Laser cutting is utilized for crafting various products. The refined edges it creates give the products a stunning look. Its refined cutting and engraving make it the best choice for stencil cutting. Laser cutting facilitates the intricate process of stencil manufacturing and offers you perfect stencils.

In this blog post, you’ll learn about the process of cutting stencils by using laser technology. You’ll also explore its advantages and precautions you should take during laser cutting stencils.

Overview of Laser Cutting

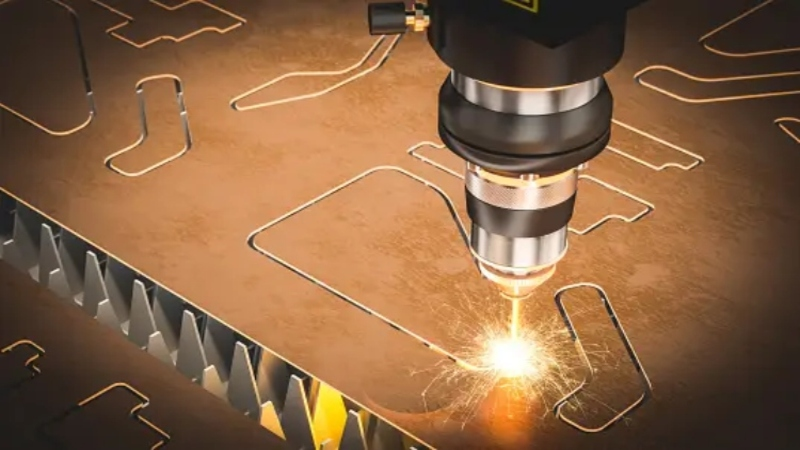

Laser cutting is gaining popularity due to its high accuracy and simplicity. An outline or template is cut out from a thin sheet to create different designs over surfaces by using a high-energy laser beam. The high-intensity beam melts and vaporizes the material.

This technique is implemented to cut different materials, including wood and metal. The most commonly used material for laser-cutting is Mylan due to its durability and versatility. Designers and artists use stencil laser cutting art in numerous applications.

Do You Have Any Questions?

Let Us Solve Your Problem

Advantages of Laser Cut Stencils

Using laser cutting technology is very beneficial for the following reasons:

1. Easy Repetitive Artwork

Laser cutting stencil is a popular technique as it offers high precision and accuracy. Due to this, it is a preferable choice for industries to produce complex designs repeatedly.

If the correct stencil design principles and laser cutter settings are used, these laser cutters can create repetitive artwork in less time. According to Dinexltd, the high speed and precision of laser technology ensure the accurate repeatability of the stencil design.

2. Less Costly

Stencils save time and effort and are cost-effective. They can be reused and tweaked into new stencil designs by applying fresh spray paint. Most importantly, it is easy to patch up the design if it fades over time.

3. Enhances Overall Look

Home decor, crafts, and packaging industries extensively use laser cutting technology due to its reproducibility and quick application. They deliver an aesthetic outlook in a more budget-friendly way.

4. Variety of Sizes

Laser-cut stencils are not limited to a specific range of sizes. It is available from a few millimeters to an amazing machine limit of approximately 250cm by 130 cm. However, you must consider different factors to achieve the desired results.

What Materials are Used for Laser Cut Stencils?

Any material that can be laser cut can be used to make the stencil. According to the Cleveland Public Library, you should know which materials to cut with a laser before starting any project. Some of the most suitable materials for laser-cut stencils are described as follows:

1. Paper

The most readily available and suitable material for the laser-cut stencil is paper due to its quick and precise cutting. However, it is not preferable due to its absorbent nature and susceptibility to rapid tear, making it suitable for one-time use.

2. Mylar (Polyester)

A thin polyester film or Mylar sheet is a popular choice for the laser-cutting stencil due to its non-absorbent quality, making it suitable for repeated use. Mylar stencils can be cut quickly and precisely, giving quality graphics with accurate and detailed graphics at a relatively low cost.

