Selecting a suitable fiber laser cutting machine challenges beginners due to the market varieties. The equipment is famous in the commercial and industrial automotive industry for its precision and faster cutting speed.

You need in-depth knowledge to identify which is ideal for engraving, etching, drilling, cutting, and marking projects.

This article will discuss how a fiber laser cutting machine works and its importance in the automobile manufacturing industry. We’ll also explain their applications in manufacturing and factors to consider before selecting.

What Are Fiber Laser Cutting Machines?

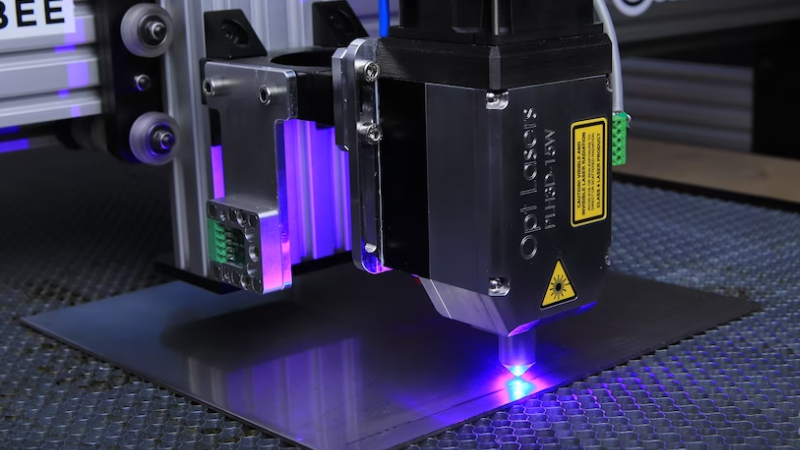

A fiber cutting machine uses a high-power density laser beam to manipulate various materials. It can process incredibly thick metal components with protective coatings into desired shapes and patterns.

The fiber laser cutting technology produces intense, concentrated heat through optics to vaporize or etch non-ferrous, non-metallic, or metallic items. They’re perfect for cutting silver, copper, galvanized sheets, aluminum, alloy, carbon, and stainless steel.

A fiber laser cutting machine has in-built technology offering consistent high-quality accuracy and unparalleled speed. It allows users to recreate specified patterns with precise automotive industry smooth cuts.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

How Do Fiber Laser Cutting Machines Work?

The laser machine works with active optical fibers that transmit a focused light beam to the cutting head.

Fiber laser cutting machine beams are narrow, bright, and easy to use in a specific direction. They’re perfect for surface modification and can mark, cut, drill, and engrave various metals.

Unlike traditional cutting, you can etch, shape, and trim objects with a laser. A fixed beam, moving arms, and beam delivery are the fiber laser marking machine’s working components at their core.

The fixed beam is a mechanical process that enables a robot to move material before the light rays. The arm allows repeated movements, letting the laser cut items into different patterns. Lastly, the beam delivers fiber optics, articulating the laser power for complex shape cuts.

Importance of Laser Cutting in the Automotive Industry

Laser cutting machines’ smooth, precise cuts and high production efficiency are essential in manufacturing the automotive industry.

A fiber laser cutting machine processes automotive materials into slimmer parts using computer numerical control (CNC) technology. It’s also versatile in design complexity and flexibility since it can process rubber, glass, fabrics, and plastics.

A laser CNC machine is cost-effective compared to conventional processing methods. It can cut materials in large, medium, and small batches to meet individual needs.

Advantages of Fiber Laser Cutting Machines in the Automotive Industry

High precision and faster cutting speed are a few benefits of laser cutting technology in the automotive sector. Machining complex materials and versatility are other pros.

1. High-Precision Laser Cutting Machine

These industry tools have an innovative approach offering quick turnaround with high cutting precision when cutting materials. The accuracy of a laser cutting machine is due to its in-built computer numerical control (CNC) technology.

A laser CNC machine has a thin laser beam, enabling precise cuts without material waste. It’s ideal for laser welding and etching intricate patterns and designs. It ensures cutting precision on an industrial mass-produced product like a fender, body panel, hood, and door.

2. Faster Cutting Speed

Fiber laser machines offer faster cutting speed that frequently replaces conventional processes.

The technique takes less time with the right equipment in the automobile manufacturing industry. The laser machine speed efficiency directly relates to the equipment’s power.

You can cut materials five times faster with it, unlike utilizing CO2 laser conventional manufacturing methods.

3. Versatility in Laser Processing

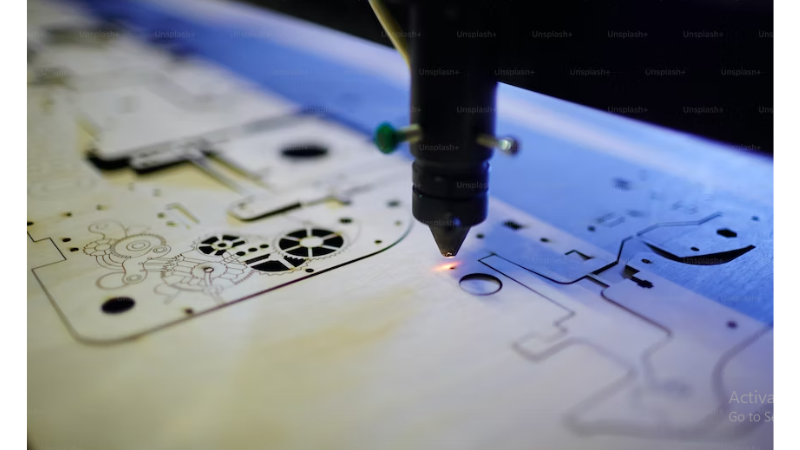

Another advantage of a fiber laser cutting machine is its versatility. It’s ideal for cutting rubber products, sheets, metal, paper, silicone, and wood for commercial and industrial purposes. Users can process items into styles and patterns based on the operator’s settings.

