Choosing a laser cleaning machine and rust removal with security and operational features challenges novices. The tool is handy in the automobile manufacturing, electronics, and medical industries for its quick grime removal without surface damage.

Understanding the equipment helps you select the best tool for your industrial and mechanical applications.

This article will explain laser cleaning machines and rust removal in depth. You’ll also learn the types, materials to cut, and factors to consider when selecting the tool for your projects. Let’s get started.

What is the Laser Cleaning Process?

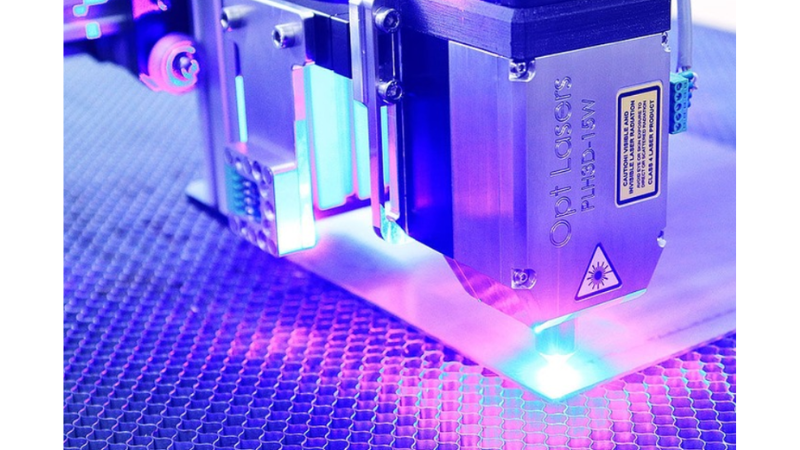

Laser cleaning is an eco-friendly way to remove unwanted contaminants from a surface. Using this technology, you can evaporate oxide, paint, rust, and coating from items.

The cleaning process involves using high-intensity laser beams emitting energy in photon forms. The light rays make unwanted materials or contaminants evaporate when they hit the surface, leaving it polished and clean.

Laser cleaning is famous for its industrial applications in the automotive, aerospace, and manufacturing industries. It’s ideal for restoration and conservation projects involving grime and paint removal from cultural treasures and historical artifacts.

What Materials Can Be Cleaned by Lasers?

Fiber lasers are efficient when cleaning materials that can withstand heat.

Items to clean with laser rust remover include the following:

- Marble

- Granite

- Stone

- Limestone

- Concrete

- Steel

- Aluminum

- Inox

- Plastics

- Cast iron.

When Does Laser Ablation Phenomenon Occur?

The laser ablation phenomenon happens when you focus a high-intensity and focused pulsed beam on a material. It occurs when the target item absorbs sufficient energy through rapid heating, leading to vaporization. The process essentially removes contaminants from the surface of your object.

You can control the ablation process by adjusting the technical parameters such as wavelength, pulse duration, and laser energy.

Modifying their levels to achieve desired heating results is also possible. It’s handy in various fields, such as biomedical or industrial applications, surface modification, and material processing.

Laser Rust Removal

Removing rust means eradicating decay from metal surfaces using the focused pulsed beam technology. It’s also called ablation and offers the safest way to draw out corrosion from steel, copper, brass, or iron.

Laser rust removal comes hand in hand with the manufacturing and refurbishing industry. It’s also for repairing metal parts of any equipment. It reduces costs and increases efficiency due to the technology’s pollution-free, repeatable, and fast nature.

Laser rust removes organic pollutants and inorganic substances such as dust, particles, and rust from a metal surface.

I. Does Laser Rust Removal Really Work?

Laser rust removal is a technology that is highly effective in heating oxidized metal surfaces to remove impurities. It vaporizes the rust, decay, or rot from the item, leaving it smooth and clean.

Most users prefer this method over traditional chemical treatments or sandblasting techniques. It’s more precise and does not cause unnecessary damage to the metal surface warping.

Get laser rust removal professional training before adopting the technology to ensure its effectiveness and safety with the desired results.

II. Advantages of Laser Rust Removal

The laser rust and paint removal technology has many advantages for cleaning and polishing metals. Some of them include the following:

Quick Removal and Quality Finish. The laser rust cleaning machine delivers a consistent beam path and intense power bursts for consistent cleaning quality and faster removal.

It Reduces Material Damage. A laser rust removal machine can selectively and efficiently remove layers while protecting your item’s base.

Maintenance Free. Most laser systems do not require optical machine alignment or parts replacement, making them virtually maintenance-free and drastically lowering maintenance costs.

Versatile Industrial Applications. You can use the technology in high-pressure and temperature environments for various material processing industries.

Lightweight With Excellent Speed. The cleaner is light in weight and ensures rapid cleaning.

Environmentally-friendly Technology. The dust and rust cleaning process is eco-friendly, making it handy in various industries.

What Compose a Laser Cleaning System?

The laser, mechanical, and operating systems are the components that comprise the cleaning system. Let’s dig into the details:

Laser refers to producing high-power density and energy beams to remove rust, dirt, and debris. It contains a semiconductor diode pump and optical fiber for heat focus.

