This comprehensive guide will help you with the knowledge and confidence to navigate this exciting realm of a potential new business. We’ll delve into the fundamental principles, and the advantages of laser cutting for plastics, and guide you through material selection, equipment options, and essential cutting techniques.

Basics of Laser Cutting

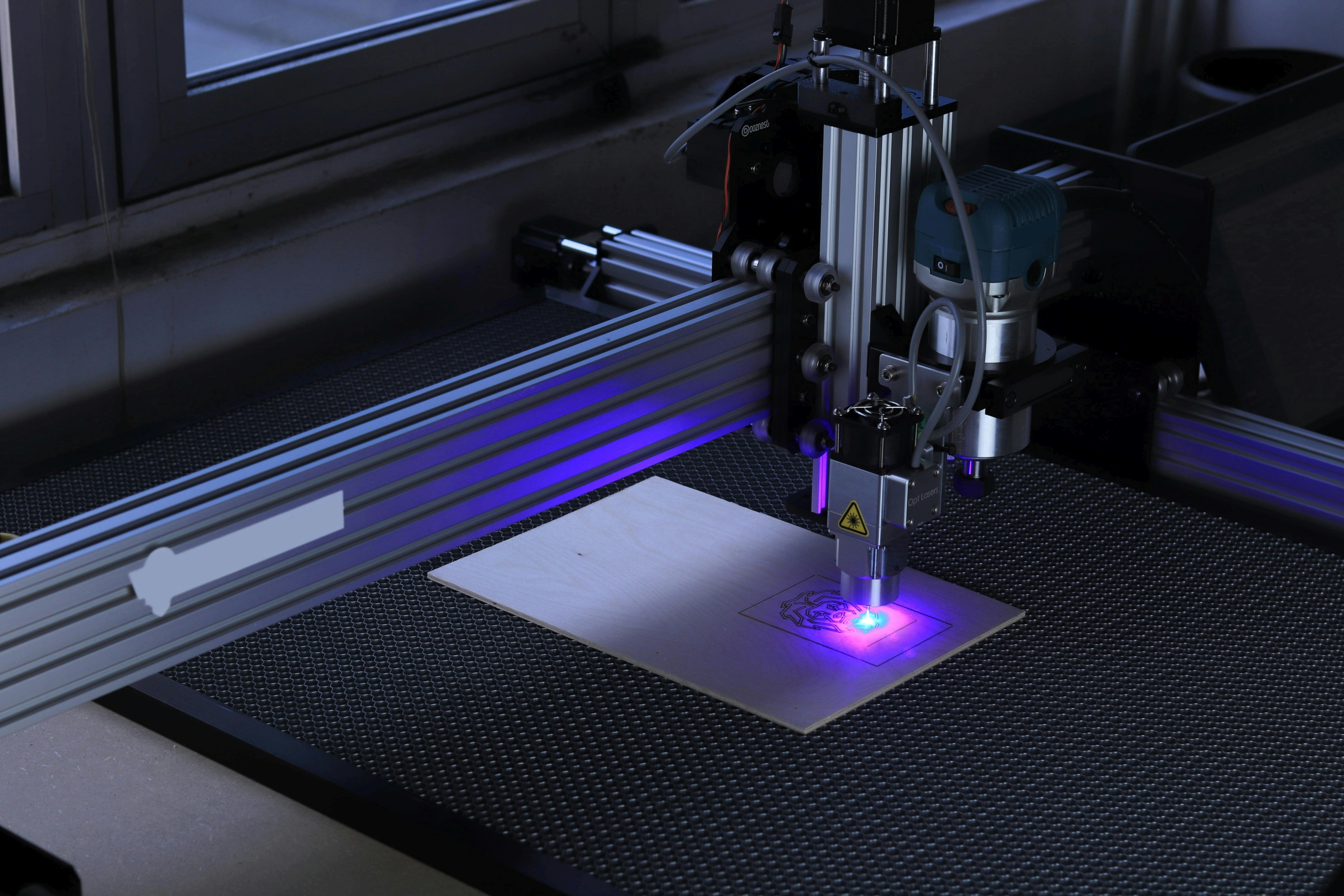

Laser cutting works by focusing a high-powered laser beam onto the material, melting or vaporizing it along a predetermined path. This precise process creates clean cuts with minimal waste, ideal for intricate designs and detailed projects.

