What is a Fiber Laser Cleaner?

Laser cleaners use laser power to clean the surface of the material. Laser cleaning can be used to clean various materials, including ceramics, different metals, and alloys. A fiber laser system is the most efficient type of laser that uses a straight and smaller beam for focused cleaning.

It’s a non-contact cleaning method that does not involve any chemicals, abrasives, or mechanical force to remove the contaminants from the material surface.

A fiber laser amplifies the laser light within a special optical cable. The laser beam generated by a fiber optic cable is more focused and powerful with better control. Fiber laser cleaners are also advanced machines that are more energy-efficient and environmentally friendly than ordinary laser systems.

These high-tech machines can be fine-tuned to clean delicate surfaces with precision. Fiber laser cleaners are far more efficient and preferred in high-demand industries requiring accuracy and quality.

How Does a Fiber Laser Cleaner Work?

Fiber laser cleaner uses fiber laser technology to remove dust, debris, oil, rust, or other contaminants from the surface of the metal using the high-density laser beam.

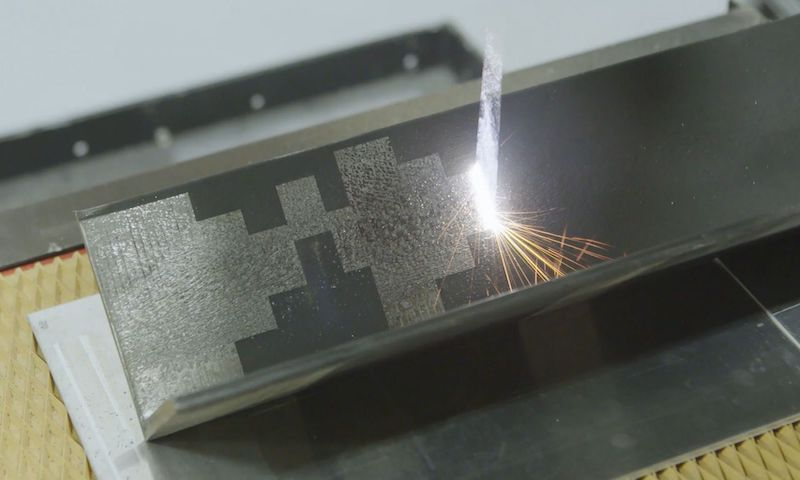

Laser generation or beam delivery works like any other laser machine. A fiber laser generates the highly focused nanosecond-length pulses of the laser beam. The beam is transferred to the metal workpiece through an optic fiber cable.

The fiber laser control system controls the beam’s movement and intensity. It ensures the fiber laser position is accurate and focused on the workpiece.

When a laser beam strikes the metal surface, the energy is absorbed by the top layer. The substrate covering the metal or containments will turn into gas, or the pressure and heat will separate them from the metal surface.

Fiber laser cleaning is the most accurate, efficient, and easy way to clean metal of various densities. However, the correct laser setting is essential for precise laser cleaning results.

What Contaminants Can the Fiber Laser Cleaner Remove?

Laser cleaners can work effectively on several contaminants. Here are some contaminants that fiber laser cleaners can remove.

1. Rust

Rust is a common contaminant that can be found on metal pieces. Not only cleaning this rust is essential for the aesthetic of finished products, but cleaning rust is also important as a pre-treatment before welding, joining painting, or gluing process. Unlike traditional methods, laser beams remove rust quickly without any risks involved.

2. Varnish and Paint

Paint and varnish are difficult to remove. During metal fabrication, stripping paint, varnish, or powder coating becomes a nuisance. Materials like aluminum alloy, copper, and steel can easily get scratched if cleaned with any abrasive material.

Laser energy vibrates even the thick and old paint coating and removes it neatly. Laser paint removal is easy and hassle-free. They can even remove the epoxy coating.

3. Grease and Oil

Grease and oil stains are hard to remove from metal surfaces. Laser beams remove these stains without damaging the metal surface beneath.

4. Adhesives and Glue

Adhesives and Glue are common in joining different meal or non-metallic pieces. Poor application can stain the surrounding material, which looks ugly, and may prevent further processing. Laser beams can work on targeted areas and remove adhesive and glue stains from narrow, difficult-to-reach spaces.

5. Scale and Oxide removal

Scale is the deposit of minerals on a metal surface that can be difficult to remove if left for longer periods. Laser cleaners can remove oxidation marks, scale, and even heat discoloration from metal surfaces.