This device creates an intense beam of light with consistent electromagnetic waves through a process known as stimulated emission. It’s an electronic process where molecules get exposed to an external power source to emit photons.

The operating system provides the machine energy and adjusts the laser’s working state. It controls the technology pulse length and output power per unit area.

The mechanical system consists of the focusing heat and working table. Users place the material they’re working on the table. It allows the optical fiber to convex focus before cleaning by casting light on the surface.

Different Types of Laser Cleaning Machines

Handheld, manually loaded, conveyor, and fiber laser cleaning solutions are various types of new technology.

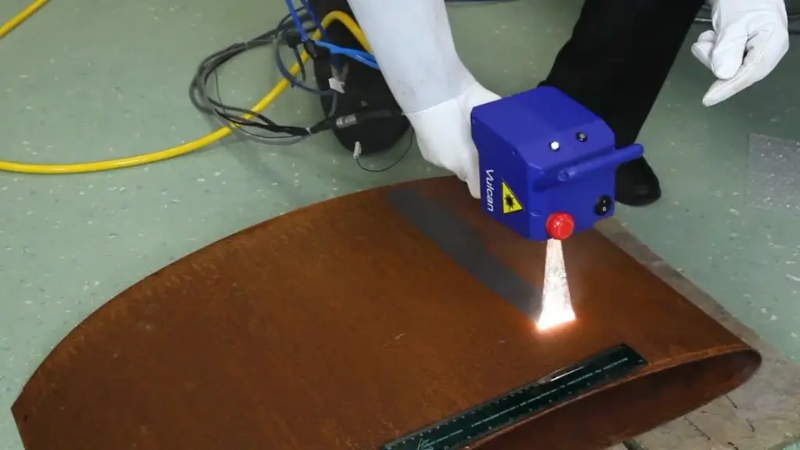

1. Handheld Laser Cleaning Machines

Handheld laser cleaners, also called workstations on wheels, are easy to move from one location to another. It’s often held like a gun and easily positioned on large workpieces in specific areas.

The handheld laser cleaner has various laser configurations. You’ll need the settings for removing corrosion, rust, and paint from metal and steel items.

2. Fiber Laser Cleaning Machines

The laser technology removes dirt and impurities on various materials, such as ceramics and metals. It uses focused laser energy to vaporize contaminants like paint, rust, and oil, which is ideal for industrial cleaning.

The fiber laser cleaning system is low maintenance and can remove unwanted materials without damaging the surface texture.

Manufacturers looking to clean metals with laser beams will find this fiber laser cleaning machine handy.

3. Manually Loaded Cleaning Machines

Unlike handheld laser cleaning machines, these devices are 100% safe for operators. You load parts into the device before triggering the cleaning process. Depending on their chosen tool, users might perform other tasks, such as managing fixtures and opening the door.

Manual workstations often come with a rotary table, helping you to meet the high throughput requirements. You can install it offline or directly into the production line.

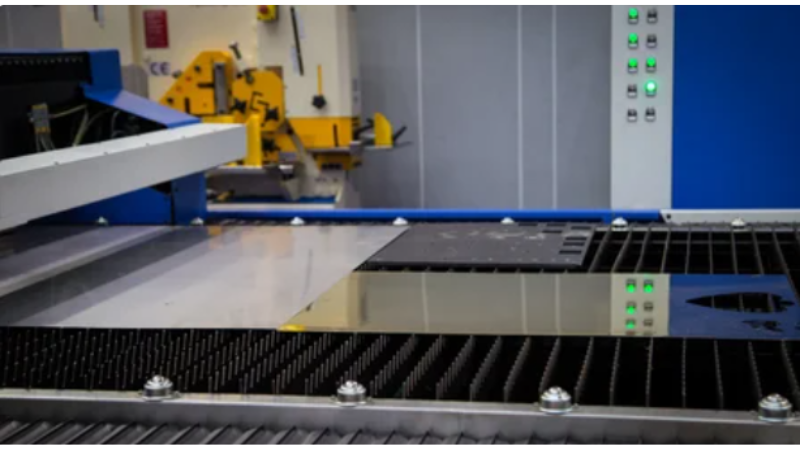

4. Conveyor Laser Cleaning Machines

You install these devices directly on conveyors for surface texturing and automating impurities removal before operations. It offers advanced features to manage inconsistencies when processing large parts in areas that need cleaning.

Conveyor laser cleaning system is handy in the automotive industry, where manufacturers move different parts during production.

Laser Cleaning vs. Other Methods

The laser cleaning system produces focused laser pulses in thousands per second onto the target surface. They differ from other traditional cleaning methods, and we’ll highlight the differences below:

Laser cleaning is environmentally friendly, does not contain abrasive chemicals, and is ideal for environmental protection.

Chemical cleaning methods are traditional method involving acids, solvents, and detergents. It’s a solution that removes grime from the surface but causes environmental pollution. The toxic components can remove metal rust but might cause respiratory problems.

