Though a few solutions are available in the market today, most cannot meet customers’ expectations. And this spans various needs from commercial to industrial and even historic object cleaning. The need for efficient and professional surface cleaning is growing; this is where sandblasting and laser cleaning come in to fill that need.

Why is there a need for surface cleaning?

When it comes to surface cleaning, the number one culprit is oxygen. Yes, it is one of the most crucial elements people need to breathe and live. But as beneficial as it is to humans and most living things, it is a primary component in breaking down objects usually made of metal. Oxidation is a process where corrosion sets in as a result of rust.

Given enough time, oxygen and water on the surface of any piece of iron will generally result in corrosion. It can also occur in the smallest piece of metal, heavy machinery, and everything in between. This is why sandblasting, and laser cleaning are both increasing in demand. But between the two – which one is better?

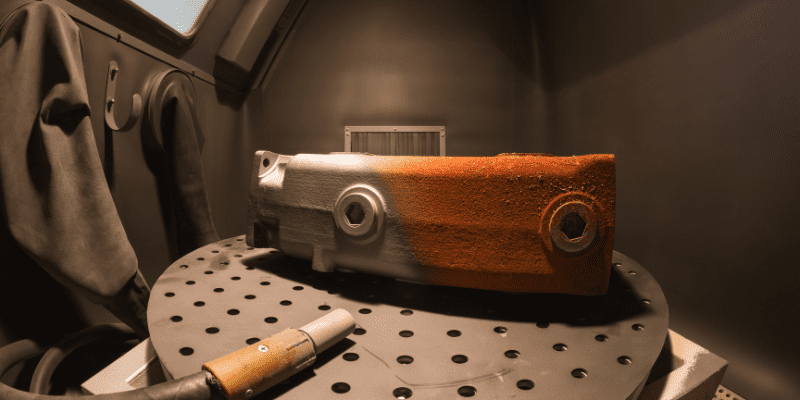

What is Sandblasting?

This process removes surface contaminants by high-pressure force by propelling media on the affected surface. And the reason why it is referred to as sandblasting is that the media used in the process is sand-mixture. Though there are other items you can use, like walnut shells and glass beads, sand-mixture is the most common.

You might come across the term ”abrasive blasting“when it comes to sandblasting. The sand mixture (an abrasive material) is pushed out at high speeds on a surface. The powerful propulsion of the media is generally possible with the help of compressed air or even water. And the uses of this are not limited to simply rust cleaning. Sandblasting can also deal with and take out different oxides, grease, and even paint.

If you were wondering, sandblasting is the more current version of sanding. But rolling your sleeves and standing up and down, left to right, is often cumbersome. Not only that, it will take you a long time to clean a large surface. But with sandblasting, surface cleaning becomes a breeze, with the process done much faster.

The pros and cons of sandblasting

As with most surface cleaning processes, sandblasting has benefits and downsides. It is a good idea to dig into these two sides to help you understand this option better. This is most helpful when comparing sandblasting with other surface cleaning options.

Pros of sandblasting

When you are working on cleaning a large surface area, sandblasting is an excellent option for you. Compared with other alternatives, it can get the job done much faster. Not only that, but it can also work with thicker contaminants on the surface. Since you are blasting sand mixture at high speeds, it quickly breaks through rust and other oxides.

Here are some more of the upside when using sandblasting in surface cleaning:

- The process was invented around 1870. This means the process has undergone different improvements over the past decades.

- The process is quite flexible and relatively easy to use and operate.

- You only need fewer pieces of equipment when cleaning surfaces through sandblasting. At the minimum, you only need the sand mixture, a blasting pot, and a compressor and nozzle.

- Sandblasting is already used in various industries for surface cleaning. This speaks volumes about the effectiveness of the process.

Cons of sandblasting

Much like any process, there will always be two sides to every result – the good and the bad. Now that you have an idea of the upsides of sandblasting, we now look at some of the challenges when choosing this process. One of the most glaring is that media blasting has been known to harm the environment. On top of this, the post-process clean-up requires specialized handling.

Here are some more of the drawbacks when using sandblasting in surface cleaning.

- The media used can contribute to equipment breakdown because of its abrasiveness.

- The high-speed delivery of the media, as well as its abrasiveness, could potentially damage the surface you are cleaning.

- It is a requirement to wear Personal Protective Equipment (PPE) when working on large installations in sandblasting. This is because it can cause harm to the exposed skin area in the operator’s body.

- Sandblasting requires ventilation and a large area because long-term exposure to the cleaning solutions could result in some severe health risks.

- You need to replace the media now and then, which adds to your operating costs.

- EPA legislation requires careful and costly handling and management of the media as it separates from the contaminant.

What is Laser Cleaning?