6. Welding Residues

Welding is the process of joining two metal pieces after melting them. It can leave marks on the sides and even scratches on the metal surface, which are easier to remove from the metal surface.

7. Dirt and Debris

Dirt and debris are commonly found on metal pieces. They can build up with time and get hard. The Laser cleaning process removes dust and debris from the metal surface.

Advantages of Using Fiber Laser Cleaners for Metal

Here are a few advantages of using Fiber Laser Cleaners.

1 – Less Time-Consuming

Whether it is debris, paint, oil, or rust, any cleaning process through traditional means takes time and effort. Fiber laser machines’ cleaning speed does not match other traditional paint or rust removal methods. Laser systems are high-speed cleaning machines that save time in the manufacturing process.

You may want to know how different cleaning methods compare, such as fiber laser cleaning and thermal cleaning.

2 – Protect Base material

Any other traditional cleaning methods involve abrasive materials or chemicals that can leave scratches or damage the base material. A laser cleaning device does not need to scratch or scrap the material. It is a non-contact way of cleaning, and laser power does not damage the metal surface.

3 – Environmental Protection

Fiber lasers do not use chemicals or solvents to remove the tough contaminations, so they do not cause environmental issues. Laser machines are high-tech devices that pose no threat to the environment if used properly.

4 – Cost-Effective Solution

While one may think laser machines are expensive, they are perfect for big industries for saving time and labor. They work fast and can clean a great amount of metal pieces in less time.

Cleaning these metal pieces takes a lot of energy and time if we go the traditional way. So, a laser machine may be a one-time investment, but it saves lots of labor and time with lower operating costs and becomes a cost-saving solution in the long run.

5 – Spatially Selective

Laser beams are highly focused, narrow beams. A laser machine is also controlled by an efficient control system that monitors and controls the delivery and position of the laser beam on the metal surface. It contacts the metal surface on a selective area and saves energy and time.

6 – Non-Contact Process

Laser cleaning machines are the non contact process of cleaning. The machine can work almost automatically and requires little to no monitoring. The whole process can be fully automated and thus save on labor costs.

7 – Precise Cleaning

One of the biggest advantages of laser cleaning machines is their precision. It can be used in various industrial applications requiring high precision and finesse.

Applications of Fiber Laser Cleaning Metal in Various Industries

According to an analysis report, the global market of laser cleaning machines has reached around $850 million. It is estimated to keep growing with new technology making it easier to clean all types of material in less time and with more efficiency.

Laser cleaning has a wide variety of applications. Fiber laser cleaning machines can be used in big and small industries to help in product manufacturing and save time and labor. Here are a few fiber metal cleaning applications.

1. Surface Preparation and Profiling

Surface cleaning is a crucial phase in manufacturing and production. It can determine the overall quality and finish of the product. Conventional cleaning methods in industries such as polishing, scraping, blasting, or brushing take much time and effort.

They are not all the time saved as well. There are industries like the manufacturing of medical instruments that require a high level of care. Base metal quality should not be affected during surface cleaning and Profiling. The use of chemicals is also an option, but it may not work for all types of contaminants and materials as chemicals can damage the surface.

2. Anode Assembly Cleaning

Anode assembly is a critical component in various electromagnetic and electroplating industries. These anode assemblies are used in the electrochemical process and transfer ions and current distribution.

Over time, these anode assemblies can accumulate debris dust and containments that impede electrochemical reactions. Laser cleaning technology removes the carbon residues, debris, and all other types of containments from the thimbles and stub rods.

3. Adhesive and Bonding Preparation for Manufacturing

All important industries like aerospace, automotive, electronic, and construction industries require adhesive and bonding preparation. Quality preparation is necessary for structural integrity, strength, and bonding finish.

Laser cleaning prepares the metal surface and ensures the bonding is meticulous and reliable. Laser cleaning removes oxides, oil, grease, and other impurities that can degrade the adhesive bonding.

4. Pre-treatment for Blazing and Welding

Blazing and welding are important parts of Metal fabrication in various industries. Shipbuilding, construction, railway, energy generation, and electronic manufacturing industries. Fiber laser cleaners prepare surfaces for seamless welding results.

Laser cleaning removes all lubricant contaminants and ensures smooth and pore-free blazing and welding. Removing oil, grease, and oxidation layers is a routine and daily practice in different industries. Laser cleaners can ensure the welding’s longevity, quality, and integrity.