Laser cleaning operates faster than plasma because the duty cycle is slow. It’s because the machine spends more time moving mechanical parts and has a small portion for cleaning materials.

The cleaning processes require a gantry system to move a nozzle above the surface. Unlike laser machines, it leaves carbonized contaminants stuck to the surface, which can be challenging to remove.

The sandblasting process is similar to laser cleaning but might leave marks and scratches on the item. This method can be applied to stone, metal, wood, plastic, and paint layers.

Unlike sandblasting, laser cleaning is an environmentally friendly option. It removes impurities with little to zero impact on the material.

- Water Blasting vs. Laser Cleaning

Unlike laser surface cleaning with effective beams, this method removes contaminants using high-pressure water. It’s suitable for cleaning outdoor surfaces such as parking lots, sidewalks, and buildings. It’s better than abrasive blasting but not ideal for delicate items.

Environmental Impact of Laser Cleaning Compared to Traditional Methods

High-power laser cleaning has a significantly lower environmental impact, unlike conventional methods. It’s because the system doesn’t use harsh chemicals polluting the environment. It also reduces the material you need to remove, allowing you to target specific surface areas.

Laser cleaning systems have more energy efficiency than traditional techniques, which lowers environmental impact. The result depends on your item, cleaning conditions, and waste produced.

Applications of Laser Cleaning Technology

Laser properties for metallic and non-metallic surface preparation make the tool handy in the automotive industry. Its coating removal, precise paint stripping, and composite lay-up tool are helpful in aerospace.

Other industries adopting the laser rust removal machine include the following:

- Manufacturing industry

- Military and defense industry

- Power generation

- Mechanical industry

- The tyre and rubber industry

- Shipbuilding industry

- Electronics industry

- Precision instrument industry

- Mold industry

- Rail industry

- Maintenance and repair facilities.

Cost-Effectiveness of Laser Cleaning in the Long Run

Laser cleaning cost-effectiveness can vary based on different factors. They include the substrate and equipment size, intensity, and frequency.

These systems can be more economical in the long run because of their energy efficiency and reduced need for chemical cleaning agents. Minimal labor and maintenance will also play a crucial factor.

Many laser cleaning machines have a longer lifespan. It further enhances their long-term cost-effectiveness. The sustainability of laser cleaning depends on each application’s circumstances and specific needs.

What to Consider When Choosing a Laser Cleaning Machine

Here are factors about how to choose laser cleaning machines.

1. Laser Power

The laser rust remover’s power is often in watts, representing the average energy released via the laser beam.

A laser technology with 100W watts can pulse beams with a peak power of 10,000W. The energy surge can increase when ejecting contaminants from metal surfaces, but the more power, the faster it cleans.

The most efficient and powerful cleaning machines typically have multi-mode lasers. Their energy production can reach 3,000W, making them ideal for demanding applications.

2. Safety

Safety is an essential factor to consider when selecting these machines because they produce intense heat. Pay attention to the safety precautions before choosing a device suitable for your projects.

Most laser machines require a class-1 laser safety enclosure to meet safety regulations worldwide. A product with this rating does not need personal protective gear (PPE). If you’re using a hand-held device, it could be class-4 rated, requiring extra PPE.

We have prepared this article so that you can learn about laser ratings and safety.

3. Fume Extraction

Another factor to check during laser cleaning machine selection is the fume extraction nozzle.

After removing contaminants, they become fumes or dust that need the extraction to keep the work area clean. It’s crucial for paint stripping applications because hazardous substances get released into the air.

4. Single vs. Multi-mode Properties

Many laser cleaners have multi-mode and clean surfaces faster due to their sizeable optical fiber core. Machines with single modes have a low tolerance for depth variations.

Multi-mode lasers have large spot sizes and get pulsed over a wide surface area. They can also generate more energy to reach higher power levels for efficiency.

5. Fiber Cable Length

Pay close attention to the machine’s fiber cable length when using a mounted or handheld device. Those with longer lengths enable more movement freedom but reduce the pulse energy. The longer it gets, the lower the energy it produces.

Emerging Market Trends for Laser Cleaning

As laser cleaning technology advances, it is continuously gaining recognition as an efficient and effective solution in various industries. One emerging market trend is the growing demand for eco-friendly products.

Laser cleaning provides a sustainable alternative to conventional chemical-based solutions. It’s an attractive option for industries looking to minimize their environmental impact.

Their increasing use in aerospace engineering and automotive manufacturing is another trend. As technology advances, we might see new usage emerge for these machines in medical and electronic device production.

Conclusion

After learning about laser cleaning machines and rust removal, consider buying the best equipment for your projects. Your ideal tool should produce excellent power in watts and clean metal surfaces.

For desired results, consider products with multi-mode properties, reliable fume extraction, and excellent fiber cable length.

Buy a Premium Laser Cleaning Machine from Baison Laser

Buy high-quality laser rust removal machines with versatility and effectiveness only from reputable manufacturers. Baison Laser fits the description of the best producer of these tools.

Contact us today for a consultation, and you’ll get the best products for your projects.