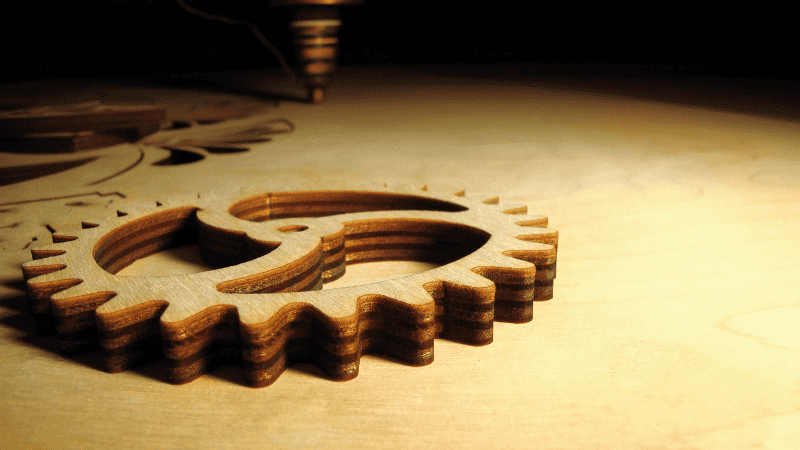

Gears are a crucial component of numerous machines and mechanical devices. Laser cutting is a precise technique that allows you to prepare gears with better quality. It also improves the production rate, enabling you to create various types of gear.

In this blog post, we’ll help you explore the process of cutting gears by using laser technology. You’ll also learn about the advantages and drawbacks of laser-cutting gears. So, let’s get into it.

Difficulty of Gear Cutting

Gear cutting is not as easy as most manufacturers think. However, employing traditional methods poses several limitations to creating gears. Here are some challenges of using traditional methods for gear-cutting:

- Gear cutting involves cutting material from the workpiece. Improper cutting speed and unsharpened cutting tools result in chipped teeth. These chipped teeth of gears interfere with the smooth movement of gears and may damage the entire machine.

- Another challenge of gear cutting is the smooth finish. The smooth finish of the gear minimizes friction and ensures convenient movement of the moving parts. A rough finish gives an unpleasant appearance and decreases the lifespan of your machine.

- Chatter marks are a great challenge while cutting gears. According to the ZHY Gear, it occurs due to the vibration of the cutting machine. Chatter marks degrade the quality of gears and lead to structural weakness.

- Another difficulty of gear cutting is gear runout. It involves deviation of the rotational axis from its center. It arises due to the inaccuracy of the cutting tool and misalignment of the workpiece or cutting tool.

- Gear cutting can also lead to machine overload. It occurs when the applied force exceeds the machine’s capacity. It results in excessive removal of material from the workpiece.

- Moreover, the cutting process can distort the gear due to thermal or mechanical stress. It leads to inaccurate tooth profile and dimension.

Pros and Cons of Laser Cutting Gears

Laser cutting gears are crucial for the operation of numerous devices. However, this beneficial technique also has some cons. Here is an overview of some pros and cons of laser cutting gears:

Pros of Laser Cutting Gears

A laser cutter machine makes the gear cutting more precise. Here are some notable advantages of laser-cutting gears:

- Improves Gear Quality

Laser cutting is a precise technique that employs a high-energy laser beam. The laser burns the material as it strikes, resulting in a clean and precise cut. Adjusting the power and speed of the laser machine enables you to cut the required pattern of the gears accurately. Employing computer-aided design (CAD) further minimizes the risks of errors by limiting manual operations.

- System Flexibility

Laser cutters allow you to create different shapes and patterns. You can use a single setup to create various types of gears. You don’t need to employ multiple tools for making different types of gears. You can alter the cutting pattern by changing the parameters; the cutter will engrave or cut your desired gear in no time. This feature of the laser cutter saves you considerable costs while manufacturing various types of gears.

- Versatility of Materials

Unlike traditional cutters that limit you to certain materials for gear cutting, laser offers you a versatile option. You can work with several materials for manufacturing gears for multiple purposes. Laser cutting can be used for several materials, like acrylic, wood, stainless steel, and tungsten. It allows manufacturers to create gears to cater to the needs of various industries, including automobiles, aerospace, and electronics.

