Laser cutters and 3D printers are utilized extensively in the manufacturing process. Since both of these technologies are used for making things, it can lead to confusion for many people. And it’s perfectly normal!

Now, think of a laser cutter as a device through which we cut materials precisely with the help of a laser. And because it involves cutting and removing parts of the material, it is a subtractive manufacturing process. On the other hand, 3D printing is used to create 3D items and designs. Therefore, it is an additive manufacturing process.

So, in a nutshell, the laser cutter is used for cutting and removing portions of the provided material. In contrast, a 3D printer makes 3-dimensional items and designs from scratch. This is why it is an additive process.

Accordingly, we can say that the additive versus the subtractive process is what distinguishes 3D printers from laser cutters. In case this is still confusing for you, don’t worry!

Today, we will take an in-depth look at these technologies to give an idea of how they work. We hope by the end of this article. You can decide which technology to use for your next project!

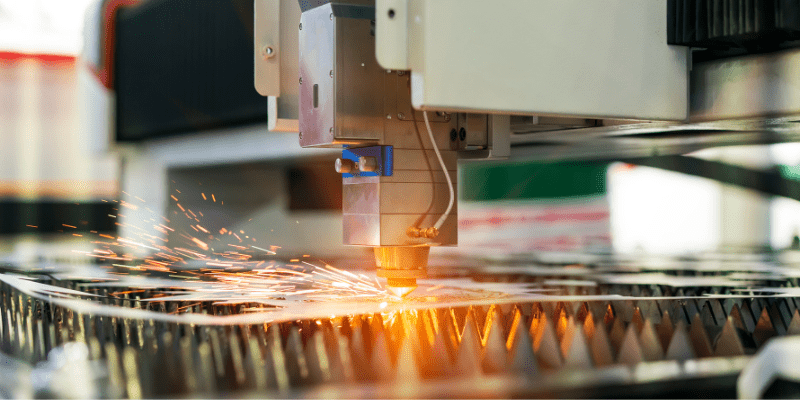

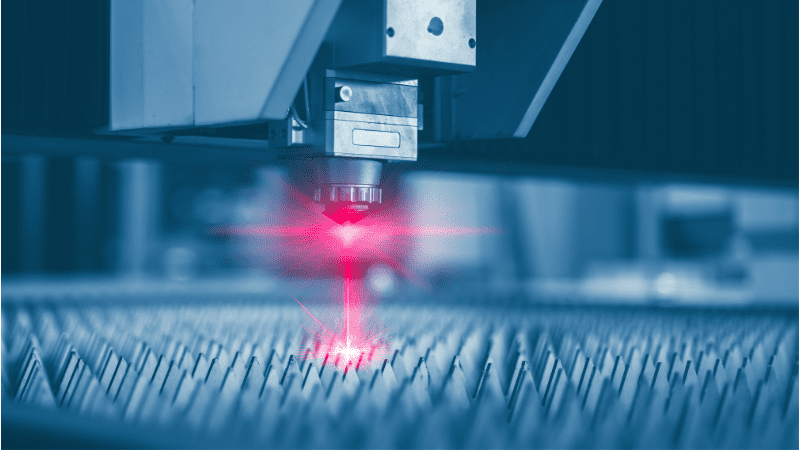

What is a Laser Cutter?

A laser cutter utilizes a high-power laser to cut through materials to make designs and patterns. Depending on the material and the type of laser, the laser beam melts or burns the material to make the intended design. Normally, a laser machine can cut through many different materials, such as wood, metal, plastic, etc.

One of the major benefits of laser cutters is that they offer a non-touch method of cutting with very high precision. They also provide numerous benefits over mechanical cutting methods. This includes fast speed, low cost, repeatability, precision, and automation.

Despite the name ‘laser cutter,’ it can be used for more than cutting, such as engraving and marking. Most laser cutters are used in engraving and marking for making designs.

If we look at the history of laser cutters, it was first invented by Kumar Patel in 1963 – He created a Co2 laser which was the first of its kind. So, thanks to him, this technology has become an effective instrument for businesses.

Laser Cutting Process

In the laser cutting process, the main component is the laser. This leads us to another question; what is a laser?

Simply, you can think of it as a form of energy that can melt, heat, or vaporize a material upon contact. Therefore, it is generally considered a thermal process. For instance, a gas jet (co-axial) is usually used to propel the molten material to create a kerf.

