Fiber lasers have become a multi-million dollar industry over a decade just because of their phenomenal efficiency and vast applications. These laser machines can perform all the traditional manufacturing processes like cutting, welding, drilling, cladding, etc. but on a higher level. It’s practical for commercial and small-scale businesses alike, which is impressive.

To give you an idea of how efficient, precise, and cost-effective industrial manufacturing has used this technology, we have gathered a list of the most exciting fiber laser applications. Let’s get started.

Fiber Laser Applications

Lasers have been around for a few decades and have found use in various settings. Fiber lasers have become increasingly popular in recent years due to their compact size, high efficiency, and versatility. Here are six typical applications for fiber lasers:

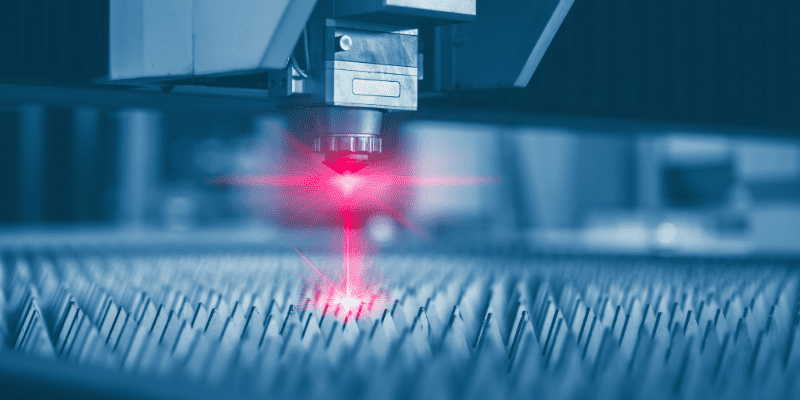

1. Fiber Laser Cutting

Cutting is a fundamental part of any manufacturing process. Fiber laser machines can cut metal, sheet metal, plastics, acrylics, composites, etc. No matter how complex the part is, a fiber laser can cut it with the least tolerance.

It has also transformed the micromachining industry as engineers can machine parts as small as one thousand millimeters using fiber laser technology.

Traditional cutting machines lacked precision and required higher operating costs, decreasing overall profits. Fiber laser solved this issue by producing higher yields in a limited time resulting in greater profits.

Furthermore, continuous research is being done to improve laser cutting technology. The cutting capacity of lasers depends upon their output power (measured in watts) and source. Pulmonary energy, peak power, and beam quality influence it. They are also known as CW lasers (Continuous waves).

Laser is an umbrella term, and many different types are available in the market. Most commercial-grade fiber laser cutting machines use ytterbium (Yb3+) pulsed fiber lasers, which are considered extremely powerful.

It has a wavelength range of 970-1200 nm and can produce >10 KW of output. To get an idea of how powerful this laser is, consider that it can easily cut through a 25 mm thick sheet of mild steel.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

2. Fiber Laser Welding

Fiber laser welding is a remarkable process of joining metallic parts during manufacturing. It gives a clear advantage in speed, cost, efficiency, and lower deformations.

The most popular fiber laser welding application is “Fusion type welding,” where two metals are heated and fused. However, welding using filler electrodes is also possible and gives incredible results.

Unlike traditional welding, the fiber laser welding process produces less heat, reducing warping defects. More extensive and accurate welding seams can be achieved without porosity, cracks, and undercuts. And it doesn’t require a highly skilled welder because it’s easier than most welding procedures. Even a novice can be trained to weld difficult positions with little training.

However, these machines are expensive, but low power consumption, higher efficiency (up to four times), and lesser deformation can save a fortune in any manufacturing business.

Owing to the growing demand for welders in the USA, which is increasing by 2% every year, fiber laser welding machines will be the future.

Eye safety during the welding process has always been crucial. Unlike traditional welding, where the intense flame is visible, and the dangers are apparent, laser welding is not always the case. Because fiber laser welding produces lasers that are not in the visible spectrum of humans. So, the experts recommend following the safety protocols and extra caution while doing the work.

3. Laser Marking and Engraving

Laser engraving is a process of imposing some text or image by using a high-power laser beam that removes or agitates the surface layer of any material without damaging its integrity. This art is growing in popularity every day, and chances are you might even own an item marked by fiber laser.

Fiber laser marking is mainly used to mark bar codes, serial numbers, product details, instructions, and logos on the product. This adds uniqueness to products and prevents counterfeiting.

What separates Fiber laser marking from others is that it can engrave various materials, even metals which lasers like CO2 don’t.

It’s estimated that Fiber laser can engrave more than thirty different materials such as metal, aluminum, brass, copper, glass, plastics, etc. Find out more details in this article.

What’s most interesting about Fiber laser is that it can even be engraved on organic materials like wood and leather.

Commercial-scale Fiber laser machines can be used by small to large manufacturing businesses.

Furthermore, your everyday hobbyist can also benefit from small-sized portable fiber laser machines available online. Typically a 20-30 Watts laser machine is enough to engrave on any materials. It can even cut very thin sheet metal.

4. Fiber Laser Cleaning

Fiber lasers have the unique ability to remove rust, corrosion, paint, and dirt from metal parts by burning and vaporizing the harmful layer. Technically the process is known as “Laser Ablation” and has vast applications.

