You will be able to understand what a laser-cutting machine is and what sets it apart from other cutting machines, especially when working with stainless steel. The article also explains the different types of laser-cutting machines and the benefits of owning one. There are also some crucial factors to remember when choosing a laser-cutting machine and the article lists them.

What is a Laser Cutting Machine?

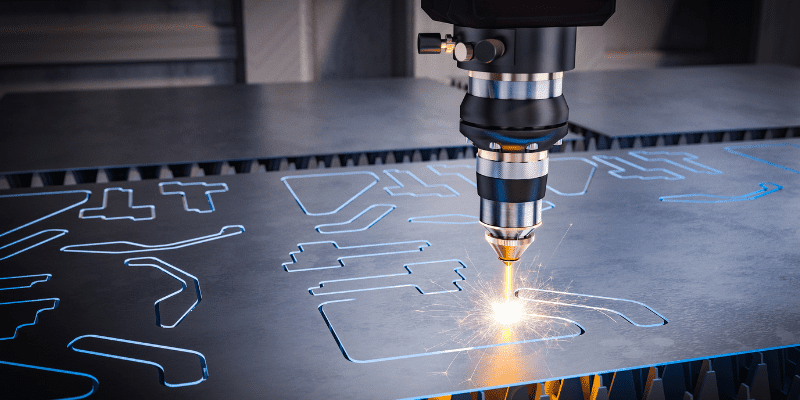

A laser-cutting machine uses a high-powered laser beam to cut various materials used in various applications. The precision cutting ability of laser beams makes it one of the most sought-after cutting technologies within industrial manufacturing applications.

Laser-cutting machines are popular across several industries because of their flexibility and ability to work with numerous materials. It can cut, etch, or even mark small designs for huge installations, from small wearables like bracelets and dog tags to huge equipment like elevators. The automotive and even aerospace industries also use laser-cutting machines for several parts in their production.

One of the reasons why several people still choose to look the other way when it comes to laser-cutting machines is the perceived complexity of the process. The introduction of laser beams, optical guides, and a seemingly complicated contraption makes people hold back from incorporating laser cutting machines in their operations.

But you must remember that technology is ever-evolving in many directions, and several industries are taking advantage of that to come up with operational efficiency and faster production time. Cutting technology is part of that progress. And there is no better example than laser cutters.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Types of Laser Cutting Machines

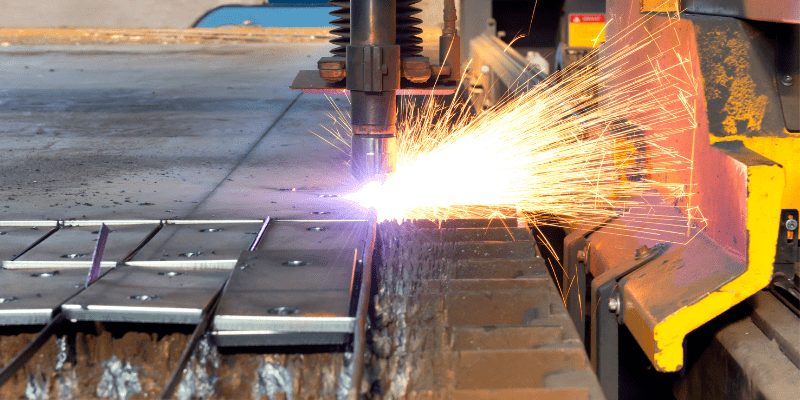

The three main types of laser-cutting machines – are CO2 lasers, fiber lasers, and crystal laser cutting machines, which use neodymium-doped yttrium aluminum garnet and neodymium-doped yttrium ortho-vanadate.

These three laser-cutting machines make use of different laser delivery methods. The CO2 laser uses a tube filled with gas mixtures that produce light beams. With mirrors on both ends of the tube, the laser can travel through the tube. The gas mixture consists mostly of helium, nitrogen, hydrogen, and carbon dioxide. One unique characteristic of CO2 laser-cutting machines is that it produces invisible laser light.

