Laser cutting has emerged as a highly precise technique for industrial and artistic purposes. Its effectiveness makes it suitable for cutting sturdy materials like rubber and silicone, which are crucial elements for several industries.

In this blog post, I’ll help you understand the process of cutting rubber and silicon using a laser machine. You’ll also explore the benefits and application of laser cutting rubber and silicon. So, let’s get into it.

Characteristics of Rubber and Silicone

Rubber is a natural material known for its extraordinary elasticity and durability. The reinforcing additives add to its strength, making it resistant to high temperatures. Silicon is a synthetic rubber manufactured by combining silicone and several other substances. Its unique molecular arrangement makes it resistant to deformation and wear and tear.

According to ScienceDirect, silicone rubber is suitable for manufacturing durable products because it is flexible and resistant to high temperatures.

Rubber and silicon are often resistant to several cutting techniques due to their high flexibility and resistance to high temperatures. However, the blades of traditional cutters often get displaced while working with these soft and flexible substances.

To slice or engrave rubber and silicone, you need a sharp-cutting technique that involves minimum contact with the material. Moreover, optimal speed is crucial for limiting the displacement of the material while cutting.

Do You Have Any Questions?

Let Us Solve Your Problem

The Benefits of Laser Cutting Rubber and Silicone

Laser cutting is an effective cutting technique for slicing various materials. Here are some benefits of using a laser for cutting rubber and silicone:

1. Accuracy and Precision

Creating small patterns on rubber or silicone is challenging. Traditional cutting techniques often fail to create intricate designs on soft, flexible materials.

Laser cutting employs a high-energy laser beam that melts and vaporizes the material where it falls without damaging the surrounding area. This feature enables you to accurately cut and engrave intricate rubber and silicone designs. You can also easily engrave small details on these materials using a laser engraver or cutter.

2. Minimum Material Wastage

Unlike traditional cutting techniques, which result in warping and damaged cuts, laser cutters create precise cuts. Software allows you to monitor the movement of the laser beam over the material, minimizing the risks of errors while creating the cuts.

By preventing errors during cutting and engraving, you can maximize your production. Moreover, the precise cutting allows you to cut maximum shapes from a single sheet, limiting material wastage.

3. Minimum Tool Wear

Traditional tools wear as they come in contact with various materials. This wear also affects their cutting ability. You need to replace them frequently to maintain the quality of cuts.

In contrast, laser cutting is a better technique for employing a contactless approach. The laser-cutting machine emits an intense laser beam that strikes the material you want to cut and melts it. The laser machine does not come in contact with the material, preventing its components from being damaged.

4. Better Productivity

Cutting and engraving rubber and silicone with traditional cutting tools is time-consuming. It often limits your productivity. Laser cutting, on the other hand, is an efficient process. Its intense laser beam enables you to engrave hard-to-cut materials conveniently. It saves you effort and allows you to complete bigger projects in a short time.

What Laser Cutting Machine is Suitable for Cutting Rubber and Silicone?

Various types of laser machines are available today that employ different mixtures of gases to create a laser beam. The CO2 laser is the most suitable laser cutter for cutting rubber and silicone.

According to Accademia, CO2 laser employs carbon dioxide. Nitrogen and xenon are auxiliary gases that generate a laser beam of a particular wavelength. That wavelength of CO2 is absorbed perfectly by rubber and silicone, allowing you to cut them precisely.

Another advantage of using a CO2 laser cutter is that it offers a controlled beam for melting the material. This feature helps in cutting silicone and rubber, which are sensitive to heat. The controlled intensity of the laser beam gives clean cuts with perfect edges.

Employing a digital CO2 laser is a better option as you don’t need to guide the laser. You can create a design using software and feed it to your laser system. The computer-aided design ensures that the laser beam moves along the set path. It helps you get an accurate design without worrying about any errors.

Do You Have Any Questions?

Let Us Solve Your Problem

What Rubber and Silicone Is Suitable for Laser Cutting and Engraving?

Rubber and silicone have several types. However, all these types are not suitable for laser cutting due to variable composition. Here are some common types of rubber and silicone that are suitable for laser cutting and engraving:

1. Natural Rubber

Traditional rubber is extracted from trees. It is known for its exceptional elasticity and durability. The consistency and purity of this form of rubber allow you to cut various patterns without error. This type is best to create intricate designs and small patterns.