3. Sticker Paper

Sticker paper has properties similar to paper but possesses an additional adhesion property after applying glue or pain, thereby giving more accurate results. This material is highly recommended for stencils when spray painting or using glue on cylindrical bodies.

4. Polypropylene (PP)

This plastic sheet is available in variable thicknesses, typically ranging from 0.3mm to 1.0mm. Industries use the material due to its flexibility and availability for repeated uses. One drawback to using this material is that it tends to melt near the cutting areas. Therefore, it is used to design less detailed graphics.

5. Cardboard

High-density cardboards are used for making stencils. This has properties similar to the paper but is more durable due to extra thickness. Laser-cutting of this material is also relatively inexpensive due to the lower cost of the material.

6. Acrylic

A common use for acrylic is to cut simple shapes out of thicker sheets. Since handling acrylic sheets can be a tougher task, they are not used for thin sections due to the high risk of cracking.

7. Magnet Sheets

The coarse stenciling on the machine steel panels and vehicles uses magnet sheets stencils. Their main advantage is maintaining their shape even when handled aggressively.

8. Silicone and Rubber

Silicone and Rubber are flexible and durable stencil materials. It’s the most expensive stencil with a high friction coefficient suitable for 2D and 3D surface stencil designs.

Do You Have Any Questions?

Let Us Solve Your Problem

Which Laser Machines Can Cut Stencils?

Picking suitable laser machines for cutting stencils depends on various factors such as material thickness, design, and required level of precision.

A CO2 laser cutter can precisely cut desired stencils. It employs carbon dioxide gas with a mixture of auxiliary gases, like oxygen, helium, and xenon, for cutting various materials. You can use it to cut mylar, paper, cardboard, and acrylic. Its use of various materials makes it a suitable match for cutting stencils for multiple applications.

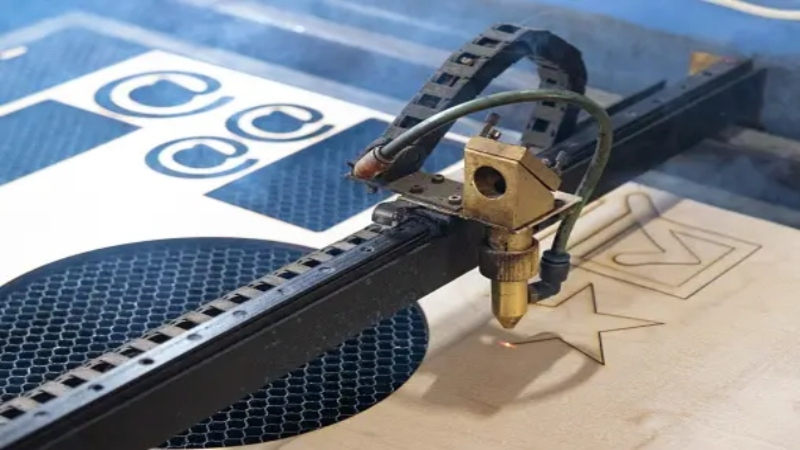

Besides the CO2 laser cutter, you can use a fiber laser cutter to manufacture stencils from easy-to-cut thin sheets. However, you can’t use diode lasers for Mylar sheets as they are thick and need more power for melting and vaporization.

7 Steps to Laser Cutting Stencils

You need a rapid, efficient, precise laser cutting machine to turn your imagination and creative ideas into reality. Here is a step-by-step guide to help you in creating laser-cutting stencils.

Step 1: Create the Stencil Design

Firstly, create your stencil design using laser cutter software like Adobe Illustrator. It should not overlap with the other design to ensure correct execution.

Step 2: Pick the Right Material

Pick the material that suits your thickness, design, and complexity needs. You also need to pick suitable laser-cutting machines.

Step 3: Set up the Laser Cutting Machine

Once you have chosen the perfect material for a stencil, adjust the laser cutting machine’s settings according to the selected material. You can adjust your material’s cutting speed, laser power, and blade setting.