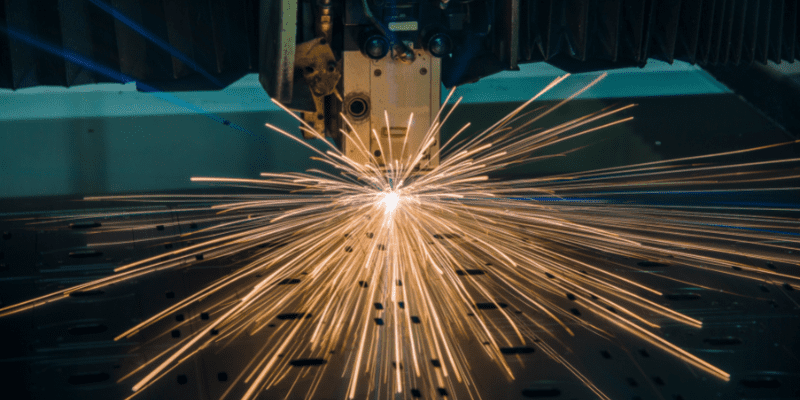

Sometimes referred to as laser ablation, laser cleaning uses laser pulses to focus on surface contamination. The unique thing about this is that the laser can transform the contaminant into gas and captures it. This is the biggest reason why this process is gaining much traction in the area of surface cleaning.

The closest similarity that laser cleaning has with sandblasting is the goal of removing contaminants on a surface. More than rust, both can remove other surface problems like paint, grease, and even oil. But that is where their similarities end. Laser cleaning has been proven to be a different process compared to sandblasting.

How does laser cleaning work?

The process begins by emitting several short laser pulses at extremely high energy levels. As it focuses on small areas of the surface you are trying to clean, it brings the contaminant’s temperature to a point where it vaporizes and changes its state from solid/liquid to gas. Once this happens, the gas collection also happens, significantly reducing the process’s by-product.

It pays to know that contaminants usually require less energy when vaporizing them compared to the energy needed to do the same for the surface. This minimum energy is what’s called the ablation threshold. Once you go over that threshold, you risk damaging the surface. This is why laser cleaning is an excellent option because you have complete control over the energy levels of your lasers.

Pros of laser cleaning

Laser cleaning is more environmentally friendly when compared side by side with sandblasting. It also uses technology to complete the whole process from start to finish. As a result, automation is much more possible with laser cleaning.

Here are a few more benefits of choosing laser cleaning.

- The laser can remove much more oxidants and operate on more types of surfaces, including paper.

- More than removing contaminants, laser cleaning can also help to intentionally modify the surface for post-cleaning needs.

- There is no need to use abrasive media, solvents, or even other types of chemicals in cleaning surfaces.

- Laser cleaning can be precisely controlled to cover a specific area on a surface.

- The process is much safer for the machine and the person operating it.

- The technology behind laser cleaning makes it ideal for easy process replication.

Cons of laser cleaning

Yes, as much as laser cleaning might seem to be a better choice in the surface cleaning industry, it also has some downsides. For one, it works best when working on small and very targeted surface areas. It could take a while to complete the job if you are trying to clean a large area using a laser.

Here are other factors to watch out for when using laser cleaning for the job.

- Laser cleaning has some restrictions when you need to clean crevices. Simply put, if the operator can’t see the surface that needs to be cleaned, the laser might not be able to clean it.

- The machine needed to get started with laser cleaning could be a significant initial expense.

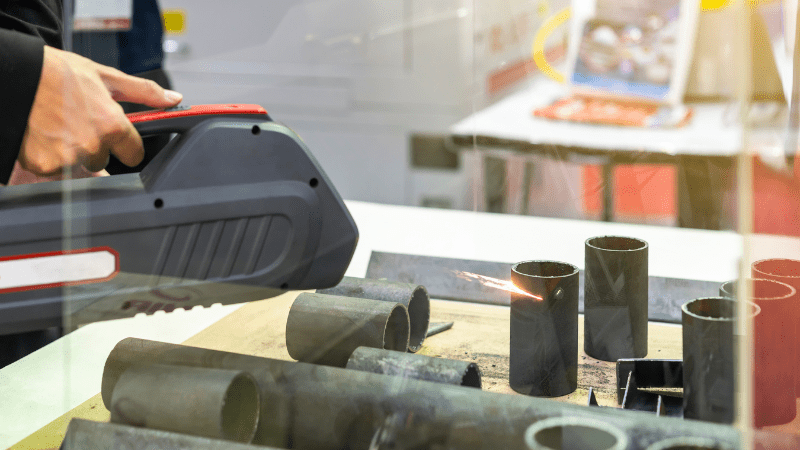

How much are laser cleaning machines?

As mentioned, the cost of the initial investment in a laser cleaning machine could be pretty significant, ranging from $11,000 to almost $17,000. These are even only for handheld-type devices. The more complex and the more giant laser machines could cost even more. The range in prices differs depending on the watts you need. Laser cleaning machines can go from 1000W to 2000W. It all depends on your need and the type of job you will use it for.

Which is better – laser cleaning or sandblasting?

There is no doubt that these two are at the forefront of the surface cleaning industry. They have unique pros and cons and can be used almost interchangeably. But at the end of the day, the best process will always depend on the job you have at hand.

If you must protect that surface, you are cleaning. Lasers might do the job better. But if that is not a concern and the focus is cleaning a large area quickly, sandblasting might be better. So take a look at the pros and cons of each process so you can carefully pick and decide which one will suit your cleaning requirement. If you still have no idea which machine is suitable, we are glad to help. Click the button below and get a professional suggestion!