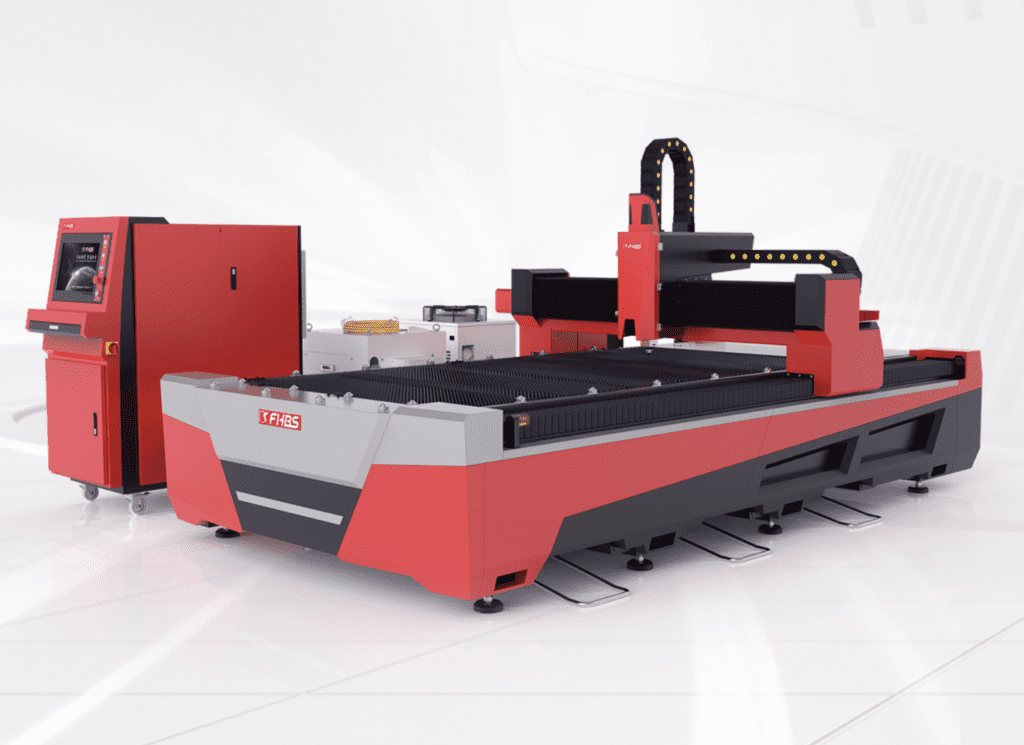

Laser cutters are classified into different types, and each laser machine possesses its laser cutting maximum thickness limit. These two machines include a CO2 laser cutting machine and a fiber laser cutting machine.

1. CO2 Laser Cutting Machines

CO2 laser cutting machine is the most frequently used for cutting laser. It is highly cost-effective but is being replaced by a fast fiber laser cutting system with modern machine parts.

This laser cutting machine is composed of a vacuum-sealed, long gas-filled tube. CO2 is usually prioritized for this purpose. The CO2 is mixed with the nitrogen gas. When the electrical connection is provided to the tube, it produces an intense light by exciting the gas molecules.

The light bounces to the series of mirrors and is redirected to the focusing lens through the mirrors. As a result, the light is concentrated by focusing the lens on a hot point. It leads to cutting materials of varying thicknesses based on thermal separation and the maximum thickness of materials.

CO2 cutting machine is used for sheet metal fabrication. The cutting machine produces smooth edges cut of metals with a maximum thickness of even more than 25″. The laser of the CO2 cutting machine can only cut to a specific cutting ability.

2. Fiber Laser Cutting Machines

The actual application process of the fiber laser cutting machine is similar to the fiber optics light. The cutting ability of this fiber laser cutting machine is much higher than other cutting machines. It includes a tube coating of various types of glass with varying reflective properties, and the laser beam enters through the glass tube in the fiber machine.

This fiber laser machine contains a few moving parts that might require adjustment and replacement and often need little maintenance. A fiber laser cutting machine is much larger and more expensive than a CO2 laser cutting machine. Click here to learn the difference between fiber laser and CO2 laser technology.

The laser diameter of the cutting machine is also reduced due to the nature of fiber optics. Consequently, the fiber cutting machine helps achieve a level of detail.

