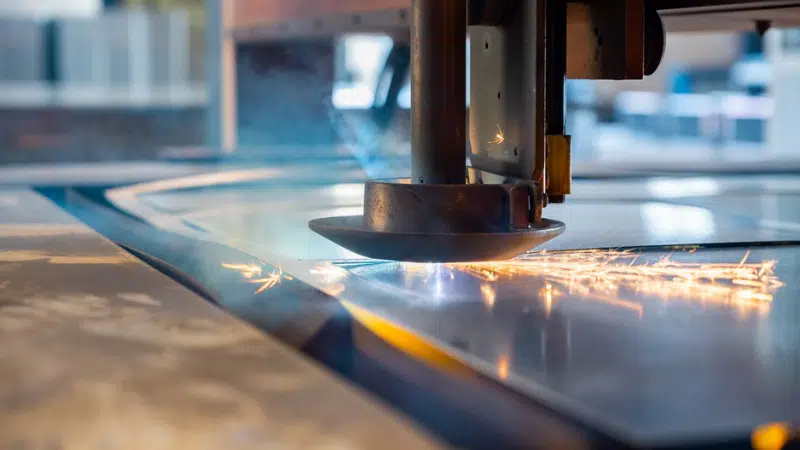

Laser-cutting machines make the process of cutting various materials an easier one. If you wish to know about the different motors used for laser machines, this guide below will help you. We have provided an insight into various motors used for laser cutting machines and how you can choose the right one.

Once you go through this guide, you will also learn why professionals favor Baison laser-cutting machines and how these offer efficiency.

Understanding Laser Cutter Motors

Laser cutting motors’ basics comprise understanding their essential components and function.

1. Control System

The control system is the main unit of the laser cutter; the design file is interpreted, and the instructions are translated for motors into the movements. The common controller boards in the system are DSP and G-code controllers.

2. Motion System

The motion system is an essential part of the laser cutting motor, and it helps the laser head move in different directions along the x, y, and z axes. The linear motion components must be of high quality to achieve accurate cutting speed.

3. Encoders

These days, innovative laser cutters comprise an encoder combined with the motor. The encoder provides feedback to the controller regarding the position where the laser head lies, ensuring better precision and control.

4. Acceleration and Deceleration

The acceleration and deceleration of the motors are managed by the laser cutter controllers so that the accuracy of movements can be achieved. It is essential for accurate cutting.

5. Pulse Width Modulation

Laser cutters use pulse width modulation to control the laser beam and its power. The laser quickly turns on and off, and it helps determine the laser’s power.

6. Driver Circuitry

The driver circuits in the laser cutting machine are equipped with the required control signals and power, which helps convert the signals from the control system to the motor movements.

The Importance of Motors for Laser Cutting Machines

The laser cutting machines are equipped with motors because they are essential to this equipment. The motors are responsible for making the laser head move and possess various significant factors, some of which are discussed below:

- Motors offer precision and high accuracy by controlling the laser head movement; hence, accurate cuts are achieved.

- The laser cutting machines have three main types of axes, which include the X axis, Y, and Z axis, and hence, the movements in all directions are controlled; the role of the motor is essential in such cases and offers higher precision.

- A motor is also responsible for determining the laser head‘s speed. They help control the speed of the machine, optimize the cutting speed and process, reduce production time, and improve product quality.

- The motor ensures that the acceleration and deceleration of the laser head are smooth, and it helps to prevent the jerks in movements of the cutting area.

- Laser engravers are also an essential part of laser cutters; hence, the motor helps execute the task of following precise paths in engraving machines.

- Achieving consistent results in the case of replication is an essential part of laser cutting when identical parts are manufactured, and the motor helps achieve its repeatability.

5 Types of Motors Used in Laser Cutters

There are various types of motors used in laser cutters, and some of these are discussed below:

1. Stepper Motor

A stepper motor takes incremental steps between the poles that are aligned in a circular form and individually energized to turn the motor shaft. The size range of most of the stepper motor is between 50 to 100 poles.

The working principle of the stepper motor comprises the following:

- The movement of the motor is carried out discreetly, and the step rotation is determined by the design of the motor.

- The electrical impulses control the stepper motor as it responds to each step, and the pulse also determines the direction of rotation.

- They do not need any feedback and hence are called open loop systems; the system sends a number of pulses, and the motor’s movement occurs.

- The high accuracy and high precision of the motor make it suitable for precise procedures like 3D printing and CNC machining.