Step 4: Position Your Stencil

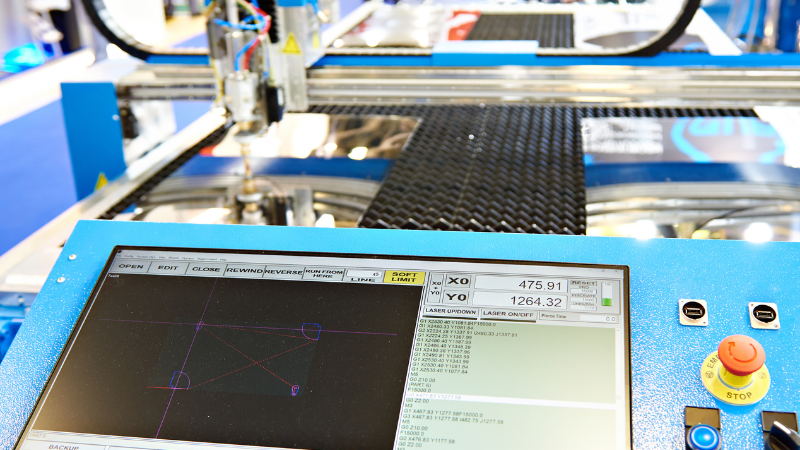

The software’s real-time preview lets you align your design to the workpiece when the stencil is on the workbed. To minimize the waste during the process, ensure you have placed the stencil in the right position.

Step 5: Start Cutting

Start the cutting process once you have made the necessary adjustments and changes. The laser-cutting machine will do the job while you can sit back to watch the process.

Step 6: Stencil Cleaning

Immediately after cutting, remove and thoroughly clean the stencil to avoid the accumulation of residue or debris. Our precise laser-cutting machines ensure a professional-looking and smooth stencil. Make sure you remove any excess material from the stencil before using it.

Step 7: Use the Stencil

Once your stencil is ready, secure it properly on the surface. Secure your stencil using ink, paint, or other medium. Baison laser machines ensure precise and clean stencil designs with consistent results.

Settings For Laser Cutting Stencils

Setting the laser-cutting machine depends specifically on various factors such as speed, frequency, and laser power. The optimal settings vary based on the laser machine’s material thickness, power, and nature.

For your ease, we have described the settings for common stencil materials. These are the approximate values; you can test close values to ensure you get the desired results.

| Material | Laser Power (%) | Speed (mm/s) | Frequency (Hz) |

|---|---|---|---|

| Mylar | 10-40 | 300-800 | 1000-3000 |

| Paper | 10-30 | 500-1000 | 1000-2000 |

| Sticker Paper | 20-40 | 300-800 | 1000-2000 |

| Polypropylene | 20-50 | 300-800 | 1000-3000 |

| Acrylic | 40-80 | 100-600 | 1000-5000 |

| Magnet Sheet | 40-70 | 300-800 | 1000-3000 |

Do You Have Any Questions?

Let Us Solve Your Problem

What Industries Use Laser Cut Stencils?

Various industries use laser-cut stencils. These include:

1. Arts and Crafts

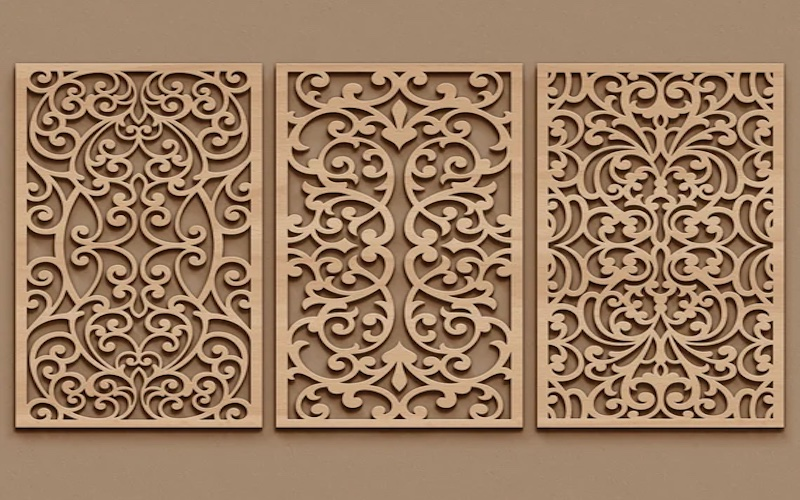

Laser-cutting stencils have revolutionized creative expression in the arts and crafts industry. Laser technology has enabled designers to craft stencils, enabling flawless reproduction of complex designs. It has enhanced the artistic process with detail and efficiency.

2. Home Decor

By designing complex and intricate designs, laser cutting stencils have redefined home decor. From customized wall art to detailed furniture decoration, laser cutting’s versatility has offered a seamless fusion of craftsmanship and aesthetics.

3. Defense and Aerospace Industries

In the defense and aerospace industry, laser cutting technology is used in manufacturing components with high precision. Laser cutting helps accurately cut materials, contributing to the manufacturing of complex aerospace parts. It has helped enhance reliability, safety, and performance in aerospace applications.

Precautions for Laser Cutting Stencils

Adhering to the precautions in the laser-cutter stencils process is crucial to ensure the process is completely safe. The following are the most important precautions:

- While operating the laser-cutting process, ensuring a proper exhaust system equipped with the workstation is imperative. The evacuation of hazardous fumes is necessary to maintain a safe working environment.

- Employ advanced fume extraction systems with filtration mechanisms. It is important to minimize the health risks by filtrating the process’s byproducts and prohibiting them from inhaling.

- Ensure real-time monitoring systems are in place to track every essential laser cutting parameter. This will help in the identification of deviations promptly, allowing immediate intervention and adjustment.

- It is necessary to install automated shutdown systems to ensure the system will immediately stop working if it notices any malfunctioning. This is essential to deal with the irregularities and help to minimize the risk of accidents.

- Regular calibration and validation of the laser cutter machines are crucial to uphold the precision in cutting parameters. Consistent calibration is critical to maintaining accuracy and obtaining the desired outcomes.

FAQs

1. How Does the Thickness of the Material Impact the Laser Cutting Process for Stencils?

The thickness of the material significantly impacts the laser cutting process for stencils. Thicker materials require more laser power and slower cutting speeds to achieve a clean cut, while thinner materials can be cut faster and with less power, reducing the risk of burning or melting the material. Additionally, the choice of material thickness can affect the level of detail achievable in the stencil design.

2. Which Gas is Used for the Laser-Cutting Operation?

The gasses used for cutting the stencils are mostly compressed air, oxygen, and nitrogen gas. The choice of the gas depends on the nature of the material and application they are used in. Technically, these gases assist in the cutting process and are not directly involved.

3. Why CO2 is Used in the Laser-cutting Stencils Process?

CO2 is a gas laser technique for processing sheet metal. It is the most popular laser-cutting technique due to its high precision and offers freedom to shape a wide range of materials with intricate shapes.

Do You Have Any Questions?

Let Us Solve Your Problem

Conclusion

Laser-cutter transforms how complex and intricate graphic designs are created. Currently, many industries are choosing laser-cutting techniques due to their high precision and accuracy.

The involvement of laser-cutting stencils is increasing widely due to their easy accessibility and usage. The material’s thickness, the design’s complexity, and the laser cutter’s characteristics all need to be taken into account to achieve the desired results.

Choose Baison Laser to Improve Laser Cutting Capabilities!

At Baison Laser, we are committed to providing cutting-edge solutions to your unique needs. Regardless of whether you are a newcomer thinking of entering the laser-cutting industry or want to elevate your laser-cutting game, our laser solutions can help you.

Get a free application evaluation now, and we’ll help you identify the best laser-cutting solution for your business. Also, our team can assist you in optimizing your laser-cutting process and boost your productivity.