Unlike traditional cutting methods, laser cutting doesn’t involve physical contact with the material, preventing wear and tear on tools and ensuring consistent, high-quality results.

Laser cutting machines are often used for different processes to create an additional design and functional element. Processes like laser marking, etching, matching, etc can be done with a laser by managing the parameters such as power, duty cycle, and speed of the laser beam.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Benefits of Laser Cutting Plastics

Plastics are malleable and easy to manipulate. So for years, plastic has been cut in various ways. But laser cutting has a lot of perks that would otherwise be missed if alternate methods were used to cut the plastic materials.

- Clean Cuts: Since the beginning, laser cutting has been so popular because of how well it can cut the subject material. The same is true when it comes to cutting plastics. Laser cutting delivers precise, melt-free edges, eliminating the need for sanding or finishing touches.

- Minimal Waste: Unlike traditional methods, laser cutting utilizes the material efficiently, minimizing waste and scrap. This is viable when the parameters for cutting plastic materials are all perfectly set up.

- Intricate Designs: From delicate curves to intricate patterns, laser cutting tackles complex designs with ease. Especially with machines capable of engraving have a huge use in the laser curing industry.

- The versatility of Materials: A wide range of plastics, from acrylic and plywood to PETG and polycarbonate, is laser-compatible, opening doors to diverse project possibilities.

- High Accuracy: Laser cutting ensures consistent, repeatable cuts with minimal deviation, ideal for precise applications.

- Rapid Prototyping: Quickly iterate and refine your designs through the fast and efficient nature of laser cutting.

What are the Best Laser Cutters for Plastics?

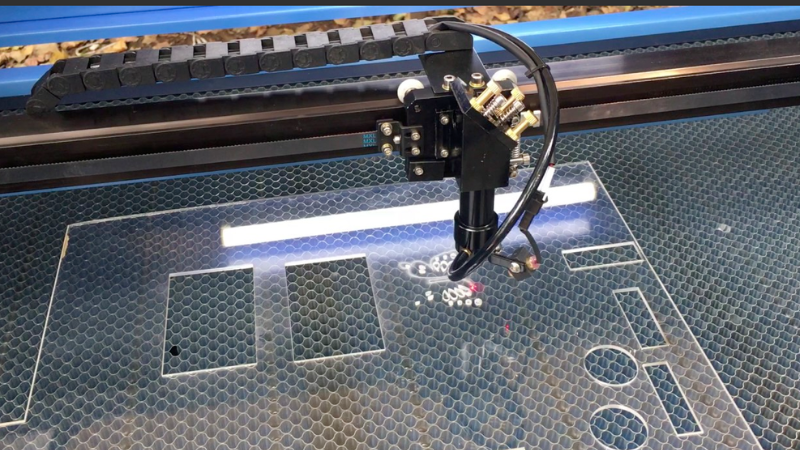

Laser machines are experts at cutting plastics and even tougher materials. However, there are some specific types of laser machines that can work best with plastics. The ideal laser cutter for your plastic projects depends on factors like project size, material thickness, and desired precision.

1. CO2 Laser Cutters

Carbon dioxide laser machines are famously known for being powerful and versatile. CO2 lasers excel at cutting thicker plastics (up to 20mm) and offer high-quality results. This one is one of the best choices for cutting plastic.

2. Diode Laser Cutters

This type of laser machine is more compact and affordable, diode lasers are suitable for thinner plastics (up to 5mm) and simpler projects. This might not be suitable for larger, bulk processes, but it does a wonderful job on a smaller scale.

3. Fiber Laser Cutters

These high-precision machines excel at intricate cuts and are ideal for working with metal alongside plastics. The fiber laser cut plastic output comes out precise and of high quality.