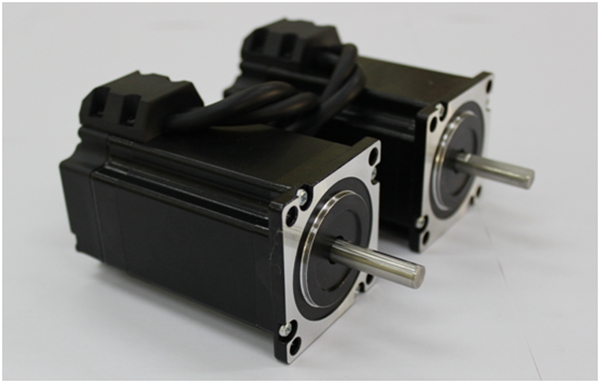

2. Servo Motor

A Servo Motor uses fewer poles for an operation ranging between 4 and 16; this motor can energize multiple poles simultaneously. The servo motor is a closed-loop motor that gives feedback to the controller about its position with the help of an encoder.

The principles on which servo motors operate comprise the following:

- This motor operates in a closed-loop system, constantly receiving speed, position, and torque feedback about the device.

- They use an encoder that consistently provides information about the motor’s position, allowing the controller to make adjustments where necessary.

- Regarding position accuracy, this motor is the best one with a minimal error chance.

- They are suitable for high and low speeds due to their torque deliverability at both instances and hence they suit responsive movements in the lasers.

- The Servo motor is energy efficient and offers smooth motion.

Check out this article to learn how to choose between Servo Motors and Stepper Motors.

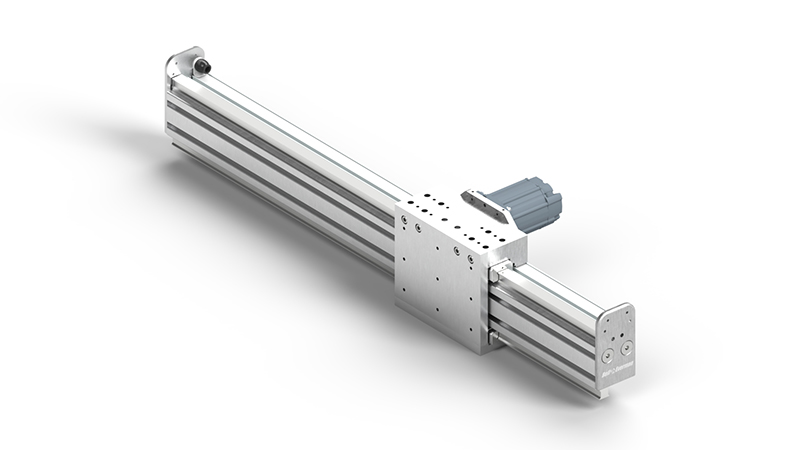

3. Linear Motor

A linear motor, as the name suggests, is an electric motor for a laser system of cutting that moves in a straight line, and the difference between a linear motor and other types of motor is that it doesn’t produce rotational movement.

The principles on which the linear motor carries out the operation in a laser machine are as follows:

- The motion of a linear motor is direct and smooth as it doesn’t rotate and hence doesn’t need mechanical transmission systems like belt drive and lead screws.

- The design of the linear motor is equipped with a direct drive, which helps minimize the backlash and improves precision when they cut materials.

- The linear motor is capable of offering high speed, so they can quickly responsively work on different materials.

4. Hybrid Servo Motor

A hybrid servo motor is used in laser cutting machine systems that use the stepper motor’s pole count and the servo motor’s closed loop function. It is a blend of the two of these motors. The hybrid motor works on the following principle.

- When used in laser cutting or laser engraving machines, the hybrid motor offers precise positioning when the movements are slow and accuracy and high torque are needed.

- In quick movements, the hybrid motor uses the closed-loop control system, which helps the motor respond quickly and maintain maximum speed, followed by high precision and accuracy.

- The hybrid motor allows the control system to adjust parameters to address the load changes and offer smooth movements.

Come here to learn how hybrid servos stack up with standard servos.

5. DC Motor

The DC motor is used in many laser cutters and laser engraver and carry out various functions. They are different from stepper and servo motors as they do not look after the movement of the laser head. The working mechanism of the DC motor is as follows:

- The DC motor helps drive the conveyor belts, and the laser cutting or engraving machines achieve a controlled material movement.

- Laser cutting machines also produce heat, and the DC motor helps drive the exhausting system in these machines.

- The DC motor also powers the cooling system in laser cutters so that the heat produced by these machines can be dissipated.

- Laser machines use reflection mirrors and lenses; to manage the movements of these, a DC motor is used.

- A laser tube in some laser cut processes holds the materials in place, and a DC motor controls the suction of these tubes.

Comparison of Different Motors

Every laser machine makes use of varied motors; however, the most common types of motors used in laser machines, like fiber laser and CO2 laser cutters, are stepper motors, servo motors, and linear motors. A comparison between these three common types of motors is provided below.

| Characteristics | Stepper Motors | Servo Motors | Linear Motors |

| Type of Control | Open-loop | Closed-loop | Closed-loop |

| Device for Feedback | No device | Encoder | Encoder |

| Accuracy and Precision | High | Very High | Very High |

| Range of Speed | Limited Speed | High Speed | High Speed |

| Energy Efficiency | Variable | High | High |

| Applications | 3D printing, CNC | Automation and Robotics | Precision Positioning |

| Cost | Low | Moderate to High | Moderate to High |

How to Choose the Right Motor?