- Contactless Approach

Laser-cutting machines produce a laser beam that penetrates the workpiece and melts it. The laser cutter does not require physical contact with the material for cutting. This non-contactless approach minimizes the risks of material contamination, which is a common issue in traditional cutting methods. This non-contactless feature of the laser cutter also contributes to providing cutting flexibility.

- Automation

Like CNC, a digital laser cutter also employs computer systems. It works with computer-aided design (CAD) files, like DXF files. Automation minimizes manual efforts for gear cutting. The laser cutter follows the software design and gives you clean cuts. It eliminates the human errors that are a significant concern in traditional cutting methods.

Cons of Laser Cutting Gears

In addition to the advantages, this advanced technology comes with some drawbacks. Here are some potential concerns of using a laser for gear cutting:

- High Upfront Cost

Installing a laser cutter is a costly pursuit that requires significant initial investment. Laser cutters are twice as costly as other cutters, such as plasma cutters or water jet cutters. This initial investment is a huge concern for small businesses short on budget. However, this investment is worth it in the long run because of its high production rate and precision.

Want to know how laser cutting compares to plasma cutting or water jet cutting?

- Emission of Toxic Fumes

Laser cutters do not release toxic fumes with all materials. However, certain materials release harmful gases when working with certain plastics. They release toxic fumes on melting. It poses a potential health and safety hazard for the operators working in the vicinity of the laser cutter. Proper ventilation and opting for materials that do not emit toxic gases can help you create a safe working environment.

- Limited Material Thickness

Laser cutters can cut a certain thickness as the laser beams can not penetrate thick materials. The thickness a laser can cut also depends on the type of material. Some hard-to-cut materials can’t be cut unless they are 15 to 20 mm thick. For some materials, the thickness is larger than this range.

- Need for Expertise

Operating a laser cutter requires technical expertise. You might hurt yourself while operating the machine without guidance and training. Take proper training or hire an expert who knows the process of setting cutters for manufacturing gears.

8 Steps of Laser Cutting Gears

Cutting gear with a laser is convenient and offers excellent quality. Here are some steps of laser cutting gears:

1. Define Gear Regions

Before getting into the laser cutting process, you need to create the design for the gear. Defining gear regions is the first step to creating gear design. It ensures the right alignment of teeth and spokes. The software allows you to design the gear regions accurately. The digital system gives you better control over the dimensions of the gears.

2. Create Teeth and Spokes Design

Once you have definite gear regions, start designing teeth and spokes. Accurate alignment of teeth and spokes is crucial for the smooth movement of the machine. It also strengthens your gear and stabilizes its weight. Using the software, you can ensure the right placement of teeth and spokes. Computer-aided design also allows you to modify the gear design and add specific features according to the requirements.

3. Choose The Right Material

Material selection is a considerable factor in ensuring the stability of the gear. It also affects the durability of the gear and the machine. Laser cutting can be used for several materials. Choose the material according to the functionality and strength required for your machine.

4. Adjust The Laser Cutter Settings

Power, speed, and focus of the laser machine are significant parameters impacting the quality of the gear. Extremely high or low power can deteriorate the corners of the gear. Too high or slow speed may produce rough edges. Deviation of the focal point can also ruin your cutting process. Set optimal focal point, power, and speed settings to achieve the desired gear design.

5. Test The Laser Cutter

Before operating the laser on the workpiece, test the setting on a small piece. This step is crucial as it enables you to determine the quality of the machine settings. You can make necessary adjustments before cutting the actual gear.

6. Position The Workpiece

Positioning the workpiece on the laser-cutting bed is another considerable step. Proper positioning of the workpiece ensures the accuracy of the gear-cutting process. It also prevents the distortion of the design of the gear due to misalignment. Use clamps or other tools to fix the workpiece.

7. Cut The Gear

Once you have adjusted the settings and the workpiece, operate the laser cutter. The laser beam from the machine melts and vaporizes the material as it strikes the surface of the workpiece. The controlled movement of the laser beam gives you the desired design of the gear. The software design ensures the laser beam follows the specified pattern.

8. Post-Processing

After cutting the gear, you may notice rough edges or discoloration. It often occurs during laser cutting due to high-energy laser beams. Post-processing of the gear eliminates the imperfect edges. Deburr the edges to remove any sharp corners. Heat treatment, coating, and polishing refine the gears and improve their aesthetics.