Moreover, if you want to control how the laser cutter produces a cut, you need a CNC machine. Usually, it accompanies the laser cutting machine.

Currently, there are three different types of laser-cutting processes available in the market:

- Fusion cutting

- Flame cutting

- Remote cutting

1. Fusion Cutting

In this process, an inert gas such as nitrogen propels molten material from the kerf. Since the nitrogen gas is inert, it doesn’t react with the molten material and does not affect the energy input.

2. Flame Cutting

This type of cutting utilizes oxygen to propel the molten material out and form the kerf. Unlike nitrogen, oxygen is not an inert gas. As a result, it leads to an exothermic reaction with the molten material and increases the energy input.

3. Remote Cutting

In remote laser cutters, a high-power laser beam evaporates the material and doesn’t require any assist gas.

Regardless of the type of laser cutters, they are all controlled via a CNC (computer numerical controlled). Thus, they require a laser cutting file for making designs or engravings.

Benefits of Laser Cutter Over 3D printers

Now that we understand what is a laser cutter and how the whole process works. Let’s look at the benefits of a laser cutter over 3d printers. This will help you decide which technology is best for you when comparing a laser cutter vs. a 3d printer:

1. Speed

Laser cutters are way faster than 3D printers, making them a good choice! For example, the average time it takes to create a 3D design is around 30 minutes up to a few days.

Laser cutters can cut through a 13 mm thick sheet of stainless steel within 5 to 15 seconds.

2. Subtractive Manufacturing

If your main objective is cutting or engraving. Then a laser cutting machine is an ideal option since it is made for subtractive manufacturing. In contrast, a 3D printer is more suited for additive manufacturing, such as making things from scratch.

3. Precision Cutting

Laser cutters are highly precise machines that can make cuts with a precision of around ± 0.0005 inches. In contrast, a 3D printer has a precision of 0.019 inches, which is way lower than laser cutters!

So if your end goal is to cut with high precision, you should go with a laser engraver. Read more about How Precise is a Laser Cutter.

4. Easy to Use

Another benefit of using laser cutting is that it is easier and more intuitive than a 3D printer. This makes it practical and less complex to cut materials.

For example, cutting a sheet of material is easier than making a 3D object from scratch. As the complexity of the process increases, the complexity of using the machine also increases.

A person can easily learn how to use laser cutters quickly. However, a 3D printer has a high learning curve & requires a lot of trial and error.

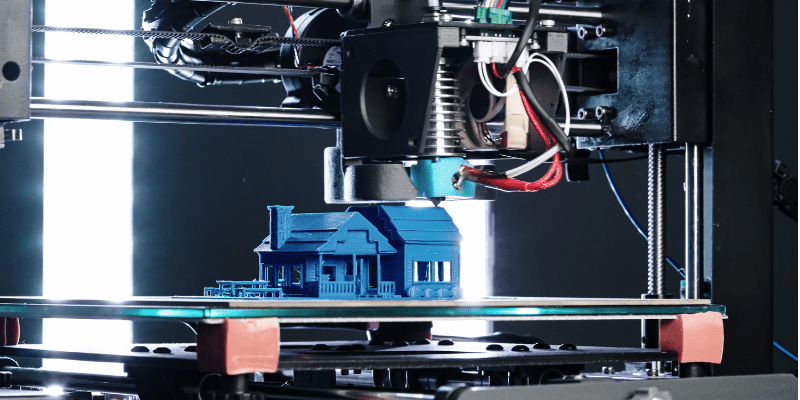

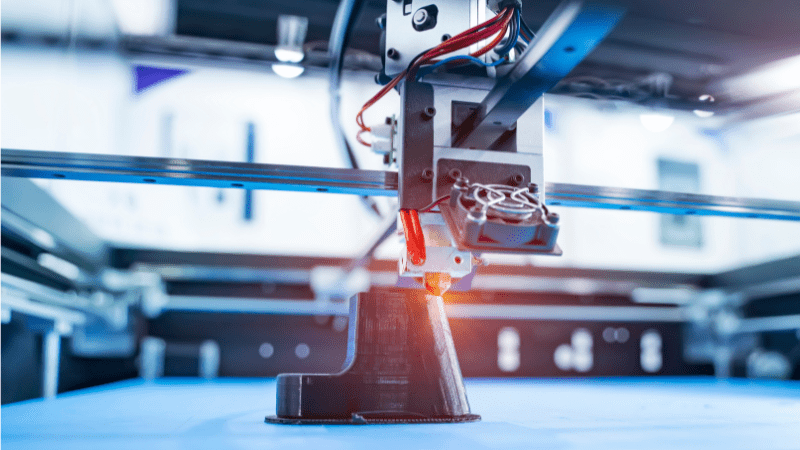

What is a 3D Printer?