You can learn more about fiber lasers vs. diode laser, and CO2 vs. fiber lasers here.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Plastics Suitable for Laser Cutting

Laser cutting is not as much of a phenomenon as it was just a few years ago. But if we talk about one of the least used materials for laser cutting, it is plastic materials. There is a huge opportunity for business expansion in this area. However, there are some types of plastics that are more suitable for laser cutting than others.

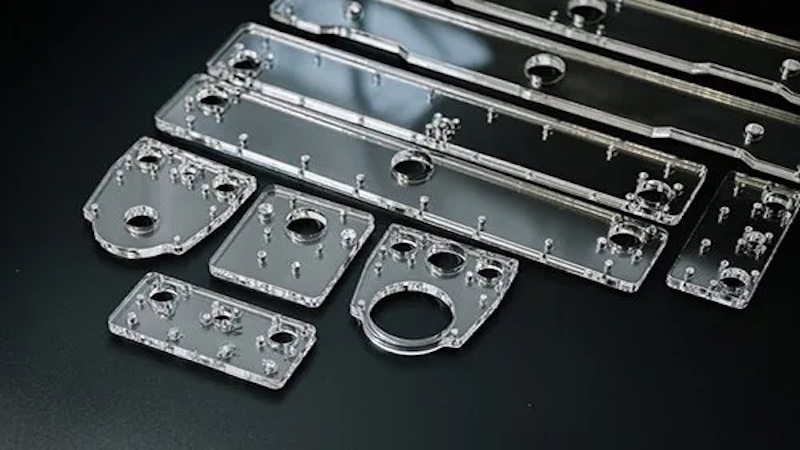

- Acrylic: Laser cutting acrylic is the most common in this area. It is a popular choice for its clarity. It also has a certain ease of cutting. But what makes it really desirable to consumers is the wide range of available colors and thicknesses.

- PETG: Polyethylene terephthalate glycol (PETG) is a type of polyester plastic material used in manufacturing. It is famous for being a durable and impact-resistant plastic ideal for functional applications and outdoor projects.

- Polycarbonate: These normally come in the form of sheets and are used for their toughness and impact resistance properties. It is mostly known for its exceptional strength and clarity, making it perfect for demanding projects.

Plastics That Cannot be Laser Cut

When learning about all the benefits of cutting plastic with a laser beam, it is important to keep in mind that there are some types of materials you should avoid. Some plastic sheets are inoperable under laser beams and must never be used in the laser cutting block.

- PVC: PVC is one of the most used plastic materials in our daily life. But it releases harmful fumes when cut with a laser and should be avoided. You will often see PVC sheets and pipes cut with mechanical equipment, such as saws.

- ABS: ABS is a type of opaque thermoplastic material. It has a glass transition temperature of 105 degrees Celsius. Because of this property, it tends to melt and deform during laser cutting, leading to inaccurate and poor-quality results.

Challenges of Laser Cutting Plastics

As plastics are much more malleable and respond to heat damage a lot more than other materials like metals or stones, there are a few challenges that you need to overcome to get the best use of laser-cut plastic.

1. Heat Distortion

- Thin materials: As mentioned, thin plastics are particularly susceptible to warping due to the concentrated heat of the laser beam. This can lead to inaccurate cuts, uneven edges, and potentially unusable pieces.

- Cutting parameters: Optimizing settings like laser power, speed, and pulse duration can significantly impact heat generation. Using lower power and faster speeds for thin materials helps minimize distortion.

- Certain plastics have lower heat thresholds than others, making them more prone to distortion. Knowing the thermal properties of your chosen plastic is crucial. The material surface that comes into direct contact with the laser beam can easily become damaged if not careful.

2. Melting

- Incompatible plastics: Some plastics, like ABS, tend to melt and re-adhere rather than vaporize cleanly under laser cutting. Choosing laser-compatible plastics like acrylic or PETG is essential.

- Focus and beam quality: A poorly focused laser beam or one with uneven intensity can lead to localized overheating and melting. Maintaining proper machine calibration and lens cleanliness is crucial.

- Improper settings: Most plastics are very sensitive to heat settings. Using excessive power or slow cutting speeds can cause the plastic to melt instead of cleanly cutting through. Finding the right balance in parameters is key.