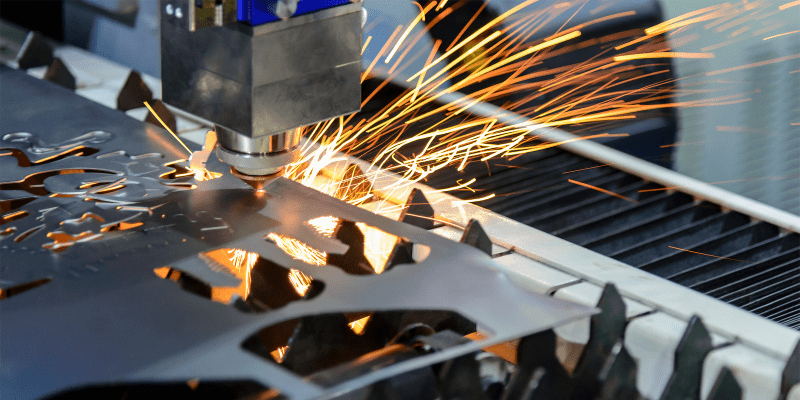

Fiber lasers incorporate glass fibers in their operation. This makes this one of the most versatile and useful types of laser-cutting machines out there. On the other hand, crystal laser-cutting machines are some of the most powerful machines at present. They are also quite flexible in cutting, marking, and engraving various materials and metal and non-metal materials.

There are also 5 types of laser-cutting machines when you start to look at their movement.

- Moving material machine – the machine where the laser beam remains in one place. The material being cut is the one that moves around. Though this helps maintain a constant distance between the laser and the cut material, this is also one of the slowest methods.

- Flying optics machine – this is when the laser beam is the one that moves around, and the material being cut is stationary. Although this is a faster option, the downside is that the beam length of the laser suffers as it moves around the material.

- Hybrid configuration – combining a moving laser beam and moving material results in a hybrid configuration. This is more energy efficient and can remain a constant distance between the two elements.

- Rotary laser cutting – this machine normally deals with pipes, steel tubes, D-type tube materials, ellipses, and even rectangular tubes.

- Axis laser cutting machine – one of the more advanced types of machines having the ability to make not only 2D but 3D profile cuts. The versatility and opportunity for cutting production for this machine are endless. We have prepared a detailed introduction about the 5-axis laser cutting machine.

Benefits of Laser Cutting Stainless Steel

Using laser-cutting machines on stainless steel provides you the precision, consistency, and speed in your cutting needs But these are just some of the advantages of laser cutting your stainless steel materials. Let’s take a deeper dive and understand why a lot of people are using laser-cutting machines, especially for stainless steel.

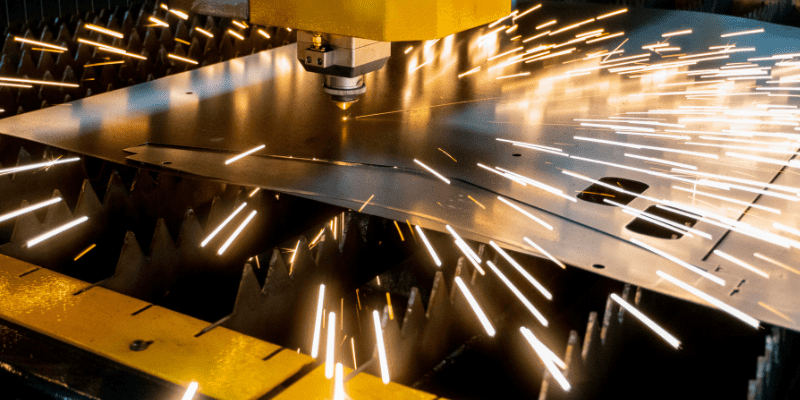

- Proper distance from the laser beam head to the metal sheet – much like how you would use scissors, the physical contact between the blade and the material you are cutting drastically increases the wear and tear of the cutting tool. This is not the case with laser cutters because there is no physical contact between the stainless steel sheet and the laser beam head. As a result, it prolongs the life of the machine.

- Manageable warping – laser cutters only produce a tiny area of heat zone on the material when cutting. The reason is that the small size of the laser beams only affects a tiny area of the material cutting with heat. As a result, there is only minimal warping, if any, on the stainless steel.

- Precision cuts – working with stainless steel and cutting them to size for various uses is a delicate process. You need to make sure that you can make precision cuts and replicate the same result over and over again. Laser-cutting machines allow you to make precision cuts and repeat the same process multiple times.