Fiber laser cleaning is simply the best when it comes to cleaning. It’s fast, effective, and cheap. Traditional rust-removing methods involved oxidation and other chemical processes, which were time-consuming and ineffective. It’s also environmentally friendly.

People often resort to manually removing the rust and corrosion using steel wire brushes, but that approach is highly inefficient and requires a lot of manual labor. Due to its flexible nature, any metallic part can be cleaned by a fiber laser beam, regardless of shape and size. Talk about convenience. It’s also highly satisfying to watch.

Fiber laser technology is getting more advanced, which has reduced the cost of rust-cleaning units drastically.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

5. Laser Drilling Materials

Lasers might not be the first thing that comes to mind when thinking about “Drilling.” But surprisingly, fiber laser is becoming the go-to technology in the precision drilling industry.

It’s different from traditional drilling, where a conventional rotary drill bit is used. In fiber laser drilling, high-intensity laser beams can penetrate a hole in a precise manner. Drilling PCBs using Fiber lasers is getting popular in the electronics industry because of micro-level precision.

It’s highly efficient and cost-saving. Unlike traditional processes, there is no need to replace the drill bit, which is a huge advantage. Take a look at the effect of process parameters on drilling results.

Modern fiber laser machines can drill through various materials such as alloys, composites, ceramics, silica glass, and metals. However, the technology is still relatively new and suitable for only large-scale production houses that can afford it.

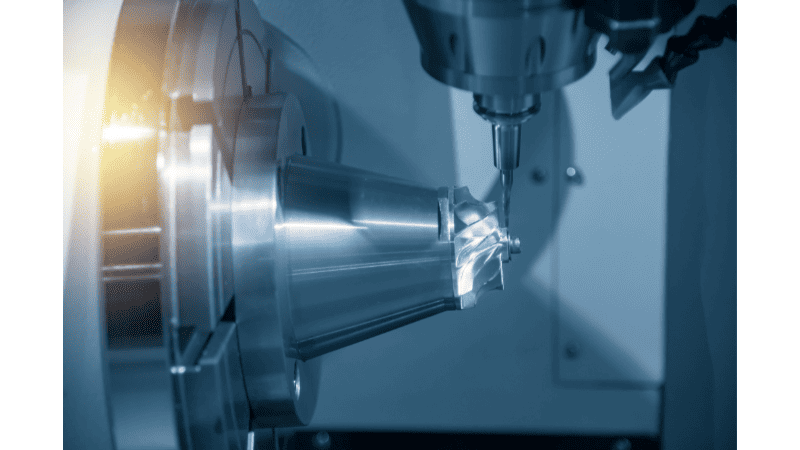

6. Laser Cladding

Fiber laser cladding is a process of depositing a material (usually in powder or wire form) onto the surface of another material. It’s essentially the coating of the mechanical components used for repairing and protecting a part.

Fiber laser creates a melt pool on the surface where the metallic powder is directed and eventually bonds with the surface. The heat is controlled, and precision is unprecedented as lasers are highly accurate with coordinates.

Interestingly, the bond between the deposited layer and metallic part during laser cladding is on the metallurgical level and hence tougher than traditional spraying or plating.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Fiber Laser in Various Industrial Applications

1. Electronics and Semiconductors

The electronics and semiconductor industry requires precision, usually on a microscopic level, which is very hard to achieve using traditional manufacturing processes. Fiber laser machines, on the other hand, are perfect for such applications. That’s why we are seeing technology keep shrinking in size while at the same time hosting extraordinary processing power.

2. Automotive, Aerospace, and Marine Industry

Cars, airplanes, ships, and trains are continuously advancing, and the demand for more efficient machines is increasing. With fiber laser’s supreme cutting and welding capabilities, we see technology in such industries boom rapidly. Nowadays, fiber lasers are used for welding the titanium skin of aircraft, which is a necessary process.

Apart from ytterbium (Yb3+) doped fiber lasers, others like Tm3+ and Ho+3 pump laser diodes also work great on non-metal and transparent material, respectively.

Fiber lasers have increased the machining process’s efficiency, resulting in higher profits and shorter lead times. It also helped reduce the cost of end products for the customers.

3. Medical Industry

Medical equipment manufacturing usually has a minute error because it directly affects human lives. Fiber laser is best suited for such an industry because of its precise and high-quality manufacturing capabilities.

Other than that, lasers are also used to treat cancerous cells and remove stones from human organs. The applications of optical fiber lasers in the medical field are vast and continuously evolving.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Conclusion

In conclusion, fiber laser technology has reshaped industries with its diverse and innovative applications. From intricate medical procedures to groundbreaking manufacturing techniques, its influence is pervasive and revolutionary.

As technology advances, we can only anticipate even more transformative uses for fiber lasers. Stay tuned to the evolving world of lasers, as the future promises more exciting breakthroughs.

Why Choose Baison Laser Machines for Fiber Laser Applications?

The excellent benefits of fiber lasers are no longer a secret, and more manufacturers are turning toward laser technology each day. However, many sub-standard laser machines are selling in the market that can harm your business. But don’t worry, as we have got you covered.

Our Baison Laser machines are of top quality, durable, and cost-effective. Moreover, our catalog includes various products, such as laser cutting, welding, marking, and cleaning machines.

We have an expert team that can suggest the best machine for your requirements and deliver high-quality products on time and within budget. So get your quote now!