2. Silicone Rubber

Silicone rubber is a synthetic elastomer known for its non-toxic nature and high flexibility. Its heat resistance makes it unsuitable for various traditional cutting techniques. However, laser cutters can slice it conveniently. Its non-toxic nature and consistency enable you to create various designs and details on it.

3. Nitrile Rubber

Nitrile rubber is another form that you can easily cut and engrave using a laser cutter. It also has a consistent structure that allows you to engrave details and cut various patterns by using a laser cutter. Its laser-cutting ability makes it ideal for several industrial applications.

6 Tips for Successfully Cutting Rubber and Silicone

Laser-cutting rubber and silicone is a versatile technique that allows you to create precise and intricate designs. However, it would be best if you considered several factors to achieve perfect results. The following tips will help you successfully slice or engrave rubber and silicone:

1. Check the Thickness of Rubber and Silicone

The laser cutter is a precise technique. However, it also has some limitations. A laser cutter is designed to cut a particular thickness of material. The thickness of the material it cuts also depends on the type of material.

While choosing a laser cutter for cutting rubber and silicone, check the manufacturer’s specifications to ensure that it is suitable for your projects. A laser machine might be suitable for cutting various thicknesses of various materials, like wood or acrylic, but it may not be ideal for slicing thick rubber and silicone.

2. Adjust Focal Point

Laser beam setting also affects the quality of cuts. An accurate focal lens setting is crucial to creating clean cuts. Calibrate the laser beam regularly to align it with the focal point. You can test various settings to determine the best one for your project. Proper adjustment of the focal point ensures that the laser machine is at an optimal distance from the material.

3. Adjust the Speed

The speed of the laser beam is another significant factor that ensures the accuracy of the laser cut. Too slow and high speed can damage your project, leaving you with a burned product. You need to find the optimal speed to achieve the desired results. You can test various speeds and choose the one that provides the best cuts without damaging the material.

4. Go With a Higher PSI Air Compressor

PSI of air compressor allows you to maintain ventilation in a working environment. Laser-cutting rubber and silicone create a hazardous environment that contains debris and several pollutants. These pollutants can damage your project and also affect your health.

To prevent the harmful effects of laser cutting, employ a high PSI air compressor. It will help you maintain a safe working environment and prevent the laser machine from being damaged.

5. Experiment With Various Features

Laser cutters offer unique features that allow you to create stunning details and intricate designs. Experimenting with features enables you to create desired products without investing in additional equipment. However, check the manufacturer’s manual to understand its specifications and setting requirements.

6. Learn From Experts

Before experimenting with your laser cutter, it’s best to consult an expert in your industry. Various groups are available on social media platforms that connect you to experienced professionals with years of experience. You can get guidance about working with various types of rubber and silicone. You can also learn about various useful settings to maximize your productivity.

Laser-cut silicone and rubber are used in various industries. Their unique features and elasticity make them ideal materials for multiple purposes. Here are some common applications of cutting rubber and silicone by using rubber:

1. Rubber Stamps

Rubber is the best material for creating customized stamps. Adding a touch of personalization to your stamp can enhance its quality. The rubber stamp’s flexibility allows you to emboss various details on it. You can employ this idea to craft various designs. Using a laser cutter, you can create the company’s logo, detailed graphics, and simple text.

2. Customized Watch Bands

Gone are the days when watch bands were used to hold a watch on your wrist. Today, it has become a fashion statement. Silicone is used to customize watch bands to suit your personality. Its flexibility and durability allow you to cut various designs with precision.

3. Baking Mats

Baking mats are a useful tool for chefs and bakers that allow you to accomplish various tasks. Company logos and measurements are engraved on these mats by laser. They offer a flexible, non-stick surface that lets you quickly remove food items.

4. Rubber Seals and Gaskets

Seals and gaskets prevent leakage and protect machinery from damage. Rubber and silicone are ideal materials for their manufacturing. However, creating clean shapes and precise designs is crucial for their functionality. Laser cutting enables you to engrave clean shapes without any burning marks.

Do You Have Any Questions?

Let Us Solve Your Problem

Other Methods for Cutting Rubber and Silicone

In addition to laser cutting rubber and silicone, several other methods are available for the same purpose. Here are some of the commonly used methods for cutting rubber and silicone:

I. Die Cutting

Die cutting is a simple process that employs steel dies for stamping out various shapes. Steel dies act like a cookie cutter that cuts through the rubber or silicone sheet. According to Walker Rubber, three types of steel dies allow you to cut rubber and silicone sheets. It includes flatbed, digital, and rotatory die cutting.