- Complicated cuts and contours – it is challenging to manually cut stainless steel when you must make complex contours of the cut. The ability of laser-cutting machines to be fully computerized makes it easier to perform complicated cuts and intricate shapes in stainless steel.

- Minimal noise – unlike old cutting machines, using lasers for stainless steel is a relatively quiet process. This helps minimize noise pollution and protects workers as well.

- Narrow kerf in the cutting – laser kerf refers to material removal when you cut, and one advantage of laser-cutting machines is a narrow kerf in the cutting process. It can do this because the laser beam is so small and precise that the materials removed from the stainless steel are minimal.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Factors You Need to Consider When Choosing a Laser Cutting Machine for Stainless Steels

The work area size, the laser cutter’s power, and even the machine’s price are some of the numerous factors to consider when choosing the best laser cutting machine for stainless steel use. Let’s take a closer look at these considerations and other aspects.

1. The Size of the Work Area

The size of the area you are working on plays a big part in the type of laser cutting machine you can use for stainless steel cutting. In the simplest sense, the bigger area you have, the bigger and more machines you can accommodate. You must also remember that it is not only about the machine. You need ample space for your stainless steel inventory before and after cutting.

2. The Power and Speed of the Laser Cutter

One thing you need to remember when it comes to the power and speed of a laser-cutting machine is that these two are directly proportional to each other. This means the higher the laser power of the machine that you have, the faster it can effectively cut stainless steel.

Factor in the number of stainless steel cutting jobs to purchase the most appropriate machine. If you accept many stainless steel cutting jobs, it is better to look for a machine with a high power rating.

3. Whether or Not the Machine is Easy to Use

Laser-cutting machines might come off as complicated pieces of equipment for some people. This is also why some prefer to look the other way when it comes to laser technology in cutting stainless steel material.

However, the ease of use of the laser cutting machine depends on the machine itself and the person using it. This means that if the person is not interested in the machine, it will be difficult to use even if they are operating the simplest types of machines. But if you like what you are doing, even the more complicated machines will be quite easy to understand.

4. The Quality of the Cuts

Laser-cutting machines are some of the most precise equipment for cutting stainless steel. That and the small kerfing after the cut make the quality a cut above the rest. It now boils down to ease of use of the machine and the power rating of the equipment you are using.

You always need to make sure that the power of the machine is exactly what you need, especially the thickness of the stainless steel you are working on. The thicker it is, the more powerful the machine you need to achieve a quality cut.

5. The Price of the Machine

In choosing a laser-cutting machine for stainless steel cutting, the price of the machine is a major factor you need to consider. There are entry-level units that would be less expensive than higher-wattage machines. It can be anywhere from $4,000-$15,000. Some fiber laser cutters can even top up to about $45,000.

Entry-level machines are the best for light-cutting work, and thin materials are for cutting, marking, and engraving. You could ruin the surface if you insist on using entry-level cutting machines for thicker and more complicated materials.

6. What Type of Warranty is Offered by the Manufacturer

Warranty from the manufacturer is a big consideration when buying any type of machine, including laser-cutting machines. For one thing, a warranty tells you that the manufacturer stands by the quality of their machines. It also gives you peace of mind knowing that your investment in the machine is covered for a certain period.

The type of warranty is something you need to be very clear about as well. The length of time the warranty is in effect, as well as the coverage, are two important factors to consider. How many months will the warranty cover, and is it only for specific parts or the machine? These are questions you need to be answered when it comes to warranty.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Conclusion

In conclusion, selecting the right laser cutting machine for stainless steel depends on your specific needs and project requirements. By understanding the unique features and capabilities of various machines, you can make an informed decision that enhances efficiency, precision, and quality in your work. Remember, the best machine is the one that aligns with your production goals and delivers consistent, high-quality results.

How Can Baison Help You With Laser Cutting Process?

Choosing the best laser machine to laser cut stainless steel does not have to be rocket science. And this is where Baison can come in to help.

Baison is one of the leading companies that can help you choose the best laser-cutting machine for your needs. A free application evaluation is provided by industry experts to help you understand your laser system investment before you even make a purchase. A sample proofing of the laser system you choose is also given so you get a feel of the actual output. Contact us for a quote now!