A fiber laser machine can efficiently cut the metal materials such as:

- Carbon steel

- Stainless steel

- Carbon steel plate

- Aluminum foil

- Aluminum plate

- A copper plate with the higher cutting power of a fiber laser.

The previously mentioned materials may vary in thickness. These machines’ actual cutting capacity or power is much higher than CO2 laser cutters.

3. Power Laser Cutting Machines

Power laser machines are high-performing machines that cut materials with maximum thickness through lasers. They have cutting machines with different cutting capacities for other materials according to the thickness of different materials.

Proper handling of laser machines can precisely cut the maximum thickness of different materials, creating a friendly cutting environment. Power laser machines commonly cut various materials with bright surface cutting.

These laser machines do not use the same laser. The machine cut copper plates, aluminum plates, stainless steel plates, carbon steel, stainless steel, and other materials with varying or the same thickness.

Materials for Laser Cutting

The cutting of different materials can be performed through the powerful fiber lasers of the fiber laser cutting machine. Modern fiber lasers can even cut materials up to 2″. Generally speaking, the cutting of 1″ steel and 1.5″ aluminum and stainless steel can be completed through an 8KW fiber laser.

The diversity of the material is used for cutting. It is commonly used to laser cut metals such as aluminum plates, stainless steel, mild steel, carbon steel, and thick steel. It can even efficiently cut carbon steel plates and copper plates. The previously mentioned different metal materials may have their thickness limit values.

1. Aluminum

Aluminum is much lighter than steel and is known for its flexibility. Therefore aluminum plate is widely used for precise laser cutting without being problematic. The aluminum plate maximum thickness is 2MM for a 500 W fiber laser cutting machine.

2. Stainless Steel

Traces of chromium are added to the steel to form stainless steel. Stainless steel is corrosion-resistant and a good choice for cutting. Stainless steel is resistant to corrosion and rusting. The maximum stainless steel thickness is 3mm for a 500 W fiber laser cutting machine. A comprehensive guide to laser cutting stainless steel is here.

3. Mild Steel

Mild steel is frequently prioritized for cutting because of its lower power of carbon concentration than carbon steel. Low carbon content makes cutting easier.

4. Carbon Steel

A mixture of carbon and iron forms steel. Carbon steel has a relatively large amount of carbon and is very malleable. The laser can cut carbon steel and provides a perfect cutting surface.

5. Other Steel Alloys

They can be used for cutting lasers, and the alloy steel is strengthened by bonding it with other elements.

6. Non-metallic Materials

Besides metal sheets, cutting is also applied to non-metallic materials such as ceramics, plastics, wood, etc. However, their strength is much lower than metals.

Main Determinating Factors for Maximum Laser Cutting Thickness

A laser can not cut through a material as thick material at one wattage. Some factors are generally considered to determine the laser’s maximum cutting thickness and capacity. These factors include:

- Material strength

- Laser cutting speed

- Cost

- Laser power

The laser uses different wattages to cut the materials with varying cutting thicknesses. Similarly, a small laser cannot cut different materials with similar thicknesses.

I. Material Strength

The proper cutting of the laser dramatically depends on the strength of the cutting material. It can cut both thicker and thinner metal materials with varying strengths. The material strength of different metal alloys depends on the ratio of the elements present in the element. The previously mentioned material also varies in its strengths.

II. Cutting Speed

The cutting speed of the laser is also affected by the thickness of different materials or cutting surfaces. The higher the laser power, the faster the cutting speed. You can quickly cut material with greater thickness using a high-wattage laser.

Cutting speed is also affected by the use of auxiliary gas. Auxiliary gas with high pressure is compulsory to produce smoother edges and bright surfaces. During the laser cutting of stainless steel, O2, and N2 are used as assist gas. Similarly, laser cutting of carbon steel uses O2 as a cutting gas.

Conclusion

Understanding the thickness limitations of laser cutting for various materials is crucial for achieving optimal results in manufacturing and design projects. Each material has its unique properties that influence how deeply a laser can cut.

By being informed about these limits, you can ensure precision, efficiency, and the overall quality of your final product. Always ensure to match your project requirements with the capabilities of your chosen laser cutter.

Maximize Your Laser Cutting Potential with Baison Laser!

Looking for a laser cutter tailored to your material needs? At Baison Laser, we offer cutting-edge technology suitable for various materials. Don’t compromise on your project’s precision. Contact us now for expert advice and competitive quotes!