A flatbed is employed for thick rubber and silicone sheets. However, the process is slow and can limit the manufacturer’s productivity. On the other hand, rotatory die-cutting is faster but involves costly installation and maintenance.

Digital die cutting doesn’t involve steel die. It employs oscillating blades to cut desired patterns or shapes. This process can be used for multiple purposes due to its efficient production. However, the method is expensive and requires a large investment for initial set-up.

Click here for a further comparison between laser cutting and die cutting.

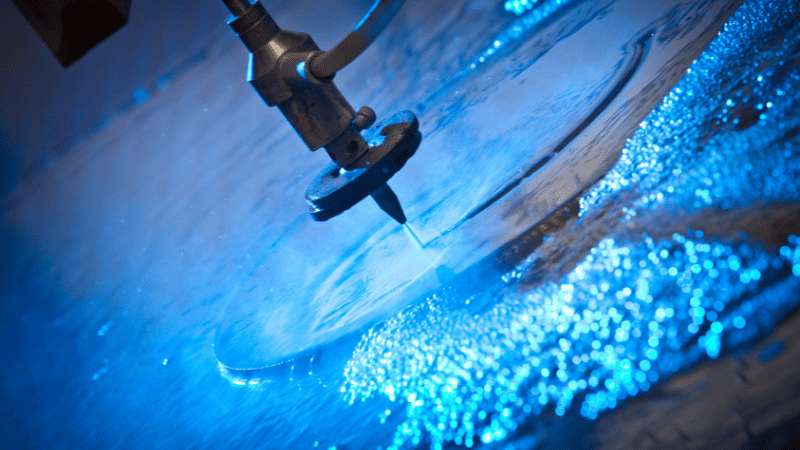

II. Water Jet Cutting

Water jet cutting is an environmentally friendly technique that uses a pressurized water stream to slice and engrave rubber and silicone.

According to Research Gate, water jet cutting is a versatile cutting method. It is effective and requires less installation costs. However, water jet cutting lags behind laser cutting when it comes to offering greater productivity. Productivity is significantly affected when working with thicker materials.

We have also prepared a detailed article for you on the comparison of water jet cutting and laser cutting.

Common Challenges and Solutions

Laser cutting is a versatile technique. However, it poses some challenges. Here are some problems with laser-cut silicone rubber and other forms of rubber and their possible solution:

- Your laser might get distracted from the original design. This occurs when the design size set in the software is too large or too small. To avoid this problem, set the design in the software to align it with your sheet dimensions.

- The edges of the cut piece may burn while cutting. This occurs when you operate a laser at high power. Adjust the power setting according to the rubber or silicone you cut to prevent burning edges.

- The edges may warp or deform during laser cutting and engraving rubber or silicone. It happens due to the heat generated by the laser. Implement a controlled cooling system to prevent this issue.

FAQs

1. Can you laser mark silicone?

Yes, you can use laser engravers to mark and cut on silicone. Although silicone is quite flexible, it is hard to cut. However, the contactless laser beam enables you to mark it without ruining its shape.

2. Is rubber safe to laser cut?

Natural and silicone rubber are generally safe for laser cutting, as they don’t release harmful fumes. However, cutting synthetic rubber materials, like neoprene or rubber containing chlorine, should be avoided because they release toxic and corrosive gases during the cutting process.

Do You Have Any Questions?

Let Us Solve Your Problem

Conclusion

Laser cutting of silicone and rubber is a highly precise and efficient technique. It enables you to prepare various products for industrial and domestic usage. However, don’t forget to employ safety measures for the intense laser beam. Avoid direct contact with a laser beam, as it can damage your eyes. Always wear safety goggles and gloves while operating the laser cutter. Moreover, choose a reliable laser cutter to get the best results.

Unleash the Potential of Laser Cutting Rubber and Silicone with Baison Laser

Are you searching for a high-end laser cutter? Baison Laser offers you the best quality laser solutions, like high-end laser cutters, cleaners, welders, and markers. Its advanced machinery allows you to create refined cuts on various materials, including rubber and silicone. So, request an instant quote today to get the best laser cutter and begin new projects.