Laser Cutting Gears in Different Materials

Laser cutting can be used for several materials. Here are some commonly used materials for creating gears by laser cutting:

- Wood is one of the most suitable materials for laser cutting. You can use plywood and MDF for creating wooden gears. Beware of the resins and oils in the wood. The intense CO2 laser beam can burn the oils and resins, leading to discoloration and rough edges.

- Polyoxymethylene (POM) is another great material for creating gears. It is a thermoplastic with unique mechanical properties, like resilience, surface tension, and thermal stability. The material is also resistant to chemicals, making it suitable for gears exposed to extreme conditions. A CO2 laser cutter is used for precise engraving and cutting POM to make gears.

- Various plastics are also used for manufacturing gears by laser cutters. However, avoid using plastics that release toxic fumes. PMMA, acrylic, and Lucite are the best plastics for gear cutting. A CO2 laser cutter is a suitable equipment for cutting plastic.

- You can also use metals, like brass and aluminum, for laser cutting. These metals are great for creating high-precision gears that require strength and durability. They can also withstand high temperatures, making them suitable for industrial gears. You can use several types of laser machines for making gears with metal sheets. Fiber lasers and CO2 lasers are commonly used for this purpose.

Applications of Laser Cutting Gears

Laser-cutting gears are of several types and are used in multiple industries. Here are some common applications of gears manufactured by laser cutting:

1. Aerospace Industry

Aerospace is a vast field that demands precision in every aspect. Any mistake can lead to deadly consequences. Laser-cut gears are used for airframes as they offer better quality and structural stability.

2. Electronics

Gears are a prominent component of various electronics. Numerous household appliances and gadgets have various gears for mechanical movement. Gears made by laser cutting ensure the durability of electronics, making them suitable for everyday use.

3. Medical Implants

Precision is also paramount for the medical industry. The preparation of medical implants employs various types of gears manufactured by laser cutting to improve the quality of the implants. Automated laser cutters eliminate the risks of any instability during gear manufacturing and ensure a high level of accuracy.

What Should Be Noted When Laser Cutting Gears?

Laser cutting is a complex process that involves various complications. Here are some considerations to keep in mind when laser cutting gears:

- Laser cutters are designed for cutting particular thicknesses of the workpiece. Choosing a thicker material for laser cutting can be challenging and leads to poor gear quality. Pay attention to the manufacturer’s instructions to pick the right thickness of the material.

- Analyze the edge quality of the gears. Laser cutting can lead to rough edges that can impact the gear’s functionality. Adjust the parameters of the laser cutter to improve the edge quality if needed. Post-processing can also improve the edges of the gears.

- Laser cutting may generate toxic fumes that can lead to health hazards. Ensure proper ventilation of the workspace to prevent the accumulation of fumes that may be harmful to health.

- Carefully design the gears to maintain proper gaps between the teeth. These gaps ensure the gears mesh perfectly after the assembly.

FAQs

1. What is the best material for laser cutting gears?

Laser cutting is a vast technique and can be used for several materials. Acrylic is considered the best material for laser cutting gears. It is known for its strength and optical clarity, making it ideal for creating precise and durable gear parts.

2. How do lasers cut things?

Laser cutting releases an intense laser beam for cutting various materials. A high-energy beam melts and vaporizes the material as it hits the workpiece. The software design guides the cutter to cut the desired pattern.

3. What protective gear is required for laser cutting?

Laser cutting releases high-energy laser beams that can damage your eyes and skin. Safety goggles, head covers, face shields, and coveralls can help you avoid harmful radiation.

Conclusion

Gears are an imperative component of various mechanical and electric devices. Laser technology enables you to create high-quality gear for multiple industries. However, take precautions while laser cutting. Maintain proper ventilation to create a safe working environment. And don’t forget to choose a premium-quality laser cutter.

Get a Laser Cutter for Gear Cutting with Baison Laser

If you are looking for the best laser cutters, Baison Laser is the best choice. It offers high-end laser solutions for manufacturing various gears and several other purposes, including laser cutting, welding, marking, and cleaning machines for the best results. Contact us today to purchase a laser-cutting machine and unleash your creativity with precision.