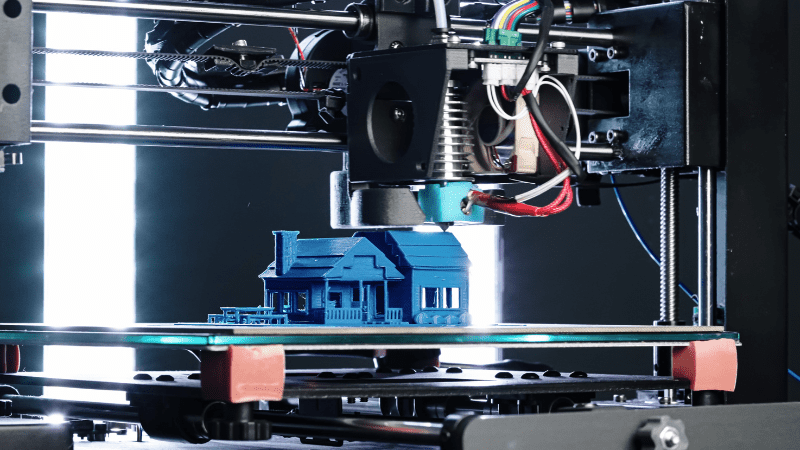

Before we look at what a 3D printer is, let’s look at a normal printer first. If you have ever used a printer, you would know it is used for printing 2D images. A 3D printer works based on the same principle. However, instead of making a 2D image, it makes 3D objects and shapes.

A 3D printer uses a liquid material such as plastic to create a 3D shape layer by layer. So, because 3D shapes are created from scratch, it usually takes around 30 minutes up to several days to finish.

Normally, it can take a few days to several weeks for a company to manufacture something. But with the help of 3D printing, any custom component can be made in way less time.

A 3D printer can be used to make anything from a small kids’ toy to the components of a full-sized building. As long as you can design something, a 3D printer can create it without a problem!

Currently, these types of 3D printers are normally used:

- Stereolithography 3D printers

- Selective Laser Sintering 3D printers

- Digital Light Process (DLP)

- PolyJet

- Electron Beam Melting (EBM)

- Multi Jet Fusion (MJF)

- Fused Deposition Modeling (FDM)

And if we talk about the price of a 3D printer, it usually differs. If you are a hobbyist and want to get started, you can get a device from $400 up to $1500. But if you are a 3D printer enthusiast, you can get a device starting from $1000 up to $4000.

The price of professional 3D printers usually starts from $4000 and goes up to $20,000!

3D Printing Process

There are different manufacturing processes, and the one used by 3D printers is additive manufacturing. This method creates an object or a shape by adding successive layers until the 3D object or shape is complete.

The first step in 3D printing is the modeling phase. This involves modeling the design of the 3D shape/object using computer software. This step is all about instructing the 3D printer on what and how to create the 3D object.

To make a 3D model, various computer software is used. It is normally referred to as a computer-aided design or a CAD package. After finishing an object model, it is saved in the STM or AMF format.

Once a 3D object/shape is made by a computer tool, it is provided to the 3D printer. This takes us to the second stage, where 3D printing starts.

In this stage, the 3D printer builds the object/shape from scratch from composite materials until it is finished. A giant robotic arm deposits the material layer by layer to make the desired shape. If the AMF or the STL file has no errors, the process will be completed successfully!

The last stage of 3D printing is to check the finished product and make any final touches. This process usually involves removing any extra pieces, refining edges, or coating with solvents.

Some commonly used materials include powders, resins, paper, carbon fiber, biocompatible plastics, cut wood, metal…, etc.

Depending on the usage, a 3D printer can be used for industrial purposes, in a small business setting… or even as a hobby.

Benefits of 3D Printers Over Laser Cutters

Now that we understand how 3D printing works let’s highlight some of the benefits of 3D printing over laser cutting:

1. Creating 3D Objects

A laser-cutting machine can make laser engraving with the help of a laser beam. However, it can’t be used for making 3D objects from scratch. And that’s where a 3D printing machine prevails since its purpose is to make 3D objects.