Fiber laser machines can engrave and etch materials for various applications under different operating conditions. Manufacturers use these tools for marking automotive parts to identify products through the supply chain.

4. Machining Complex Functional Materials

Fiber laser machines are helpful in the automotive industry for machining complex functional material properties. They have excellent adaptability to difficult-to-machine items like cemented carbide or alloy.

Ceramics are hard and brittle, making machining difficult with conventional techniques. But fiber laser machines can cut and drill through these complex automotive parts without damaging the surface.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Applications of Fiber Laser Cutting Machines in the Automotive Industry

There are various applications of fiber laser cutting. Below are the uses for the automotive manufacturing industry to cut with the tools and examples of their usage.

Automotive Components that can be Cut With Fiber Laser Cutting Machines

You can streamline producing high-quality automotive parts with a laser cutting machine. Some materials to cut with these tools include the following:

- Engine components

- Body panels

- Automobile door frames

- Car seats

- Interior panels

- Dashboards

- Car trunks and bumpers

- Car brake pads

- Automobile exhaust pipes

Examples of Fiber Laser Cutting Machines Used in the Automotive Industry

Manufacturers use a fiber laser cutting machine in different ways. They include:

Cutting Leather: Many automobile makers use laser machines to cut leather in comfortable car seats.

Sealing or Cutting Seat Belts and Airbags: These machines can cut and seal airbags without damage. You can trim and shape these materials in a fitting and paneling area with a laser cutter before stitching for excellent structural integrity.

Fabric: Vehicle interiors often contain different textiles and upholstery fabrics. Producers cut the materials faster with these tools. They seal edges to prevent fraying when assembling the seat.

Plastic Parts: Producers cut plastic components with laser machines to make dashboards, license plates, bumpers, light housing, spoilers, and interior panels.

Polycarbonate, polypropylene, high-density polyethylene, and acrylonitrile butadiene styrene (ABS) are common materials.

Metal Parts: Laser cutters can cut various metal car parts, including exhaust systems, hoods, doors, fenders, gears, shafts, and bearings.

Factors to Choose a Fiber Laser Cutting Machine

Many beginners make mistakes when choosing a fiber laser cutting machine for the automotive industry. Consider these factors when selecting suitable equipment for your manufacturing processes.

1. Power Requirements

Consider the power requirements of a fiber laser cutting machine because it determines the equipment cutting speed and quality. A tool with 1000W can cut through thicker materials than those with 500W output.

These machines have low, medium, and high power ratings. A medium and low-power tool is sufficient for most applications. With excellent cutting speed, it can cut, drill, and etch thin carbon plates and stainless steel materials.

High-power laser cutters often have hardware requirements, and upgrading comes at a cost. Consider your material thickness before selecting a tool for the project.

2. Cutting Speed and Accuracy

Since cutting speed links to the equipment power, consider the precision requirements before choosing. They’re the most influential factors, so check the machine positioning cut accuracy and laser geometric on a material.

Examine the process with a microscope for selection. Thanks to these machines’ computer numerically controlled (CNC) technology, you’ll correctly cut and drill various metals. It ensures flexible processing and low maintenance costs for automobile production.

3. Types of Materials that can be Cut

Fiber laser machines are best for cutting materials up to 13mm thick. Although the cutting capabilities depend on the equipment’s power, consider the item you’re cutting before choosing any tool to fulfill your needs.

When using a CO2 laser of 10kW power, you can cut aluminum up to 30mm and mild steel up to 2mm. It might also drill and engrave thicker leather, plastic, ceramics, and glass.

4. Size and Capacity of the Laser CNC Machine

Another factor to consider when choosing a laser cutter is the computer numerical control (CNC) machine size and capacity. Carefully select equipment based on your project requirements.

A laser cutting machine can perform the cutting and etching job excellently. Be careful with selection, as smaller bed sizes and those with capacity limitations will affect your ability to produce automobile bodies in large volumes.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

What is the Future of Laser Technology in the Automotive Industry?

Laser technology will play a significant role in the future of the automotive industry. Manufacturers can also weld different car components and insulation mats and cut metal sheets into various shapes.

This technology with heat absorbent fiberglass composites offers accuracy and superior precision. It ensures each component fits the other seamlessly. Laser engraving can create decorative surface designs such as automobile doors, car wheels, handles, and dashboards.

The future looks promising for these machines as they can design items for tracking and detecting. Adopting the technology will continue to improve in speed and efficiency of production processes. So users should expect to see more innovative applications in the future.

Conclusion

Now you know the importance of laser technology in the automobile industry, consider choosing the right equipment. The best tool should offer carbon fiber reinforced composites with high precision, versatility, and faster cutting speed.

With the technology, you design car doors, dashboard and shape seats, fenders, bumpers, knitted spacer fabrics, and engine components.

Buy Premium Fiber Laser Cutting Machine from Baison Laser

Buy efficient fiber laser cutting equipment with excellent features only from reputable producers. Baison Laser is the best manufacturer of this commercial and industrial tool.

Contact us today for a consultation, and we’ll provide products processed nowadays in many industrial countries to satisfy your needs.