5. Partial De-Coating

Some industries require partial coatings of a particular material. Fiber laser machines are instrumental in partially decoating almost all types of surfaces. It can be used for strip coating removal in electronic and automotive industries.

The precision of laser machines enables industries like automotive, aerospace, and electronic industries. It can de-coat and remove the paints or other materials without damaging the integrity of the base material. The targeted and focused beam of fiber lasers also helps to remove coats and paints from seams and joints just enough for inspection purposes.

Factors to Consider When Choosing a Fiber Laser Cleaner

Here are a few things you should consider while choosing a fiber laser cleaner:

1 – Power

Fiber laser systems come with different power options. It is essential to consider the power option to make sure you buy the laser cleaner that suits your industrial needs. Less power is suitable for small-scale industries. They are also portable and easy to use.

Mid-power laser cleaning machines are good for removing moderate levels of contaminants. High-powered cleaning machines are used in heavy industries and are efficient enough to remove tough contaminants.

2 – Type of Laser Cleaning Machine

Different types of laser cleaning machines are available. For example, fully automated, handheld, or high-powered cleaning machines.

3 – Materials

Not all lasers can clean all types of contaminations. Heavy industries require the cleaning of thick metal sheets and pipes. Different metal alloys and delicate materials like high resistance and reflective materials are also used. A vast majority of industries require cleaning non-metallics. So make sure the laser machine you select can clean ceramic, stone, historical artifacts, or other delicate materials.

4 – Features

Check the control system and different parameters to ensure it suits your future needs, whether you need pulse lasers or continuous waves to clean different materials. Safety and Environmental Security features are also very important to check.

5 – Size

The size of the machine corresponds somewhat with the power. Handheld devices are great for on-site operation. They are easy to carry and can be used to reach difficult-to-reach spaces. High-powered machines are heavy but more efficient to clean heavy pipes and large sheets.

6 – Cost

The cost of the machine is one of the most important factors to consider when choosing the machine. These laser machines are high-tech machines equipped with the latest technology. Not only the upfront price, but you should also consider the operational cost, electricity consumption, and the cost of paying the high-tech staff to operate the laser machine.

Tips to Improve the Laser Cleaning Metal Quality

Here are some tips to improve laser cleaning quality:

- Make sure you know the right parameters like power, pulse duration, or frequency to clean different materials and how to operate the machine.

- Focus the beam in the right direction.

- Maintain the optimal distance between the cleaning head and the material.

- Follow all safety protocols while using the machine each time.

- Remove detachable debris from the material surface.

- Regularly inspect the fiber laser machine to ensure all lenses and optics and the laser cleaning machine work efficiently.

- Regular maintenance of fiber laser machines enhances your machine’s lifespan. Inspect and replace the worn-out parts when and if needed.

Future of Fiber Laser Cleaning System

Laser cleaning has become rampant recently, and its future is bright. It is widely replacing traditional cleaning techniques due to its high efficiency, precision, and accuracy.

As technology improves each day, laser cleaning machines will also keep evolving. The technology is improving with better beam quality, control, and focus. As AI rules all industries, we expect it to improve the fiber laser cleaning technology. Robotics and fully automated cleaning machines will increase the efficiency of laser cleaners.

Laser machines will become smarter and more adaptive with more environmentally friendly and safe options. Laser machines will also improve in terms of energy consumption. New features like data collection, remote monitoring, and predictive maintenance will revolutionize the industrial use of these machines.

Lastly, laser machines have become more cost-effective compared to the past, and they will continue reducing costs. Cost reduction will ensure the widespread use of this sophisticated technology in small to large industries.

Conclusion

Fiber laser cleaning machines are smart and efficient, removing oxides, oil, grease, paint, and rust from different materials in less time. Their optimal use can reduce labor and production costs in many industries.

Laser cleaning has many advantages over other traditional methods of cleaning. These machines have a promising future in various industries due to their precision and accurate results. The laser technology removes all oil or paint, keeping the metal underneath unharmed.

Upgrade your Metal Cleaning Process With Baison’s Fiber Laser Cleaning Systems

Baison is your one-stop for selecting different laser cutting, welding, and cleaning machines. We offer high-tech fiber laser cleaning machines that are innovative and efficient. These machines can revolutionize the production line of any industry.

Our friendly staff is always ready to assist you in choosing the suitable machine for versatile applications. We also provide free sample proofing and free application evaluation to help you choose the best laser cleaning system.