3. Gas Selection

- Fume control: Different plastics release varying amounts of fumes during laser cutting. Choosing the right gas, like compressed air or nitrogen, helps suppress harmful fumes and protect the operator.

- Cut quality: The chosen gas can influence the edge quality and cleanliness of the cut, especially in laser engraving. Nitrogen minimizes charring and produces smoother edges, while compressed air might be sufficient for simpler projects.

- Material compatibility: Certain gases can react negatively with specific plastics, affecting the cutting process and potentially damaging the material. Consulting the laser cutter’s manual and material recommendations is vital.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Tips for Successful Laser Cutting of Plastics

Laser cutting seems to be one of the easiest cutting technologies because it is almost 100% automatic and mechanical.

But because of those features, laser cutting requires a high level of skills, confidence, and experience. When we talk about laser cutting plastic products, this fact is even more true. Here are some tips to cut plastic successfully with laser.

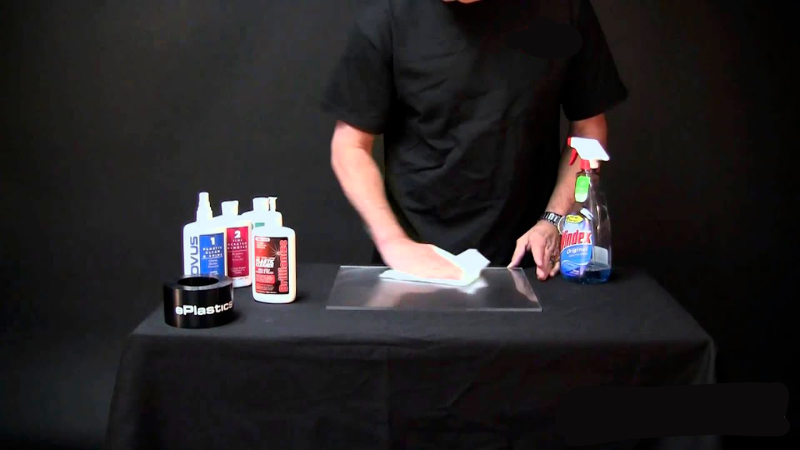

- Careful Material Preparation: Material preparation is a big part of getting the desired output. You must ensure your plastic sheets are clean, dry, and free of debris to avoid imperfections.

- Parameter Settings: Consult the laser cutter’s manual or material recommendations for optimal power, speed, and gas settings for your chosen plastic.

- Test Cuts: Perform test cuts on scrap material before tackling your final project to fine-tune the settings.

- Post-Processing: Depending on the plastic and desired finish, sanding or polishing might be necessary for a professional touch

Ideas for Laser Cutting Plastics

Laser-cut plastic, especially acrylic sheets and decorative thin sheets has huge demand in the market among consumers.

So as a business, you can not only get contractual jobs for various industries but also acquire business from individual consumers. Thus laser cutting of plastic is in high demand.

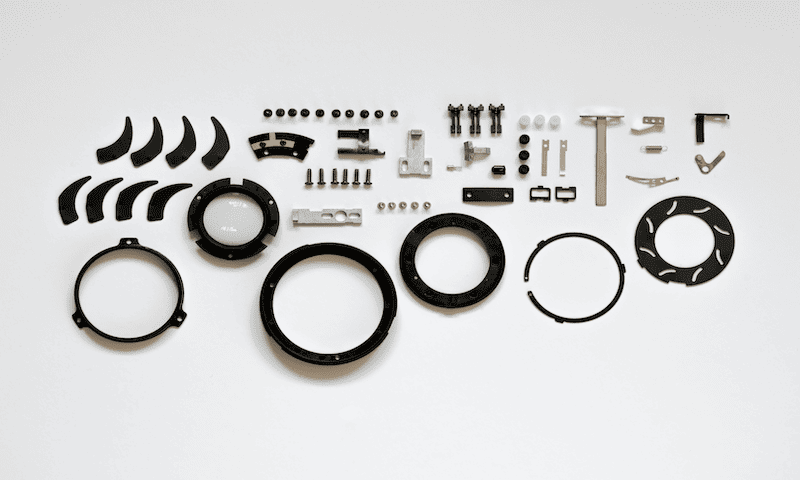

- Functional prototypes: You can make very useful things like product mockups, engineering models, and custom enclosures with precisely cut plastic.