2. Additive Manufacturing

There are two types of manufacturing methods: Additive and subtractive. The 3D printers work on additive manufacturing and add layers of selected materials to create the final product. On the other hand, a laser machine works on flat surfaces and is used for engraving materials or cutting only.

3. Better Prototyping

A laser cutter is usually limited to flat solid objects and surfaces. Whereas 3D printers can be utilized for diverse projects of 3-dimensional shapes. So if your work involves making product prototypes, then it is only possible with the help of a 3D printer.

You can create an object by joining different materials cut through a laser cutter. However, the final object will be a simple one. But with 3D printers, even complex prototypes can be made relatively easily!

What are the Differences Between Laser Cutting and 3D Printing?

Let’s look at some key differences between laser beam cutting and 3D printing to understand how these two machines work:

1. Different Materials

The key difference between laser cutting is the different materials used in the process. Laser cutting usually involves using a laser beam for cutting and engraving. So, it can be used for various flat surfaces such as cork, plastic, polycarbonate, plywood, steel, pelt, aluminum, brass, alloy…, etc.

As for 3D printing, the commonly used materials include plastic, resin, metal, stainless steel, thermoplastic, titanium, carbon fibers, nickel, boi-ink, and graphene. Since 3D printing involves creating objects from scratch, these materials are usually in the motel or powder form.

2. Speed and Accuracy

If we talk about speed, there is also a major difference between laser cutting and 3D printing. The process of laser engraving with the help of a laser beam is very fast compared to 3D printing.

Only a few seconds are needed from the cutting process’s beginning to its end. On the other hand, 3D printing is a complicated process that can take around 30 minutes up to several days. The actual time taken by 3D printing usually depends on the complexity of the final 3D product/shape.

As for precision, a laser engraving machine wins the race. The average precision offered by a good quality laser engraving machine is ± 0.0005 inches. As for 3D printing, it offers a precision of ± 0.019 inches.

So in terms of speed, we can safely say that laser cutting is a high-speed process, while 3D printing takes considerable time.

However, let’s not forget that laser cutters and 3D printers are used for different purposes!

3. Working Areas

Another difference between these two machines is in their respective working areas. A 3D printer makes 3D objects, while laser cutters tend to cut and engrave flat surfaces. So in that regard, their working areas are very different. One is used to create and add things, while the other is used to cut and remove things.

So, you can use a 3D printer to make intricate designs and a laser cutter to cut and engrave flat surfaces.

4. Fields of Application

Laser cutting has various practical applications in different sectors such as manufacturing, engineering, automotive, electronics, medical, aerospace, etc. Anything that involves cutting and engraving, such as making custom visit cards, engraving designs on sheet metal, custom key rings, etc.

Similarly, a 3D printer also has a variety of practical applications as well. It’s used in medicine, manufacturing, gifts, toys, shoe designs, furniture, and even for making houses!

5. Cost

The cost of a 3D printer starts from $400 and can go up to $20,000 or even more! An expensive 3D printer can make larger objects and even more complex designs.

As for a laser cutter, the initial investment is around $3000 for a brand-new machine. And the price can be as high as $15,000. Once again, a machine with a higher price tag comes with more powerful features than a cheaper one!

So in terms of price, you can get started with 3D printing at a lower price compared to a laser cutter! However, most people who go for laser cutting usually want to engrave materials on an industrial or small business scale.

Whereas 3D printing is quite popular among hobbyists who want to try new innovative technology.

Conclusion

Laser cutting and 3D printing are two different processes and thus have unique applications! So if you aim for cutting and engraving, you should go with laser cutting! But if you are interested in making 3D objects from scratch, then buying a good quality 3D printer would be a wise choice!

Normally, laser cutting machines are used by businesses and industries since it offers precision cutting at fast speeds. On top of that, it can make thousands of copies of a design with high accuracy.

On the other hand, 3D printing can be used by a hobbyist and even on an industrial scale. For example, you can create a small 3D object with the help of a 3D printer and even large objects.

Buy Laser Cutting Machine At Affordable Rates!

Do you want to buy a laser-cutting machine for your business? Maybe you want to upgrade your current setup with more modern laser-cutting machines. Then you can rely on Baison Laser, a world-class manufacturer of laser-cutting machines from China!

Baison Laser has everything you need, from laser cutting to welding and even laser cleaning! And if you still have some questions about laser-cutting machines, feel free to contact us today!