You have multiple choices between the different motors. Among them, the most important thing is to choose a motor that not only offers laser power but is also suitable for the machine in terms of its working mechanism and functionality.

Some of the factors that you must keep in mind when choosing the right motor for laser cutters are as follows:

- The laser cutting applications must be assessed when opting for the motor; the intricacy of the cut and the use of relevant materials must be kept in mind.

- The required precision for the laser cuts also must be kept in mind; the applications that need high precision must have laser cutters equipped with a server or linear motor.

- Certain applications need high-speed laser cutting; in case of such quick acceleration and deceleration, the motors needed are servo motors and linear motors.

- The material being cut through the laser machine is also a factor to consider when opting for a motor; every motor may only support some material cutting. The options usually include non-metal materials, metal, glass, paper, and even plastic.

- Most of the time, laser cutter machines are used for thicker materials; when opting for a motor for the lasers used for thick materials, it should be assessed that the motor can handle the needed movements to handle the required thickness.

- The motor used for different laser cutters will have different maintenance requirements; assess the requirements and whether you can fulfill them.

- The laser cutting process is usually one that people wish to be under a certain budget, and for this, the cost of the motor must also be affordable.

Best Laser Cutters with Exceptional Motors

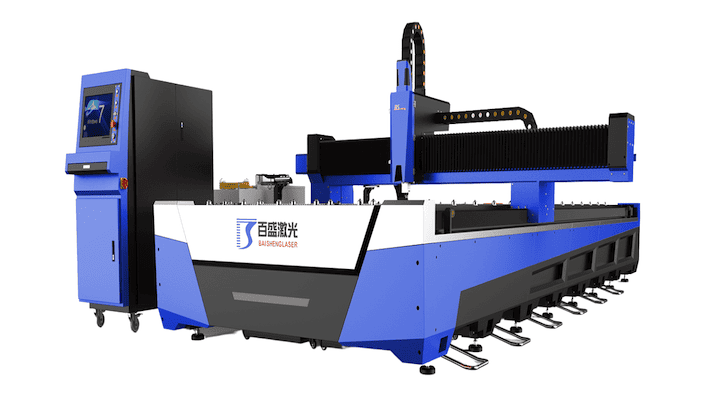

Laser cutters that comprise seamless motors are offered by Baison Laser, a pioneer in providing exceptional cuts with high speed and precision, followed by clean cuts. The two of the most popular cutting machines are as follows:

I. Entry-level Sheet Metal Cutting Machine

The entry-level sheet metal cutter offered by Baison Laser falls under fiber laser cutters, and being a basic cutter, it still offers the ability to create professional-looking cuts.

These machines are low-cost, low-noise cutting machines. These machines are ideally suitable for medium-sized businesses as they offer reliable and cost-effective techniques to cut sheet metal.

This machine offers a laser power of 1500W to 6000W in the KE model and 1500W-4000W in the E model. It covers a cutting area of 3000x1500mm for the KE model, and the E model offers multiple options, which comprise 3000 mm×1500mm, 4000mm×2000mm, 6000mm×2000mm, and 6000mm x 2500mm.

This equipment is easy to operate and takes a very small amount of space, being a highly compact machine, and the speed for cutting offered is 140m/minute.

II. Small Fiber Tube Laser Cutter

The small fiber tube laser cutting machine by Baison Laser comprises highly advanced features, and it helps increase the productivity of laser cutting in various applications. The laser power offered by this machine is 1500W to 3000W for both its K12 and K12x models.

This laser cutter is cost-effective and offers high-quality laser cuts. Moreover, due to its high speed, it can carry out laser cutting in a considerable volume, and the accuracy level is maintained. The machine is easy to operate and has a compact, dust-resistant option that works on point.

FAQs

1. Why is a servo motor chosen for high-precision cuts?

The servo motor works on the closed-loop control system and has feedback devices that help with position accuracy and offer exact cuts.

2. Which motor is suitable for a CO2 laser cutter?

A CO2 laser cutter can use multiple motors that comprise a stepper motor and servo motor.

3. Which motor is suitable for fiber laser cutters?

Fiber laser cutters usually carry out high-precision cutting, so a servo motor is the best choice.

Conclusion

As you have gone through this guide above, it must have helped you understand the difference between the multiple motors used in laser cutting machines. To keep up with the laser cutting process, the need for highly equipped and advanced equipment is critical. Leading laser companies are incorporating these features into their equipment.

Experience State-of-the-art Laser Cutting Equipment at Baison!

Baison Laser consistently strives to bring new and improved versions of its laser cutting machine and explores innovative technology to incorporate into the laser cutters. If you also want to make your laser cutting experience commendable, contact our team today and have your choice of equipment designed.