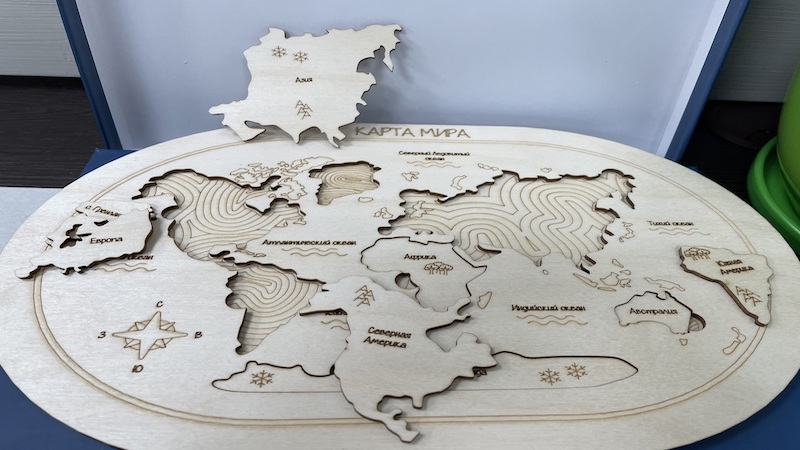

- Educational tools: There is a huge market for educational tools like puzzles, gears, and interactive models for STEM learning. These tools need added skills and have the potential to increase in demand.

- Personalized gifts: There are a lot of options for making plastic and acrylic products like coasters, keychains, showpieces, jewelry, and decorative ornaments with custom designs. Intricate engravings can really come in handy in these ideas.

- Home décor: There are a lot of wall art, lampshades, organizers, and furniture accents being made with laser cut plastics in the modern interior decorations. These can be a really good business idea to look into.

- Arts and crafts: When you are at it, why not go bold? You can look into making jewelry components, art supplies, scrapbooking embellishments, and creative 3D stickers with plastics that have been cut with laser.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

FAQs

1. Can I paint or engrave laser-cut plastic?

You can definitely paint over or even engrave plastic that has been cut with laser. Many laser-cut plastics can be stained for further customization. Make sure that you choose the correct type of paints and adhesives compatible with the plastic type.

2. Is laser cutting plastic safe?

Laser cutting plastic can be safe, but it’s crucial to prioritize safety measures. Even though there are not a lot of records of safety hazards for plastic cutting compared to other types of materials it is good to be careful.

Always wear appropriate personal protective equipment (PPE) like safety glasses, gloves, and a respirator to protect yourself from fumes and debris. Ensure proper ventilation to remove harmful gases and smoke. Never leave the laser unattended while operating.

For more, click on these two articles to learn more: Laser Class & Safety, and Laser Cutter Exhaust Systems.

3. What are some advanced techniques for laser cutting plastic?

Once you master the basics, there are a lot of more advanced techniques. For example, you can try selective cutting where you create different depths or textures within the same material.

With raster engraving, you can achieve photorealistic images or detailed patterns. You can make tiny holes of plastic for ventilation or creative effects with a technique called perforation.

Conclusion

Laser cutting is such a big way of fastening the process, increasing efficiency and accuracy, and also bringing more newness and uniqueness to the task. From the construction industry to more intricate procedures in the technology industry, laser cutting plastics has a bright future.

If you already have a cutting business or are thinking of starting a new business about manufacturing plastic materials, then you should definitely learn all there is to know about this idea. Here at Baison, we have a plethora of machines and resources to help you with anything you need to become successful in your venture.

Enhance Your Knowledge of Laser Cutting Plastics with Baison!

Before embarking on your new journey with plastic cutting with the laser, make sure to get rid of all types of confusion. Contact us at Baison now to find the answers to all your questions. We are always happy to help you build a successful business!